文章编号:1004-0609(2008)05-0805-07

真空自耗电弧重熔V-4Cr-4Ti合金的微观组织结构

李鱼飞,罗 超,王志钢,任大鹏,贾建平

(表面物理与化学国家重点实验室,绵阳 621907)

摘 要:采用扫描电子显微镜(SEM)和透射电子显微镜(TEM)分析钒合金在退火前后的微观组织结构。研究表明:铸态合金基体的晶格常数为0.293 8~0.294 3 nm,与纯V相比,晶格收缩了约2.8%,晶内主要析出相为盘状,该相为复杂FCC结构的富Ti型Ti-CNO相,晶格常数为0.423 4~0.428 8 nm,厚度约100 nm,其它两维尺寸达1~2 mm,在晶界上则呈网状连续分布;合金中存在大量位错。约1 000 ℃,1 h退火后,合金基体晶格有所膨胀;组织发生了变化,出现了新的方形第二相,尺寸约为500 nm,原先晶内普遍存在的盘状第二相的尺寸减小。

关键词:钒合金;微观结构;第二相

中图分类号:TG 146.4;TG 113.12 文献标识码:A

Microstructure of V-4Cr-4Ti alloy fabricated by vacuum

arc remelting of consumable electrode

LI Yu-fei, LUO Chao, WANG Zhi-gang, REN Da-peng, JIA Jian-ping

(National Key Laboratory for Surface Physics and Chemistry, Mianyang 621907, China)

Abstract: The microstructures of vanadium alloys before and after annealing were studied by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The results show that the lattice parameter of the as-cast alloy is 0.293 8-0.294 3 nm and the shrinking ratio is 2.8% compared with the pure vanadium. The main precipitation in the bulk grains is the complex Ti rich Ti-CNO phase, which has a plate shape with the width of about 100 nm and the other two dimensions reach up to 1-2 mm. The crystal structure is FCC and the lattice parameter is 0.423 4-0.428 8 nm, while this type precipitation at the grain boundaries forms continuous films. There are amount of dislocation in the ingot. After annealed at 1 000 ℃ for 1 h, the microstructure is changed. The crystal lattice of alloy has expanded and there is a new type of precipitation, which has a square shape and the size is about 500 nm. The size of plate shape precipitation is reduced.

Key words: vanadium alloy; microstructure; second phase

钒合金是聚变核反应堆第一壁结构材料的候选材料之一。目前,世界范围内钒合金的参考成分为V- (3%-5%)Cr-(3%~5%)Ti,并以V-4%Cr-4%Ti(记为 V-4Cr-4Ti)为基准成分[1-4]。除了少数采用磁悬浮熔 炼[5-6]及粉末冶金方法[7]外,钒合金的制备大都采用真空自耗电弧重熔(Vacuum arc remelting of consumable electrode,VAR)方法[8-10]。VAR铸锭质量从几百克到几百千克不等,甚至可达到1.2 t[11]。自20世纪90年代以来,我国核工业西南物理研究院开始利用磁悬浮方法制备钒合金[1, 4-5]。但磁悬浮熔炼不足的是规模较 小,适合在实验室规模研究。为此,在国内开展国际通用的VAR法,探索大质量钒合金的制备工艺非常重要。我国采用VAR法制备名义成分为V-4Cr-4Ti的合金。

目前,关于V-4Cr-4Ti合金铸态性能及组织结构的研究资料很少。TYUMENTSEV等[12]认为VAR铸锭中的主要析出相为片状第二相,成分是十分复杂的,是富含Ti、并含有少量FCC结构的V和Cr的高碳型氧-碳-氮化物,晶格常数为0.424~ 0.428 nm(记为Ti-CON),厚度为100~150 nm,另外两维尺寸达到数个微米。日本和美国的铸锭中也大量存在这种富Ti相,只是晶格常数有所差别,这是由于各种合金化学成分和热处理工艺不同造成的。当杂质含量总量(C+O+N )超过0.08%时,这种主要的Ti-(CON)第二相必然会出现[13]。合金杂质含量越高,Ti-CON相的尺寸和密度越大[14]。

