DOI: 10.11817/j.ysxb.1004.0609.2021-36453

载流搅拌摩擦焊对2219铝合金显微组织和力学性能的影响

白亚锋1,蒋晓青1,陈树君1,张洪玮2,韩 阳1,袁 涛1

(1. 北京工业大学 汽车结构部件先进制造技术教育部工程研究中心,北京 100124;

2. 北京新能源汽车股份有限公司,北京 100176)

摘 要:采用载流搅拌摩擦焊方法对6 mm厚AA2219铝合金板进行了不同脉冲电流大小的对接焊实验,研究焊接接头显微组织形貌和力学性能,结合断口宏观形貌及不同区域的硬度分布趋势,揭示电流对接头性能的影响。结果表明:随着电流增加,热输入增高,晶粒动态再结晶区域增多,接头抗拉强度和断后伸长率提升,拉伸试样断裂均发生在前进侧搅拌区和热机影响区的交界处。通过研究断口微观结构发现,载流接头更佳,增强了接头的韧性断裂。对焊接接头横截面硬度进行研究,其硬度变化趋势呈现“V”分布,焊核区硬度提高。焊缝中不同区域受搅拌针作用和热量分布情况不同,导致焊缝中析出相分布不同,影响了接头硬度,改善了焊接接头力学性能。

关键词:2219铝合金;载流搅拌摩擦焊;显微组织;力学性能

文章编号:1004-0609(2021)-03-0556-10 中图分类号:TG456.9 文献标志码:A

引文格式:白亚锋, 蒋晓青, 陈树君, 等. 载流搅拌摩擦焊对2219铝合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2021, 31(3): 556-565. DOI: 10.11817/j.ysxb.1004.0609.2021-36453

BAI Ya-feng, JIANG Xiao-qing, CHEN Shu-jun, et al. Effect of electrically assisted friction stir welding on microstructure and mechanical properties of 2219 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 556-565. DOI: 10.11817/j.ysxb.1004.0609.2021-36453

AA2219铝合金作为性能优异的低温Al-Cu-Mn合金,具有良好的焊接性、高比强度和抗应力腐蚀性,在汽车、航空及航天等领域应用广泛,在推进结构轻量化方面发挥了不可替代的作用,以AA2219作为原材料的航天贮箱,已经将搅拌摩擦焊接作为关键制造工艺[1-2]。搅拌摩擦焊接技术(Friction stir weld, FSW)是由英国焊接研究所(The welding institute, TWI)于1991年发明的一种新型固相焊接技术,它具有不变形、残余应力小、无孔隙、节能环保等优点,在低熔点有色金属中有着广泛的应用,但对于碳钢、钛合金等高熔点合金来说,低热输入限制了其进一步的发展[3-4]。为了解决该问题,研究学者提出并应用了辅助热源搅拌摩擦焊的复合焊接方法,采用等离子弧、激光、感应热和电阻热等作为辅助能源[5-6]。其中,载流搅拌摩擦焊接(Electric current aided friction stir weld, EFSW)作为一种新的焊接方法正吸引着越来越多的关注,旨在产生更多的热输入,改善焊接接头的性能,减小搅拌头的磨损,并扩大搅拌摩擦焊的应用范围。

罗键等[7]研发了电流辅助搅拌摩擦焊方法,分别以搅拌头和工件端部作为两个电极,使电流流过工件内部产生电阻热,该电阻热和搅拌摩擦热形成复合热源,在复合热源共同作用下搅拌头邻近区域的材料受热变软达到热塑化状态,最后在轴肩的顶锻力作用下实现工件之间的固相连接。罗键课题组[8-12]对电流辅助搅拌摩擦焊进行了数值模拟,设计了搅拌工具,研究了搅拌头的磨损,并分析了镁、铝和钢的接头组织和力学性能,发现电流辅助电流产生的电阻热细化了镁合金焊核区晶粒组织,提高了其显微硬度,增强了塑性变形。而对于铝合金,焊核区和热影响区的晶粒尺寸随着电流密度的增大而轻微增加。陈峥等[13]采用电流辅助搅拌摩擦焊方法成功实现了镁合金厚板的单面单道对接焊,并分析了接头的组织和力学性能。SANTOS等[14-15]改进了电流辅助搅拌摩擦焊,其在搅拌头的轴心增加一个铜芯,并在背部垫板上相应地增加一个铜键,使电流在工件中的分布更加集中,解决了常规搅拌摩擦焊由于底部产热不足引起的未焊透等根部缺陷,并通过此方法提升了Al/NiTi复合材料的力学性能。LIU等[16]研发了两个可以直接施加在工件上的电极,形成一个随搅拌头移动的电流场,产生“电塑性(高密度电流引起的金属软化)”,以达到显著降低焊接载荷的目的,并分析了外加电流对铝-钢接头的焊接力以及焊接界面金属间化合物层的影响。

