氮化硅基体多层膜结构金刚石涂层车削硅铝合金的切削性能

来源期刊:中国有色金属学报(英文版)2013年第7期

论文作者:陈乃超 孙方宏

文章页码:1985 - 1992

关键词:硅铝合金;多层膜结构金刚石涂层;氮化硅;切削性能

Key words:aluminum-silicon alloy; multilayer diamond films; silicon nitride; cutting performance

摘 要:硅铝合金非常难以进行切削加工,金刚石刀具被认为是当前切削该类材料的最好工具。考虑到高附着力和好的表面形貌对化学气相沉积(CVD)金刚石涂层的应用具有重要影响,提出了基于热丝化学气相沉积(HFCVD)方法的多层膜技术,并在氮化硅刀具上沉积出多层膜结构的金刚石涂层,微米金刚石(MCD)/纳米金刚石(NCD)结构。为了与多层膜金刚石涂层进行比较,同时制备出单层MCD和NCD涂层。采用场发射电镜(FE-SEM)和拉曼光谱对沉积的金刚石薄膜进行表征。研究了有沉积金刚石涂层和没有涂层的刀具车削硅铝合金的切削性能。结果表明:MCD/NCD多层金刚石涂层表现出优异的耐磨性能,具有较小的后刀面磨损量,涂层无脱落。

Abstract: Aluminum-silicon (Al-Si) alloy is very difficult to machine and diamond tools are considered by far the best choice for the machining of these materials. Experimental results in the machining of the Al-Si alloy with diamond coated inserts are presented. Considering the fact that high adhesive strength and fine surface morphology play an importance role in the applications of chemical vapor deposition (CVD) diamond films, multilayer technique combining the hot filament CVD (HFCVD) method is proposed, by which multilayer diamond-coating on silicon nitride inserts is obtained, microcrystalline diamond (MCD)/ nanocrystalline diamond (NCD) film. Also, the conventional monolayer NCD and MCD coated inserts are produced for comparison. The as-deposited diamond films are characterized by field emission scanning electron microscopy (FE-SEM) and Raman spectrum. All the CVD diamond coated inserts and uncoated insert endure the aluminum-silicon alloy turning to estimate their cutting performances. Among all the tested inserts, the MCD/NCD coated insert exhibits the perfect behavior as tool wear due to its very low flank wear and no diamond peeling.

Trans. Nonferrous Met. Soc. China 23(2013) 1985-1992

Nai-chao CHEN, Fang-hong SUN

School of Mechanical Engineering, Shanghai Jiao Tong University, Shanghai 200240, China

Received 9 June 2012; accepted 4 September 2012

Abstract: Aluminum-silicon (Al-Si) alloy is very difficult to machine and diamond tools are considered by far the best choice for the machining of these materials. Experimental results in the machining of the Al-Si alloy with diamond coated inserts are presented. Considering the fact that high adhesive strength and fine surface morphology play an importance role in the applications of chemical vapor deposition (CVD) diamond films, multilayer technique combining the hot filament CVD (HFCVD) method is proposed, by which multilayer diamond-coating on silicon nitride inserts is obtained, microcrystalline diamond (MCD)/ nanocrystalline diamond (NCD) film. Also, the conventional monolayer NCD and MCD coated inserts are produced for comparison. The as-deposited diamond films are characterized by field emission scanning electron microscopy (FE-SEM) and Raman spectrum. All the CVD diamond coated inserts and uncoated insert endure the aluminum-silicon alloy turning to estimate their cutting performances. Among all the tested inserts, the MCD/NCD coated insert exhibits the perfect behavior as tool wear due to its very low flank wear and no diamond peeling.

