一种在微挤压中确定材料真实流动应力的方法

来源期刊:中国有色金属学报(英文版)2012年第z2期

论文作者:林俊峰 李 峰 张晋锋

文章页码:232 - 238

关键词:微成形;流动应力;摩擦;挤压

Key words:micro-forming; flow stress; friction; extrusion

摘 要:不同于传统的常规成形,摩擦效应在微成形过程中非常重要。提出了一个采用微挤压实验中的摩擦因子来评估材料真实流动应力的方法。应用理论分析、数值模拟和实验研究对微挤压过程中的摩擦行为和流动应力进行研究。研究不同的试件尺寸对流动应力的影响,确定出真实的摩擦因子。结果表明,随着试件尺寸的变小,流动应力也随之减少,鼓度值随着摩擦因子的增加而增加,并获得到了纯铜的真实应力-应变曲线。

Abstract: The friction effect is very important in micro-forming process and differs from the usual forming process. A new method of evaluating the friction factor in tests by combining micro-compression was presented. The friction behavior and the flow stress were investigated in micro-expression by theory analysis and experiment. To investigate the effects of specimen size on the flow stress, a series of compression tests were carried out for specimens with different diameters. The results show that with the decrease of specimen size, the flow stress shows a gradually downward trend. The bulging value increases with increasing the friction factor. Combining the bulging method and theory analysis, the experimental friction factor was obtained and the flow stress was calibrated without friction. Thus, the real stress-strain curve was obtained, which provides the accurate material model for the subsequent finite element simulation on micro-forming.

Trans. Nonferrous Met. Soc. China 22(2012) s232-s238

LIN Jun-feng1, LI Feng2, ZHANG Jin-feng1

1. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

2. College of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150001, China

Received 28 August 2012; accepted 25 October 2012

Abstract: The friction effect is very important in micro-forming process and differs from the usual forming process. A new method of evaluating the friction factor in tests by combining micro-compression was presented. The friction behavior and the flow stress were investigated in micro-expression by theory analysis and experiment. To investigate the effects of specimen size on the flow stress, a series of compression tests were carried out for specimens with different diameters. The results show that with the decrease of specimen size, the flow stress shows a gradually downward trend. The bulging value increases with increasing the friction factor. Combining the bulging method and theory analysis, the experimental friction factor was obtained and the flow stress was calibrated without friction. Thus, the real stress—strain curve was obtained, which provides the accurate material model for the subsequent finite element simulation on micro-forming.

Key words: micro-forming; flow stress; friction; extrusion

1 Introduction

The rapid advancement of micro-forming technology in the past few years has led to the creation of several novel products and applications that have a significant impact on a variety of fields such as electronics, communications, biotechnology, medicine, optics and environmental monitoring. The recent trend towards miniaturization of products and technology has produced a strong demand for such metallic micro-parts with extremely small geometric features and high tolerances. But micro-forming technology is different from the conventional forming technologies. It has encountered new problems and challenges.

First, when the size of the parts is reduced to be smaller than 1 mm, the so-called size effect comes into being [1], which makes the know-how, empirical and analytical methods in traditional forming processes unavailable in micro-forming fields. Investigations were done by MESSNER and showed a decrease in the flow curve if the specimen was scaled down from a diameter of 4.8-0.5 mm [2]. This can be explained by the increasing relation of surface grains to grains inside the material if the specimen is scaled down. A non-local crystal plasticity model was presented by EVERS et al that considered different dislocation interaction, and can automatically predict a “the smaller, the stronger” or “smaller weaker” [3,4].

Second, the flow stress about size effect has been taken into account to a large extent in numerical simulation of micro-forming. But the size effect of friction was considered relatively seldom. The selection of friction factors was all referred to the macro-plastic forming in general [5-8]. The model of surface roughness was used to describe the contact surface, which is mainly in the current research area, and this model has made a preliminary research results. JUSTINGER studied the effects of a decrease of flow stress on micro-forming process using a basic model of a unit volume cube with different numbers of grains inside by Taylor factors [9,10].

The size effect on the flow stress in cylinder compression was investigated by several researchers using different materials. But the exact flow stress value was not confirmed accurately.

However, in the previous studies, the method of determining flow stress was still only a single way. In this work, a comprehensive method is adopted by revising and iterating continuously to determine and get closer to the real flow stress. In tandem with this, a methodology for establishing the real flow stress is presented.