本研究采用脉冲电流对AA2219铝合金进行了不同电流值下的搅拌摩擦焊,分析了焊接接头的形貌、显微组织和力学性能等,与常规搅拌摩擦焊进行了对比,旨在利用辅助电流提高焊接过程中的热输入,改善焊接接头的力学性能。

1 实验

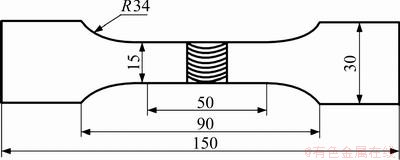

实验选用中厚度AA2219-T87铝合金板材,母材尺寸为180 mm×100 mm×6 mm。其化学成分如下表1所示,母材的抗拉强度是445MPa,断后伸长率是13%。搅拌摩擦焊接实验在北京CFSW 技术有限公司设备FSW-TS-S08上进行,焊接平台如图1,焊接参数如下:转速为800 r/min,焊接速度为160 mm/min,搅拌头倾角为1.5°。搅拌头材料为H13钢,轴肩直径为15 mm,搅拌针根部直径6 mm,端部直径3 mm,针长5.8 mm。SANTOS等提出铝合金对电流不敏感,需要大电流才能显著提升铝合金载流搅拌摩擦焊接效果,所以本文选取的脉冲直流电流平均值为0、400和600 A,脉冲频率为30 Hz,脉冲占空比为50%。焊后将工件沿横截面用线切割机切割制成金相试样,打磨抛光后用Keller试剂(1.0%HF+1.5%HCl+2.5%HNO3+95.0%H2O)对金相试样进行腐蚀,采用OLYMPUS LEXT 3100激光共聚焦显微镜观察各金相试样的显微组织,用FEI Quanta200型扫描电镜对拉伸试样断口进行观察。按GB/T 2649—1989《焊接接头机械性能试验取样方法》和 GB/T 228—2002《金属材料室温拉伸试样方法》沿垂直焊缝方向制取拉伸试样,如图2所示,用CSS-1110型电子万能试验机进行室温拉伸实验,拉伸速率为2 mm/min。用DHV-1000显微维氏硬度计进行显微硬度测试,间隔0.5 mm取点,试验力为0.98 N,载荷时间为15 s。

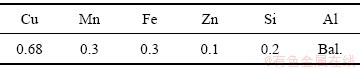

表1 AA2219-T87铝合金的化学成分表

Table 1 Chemical compositions and mechanical properties of AA2219-T87 Al alloy (mass fraction, %)

图1 载流焊接平台

Fig. 1 Current-carrying friction stir welding platform

图2 拉伸试样示意图

Fig. 2 Schematic diagram of tensile specimens (Unit: mm)

2 结果与讨论

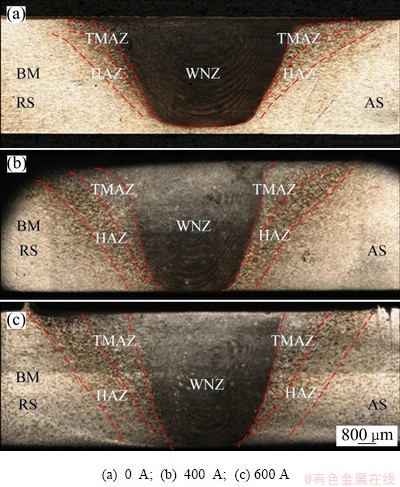

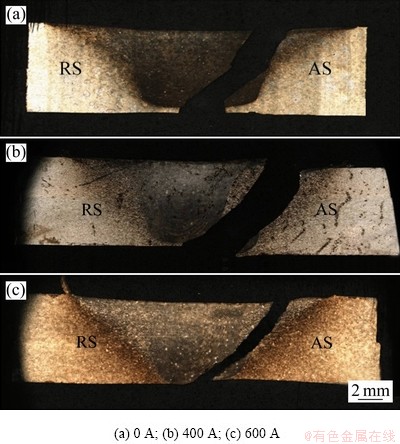

2.1 脉冲电流对接头横截面宏观形貌的影响

同常规搅拌摩擦焊接相同,脉冲载流搅拌摩擦焊接接头也分为4个区域:焊核区(WNZ)、热机影响区(TMAZ)、热影响区(HAZ)、母材区(BMZ)。由实验数据得知,焊核区受电流热输入影响变化不大,热机影响区和热影响区受热输入影响较大。因为脉冲电流大小变化,载流焊接过程中热输入增加程度不同,导致各区域范围呈现不同程度变大。