Key words: aluminum-silicon alloy; multilayer diamond films; silicon nitride; cutting performance

1 Introduction

Diamond coated materials possess excellent mechanical and tribological properties, such as high hardness, high elastic modulus, good wear resistance, good corrosion resistance, low friction coefficient and thermal conductivity. Currently, the utilization of diamond films deposited by chemical vapor deposition (CVD) method has been increased in the important market of machining nonferrous materials [1]. It is worth noting that silicon nitride ceramic is considered an attractive substrate for depositing diamond films due to its low thermal expansion mismatch to diamond [2], which is useful for the improvement of adhesive strength between diamond film and substrate, and thus the prolonged lifetime of CVD diamond coated cutting inserts [3,4]. Therefore, CVD diamond coated silicon nitride inserts have gained considerable interest and are increasingly used for turning abrasive and hard materials, such as graphite, tungsten carbide, aluminum–silicon alloys and aluminum matrix composites [5-8].

Many types of diamond coated silicon nitride substrates are designed to examine their mechanical properties, including cutting performance. ALMEIDA et al [9] employed the hot filament CVD to deposit microcrystalline and nanocrystalline diamond coated inserts. The experimental results indicate that the smoother nanocrystalline coatings can obtain a better workpiece surface roughness than the microcrystalline ones, in turning the electrical discharge machining (EDM) graphite. It was also reported by HU et al [10,11] that nanostructured diamond films have a better wear resistance than the micro-structured one. Therefore, nanostructured diamond film had been considered an outstanding candidate for the machining of nonferrous metals [12]. However, the brale tip indentation testing suggests that microcrystalline diamond (MCD) grade exhibits the best behavior of adhesion strength due to its crystallinity and superior hardness. In contrast, nanocrystalline diamond (NCD) coatings show the less effective chemical bonding to the ceramic substrate due to the higher degree of sp2 content [13]. Therefore, to achieve the combination of strong adhesive strength and refined surface morphology, many investigations on depositing nano-microcrystalline diamond films on the Co-cemented tungsten carbide (WC-Co) substrate using hot filament CVD (HFCVD) method were reported in Refs. [14,15]. Such diamond films already prove their adequacy in metal product industry. Compared with the cemented carbide drawing die, the working lifetime of the diamond-coated drawing die increases by a factor of above 15, and the quality and smoothness of drawn products can be greatly improved [16]. However, the cutting performance of the nano/microcrystalline diamond coated silicon carbide inserts has less been investigated, and the interface adhesion and wear endurance against the hardmetal parts are not clear. On the other hand, there is also lack of literature discussing the performance of multilayer diamond films, although their extraordinary wear resistance has been predicted [7].

In this work, multilayer diamond films with two layers and distinct grades of nanocrystalline and micrometric grain sizes are fabricated by the HFCVD technique on silicon nitride inserts. The corresponding monolayer MCD and NCD films are also grown for comparative purpose. The as-deposited diamond films are characterized by field emission scanning electron microscopy (FE-SEM) and Raman spectrum. Their cutting performance is evaluated by turning aluminum- silicon alloy workpieces.

2 Experimental

2.1 Multilayer diamond coated silicon nitride inserts

The plane silicon nitride inserts with square geometry produced by the reaction-sintered processing route were used as the substrates for fabricating the multilayer diamond films. Prior to deposition, all substrates were submitted to the three-step pretreatment to strengthen the adhesive strength between the diamond films and the substrate: 1) ultrasonically cleaning in distilled water for 30 min to remove binder phases from the surface; 2) scratching by hard cloth for 30 min in the suspension with 50 μm diamond power; 3) dipping the substrates in high-purity acetone ultrasonic vessel for 20 min to eliminate impurities adhered on the surface.

The diamond films were fabricated by HFCVD technique in a home-made bias-enhance apparatus. Six pair-twisted tantalum wires were used as the hot filaments, and all of them were dragged to be straight by the high temperature springs in equidistance and parallel manner. The substrates were put below the filaments, and the distance between the filaments and substrates was fixed at about 12 mm. A DC bias was applied between the filaments and substrates so as to enhance the diamond nucleation density. The detailed deposition parameters are listed in Table 1.

In this work, nano-microcrystalline diamond films, namely MCD/NCD coating, were deposited to evaluate their cutting performances. The monolayer MCD and NCD films were also produced for comparison under conditions A and B, as shown in Table 1, respectively. For depositing MCD/NCD film, a layer of fine-grained MCD film was deposited on the silicon nitride substrate firstly under the condition A. Thereafter, the surface of as-deposited MCD film was polished with diamond grits (50 μm) and subsequently a layer of NCD film was deposited on the polished surface under the condition B.