This paper will focus on the friction behavior and the flow stress by theory analysis and experiment with the material of Cu to investigate the effect of different friction factor on the micro-extrusion process. Combining the barreling method with theory analysis, the experimental friction factor was obtained and the flow stress was revised. Thus, the real stress—strain curve was obtained, which provides the accurate material model for the subsequent finite element simulation on micro-forming.

2 Research methodology

The material deformation behaviors to be investigated include flow stress, material flow rule and formability. The focus of this work is on exploring the size-effect and friction-effect on material flow stress and flow behaviors and further identifying the real flow stress in micro-compression via filtering the friction effect.

First of all, a series of materials mechanical tests with different dimensions were conducted. The generated stress—strain curve includes both the friction-effect and size-effect on material flow stress due to their simultaneous existence in the process. To filter the friction-effect, it needs to determine the flow stress based on the σ—ξ curves obtained from micro-compression test via eliminating the friction-effect.

This idea can be represented as

(1)

(1)

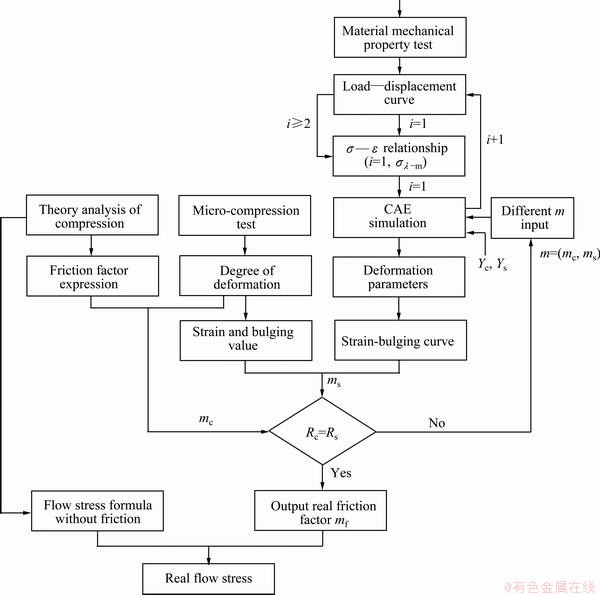

where  denotes the flow stress affected by both size-effect and friction-effect, ε refers to the effective strain, λi (i=1,2,3,4,5) is the size-effect parameters representing the billet geometry in three coordinate directions, and σλ is designated as the flow stress after eliminating the friction-effect. Figure 1 presents a research paradigm to generate the flow stress based on the experiment results via eliminating the friction effect through simulation. In order to obtain the real flow stress without friction, the actual friction factor in experiment will be confirmed first. The friction factor was confirmed in micro-expression by theory analysis, simulation and experiment.

denotes the flow stress affected by both size-effect and friction-effect, ε refers to the effective strain, λi (i=1,2,3,4,5) is the size-effect parameters representing the billet geometry in three coordinate directions, and σλ is designated as the flow stress after eliminating the friction-effect. Figure 1 presents a research paradigm to generate the flow stress based on the experiment results via eliminating the friction effect through simulation. In order to obtain the real flow stress without friction, the actual friction factor in experiment will be confirmed first. The friction factor was confirmed in micro-expression by theory analysis, simulation and experiment.

Fig. 1 Methodology paradigm

In the methodology paradigm, the uniaxial tension experiments were first carried out with five different sizes of 2.0, 1.5, 1.0, 0.75 and 0.5 mm in diameter. The deformation load—displacement curves and stress—strain curves were then obtained. The stress—strain curves were used as the material model in the next simulation.

In the first simulation,  and different friction factor of 0.05, 0.10, 0.20, 0.25, 0.30, 0.5 were used as the input. The output is the deformation parameters such as the maximal and the minimum diameter after deformation, the height of specimen after deformation. Based on these information the bulging value and the strain can be calculated.

and different friction factor of 0.05, 0.10, 0.20, 0.25, 0.30, 0.5 were used as the input. The output is the deformation parameters such as the maximal and the minimum diameter after deformation, the height of specimen after deformation. Based on these information the bulging value and the strain can be calculated.

In order to describe the barreling of part quantitatively, the bulging value θ is defined as

(2)

(2)

where θ is the bulging value, dmax is the maximal diameter after compression, and dmin is the minimum diameter after compression.

The logarithmic strain of highly direction may be obtained by the punch displacement Δh and the original height of specimen h0:

(3)

(3)

where ε is the logarithmic strain of highly direction in compression test, h0 is the original height of specimen, Δh is the punch displacement.