图3所示为不同脉冲载流搅拌摩擦焊接接头宏观形貌。其中3种接头位于前进侧的焊核区和热机影响区处分界线都很清晰,而后退侧两区域界线不明显,这种与金属塑性流动形态有关。在以设定焊速实验中,搅拌针后侧材料随搅拌针流入前进侧,后侧出现空腔,由搅拌针前进侧材料填补进来,同时,受焊接速度影响,前进侧材料也会流入搅拌针后侧孔洞内,导致前进侧材料流动方向相同,而后退侧材料流动方向较为复杂,由此前进侧出现明显分界线。同时,受搅拌针和轴肩旋转作用,搅拌区材料流塑性速度较快,热机影响区材料受搅拌针作用较弱,其材料塑性流动速度较慢,与搅拌区材料流动形成速度梯度,两区域过渡不均匀,存在应力集中现象。接头拉伸试样断裂在前进侧搅拌区与热机影响区的交界处也证明了这一观点。

受不同焊接参数的影响,铝合金搅拌摩擦焊接接头宏观形貌会产生变化,主要表现在接头各区域组织形态和面积不同。从图3(b)和(c)中可以看到,脉冲电流400 A和600 A接头的热机影响区和热影响区面积明显变大,载入脉冲电流,热输入增加,产生附加的电阻热导致附加的热输入增强金属流塑性,焊接温度的提升,引发晶粒再结晶区域增加,由此热机影响区和热影响区面积变大。

图3 不同脉冲载流搅拌摩擦焊接接头宏观形貌

Fig. 3 Macroscopic morphologies of friction stir welding joints with different pulse currents

2.2 脉冲电流对接头显微组织的影响

不同的热输入影响接头内部晶粒形貌和分布,在传统搅拌摩擦焊接过程中,热输入一部分来源于搅拌头与工件之间摩擦产生的热量,还有一部分来源于塑化金属材料间充分流动产生的热量。当温度达到金属再结晶的温度时,金属内部开始形成晶核,晶粒开始长大。在搅拌区动态再结晶过程中,晶粒来不及长大,便被搅拌针搅碎,形成细小的等轴晶粒;位于热机影响区晶粒,对比搅拌区其受搅拌头机械搅拌作用较小,其晶粒尺寸较大;由于热影响区距离搅拌头较远,不受搅拌针的机械搅拌作用,晶粒在动态再结晶过程中,不会被搅碎,出现晶粒粗化现象。但与母材相比,晶粒并无因轧制生产铝材而出现细长条形状。