本VAR合金铸锭的质量和化学成分(杂质含量)等与国外均不同,其微观组织结构也必然有所差别。材料组织结构决定性能,而V-4Cr-4Ti合金最典型的微观组织结构就是固溶体中分布多种第二相。那么研究VAR钒合金的微观组织结构,特别是析出相的形 态、位置、成分和结构等,这对认识工艺—成分—组织结构之间的关系,为其它相关研究工作的开展都具有重要的意义。众所周知,退火处理可以使得铸态合金的成分均匀化,并通过改变析出相的数量、分布及形貌来改变组织结构,从而影响合金的力学性能。为此,本研究对VAR铸锭的铸态和退火态的组织结构利用电子显微镜技术进行分析,旨在认识本VAR钒合金的典型组织结构,特别是第二相的形貌、成分、结构和分布位置。

1 实验

1.1 材料制备

采用纯金属粉末为原料,按V-4.5Cr-4Ti(质量分数,%)的实际比例配料约1.1 kg,混料后压制电极并焊接自耗电极。在ZD-5型真空自耗电弧炉上熔炼合金。化学分析得到合金的实际成分为V-3.7Cr-3.6Ti- 0.027C-0.23O-0.01N。取样在真空炉中进行退火处理 (1 000℃,1 h),真空度小于10 mPa。将两种状态的合金用电火花切割成10 mm?10 mm?1 mm的薄片待用。

1.2 分析方法

采用Sirion 200型场发射扫描电镜上(EDS分辨率为129 eV)分析试样表面形貌,腐蚀液中HF、HNO3和H2O的体积比为1?1?3。采用FEI Tecnai F30型场发射透射电子显微镜对合金铸态和退火后的微观组织结构进行分析。F30的加速电压为300 kV,能谱仪的能量分辨率约为132 eV。试样在水砂纸上减薄至约70 mm后,冲成d 3 mm的样品,使用MTP-1型电解双喷仪进行最后减薄,电解液为5%硫酸+95%甲醇(体积比),电压约为10 V,温度约为-5 ℃。

2 结果及分析

2.1 铸态组织结构

图1所示为铸锭的SEM像。从图1可看出,晶粒内部和晶界上都分布有大量的析出相。晶粒内部的析出相似乎为片状的,镶嵌在基体之中,其厚度约为100~150 nm,宽度达1~2 mm。EDS半定量分析结果表明:析出物较基体富Ti,但EDS谱中的析出物与基体的峰强并无明显区别,这与晶内析出物较薄和EDS的空间分辨率有关。但晶界上的第二相(见图1(b))则呈现连续的网状分布,较晶内的更为粗大。EDS结果表明晶界上的析出相明显富含Ti。

图1 铸锭的SEM像

Fig.1 SEM images of ingot: (a) Low magnification; (b) High magnification and EDS results of precipitations at grain boundaries

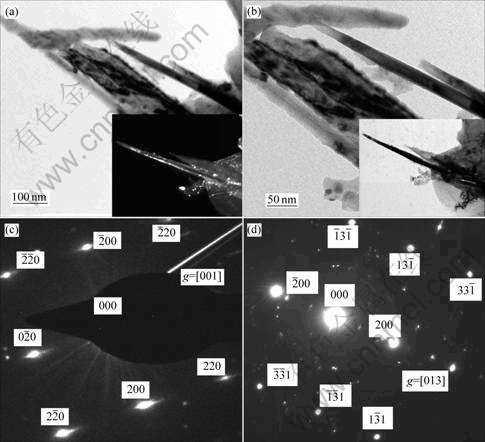

铸锭试样TEM微观组织及微区能谱分析结果如图2所示。由图2可看出,在合金基体中,分布有大量的、形貌类似于针状的析出相,这与SEM结果不同,这是由于取向不同造成的。这种析出物相互平行或相互垂直,说明其与基体之间存在某种固定的取向关系。EDS结果说明这种针状析出相是富Ti的。根据图2(b)和(c)的电子衍射结果可知,固溶体确为bcc结构,并计算出钒固溶体的晶格常数为0.293 8~ 0.294 3 nm。

