文章编号:1004-0609(2012)04-1242-06

钨渣回收制备四氧化三锰新工艺

戴艳阳,钟 晖,钟海云

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:研究从钨渣中回收锰的新工艺,通过钨渣的低温硫酸化焙烧、烧结块浸出、浸出液除杂、溶液中水解沉锰及氢氧化锰氧化获得Mn3O4粉末,采用SEM和XRD对产品粉末进行分析。结果表明:在浓硫酸过量150%、焙烧时间90 min、浸出温度98 ℃、浸出时间120 min的条件下,Mn浸出率达到88.9%。浸出液可以通过硫化物沉淀除重金属、硫酸复盐沉淀法深度净化除杂、中和水解除Fe,水解沉锰也有一定的净化作用,溶液pH值为6.56时,除铁率达到99.91%。净化液经水解沉锰后采用10%H2O2氧化,在氢氧化锰氧化过程中,溶液pH值对产物物相的影响较大;溶液pH值为8时在50 ℃沉锰,并以过量150%的H2O2氧化反应20min,获得粒度小于0.1 μm的Mn3O4粉末。

关键词:四氧化三锰;钨渣;回收;焙烧

中图分类号:TF09 文献标志码:A

Novel process for preparation of

mangano-manganic oxide from tungsten residue

DAI Yan-yang, ZHONG Hui, ZHONG Hai-yun

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: In order to recover manganese from tungsten residue, a corresponding technology to prepare mangano-manganic oxide was adopted as follows: low temperature sulfating roasting tungsten residue, leaching, removal of impurities in leachate, precipitation of manganese and oxidation of manganese hydroxide. The product was analyzed by SEM and XRD. The results of roasting and leaching show that the recovery of Mn is 88.9% after roasting with 150% excess of concentrated H2SO4 for 90 min and leaching at 98 ℃ for 120 min. The purification of leaching liquor can be carried out through sulfide precipitation and complex sulfate precipitation and neutralizing hydrolysis. In addition precipitation in Mn by hydrolysis favors the purification of the leach liquor. The removal of iron reaches 99.91% when the pH value of solution is 6.56. The precipitate bearing Mn from the leach liquor was oxidized with 10% H2O2 (mass fraction). The results show that the pH value of solution in the oxidation process has significant effect on the products. The mangano-manganic oxide with diameter of less than 0.1 μm is prepared as oxidizing with 150% excess of H2O2 for 20 min after precipitating at 50 ℃ from the liquor with pH value of 8.

Key words: mangano-manganic oxide; tungsten residue; recovery; roasting

据美国USGS统计[1-2],中国陆地锰矿资源约占全球总量的2.5%,且锰矿石品位偏低,几乎都在15%~30%。而近几年来,中国锰矿产量达到全球产量的30%~40%,国内富锰矿基本开采完毕,资源供应量已经锐减,中国进口锰矿量占世界锰矿贸易量的比例也由2004年的35%上升到2008年的42%[3]。国内存在的锰资源稀缺,资源利用率不高、长期以来进口等问题严重制约锰系合金以及含锰磁性材料等产业的发展。为了提高低品位锰矿资源的利用率,不少学者进行了有益探索,但尚未形成回收率高、 污染少的工业技术[4-6]。因此,为满足国内锰系铁合金生产所需以及含锰磁性材料等产业对锰不断增长的需求[7-9],开发新的锰源也显得非常重要。

目前,钨矿处理以碱法为主,原料主要是大部分以黑钨为主,含有部分白钨的混合矿,因此,几乎所有的钨矿碱浸渣(以下简称钨渣)中都含有少量的钨和锰等有价金属。钨渣中主要含1%~4%W、10%~25%Fe、3%~20%Mn、1%~20%Ca、3%~8%Si(质量分数)。对钨渣综合回收的研究已经涉及多种金属,如以人造白钨的形式回收钨[10],以氧化物形式回收钪[11],以精矿形式综合回收铋、钨和锡[12],以具有工业应用的富集物回收钽铌[13],以铁氧体形式综合回收铁锰[14]以及多种金属的综合回收[15]等。工业生产中也已经有不少钨冶炼企业和私人小企业对钨渣进行回收,但大多是采用强化碱法处理条件的方法从钨渣中进一步回收钨,对其他有价金属的回收基本没有考虑,或仅以碳酸锰等价值不高的产品形式初步进行了回收。