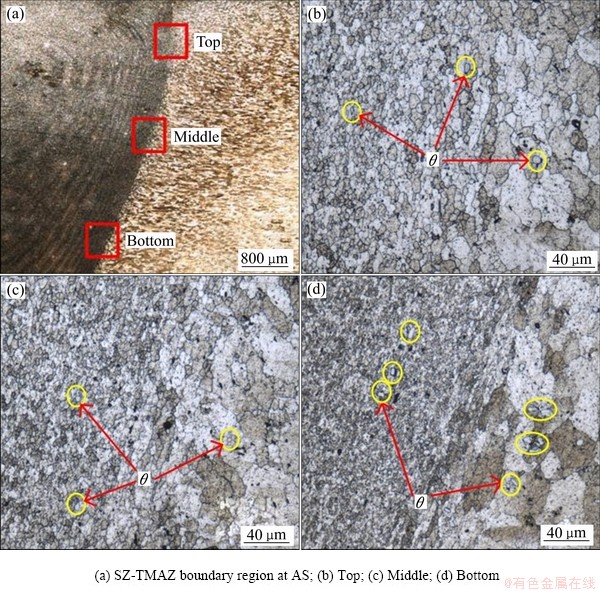

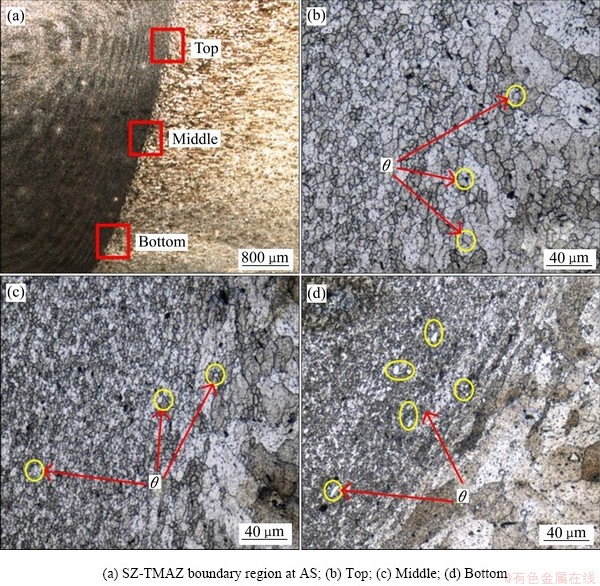

搅拌区塑性材料受搅拌针搅拌作用,材料流动形态影响析出相在前进侧和后退侧分布情况,同时同一焊接接头截面上、中、下部显微组织分布情况也不相同。图4所示为有效电流为400 A脉冲载流搅拌摩擦焊接接头搅拌区与热机影响区过渡区的显微组织对比图,其中可以看到位于上、中部搅拌区存在极少量θ相(Al2Cu),而在搅拌针底部区域出现较多θ相,同时发现θ相聚集现象。图5所示为有效电流为600 A脉冲载流搅拌摩擦焊接接头搅拌区与热机影响区过渡区域的显微组织对比图,其出现与图4相同的分布情况,但图5(d)中的θ相较图4(d)中的θ相形状大。出现这种情况可能是在搅拌区,上、中、下不同区域受搅拌针搅拌和塑性材料流动作用不同,同时两接头受到大小不同的脉冲电流影响,600 A脉冲电流情况下,热输入更高,析出相发生粗化,造成形状大小不同[17]。同时,从图中均能发现搅拌区从上到下的晶粒尺寸逐渐变小,上部受搅拌头轴肩作用,热输入最大,晶粒动态再结晶过程中,受到热量积累最多,使得晶粒最大。

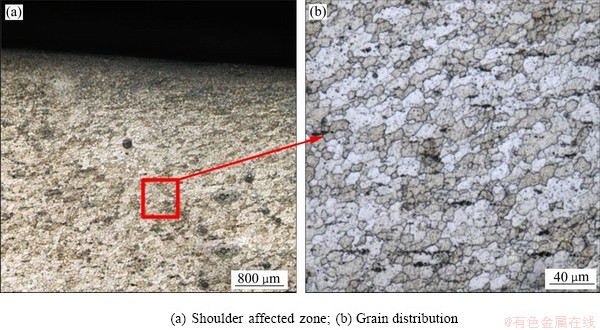

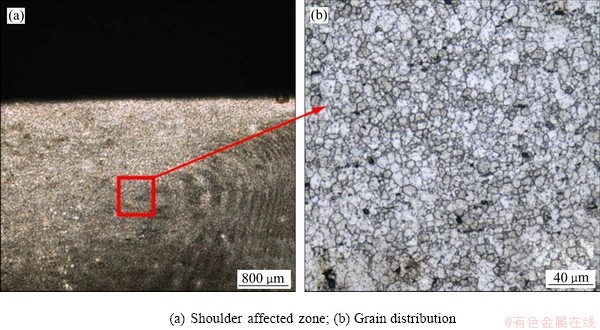

在传统搅拌摩擦焊接过程中,轴肩影响区(SAZ)位于搅拌区上端,搅拌头轴肩下侧,受轴肩机械摩擦作用,显微组织由细小等轴晶构成。大量热源分布在轴肩与母材,下侧材料在塑性状态下做高速旋转,轴肩影响区材料运动速度不同,存在速度梯度,轴肩影响区发生动态随机再结晶现象,同时受到轴肩较大的向下锻压力,晶粒在再结晶过程中来不及长大,便形成细小等轴晶粒。

图4 400 A脉冲载流搅拌摩擦焊接接头搅拌区与热机影响区过渡区显微组织

Fig. 4 Microstructures of transition between SZ and TMAZ 400 A pulsed current-carrying friction stir welding joint

图5 600 A脉冲载流搅拌摩擦焊接接头搅拌区与热机影响区过渡区显微组织

Fig. 5 Microstructures of transition between SZ and TMAZ 600 A pulsed current-carrying friction stir welding joint

如下图6所示400 A轴肩影响区,电流从搅拌头轴肩区域流经待焊板材中,对铝合金SAZ区域热量积累较多,其晶粒尺寸为(10.23±0.92) μm。而在图7所示600 A脉冲载流搅拌摩擦焊接过程中,SAZ区域晶粒动态再结晶后细小等轴晶较多,其晶粒尺寸为(7.64±1.17) μm,晶粒细化造成600 A接头性能更加优异。