图2 析出相的TEM明场相形貌和EDS结果(a)以及基体选区电子衍射花样(b),(c)和(d)

Fig.2 TEM bright field and EDS pattern of precipitations(a) and SAD patterns of matrix(b), (c) and (d)

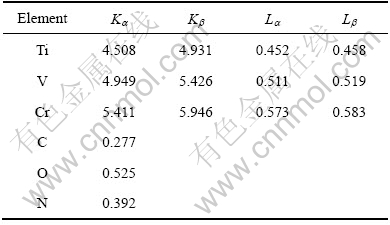

图1和2中Ti、V和Cr峰重叠是由于Ti、V和Cr的特征能量十分接近(见表1)。由表1可知,杂质元素C、N和O由于能谱仪的分辨率限制,会被Ti和V等元素的L峰所覆盖而无法在能谱图和半定量结果中分辨出。

表1 元素的特征X射线能量

Table 1 Characteristic X-ray energy of elements (keV)

图3所示为析出相的能谱线扫描结果。由图3可见,析出相富含Ti(见A和B两个箭头处),相应位置的V含量减少,而Cr在基体和第二相中的分布相对较均匀。

图3 析出相的STEM像及能谱线分析结果

Fig.3 STEM image of precipitations and EDS line-scanning analysis results

图4所示为析出相的结构分析。图4(a)和(b)中的右下脚插图分别是试样在暗场和明场下的初始形貌析出相的结构分析。图4(a)和(b)中的右下脚插图分别是试样在暗场和明场下的初始形貌(倾转角0?)。由于该方向试样太厚而倾转到(-6.61?,8.03?)(见图4(a))和(-2.69?,15.95?)(见图4(b))后的形貌及相应的电子衍射花样结果(见图4(c)和(d))。根据电子衍射花样得出该相为fcc结构,晶格常数为0.423 4~0.428 8 nm。图4中析出相倾转而呈现出的不同形貌,这说明图1和2中的片状和针状第二相实际上是三维盘状的,厚度约为100 nm,其它两维尺寸达1~2 mm。

图4 析出相的明暗场相及电子衍射结果

Fig.4 TEM field(a), (b) and SAD results (c), (d) of precipitations

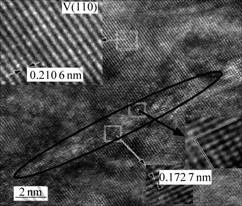

试样内部的某盘状析出相(图中所圈部位)的HREM分析结果如图5所示。从晶格条纹测量出基体V的晶面间距为0.210 6 nm,与纯V(0.214 1 nm)比较后可知这是V(110)面,这也正是bcc结构金属的密排面,盘状析出相和母相夹角约为90?,第二相的晶面间距为0.172 7 nm。

图5 含有盘状析出相合金的高分辨像

Fig.5 HREM image of alloy with plate shape precipitations

将试样倾转到一定角度时,可见铸态组织中还存在着许多的位错(见图6)。由图6可看出,位错密度非常高,且互相缠结成位错网形态。

图6 铸态合金中的位错结构

Fig.6 Dislocation structure of as-cast alloy

2.2 退火态组织结构

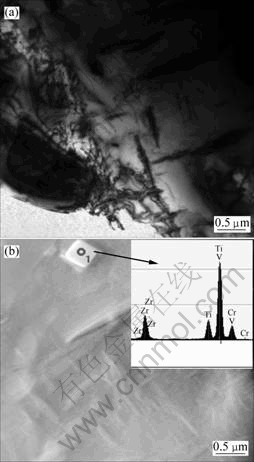

图7所示为合金经1 000 ℃,1 h退火后析出相的形貌。由图7可看出,经热处理后,合金的微观组织产生了一定变化,出现了新的方形第二相,大小约为500 nm。图7(b)的EDS结果表明,这种新相富Ti和Zr,盘状析出相的尺寸也有所减小,变得更粗短。