调查表明,我国各钨冶炼厂近40年来产出的钨渣或经过再次碱法回收钨之后的含锰渣已近百万吨,且每年仍在增加。因此,经济有效地综合利用这些废钨渣,对保护环境、充分利用资源具有重要意义。

本文作者近年来对钨渣中有价金属W、Ta、Nb、Fe和Mn的回收进行了一系列研究[13-15]。在此,研究以钨渣为原料制备四氧化三锰粉末的工艺,为锰业发展提供了新的可选资源。

1 实验

1.1 实验原料

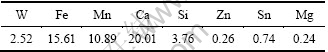

实验选用钨渣(化学成分见表1)来自江西某钨冶炼厂,经105 ℃烘干24 h,研磨至粒径96 μm以下。

表1 钨渣化学成分

Table 1 Chemical composition of tungsten residue (mass fraction, %)

XRD分析表明,钨渣中的铁锰绝大部分以Fe2O3和Mn3O4形态存在,少量呈(Fe,Mn)WO4形态,钙大部分以CaO形态存在。在实验中,所用药品均为分析纯,溶液配制采用一次蒸馏水。

1.2 实验过程

1.2.1 低温硫酸化焙烧与酸浸出

随着黑钨资源的不断减少和白钨资源应用的越来越多,近年来,钨冶金原料中的钙含量越来越高,而钨渣中的钙含量也越来越高。考虑到原料中Ca含量高达20%,实验选择H2SO4为浸出剂,使Ca生成CaSO4与Mn分离。取100 g钨渣与一定量的浓硫酸混合,在约300 ℃的温度下焙烧5~150 min,然后烧渣转移到烧杯加水300 mL配成溶液水浴加热至95 ℃浸出60~120 min,过滤得酸浸出滤液和滤渣。

1.2.2 浸出液除杂

加入10 mol/L的氢氧化钠溶液调节滤液pH值在5左右,加热滤液,搅拌下加入Na2S固体,使重金属生成硫化物沉淀除去。

分析Na2S净化溶液中Fe3+的含量,往溶液中加入一定量的铁粉,在90 ℃下水浴加热搅拌60 min,使Fe3+还原为Fe2+。随后在溶液中加入一定量的(NH4)2SO4,水浴加热搅拌至(NH4)2SO4完全溶解。继续加热使溶液沸腾,当大量硫酸复盐晶体析出时,自然冷至室温,得到的硫酸复盐晶体溶解于纯水中,即得到所需的沉淀前液。

在沉淀前液中加入硫酸使之酸化至pH值为1~2,再以10%过氧化氢溶液,使Fe2+氧化为Fe3+。随后以NaOH为中和剂,在95 ℃反应60 min,再放置120 min,调节滤液pH值在4~6左右使铁以氢氧化物沉淀除去。

1.2.3 四氧化三锰粉末的制备

用1:1氨水调节净化液pH约为7~10左右,在50~70 ℃使Mn水解为Mn(OH)2并过滤,在沉淀物中加入过量150%~250%的H2O2,反应10~30 min后抽滤,沉淀物110 ℃真空干燥,即得到黑色粉末。