2.3 脉冲电流对接头力学性能的影响

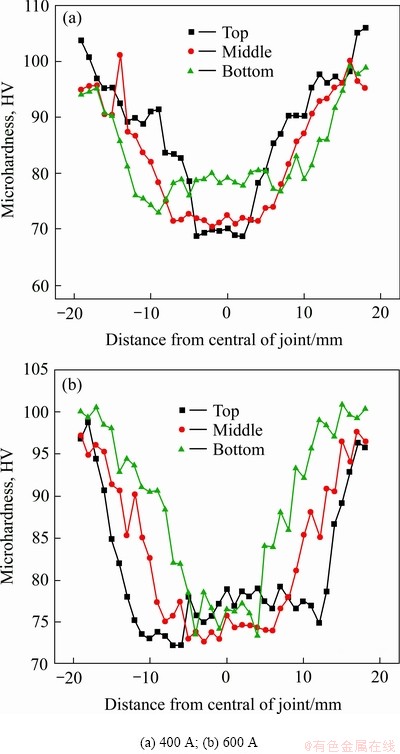

2.3.1 脉冲电流对显微硬度分布的影响

焊接参数影响焊接过程热输入,影响接头显微组织形成和分布。在搅拌摩擦焊接过程中,搅拌针为锥形,同时中间加工螺纹,造成焊接接头在厚度方向受搅拌头作用力不同。其中接头因受焊接过程中的热循环作用,导致硬度比母材低。如图8脉冲载流搅拌摩擦焊接接头硬度分布为“V”形状,但前进侧较后退侧硬度有提升,这与之前研究的常规和直流载流搅拌摩擦焊接接头呈现的硬度分布相同[18],但脉冲接头在搅拌区硬度会上升。载流后,在接头厚度方向上底部硬度均比上端和中间位置硬度大,其显微硬度分布是显微组织的反映。搅拌区受搅拌针作用发生动态再结晶,其中位于下侧的晶粒受到搅拌针搅拌作用更强,动态再结晶的晶粒还没来得及长大,就被搅拌针搅碎,形成细小等轴晶粒[19],其比中部和顶部晶粒更加细小,所以位于底部的显微硬度最大。

图6 400 A脉冲载流搅拌摩擦焊接接头轴肩影响区的显微组织

Fig. 6 Microstructures of SAZ with 400 A pulsed current-carrying friction stir welding joint

图7 600 A脉冲载流搅拌摩擦焊接接头轴肩影响区的显微组织

Fig. 7 Microstructures of SAZ with 600 A pulsed current-carrying friction stir welding joint

图8 不同脉冲载流搅拌摩擦焊接接头显微硬度分布

Fig. 8 Microhardness distribution profile of welding joint with different pulse currents

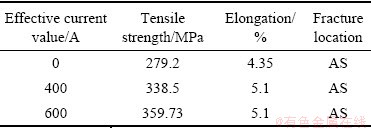

2.3.2 脉冲电流对接头抗拉强度的影响

传统搅拌摩擦焊接接头抗拉强度为279.2 MPa,达到母材抗拉强度445 MPa的62.74%;其接头断后伸长率为4.35%,母材断后伸长率为13%。表2所示为不同大小脉冲电流下拉伸试样的抗拉强度和断后伸长率。由表2可以看到,经脉冲电流复合后,有效电流为400 A的焊接接头抗拉强度为338.5 MPa,断后伸长率为5.1%,比传统搅拌摩擦焊接接头的抗拉强度和断后伸长率分别提高了59.3 MPa和0.75%,其接头抗拉强度达到母材的76.07%。增大脉冲电流到600 A,焊接接头抗拉强度为359.73 MPa,断后伸长率为5.1%,比传统搅拌摩擦焊接接头的抗拉强度和断后伸长率分别提高了80.53 MPa和0.75%,其接头抗拉强度达到母材的80.84%。这是由于600 A时热输入更大,材料流动性更好,搅拌区的晶粒尺寸更小,起到了细晶强化的作用,同时搅拌区θ相也更加细小,具有一定的析出强化效果增强[20]。

载流搅拌摩擦焊在传统搅拌摩擦焊的基础上增加了电阻热,复合热源的增加,增强了热输入,改变了焊接材料的流塑性。保持相同焊接参数,当有效热输入少时,接头搅拌区在搅拌针的搅拌作用下,仅能保证搅拌针直径范围内材料的流动性好,由于接头其他区域不受搅拌作用,热输入较搅拌区略微变少,产生温度梯度,造成材料流动速度不同,最终影响搅拌区和热机影响区的组织发生变化。