Field emission scanning electron microscope (FE-SEM) was employed to characterize the surface morphology of coatings. The identification of diamond and graphitic phases was done by Raman spectroscopy at room temperature.

2.2 Machining test

Dry machining tests were performed in an industry facility, INDEX G200 turning machine, which is a high performing CNC multi operations millturn lathe with 10 controlled axes (including Y- and B-axis) and counter spindle, bar capacity 60 mm and 28 tool stations (14 in each revolver) with every station equipped for both rotating and rigid tools. All of the inserts were mounted on PSSNR2020K12 tool holder. Aluminum-silicon (Al-Si) alloy with about 14% silicon was used as the work piece material because the trend to substitute the steel and cast iron vehicle components by Al-Si light alloy is part of the effort to allow improved fuel economy and lower the emissions of pollutants. On the other hand, such material is also suitable for machining studies because it has a tendency to form considerable dust during machining due to the presence of hard Si-rich phase particles in the alloy matrix [7]. Experimental results indicate that the cutting performance of Al-Si alloy is widely influenced by the silicon content. Increasing amount of Si results in harder, stiffer and more wear resistant alloy. However, Si contents above 12% result in extremely abrasive materials with detrimental effects on their workability and on the wear of the tools used to shape them [17]. Thus, Al-Si alloy is very difficult to machine, and many machining experiments suggested that diamond tools are considered the best choice for the machining of these materials. In our following tests, the cutting parameters were set as follows: cutting speed of 350 m/min; cutting depth of 0.4 mm; feed rate of 0.1 mm/r.

Table 1 Deposition parameters of as-deposited multilayer diamond films

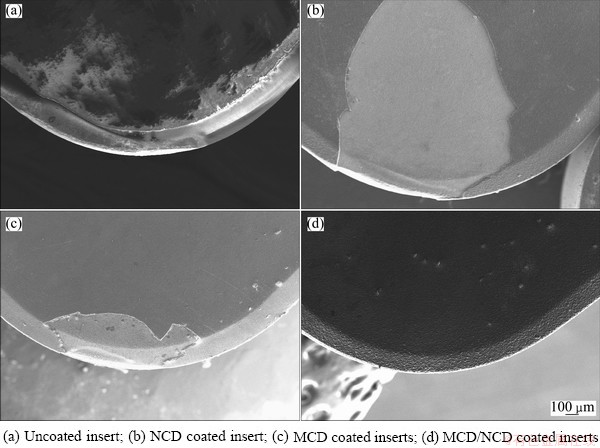

Fig. 1 SEM images of as-deposited diamond films

Tool wear was conducted to evaluate cutting performance of inserts. The criterion used for the tool wear measurement was the maximum width of the flank wear width because the tool was not regularly worn and chipping was the major reason for the failure [7]. The lifetime of the examined insert is evaluated by the flank wear where one insert will be thought as failure once its tool wear surpasses 0.3 mm or the diamond coating peels off from the substrate. All measurements were taken near the nose radius. Prior to the wear measurement, the hydrofluoric acid was used to etch off the workpiece material that was adhering to the edge of the tool. The tool wear of the insert was evaluated in an analysis of the images of the flank wear using a tool microscope. All of values were measured after each turning 375 m of cutting length by a digital image processing system. Then the terminal flank wear was examined by measuring scars that appeared on the cutting edge with FE-SEM.