图8所示为经1 000 ℃,1 h退火后试样边缘的非晶层及对应的HREM像。从图8可见基体的V(110)晶面和薄区边缘的非晶层。通过晶面间距可知,热处理后V(110)面的面间距从0.210 6 nm增加到0.212 0 nm。基体晶格发生膨胀原因是由于部分第二相重新溶解,使得更多的元素(Ti、C、N、O)重新固溶到基体中,导致基体晶格膨胀。

图7 合金经1 000 ℃,1 h退火后析出相的形貌

Fig.7 Morphologies of precipitations for alloy annealed at 1 000 ℃ for 1 h: (a) TEM filed; (b) STEM field

图8 经1 000 ℃,1 h退火后试样边缘的非晶层及对应的HREM像

Fig.8 HREM images of amorphous at edge of sample after annealed at 1 000 ℃ for 1 h

3 讨论

3.1 组织结构

根据图5中的d(110)计算出V固溶体晶格常数a=0.297 8 nm,而据电子衍射得到基体的晶格常数为0.293 8~0.294 3 nm。考虑到测量误差,据HREM中晶面间距推算和电子衍射测量得到的合金基体晶格常数是一致的。与纯V晶格常数a=0.302 7 nm相比,固溶体晶格收缩了约2.8%。晶格收缩是原子半径较小的Cr固溶于V中形成替代式固溶体所致。较大的Ti原子和较小的间隙式杂质C、N和O则由于倾向形成第二相而降低了对V的固溶膨胀作用。由图1可见,该相相互平行、垂直,说明该相与基体有固定的取向关系。那么根据本研究结果可以得出fcc结构的富Ti析出相的惯析面为(110)面。CHEN等[15]分析认为析出物具有<100>取向。

SEM结果表明,析出相在晶内呈盘状形态,厚约100~120 nm,长宽达微米量级;晶界处则呈连续网状分布。SEM和EDS分析表明,该相是富Ti的。这与TEM分析结果一致。本研究中的盘状第二相(见图1、2和4)的形貌、尺寸和主要成分与TYUMENTSEV等[12]的实验结果十分吻合。那么,根据本研究的分析结果,本研究铸锭中的盘状析出相也是富Ti型的Ti-CON相,析出相的位置、成分和结构等都几乎一致。从本研究和一些资料[12, 14]也可见,VAR钒合金中铸态和热处理态中都存在最主要的Ti-CON相,但由于不同合金的成分和熔炼工艺等不同,富Ti相的化学成分、尺寸、形貌和数量也有不同。

高密度盘状析出相在提高合金强度的同时,由于部分沿晶界呈网状连续分布,必然会使合金的晶界脆化,产生沿晶断裂,降低合金的塑性。合金经1 000 ℃,1 h退火后,主要析出相仍然是这种盘状Ti-CON相,位置和成分并无太大变化,只是尺寸变得粗大。新的方形相含有Zr,说明退火过程中Zr元素倾向于聚集。该相推测可能也是Ti-CON相,只是形貌和成分有所不同。由此可见,经1 000 ℃,1 h的退火工艺对合金组织结构的影响较小,并没有明显改变盘状相的分布位置。但方形新相的出现和原先盘状相变得短小粗大,这说明了退火处理改变析出相形态的可能性,也说明了该均匀化工艺对减轻晶内偏析的作用是明显的。期望以后通过更高温度或更长时间的退火处理来改变盘状析出相的分布位置和形貌,一定程度地提高合金的塑性和成分的均匀性。