表2 不同脉冲载流搅拌摩擦焊接接头拉伸性能

Table 2 Tensile properties of friction stir welding joints with different pulse current carrying capacity

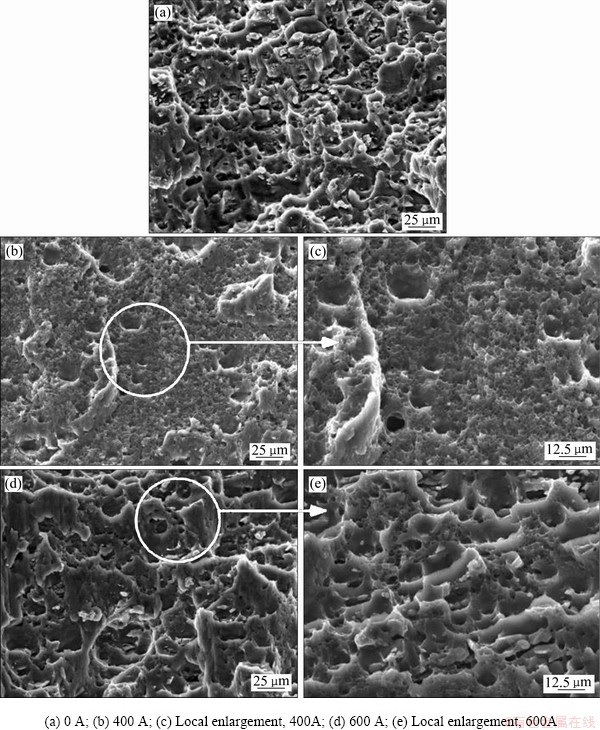

2.3.3 脉冲电流对拉伸试样断口形貌的影响

接头断裂位置与晶粒大小和显微硬度有关,通过对搅拌摩擦焊接接头拉伸试样断口分析,得到接头断裂位置和断裂模式。如图9所示,断口出现45°角度断裂,脉冲载流搅拌摩擦焊接接头断裂位置位于前进侧搅拌区与热机影响区交界处。发生这种现象通常是接头搅拌区晶粒比较细小,在焊接温度下,析出相在搅拌针作用下被打碎,均匀的分布在搅拌区。离搅拌针较远的热机影响区,受到机械搅拌作用较少,但在高温条件下晶粒较搅拌区晶粒尺寸变大,接头搅拌区、热机影响区和热影响区晶粒尺寸过渡较突兀,显微组织过渡不匀称,容易产生应力集中现象,造成此位置力学性能差。脉冲电流峰值提供更高的热输入,较直流载流搅拌摩擦焊接接头搅拌区细化晶粒更均匀细密,增强搅拌区硬度。

图9 不同脉冲载流搅拌摩擦焊接接头断口宏观形貌

Fig. 9 Fracture appearances of welding joint with different pulse currents

直流载流搅拌摩擦焊接接头断在搅拌区,说明搅拌区硬度最低,也说明了脉冲载流搅拌摩擦焊接接头性能更加优异。

通过对有效电流值为400 A和600 A脉冲载流搅拌摩擦焊接接头断口进行扫描,通过观察图10发现断口中韧窝分布情况,均为韧性断裂。

其中图10(b)和(c) 400 A接头断口中看到韧窝形状较大,孔坑较深,其中小韧窝分布较少。图10(d)和(e) 600 A接头断口中看到明显分布的撕裂棱,在大韧窝周围和撕裂棱上还分布有等轴状小韧窝,这些韧窝是由微孔在空间三个方向上长大,其速度相同,最终形成圆形的等轴韧窝[21],搅拌头轴肩和搅拌针的搅拌作用,结合向下的锻压力,使晶粒破碎、细化,形成的等轴晶组织,其分布均匀细密,使接头均匀性和一致性较好,在拉应力情况下断口出现等轴韧窝。合金中强化相是形成韧窝的主要原因,其在外力作用下,滑移形成微型孔洞,然后大量孔洞不断聚集,产生新孔洞,最后导致工件断裂[22]。随着脉冲有效电流的提高,断口中出现的小韧窝更加密集,由400 A的穿晶断裂较多的细长抛物线形态变为600 A的沿晶断裂的圆形等轴韧窝,受脉冲峰值电流较高,热输入较多,析出相较多,高速旋转的搅拌针,会对析出相进行搅拌破碎,造成析出相分布更加均匀,导致产生等轴韧窝较多,提升了焊接接头的力学性能。

图10 不同脉冲载流搅拌摩擦焊接对断口韧窝分布

Fig. 10 SEM micrographs showing fracture surface characteristics of tensile specimens machined at different currents