2 结果与讨论

2.1 锰的浸出率及其影响因素

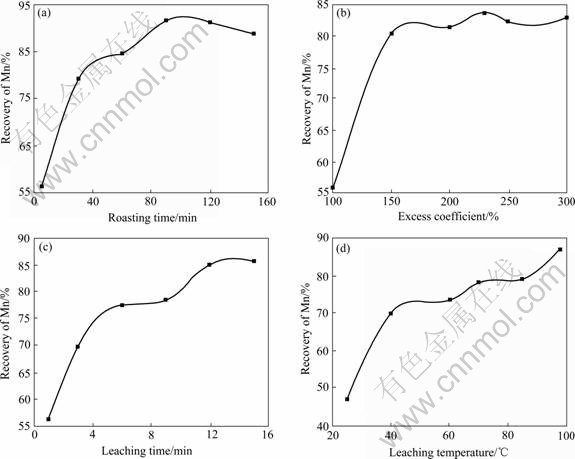

钨渣的浓硫酸低温焙烧及浸出过程中焙烧时间、硫酸过量系数、浸出时间和浸出温度对锰浸出率的影响分别如图1中(a)~(d)所示。锰的浸出率以钨渣中的锰和浸出液中的锰进行计算。

从图1可以看出,随着焙烧时间的增加,锰的浸出率逐渐增大。但焙烧时间过长,浸出率反而降低,其原因在于长时间烧结使烧结块硬度增大,浸出更困难。而从工业生产考虑,焙烧时间长不仅使生产效率降低, 设备损耗及能耗也会随之增加,故要选择合理的焙烧时间,在本研究中,焙烧时间定为90 min。

图1 浸出条件对锰浸出率的影响

Fig. 1 Influence of leaching conditions on recovery of Mn

浸出时间和温度对锰的浸出率影响较大,随着时间的延长和温度的增加,锰的浸出率增加较快,尤其在温度达到90 ℃以上时更明显。由此可见,在实验条件下,锰浸出率随温度的变化没有受到其溶解度性质的影响。究其原因,硫酸锰极易溶于水,虽然在高于27 ℃时随温度升高其溶解度反而逐渐下降,但100 ℃时,其溶解度仍达到0.262 g/mL,因此,随着浸出时间与温度的升高,锰的浸出率增加。

硫酸过量系数高于150%时,对锰的浸出影响较小,从成本来考虑,硫酸过量150%即可。优化实验在浓硫酸过量150%、焙烧时间90 min、浸出温度98 ℃、浸出时间120 min的条件下,Mn浸出率达到88.9%。

适宜的焙烧温度是低温硫酸化焙烧的重要环节。如果炉料的温度达到硫酸的沸点338 ℃以上,大量H2SO4将挥发,不利于物料的硫酸化。实验约在300 ℃进行,从锰的浸出率可以看出,绝大部分的锰完成了硫酸化。

此外,对钨渣及其浸出液中其它元素的分析结果表明,硫酸浸出时,钨渣中的主要杂质金属Fe大部分进入溶液,其浸出率可达到87%;而Ca生成CaSO4留在渣相与锰初步分离,XRD分析表明,渣中主要成分是CaSO4,化学分析表明渣中CaSO4含量达到75%,90%以上的W 和Si留在渣中,其它杂质如Mg、AL、Cu、Zn和Sn等均部分或全部进入溶液。