3 Results and discussion

3.1 Characterization of as-deposited diamond films

Figure 1 shows the surface morphologies of as-deposited diamond films. For the monolayer NCD film, the FE-SEM image of its surface (Fig. 1(a)) shows that the substrate is covered by a layer of NCD films with diamond grains in nanometric level. Figure 1(b) shows the surface morphology of the monolayer MCD film, which indicates the typical features of conventional microcrystalline diamond coating with highly faceted grains and the columnar structures. For MCD/NCD film, firstly, a layer of MCD film is deposited on the silicon carbide insert. This layer of MCD film can facilitate adhesion strength enhancement of deposited multilayer diamond films on silicon carbide substrate due to the mechanical interactions between diamond and SiC grains of substrate [15]. The surface morphology suggests that the MCD film has a columnar structure, originating from large diamond grains at the free surface (Fig. 1(c)). These are responsible for the high values of roughness. Therefore, the as-deposited MCD film was polished with diamond grits in order to produce a flat surface. Subsequently, a layer of NCD film was deposited on this polished MCD film. Then, the surface morphology of as-deposited MCD/NCD film can be seen in Fig. 1(d), which shows that the micron-sized diamond grains are completely covered by many nano-sized diamond crystallites. It is clear that MCD and NCD films have a very distinct kind of structure as grain growth is suppressed by decreasing the atomic H density with the increment of partial substitution by Ar, thus increasing the renucleation of diamond [6]. The cross-sectional SEM image (Fig. 1(e)) indicates a thickness of 12–14 μm for the deposited MCD/NCD film.

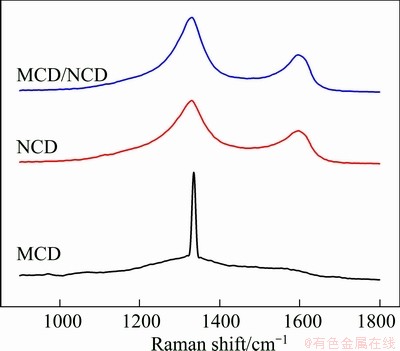

The quality of as-deposited coatings was examined by their physical properties by the corresponding Raman signatures. The typical NCD features present in the Raman spectrum of as-deposited NCD and MCD/NCD films, as presented in Fig. 2. A significantly broadening peak near 1332 cm-1 can be observed due to the decrease in grain size and phase purity, which is indicative of sp3 diamond. Another peak located at approximately 1560 cm-1, which can be assigned as the G band (1550-1580 cm-1) [18,19], is responsible for the contribution from the sp2 component. The presence of scattering intensity at 1560 cm-1 is due to increasing graphite-like sp2 bonded components at the grain boundaries in films. On the other hand, the Raman spectrum for the monolayer MCD film shows a sharp peak located in 1335 cm-1 and no graphitic peaks, which reveals the high purity and excellent quality of the film. The shift between the sharp peak and the diamond peak (1332 cm-1) is associated with the residual stress of the MCD film [20].

Fig. 2 Raman spectra of as-deposited diamond films

Fig. 3 Flank wears (VB) of uncoated Si3N4 insert, MCD and MCD/NCD coated inserts as function of cutting length

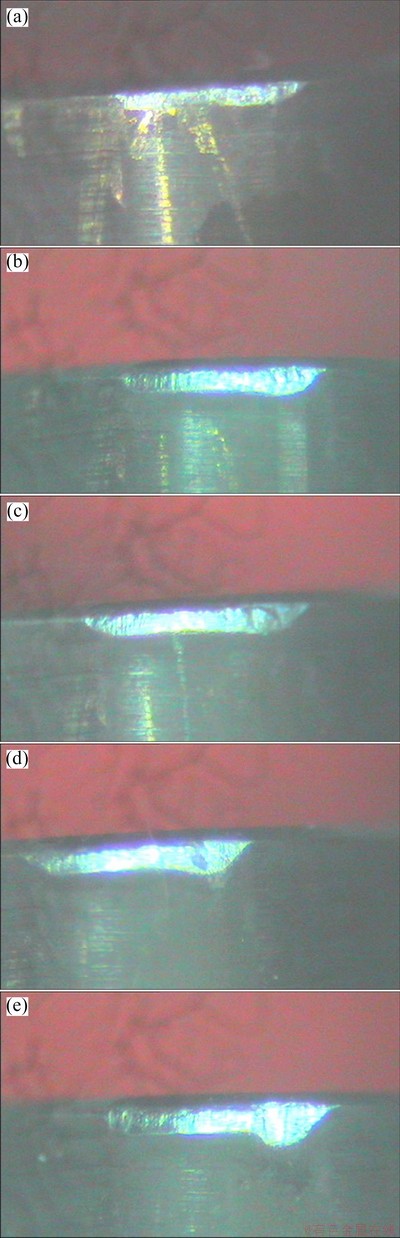

Fig. 4 Images of flank wear of uncoated insert after turning 375 m (a), 750 m (b), 1125 m (c), 1500 m (d) and 1875 m (e) of cutting length