3 结论

1) 载流搅拌摩擦焊接增加了焊缝区横截面区域面积,同时焊缝面积随着电流数值的变大而变大,其中热影响区面积提升明显。电流参与搅拌摩擦焊接,增强了原焊接参数的热输入,改变了原焊核区、热机影响区、热影响区的晶粒形貌和分布。

2) 载流后接头抗拉强度和断后伸长率皆有提升,平均电流的600 A脉冲实验中,其接头抗拉强度提升了28.84%到359.73 MPa。在焊接过程中,电流提供额外热源,提升了传统搅拌摩擦焊接接头的力学性能。载流接头焊缝各区域硬度随电流变大提升程度依次递增,硬度总体分布为“V”形,在焊核区硬度略有提升,在焊缝底部位置,硬度提升效果最为显著。

3) 传统搅拌摩擦焊接断裂位置为前进侧WNZ与TMAZ的交界处,脉冲载流接头断裂位置仍然在前进侧WNZ与TMAZ位置,虽然抗拉强度和硬度提升,但此处应力集中明显,两侧晶粒变化大,无明显过渡状态,导致断裂位置发生在前进侧WNZ与TMAZ位置。电流引入,使得大韧窝周围分布更多的等轴小韧窝,发现细小等轴韧窝分布均匀,密集程度更高。

REFERENCES

[1] WANG G Q, ZHAO Y H, HAO Y F. Friction stir welding of high-strength aerospace aluminum alloy and application in rocket tank manufacturing[J]. Journal of Materials Science & Technology, 2018, 34(1): 73-91.

[2] KAYODE O, AKINLABI E T. An overview on joining of aluminium and magnesium alloys using friction stir welding (FSW) for automotive lightweight applications[J]. Materials Research Express, 2019, 6(11): 112005.

[3] LI K, LIU X M, ZHAO Y. Research status and prospect of friction stir processing technology[J]. Coatings, 2019, 9(2): 129.

[4] PADHY G K, WU C S, GAO S. Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review[J]. Journal of Materials Science & Technology, 2018, 34(1): 1-38.

[5] 孙金睿, 朱 海, 孙 龙, 等. 外加能量辅助搅拌摩擦焊的最新研究进展[J]. 热加工工艺, 2018, 47(5): 15-20.

SUN Jin-rui, ZHU Hai, SUN Long, et al. Latest research progress of energy assisted friction stir welding[J]. Hot Working Technology, 2018, 47(5): 15-20.

[6] PADHY G K, WU C S, GAO S. Auxiliary energy assisted friction stir welding-status review[J]. Science and Technology of Welding and Joining, 2015, 20(8): 631-649.

[7] 罗 键, 王 颖. 导电-搅拌摩擦复合热源焊接方法及设备. CN101323054[P]. 2018-12-17.

LUO Jian, WANG Ying. Method and equipment of resistance-friction stir welding heat source. CN101323054[P]. 2018-12-17.

[8] LUO J, CHEN W, FU G. Hybrid-heat effects on electrical-current aided friction stir welding of steel, and Al and Mg alloys[J]. Journal of Materials Processing Technology, 2014, 214(2): 3003-3012.

[9] LUO J, LI F, CHEN W. Experimental researches on resistance heat aided friction stir welding of Mg alloy[J]. Quarterly Journal of the Japan Welding Society, 2013, 31(4): s65-s68.

[10] 付 根. 载流搅拌摩擦焊多物理场耦合数值模拟[D]. 重庆: 重庆大学, 2014.

FU Gen, Multiphysics field coupled model on electronic current aided friction stir welding process[D]. Chongqing: Chongqing University, 2014.

[11] 李龙飞. 载流-搅拌摩擦焊搅拌工具的设计制造方法和磨损性能[D]. 重庆: 重庆大学, 2014.

LI Long-fei. Method on design, manufacturing and wear property of electronic current aided friction stir welding tool[D]. Chongqing: Chongqing University, 2014.

[12] 陈 伟. 载流-搅拌摩擦焊接内生电阻热效应及搅拌头磨损行为的研究[D]. 重庆: 重庆大学, 2015.

CHEN Wei. Study on resistance heating effects and tool wear behavior in electric current aided friction stir welding[D]. Chongqing University, 2015.

[13] 陈 峥, 李坤宏. 镁合金厚板载流搅拌摩擦焊接头的组织与力学性能[J]. 电焊机, 2015, 45(6): 95-99.