2.2 杂质脱除

2.2.1 浸出液除杂

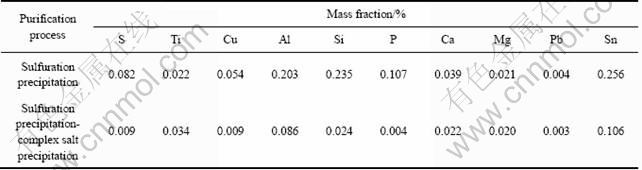

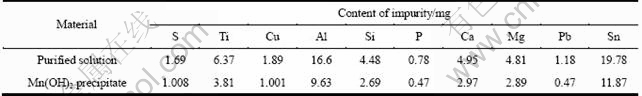

表2所列为单独采用硫化沉淀法除杂后液获得的Mn(OH)2沉淀(A)和采用硫化沉淀-硫酸复盐沉淀法除杂后液获得的Mn(OH)2沉淀(B)中杂质含量的比较。

从表2可以看出:硫化沉淀法除杂可以除去大部分杂质,这与金属硫化物的溶度积有关。同时可以看出:单独采用硫化沉淀法除杂获得的Mn(OH)2沉淀(A)中Al、Si、P、As、Cu、Cd和Sn等离子含量均较高,因此,必须进行深度净化除杂,而用硫酸复盐法使铁、锰、锌生成硫酸复盐的形式结晶沉淀,可以有效分离铁、锰、锌与溶液中的杂质离子,获得的Mn(OH)2沉淀(B)中Si、S、Ca、P和Ti等杂质的含量均在0.1%以下。

表2 两种不同净化除杂工艺获得的Mn(OH)2沉淀的比较

Table 2 Comparison between Mn(OH)2 precipitates from purification process

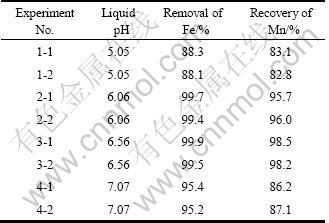

2.2.2 水解除铁过程中溶液pH值对除铁率和锰的回收率的影响

为了确定水解除铁过程中溶液pH值对铁脱除率和锰回收率的影响,在不同的pH值下进行水解除铁。溶液pH值对铁脱除率和锰回收率的影响如表3所列。由表3可以看出,在pH值约为6.56时,铁的脱除和锰的回收效果均达到最佳。根据各金属氢氧化物的沉淀pH值,其它金属杂质如Pb、Ni、Zn、Cu、Sn、Bi和Al等也可在此过程中得到进一步脱除。而数据表明,pH值大于7时锰回收率急剧降低,这与Mn(OH)2沉淀的pH值随温度升高而降低的性质有关,温度为70 ℃时Mn(OH)2的沉淀pH值降至6.55,导致部分锰在水解沉淀中损失。

2.3 Mn(OH)2沉淀及氧化

2.3.1 水解沉锰及其除杂作用

净化液中杂质含量和Mn(OH)2沉淀中杂质的含量见表4。

表3 溶液pH值对铁脱除率和锰回收率的影响

Table 3 Effects of liquid pH on removal of Fe and recovery of Mn

净化液中杂质含量的计算根据溶液体积与杂质浓度,按照100 g Mn(OH)2计算;Mn(OH)2沉淀中杂质含量根据沉淀质量、沉淀率与杂质质量分数计算。

由表4可知,水解沉锰过程同样可以起到除杂的效果。根据各金属氢氧化物的开始沉淀pH值,在 pH>7时溶液中几乎所有的金属在理论上都可以沉淀,但由于水解沉淀采用氨水中和,杂质离子Cu2+、Ni2+、Zn2+能与NH3形成络合离子,而Ca2+、Mg2+则形成溶解度较大的氢氧化物,因此,这些杂质均留在溶液中,与Mn(OH)2分离。

表4中数据表明水解沉锰过程有利于硫的脱除。水解沉锰的反应如下:

2MnSO4+2NH3·H2O=Mn2(OH)2SO4+(NH4)2SO4 (1)

Mn2(OH)2SO4+2NH3·H2O=2Mn(OH)2+(NH4)2SO4 (2)

由以上反应可以看出,氨水加入量越多,溶液pH越高,则生成的碱式硫酸锰越容易向氢氧化锰转 化,也就越有利于硫的脱除。

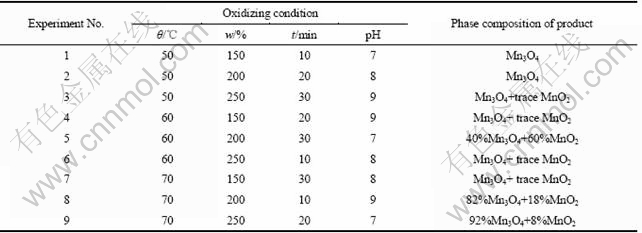

2.3.2 产物物相组成

以正交试验研究水解温度(θ)、溶液pH值、H2O2用量(过量系数m)以及氧化时间(t)对产物的影响。试验条件及结果如表5所列。

极差分析表明,对产物物相组成影响最大的是溶液pH值,其次是氧化时间、水解温度,影响最小的因素是H2O2添加量。根据上述水解沉锰反应式可以看出,溶液pH越高,越有利于Mn(OH)2沉淀的生成。而H2O2添加量过量150%时足以使反应进行完全。