Fig. 5 Image of flank wear of NCD coated insert after turning 375 m of cutting length

Fig. 6 Images of flank wear of MCD coated insert after turning 375 m (a), 750 m (b), 1125 m (c), 1500 m (d) and 1875 m (e) of cutting length

3.2 Cutting performance of as-deposited multilayer diamond films

Figure 3 shows the flank wear for all the as-deposited diamond coated inserts and uncoated insert as a function of cutting length. The worn surfaces of uncoated insert, NCD, MCD and MCD/NCD coated inserts are shown in Figs. 4-7. The corresponding surface morphologies of their cutting edges are also examined by FE-SEM (Fig. 8). The flank wear of the uncoated insert surpasses 0.3 mm after 1875 m of cutting length. An important feature of the NCD coated insert is the coating peeling during the initial 375 m turning process, as shown in Fig. 5 and Fig. 8(b). Such phenomena are a result of the higher degree of sp2 content in NCD films because the higher the graphite content at the interface, the lower the bonding strength to the substrate [21]. It is worth noting that the MCD crystalline purity is higher compared with NCD grade. In fact, the MCD sample has the smallest non-diamond phase content and thus its adhesive strength is strengthened. As a result, the MCD film relative to NCD film exhibits a significant enhancement in its cutting performance. Its flank wear shows that MCD coated insert can have a life of more than 1500 m of cutting length. However, the failure still occurs after 2250 m of cutting length because the diamond coating peels off from the substrate, as shown in Fig. 6(e) and Fig. 8(c). Comparatively, the MCD/NCD coated insert shows a slow increasing tendency in flank wear during whole turning process, which suggests that CVD diamond film can protect insert from suffering severe wear due to its extremely high hardness and unique wear resistance, and plays a decisive role in prolonging the lifetime of the inserts. The results show that the MCD/NCD coated insert exhibits very lower flank wear than MCD coated insert and uncoated insert, which may be attributed to the nanocrystalline diamond coating with smooth surface and high wear resistance [6,12]. No coating peeling is observed after turning the nearly two times longer cutting length than MCD coated insert, as shown in Fig. 7(h) and Fig. 8(d), which suggests that the adhesive strength between the MCD/NCD film and insert is strong enough to meet the cutting requirement. Compared with NCD film, MCD film exhibits a higher hardness. Thus MCD/NCD film can uphold the applied load and reduces the plastic deformation volume in the substrate [22]. As a result of all these contributions, adhesion of the diamond coating to the substrate is much improved in the MCD/NCD film compared with NCD film. On the other hand, the smoother surface of MCD/NCD film can lead to potential lower friction between the insert and workpiece material, which is beneficial to the chip evacuation and reducing the cutting force. Therefore, the tool wear of MCD/NCD coated insert is very low. However, the MCD film has a high surface toughness and thus increases cutting force. This results in the fact that the MCD coated insert exhibits the coating peeling only after 2250 m of cutting length.

Fig. 7 Images of flank wear of MCD/MCD coated insert after turning 375 m (a), 750 m (b), 1125 m (c), 1500 m (d), 1875 m (e), 2250 m (f), 2650 m (g) and 3000 m (h) of cutting length

4 Conclusions

1) Multilayer diamond films are deposited on silicon nitride inserts with a mixture of acetone, hydrogen and argon as the reactant gas by the HFCVD method. Double-layer structure (MCD/NCD) is fabricated initially by the deposition of the rough microcrystalline diamond layers and then the smooth fine-grained nanocrystalline diamond layers. Such multilayer diamond coatings not only display good adhesion and wear resistant properties, but also have high surface smoothness.