3.2 析出相形成机制

盘状Ti-CON相的形成主要是由于Ti比V和Cr对O、C和 N等杂质更具有化学亲和力,在凝固或热处理后过程中吸引杂质而形成热致析出相。且这种富Ti相是热稳定的,其形貌和位置取决于冷却过程。一个方面,由于C元素在V中的固溶度非常小,一旦超过固溶度就会以第二相的形式析出亚稳的VC(相对于TiC)。由于当温度高于500 ℃以后,Ti原子就能获得足够的热能而激活发生扩散迁移,在从熔点到500 ℃之间,Ti原子均是可动的。那么活性更大的Ti元素具有足够的时间取代VC中的V原子而形成TiC,而不需要亚稳的VC重新溶解。随后,由于TiO和TiN具有同样的FCC晶体结构,O和N元素会替代一部分C原子而形成Ti-CON相,也即热力学稳定的富Ti相可能的形成机制是通过亚稳相原位转变而来。另一个方面,由于化学亲和力最大,Ti与O形成TiOx化合物,随后杂质原子C和N等与O相互取代而形成复杂成分的Ti-CON相[12, 14]。O是最主要的杂质元素,在制备过程中热驱动形成第二相[13]。合金杂质含量越高,Ti-CON相的尺寸和密度越大[14]。本铸锭平均O含量达到0.23%,C和N含量也分别达到0.027%和0.01%,形成更为粗大、致密及尺寸不同的第二相是可以理解的。

退火后,新的方形相同样是富Ti和Zr的,推测可能是部分的盘状相的元素和基体中的元素在热激活下发生扩散而重新分布,在超过了基体的固溶度后又重新析出。由于是在高温长时间保温,元素有足够的时间向平衡相转变,形成了与铸态不同的方形相。如果时间再足够长或者温度再高,这种热转变趋势更明显,推测合金中的析出相将有更多的形貌,密度也会发生变化。

4 结论

1) 铸态合金为明显的两相结构,基体为钒基固溶体,晶格常数为0.293 8~0.294 3 nm;析出相主要为FCC结构的盘状的、富含Ti,并含有少量V和Cr的复杂的高碳型Ti-CNO相,晶格常数为0.423 4~0.428 8 nm,厚度约为100 nm,其它两维尺寸达1~2 mm,合金中存在有大量的位错。

2) 经1 000 ℃,1 h退火后,合金基体晶格有所膨胀,组织发生了变化,出现了新的方形第二相,尺寸约为500 nm,而盘状析出相尺寸减小,合金成分趋于均匀。

REFERENCES

[1] 谌继明. 合金元素和氢、氧对钒合金拉伸性能的影响[J]. 材料科学与工艺, 2002, 10(4): 366-370.

CHEN Ji-ming. Influence of alloying elements and hydrogen and oxygen on tensile properties of vanadium alloys[J]. Materials Science & Technology, 2002, 10(4): 366-370.

[2] HEO N J, NAGASAKA T, MUROGAET T. Recrystallization and precipitation behavior of low-activation V-Cr-Ti alloys after cold rolling[J]. Journal of Nuclear Materials, 2004, 325(1): 53-60.

[3] KURTZ R J, ABE K, CHERNOV V M, HOELZER D T, MATSUI H, MUROGA T, ODETTE G R. Recent progress on development of vanadium alloys for fusion[J]. Journal of Nuclear Materials, 2004, 329/333: 47-55.

[4] 陈 勇, 谌继明, 邱绍宇. 钒合金的沉淀析出行为和时效强化[J]. 稀有金属, 2006, 30(3): 295-299.

CHEN Yong, CHEN Ji-ming, QIU Shao-yu. Precipitation behavior and aging hardening of vanadium alloys[J]. Chinese Journal of Rare Metals, 2006, 30(3): 295-299.