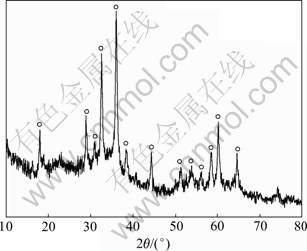

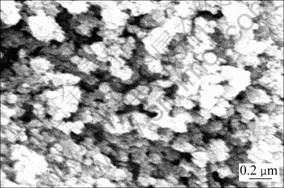

按照Mn(OH)2氧化的最佳工艺,在50 ℃、H2O2过量150%、溶液pH值为8时反应20 min,获得的四氧化三锰粉末的XRD和SEM分析结果分别如图2和3所示,化学分析结果如表6所列。可以看出,Mn3O4颗粒的粒度很均匀,且粒径基本上小于0.1 μm。

表4 净化液中杂质含量和Mn(OH)2沉淀中杂质含量的比较

Table 4 Comparison between impurities in purified solution and Mn(OH)2 precipitate

表5 Mn(OH)2氧化条件对产品物相组成的影响

Table 5 Effects of oxidizing conditions of Mn(OH)2 on phase composition of product

图2 四氧化三锰粉末的XRD谱

Fig. 2 XRD pattern of mangano-manganic oxide powder

图3 四氧化三锰粉末的SEM像

Fig. 3 SEM image of mangano-manganic oxide powder

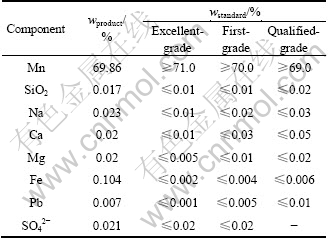

表6 产物Mn3O4粉末化学成分及HG/T 2835—1997标准

Table 6 Chemical composition of mangano-manganic oxide and / HG/T 2835—1997 standard

由表6可知,产物除铁含量以外,均达到化工部HG/T 2835—1997标准的要求(见表6)。因此,除铁方法需进一步研究,尤其是要进一步研究保证锰回收率的情况下除铁的方法。

3 结论

1) 采用钨渣的低温硫酸化焙烧与浸出-硫化物沉淀除重金属-硫酸复盐法深度净化-中和水解除Fe-水解沉锰-H2O2氧化分解的新工艺。获得粒度小于0.1 μm的超细四氧化三锰粉末,产品质量基本达到化工部HG/T 2835—1997标准的要求。

2) 在浓硫酸过量150%,焙烧时间90 min,浸出温度98 ℃,浸出时间120 min的条件下,Mn浸出率达到88.9%;浸出液通过硫化物沉淀除重金属、硫酸复盐沉淀法深度净化除杂、中和水解除Fe,水解沉锰也有一定的净化作用。净化液在50 ℃、溶液pH=8时水解沉锰,再以过量150%的10%H2O2为氧化剂在 50 ℃反应20 min,获得粒度小于0.1 μm的超细四氧化三锰粉末。

3) 该工艺流程比较简单,原料价廉易得,成本较低,既可以充分利用资源,将钨渣作为一个新的锰资源,同时可以解决钨渣大量堆积的问题。

REFERENCES

[1] US Geological Survey. Mineral commodity summaries, Menganese 2009[EB/OL]. http://minerals.usgs.gov/Minerals/ pubs/, 2009-04-15.

[2] US Geological Survey. World metal statistics yearbook, Menganese 2007-2009[EB/OL]. http://minerals.usgs.gov/ Minerals/pubs/, 2009-04-15.