2) For comparative purpose, the uncoated insert and monolayer NCD and MCD coated inserts are also adopted in this work. The respective coating structure results in dissimilar cutting performance in dry turning of Al-Si alloys at 350 m/min of cutting speed, 0.4 mm of cutting depth and 0.1 mm/r of feed. The MCD/NCD coated insert exhibits the prefect behavior as tool wear.

For this coating, the flank wear is very low after turning 3000 m of cutting length and no diamond peeling occurs. The performance of the monolayer MCD coated insert is slightly inferior due to the high hardness. The conventional monolayer NCD film, featured by a cauliflower-like morphology, suffers the coating peeling from its lower adhesion between diamond coating and substrate.

3) Compared with the uncoated inserts, the multilayer diamond film can protect inserts from suffering severe wear due to its extremely high hardness and unique wear resistance, and plays a decisive role in prolonging the lifetime of the inserts.

Fig. 8 FE-SEM images of surface morphology of inserts after turning Al-Si alloys

References

[1] KOPF A, FEISTRITZER S, UDIER K. Diamond coated cutting tools for machining of non-ferrous metals and fibre reinforced polymers [J]. International Journal of Refractory Metals & Hard Materials, 2006, 24: 354-359.

[2] AMARAL M, OLIVEIRA F J, BELMONTE M, FERNANDES A J S, COSTA F M, SILVA R F. Tailored Si3N4 ceramic substrates for CVD diamond coating [J]. Surface Engineering, 2003, 19: 410-416.

[3] BELMONTE M. Diamond coating of coloured Si3N4 ceramics [J]. Diamond and Related Materials, 2005, 14: 54-59.

[4] XU Feng, ZUO Dun-wen, LU Wen-zhuang, ZHU Yong-wei, WANG Min. Grid and substrate bias effects on mechanical properties of diamond films prepared by HFCVD [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: s722-s726.

[5] CABRAL G, REIS P, TITUS E, MADALENO J C, DAVIM J P, GRACIO J, AHMED W, JACKSON M J. Impact of surface roughness of diamond coatings on the cutting performance when dry machining of graphite [J]. International Journal of Manufacturing Technology and Management, 2008, 15: 121-152.

[6] ALMEIDA F A, AMARAL M, OLIVEIRA F J, SILVA R F. Machining behaviour of silicon nitride tools coated with micro-, submicro- and nanometric HFCVD diamond crystallite sizes [J]. Diamond and Related Materials, 2006, 15: 2029-2034.

[7] ARUMUGAM P U, MALSHE A P, BATZER S A. Dry machining of aluminum-silicon alloy using polished CVD diamond-coated cutting tools inserts [J]. Surface & Coatings Technology, 2006, 200: 3399-3403.

[8] QIN F, HU J, CHOU Y K, THOMPSON R G. Delamination wear of nano-diamond coated cutting tools in composite machining [J]. Wear, 2009, 267: 991-995.

[9] ALMEIDA F A, SACRAMENTO J, OLIVEIRA F J, SILVA R F. Micro- and nano-crystalline CVD diamond coated tools in the turning of EDM graphite [J]. Surface & Coatings Technology, 2008, 203: 271-276.

[10] HU J, CHOU Y K, THOMPSON R G. Nanocrystalline diamond coating tools for machining high-strength Al alloys [J]. International Journal of Refractory Metals & Hard Materials, 2008, 26: 135-144.

[11] HU J, CHOU Y K, THOMPSON R G, BURGESS J, STREET S. Characterizations of nano-crystalline diamond coating cutting tools [J]. Surface & Coatings Technology, 2007, 202: 1113-1117.

[12] LIANG Q, VOHRA Y K, THOMPSON R. High speed continuous and interrupted dry turning of A390 aluminum/silicon alloy using nanostructured diamond coated WC-6 wt.% cobalt tool inserts by MPCVD [J]. Diamond and Related Materials, 2008, 17: 2041-2047.