CHEN Zheng, LI Kun-hong. Research on the microstructure and mechanical properties of magnesium alloy plank by electronic current aided friction stir welding[J]. Electric Welding Machine, 2015, 45(6): 95-99.

[14] SANTOS T G, MIRANDA R M, VILACA P. Friction stir welding assisted by electrical joule effect[J]. Journal of Materials Processing Technology, 2014, 214(10): 2127-2133.

[15] OLIVEIRA J P, DUARTE J F, INACIO P. Production of Al/NiTi composites by friction stir welding assisted by electrical current[J]. Materials and Design, 2017, 113: 311-318.

[16] LIU X, LAN S H, NI J. Electrically assisted friction stir welding for joining Al 6061 to TRIP780steel[J]. Journal of Materials Processing Technology, 2015, 219: 112-123.

[17] LI G H, ZHOU L, LUO S F. Microstructure and mechanical properties of self-reacting friction stir welded AA2219-T87 aluminium alloy[J]. Science and Technology of Welding and Joining, 2019, 25(2): 142-149.

[18] CHEN S J, ZHANG H W, JIANG X Q. Mechanical properties of electric assisted friction stir welded 2219 aluminum alloy[J]. Journal of Manufacturing Processes, 2019, 44: 197-206.

[19] 张 华, 孙大同, 张 贺, 等. 2219铝合金搅拌摩擦焊接头腐蚀行为[J]. 焊接学报, 2014, 35(7): 39-42.

ZHANG Hua, SUN Da-tong, ZHANG He, et al. Corrosion behavior of friction stir welded 2219 aluminum alloy[J]. Transactions of the China Welding Institution, 2014, 35(7): 39-42.

[20] 王 健, 卢雅琳, 周 刚, 等. 热轧工艺对2219铝合金组织和力学性能的影响[J]. 金属热处理, 2018, 43(10): 98-103.

WANG Jian, LU Ya-lin, ZHOU Gang, et al. Effect of hot rolling on microstructure and mechanical properties of 2219 aluminum alloy[J]. Heat Treatment of Metals, 2018, 43(10): 98-103.

[21] 熊学辉. 超硬纳米薄膜的显微结构特征及其对性能的影响[D]. 武汉: 武汉理工大学, 2003.

XIONG Xue-hui. Microstructural characteristics and influence on the mechanical properties of superhard nano-scale thin films[D]. Wuhan: Wuhan University of Technology, 2003.

[22] 王 鸿. 镁合金载流-搅拌摩擦焊接工艺与机理研究[D]. 重庆: 重庆大学, 2016.

WANG Hong. Process and mechanism of electric current aided friction stir welded Mg alloy[D]. Chongqing: Chongqing University, 2016.

Effect of electrically assisted friction stir welding on microstructure and mechanical properties of 2219 aluminium alloy

BAI Ya-feng1, JIANG Xiao-qing1, CHEN Shu-jun1, ZHANG Hong-wei2, HAN Yang1, YUAN Tao1

(1. Beijing University of Technology, Advanced Manufacturing Technology of Automobile Structural Components Engineering Research Center of Ministry of Education, Beijing 100124, China;

2. Beijing New Energy Automobile Co., LTD., Beijing 100176, China)

Abstract: The butt welding experiments of 6mm thick AA2219 aluminum alloy plates were carried out by friction stir welding with different pulse currents. Mechanical properties, microstructure, fracture macroscopic morphology and hardness distribution trend of the welded joints were studied. The effect of current on the performance of the joint was revealed. The results show that the dynamic recrystallization region, the tensile strength and elongation of the joint increase with increasing the current value and the heat input. The tensile samples fracture at the junction of weld nugget zone and thermo-mechanically affected zone at the advancing side. Through the study of fracture microstructure, it is found that the electrically assisted joints are better and the ductile fracture of the joints has enhanced. The cross section hardness of the welded joint was studied. The hardness change trend has a “V” shape distribution, and the hardness of weld nugget zone increases. The effect of pin on different areas of the weld is distinct with different heat distribution, resulting in different distributions of precipitates in the weld, which affects the hardness of the joints and improves the mechanical properties of the welded joint.

Key words: 2219 aluminum alloy; electrically assisted friction stir welding; microstructure; mechanical property

Foundation item: Project(51604015) supported by the National Natural Science Foundation of China

Received date: 2019-10-10; Accepted date: 2020-11-26

Corresponding author: CHEN Shu-jun; Tel: +86-10-67392667; E-mail: sjchen@bjut.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51604015)

收稿日期:2019-10-10;修订日期:2020-11-26

通信作者:陈树君,教授,博士;电话:010-67392667;E-mail:sjchen@bjut.edu.cn