[5] 邱绍宇, 谌继明, 陈 勇, 粱波, 李 聪, 徐潇潇, 徐 颖. 钒合金的氢致硬化和氢脆[J]. 原子能科学技术, 2005, 39: 24-29.

QIU Shao-yu, CHEN Ji-ming, CHEN Yong, LIANG Bo, LI Cong, XU Xiao-xiao, XU Yin. Hydrogen induced hardening and embrittlement of vanadium alloys[J]. Atomic Energy Science and Technology, 2005, 39: 24-29.

[6] CHUTO T, SATOU M, HASEGAWA A, ABE K, NAGASAKA T, MUROGA T. Fabrication using a levitation melting method of V-4Cr-4Ti-Si-Al-Y alloys and their mechanical properties[J]. Journal of Nuclear Materials, 2002, 307/311: 555-559.

[7] KUWABARA T, KURISHITA H, HASEGAWA M. Development of an ultra-fine grained V-1.7mass% Y alloy dispersed with yttrium compounds having superior ductility and high strength[J]. Mater Sci Eng A, 2006, 417(1/2): 16-23.

[8] POTAPENKO M M, DROBISHEV V A, FILKIN V Y, GUBKIN I N, MYASNIKOV V V, NIKULIN A D, SHINGAREV E N, VEDERNIKOV G P, VOTINOV S N, ZURABOV V S, ZOLOTAREV A B. Manufacture of semifinished items of alloys V-4Ti-4Cr and V-10Ti-5Cr for use as a structural material in fusion applications[J]. Journal of Nuclear Materials, 1996, 233/237: 438-441.

[9] SHIKOV A K, CHERNOV V M, POTAPENKO M M, GUBKIN I N, DROBYSHEV V A, ZURABOV V S. Development of production process and study of low-activity V-(4-5)%Ti- (4-5)%Cr structural alloys for thermonuclear reactors[J]. Metal Science and Heat Treatment, 2004, 46(11/12): 497-503.

[10] HEO N J, NAGASAKA T, MUROGA T, MATSUI H. Effect of impurity levels on precipitation behavior in the low-activation V-4Cr-4Ti alloys[J]. Journal of Nuclear Materials, 2002, 307/311: 620-624.

[11] JOHNSON W R, SMITH J P. Fabrication of a 1 200 kg ingot of V-4Cr-4Ti alloy for the DIII-D radiative divertor program[J]. Journal of Nuclear Materials, 1998, 258/263: 1425-1430.

[12] TYUMENTSEV A N, KOROTAEV A D, PINZHIN Y P, DITENBERG I A, LITOVCHENKO S V, SHUBA Y V, SHEVCHENKO N V, DROBISHEV V A, POTAPENKO M M, CHERNOV V M. Effect of the modes of thermomechanical treatment on the formation of the multiphase and grain structure of V-4Ti-4Cr alloys[J]. Journal of Nuclear Materials, 2004, 329/333: 429-433.

[13] CHUANG H M. Irradiation-induced precipitates in vanadium alloys containing titanium[R]. DOE/ER-0313/11, USA: U.S.Department of Energy, 1991.

[14] SKAI K, SATOU M, FUJIWARA M, TAKANASHI K, HASEGAWA A, ABE K. Mechanical properties and microstructures of high-chromium V-Cr-Ti type alloys[J]. Journal of Nuclear Materials, 2004, 329/333: 457-461.

[15] CHEN Ji-ming, MUROGA T, NAGASAKA T, XU Yu, LI Chong, QIU Shao-yu, CHEN Yu. Precipitation behavior in V-6W-4Ti,V-4Ti and V-4Cr-4Ti alloys[J]. Journal of Nuclear Materials, 2004, 334: 159-165.

收稿日期:2007-09-21;修订日期:2007-12-22

通讯作者:罗 超,研究员,博士;电话:0816-3625361;E-mail: liyufei034@yahoo.com.cn

(编辑 李艳红)