[13] ALMEIDA F A, AMARAL M, OLIVEIRA F J, FERNANDES A J S, SILVA R F. Nano to micrometric HFCVD diamond adhesion strength to Si3N4 [J]. Vacuum, 2007, 81: 1443-1447.

[14] SHEN B, SUN F H. Deposition and friction properties of ultra-smooth composite diamond films on Co-cemented tungsten carbide substrates [J]. Diamond and Related Materials, 2009, 18: 238-243.

[15] SUN F H, ZHANG Z M, CHEN M, SHEN H S. Improvement of adhesive strength and surface roughness of diamond films on Co-cemented tungsten carbide tools [J]. Diamond and Related Materials, 2003, 12: 711-718.

[16] SUN F H, MA Y P, SHEN B, ZHANG Z M, CHEN M. Fabrication and application of nano-microcrystalline composite diamond films on the interior hole surfaces of Co cemented tungsten carbide substrates [J]. Diamond and Related Materials, 2009, 18: 276-282.

[17] CASTRO G, ALMEIDA F A, OLIVEIRA F J, FERNANDES A J S, SACRAMENTO J, SILVA R F. Dry machining of silicon-aluminium alloys with CVD diamond brazed and directly coated Si3N4 ceramic tools [J]. Vacuum, 2008, 82: 1407-1410.

[18] PRAWER S, NEMANICH R J. Raman spectroscopy of diamond and doped diamond [J]. Philosophical Transactions of the Royal Society of London Series A: Mathematical Physical and Engineering Sciences, 2004, 362: 2537-2565.

[19] ROY D, BARBER Z H, CLYNE T W. Ag nanoparticle induced surface enhanced Raman spectroscopy of chemical vapor deposition diamond thin films prepared by hot filament chemical vapor deposition [J]. Journal of Applied Physics, 2002, 91: 6085-6088.

[20] FERREIRA N G, ABRAMOF E, CORAT E J, TRAVA-AIROLDI V J. Residual stresses and crystalline quality of heavily boron-doped diamond films analysed by micro-Raman spectroscopy and X-ray diffraction [J]. Carbon, 2003, 41: 1301-1308.

[21] MALLIKA K, KOMANDURI R. Low pressure microwave plasma assisted chemical vapor deposition (MPCVD) of diamond coatings on silicon nitride cutting tools [J]. Thin Solid Films, 2001, 396: 145-165.

[22] NESLADEK M, VANDIERENDONCK K, QUAEYHAEGENS C, KERKHOFS M, STALS L M. Adhesion of diamond coatings on cemented carbides [J]. Thin Solid Films, 1995, 270: 184-188.

陈乃超,孙方宏

上海交通大学 机械与动力工程学院,上海 200240

摘 要:硅铝合金非常难以进行切削加工,金刚石刀具被认为是当前切削该类材料的最好工具。考虑到高附着力和好的表面形貌对化学气相沉积(CVD)金刚石涂层的应用具有重要影响,提出了基于热丝化学气相沉积(HFCVD)方法的多层膜技术,并在氮化硅刀具上沉积出多层膜结构的金刚石涂层,微米金刚石(MCD)/纳米金刚石(NCD)结构。为了与多层膜金刚石涂层进行比较,同时制备出单层MCD和NCD涂层。采用场发射电镜(FE-SEM)和拉曼光谱对沉积的金刚石薄膜进行表征。研究了有沉积金刚石涂层和没有涂层的刀具车削硅铝合金的切削性能。结果表明:MCD/NCD多层金刚石涂层表现出优异的耐磨性能,具有较小的后刀面磨损量,涂层无脱落。

关键词:硅铝合金;多层膜结构金刚石涂层;氮化硅;切削性能

(Edited by Hua YANG)

Foundation item: Project (50975177) supported by the National Natural Science Foundation of China

Corresponding author: Fang-hong SUN; Tel: +86-21-34206557; Fax: +86-21-62932610; E-mail: sunfanghong@sjtu.edu.cn

DOI: 10.1016/S1003-6326(13)62687-4