[3] 严旺生, 高海亮. 世界锰矿资源及锰矿业发展[J]. 中国锰业, 2009(3): 6-11.

YAN Wang-sheng, GAO Hai-liang. The resource of Mn ore & its development of Mn-mining[J]. China Tungsten Industry, 2009(3): 6-11.

[4] ELSHERIEF A E. A Study of the electroleaching of manganese ore[J]. Hydrometallurgy, 2000, 55(3): 311-326.

[5] BERG K L. Kinetics of manganese ore reduction by carbon monoxide[J]. Metallurgical and Materials Transactions B, 2000, 31(3): 477-490B.

[6] SUTYRIN Y E. Carbonate ores—The raw-materials base for manganese in Russia[J]. Metallurgist, 2002, 46(9/10): 297-300.

[7] MOZAFFARI M, EBRAHIMI F, DANESHFOZON S. Preparation of Mn-Zn ferrite nanocrystalline powders via mechanochemical processing[J]. Journal of Alloys and Compounds, 2008, 449(1/2): 65-67.

[8] 戴志云, 徐辉宇. 锰锌软磁铁氧体料粉市场的现状及发展趋势[J]. 磁性材料及器件, 2006, 37(5): 15-17.

DAI Zhi-yun, XU Hui-yu. The current status and development trend of MnZn soft ferrite powder market[J]. Journal of Magnetic Materials and Devices, 2006, 37(5): 15-17.

[9] OTT G, WRBA J, LUCKE R. Recent developments of Mn-Zn ferrites for high permeability applications[J]. Journal of Magnetism and Magnetic Materials, 2003, 254/255: 535-537.

[10] Martins J I, LIMA J L F C, MOREIRA A, COSTA S C. Tungsten recovery from alkaline leach solutions as synthetic scheelite[J]. Hydrometallurgy, 2007, 85(2/4): 110-115.

[11] 钟学明. 伯胺萃取法提取氧化钪的工艺研究[J]. 稀有金属, 2002(6): 527-529.

ZHONG Xue-ming. Technology of extracting scandium oxide by primary amine[J]. Chinese Journal of Rare Metals, 2002(6): 527-529.

[12] 罗仙平, 刘北林, 唐敏康. 从钨冶炼渣中综合回收有价金属的试验研究[J]. 中国钨业, 2005(3): 24-26.

LUO Xian-ping, LIU Bei-lin, TANG Min-kang. Experimental investigation of complex recovery of valuable minerals components containing in the residue abandoned in wet-metallurgical process of wolframite ores[J]. China Tungsten Industry, 2005(3): 24-26.

[13] 戴艳阳, 钟 晖, 钟海云. 钨渣中钽铌回收研究[J]. 有色金属, 2009(3): 87-89.

DAI Yan-yang, ZHONG Hui, ZHONG Hai-yun. Recovery of tantalum and niobium from tungsten residue[J]. Nonferrous Metals, 2009(3): 87-89.

[14] 戴艳阳, 钟 晖, 钟海云. 废钨渣中同时回收铁锰的实验研究[J]. 应用化工, 2009(4): 924-927.

DAI Yan-yang, ZHONG Hui, ZHONG Hai-yun. Study on preparation of Zn-Mn ferrite powders from tungsten residue[J]. Applied Chemical Industry, 2009(4): 924-927.

[15] 戴艳阳, 钟海云, 李 荐, 钟 晖. 钨渣中有价金属综合回收工艺[J]. 中南工业大学学报, 2003, 34(1): 36-39.

DAI Yan-yang, ZHONG Hai-yun, LI Jian, ZHONG Hui. Valuable metals recovery from tungsten residue[J]. Journal of Central South University of Technology, 2003, 34(1): 36-39.

(编辑 龙怀中)

收稿日期:2011-07-11;修订日期:2011-10-30

通信作者:戴艳阳,讲师,博士研究生;电话:0731-88830423;E-mail: dyy90404@gmail.com