In addition, the friction factor expression and the flow stress formula without friction can be obtained by theory analysis of micro-compression process. The friction measurement method was first proposed by EBRAHIMI [11]. The degree of bulging of cylinders after deformation depends on the friction condition. As a result, bulging produces a slightly lower total power. The actual shape is such that the required power is reduced [12]. It can be proved that, when the procedure described above is followed, the power obtained is always too high, except when the velocity field assumed coincides with the actual one, and then the computed power is the actual one. Based on the above description and after some simplification, equations are obtained [13-15]:

(4)

(4)

(5)

(5)

(6)

(6)

where R is the average radius of cylinder after deformation, H is the height of cylinder after deformation, b is the barrel parameter, ΔR is the difference between the maximum and top radii, ΔH is the reduction of height of cylinder after deformation, R0 is the initial radius of cylinder, H0 is the initial height of cylinder, Rm is the maximum radius of cylinder after deformation.

According to Eqs. (4)-(6), the friction factor formula can be deduced as

(7)

(7)

Because the R0, H0, Rm, and H may be exactly measured using a tool microscope in this study, the friction factors mc can be calculated.

As mentioned above, the value of drums reflects the size of friction during compression process, and it relates to the ratio of specimen height to diameter, but with the characteristics of material itself has nothing to do [16,17].

The basis of the theory formula for real flow stress is described as follows. The barreling occurs because of the existence of friction during the compression process. By studying the relevance of friction conditions and the specimen drum, the method of establishing flow stress excluding friction was proposed.

In accordance with the uniform deformation assumption in the compression process, the real flow stress of materials may be obtained by the load P, namely:

(8)

(8)

where Y is the real flow stress of materials, A0 is the original cross-section area of specimen.

The load required for the deformation increases due to the friction in compression. When the friction is equal to τ=( )Y, namely μ=

)Y, namely μ= , the solution to the principal stress on the average deformation resistance in cylinder compression is [2]

, the solution to the principal stress on the average deformation resistance in cylinder compression is [2]

(9)

(9)

where P is the average deformation resistance with friction, Y is the real flow stress of materials, m is the friction factor on contact surface, d/h is the instantaneous ratio of height to diameter of part in test.

The flow stress is obtained without friction as follows:

(10)

(10)

So the flow stress Ys and Yc may be calculated by the above known mc and ms according to Eq.(10).

Then, the mc and Y c, ms and Ys are used as the input respectively in the CAE simulation, and the above process is repeated. Furthermore, the different value of friction factor m is selected between ms and mc. These different m value and corresponding flow stress Y are input again in the CAE simulation until the deformation results Rs in simulation are very close to Rc of the experiment results according to the research paradigm shown in Fig. 1. Here the friction factor mf is considered to be the real friction factor in the test. Finally, the real flow stress was calculated without friction by Eq. (10).

3 Experimental

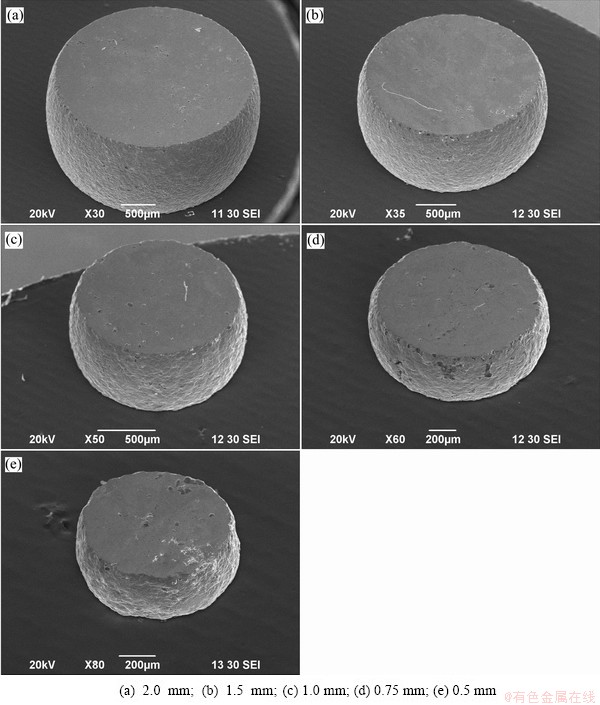

To investigate the size effect on the friction in micro-compression, the specimens with five different diameters of 2.0, 1.5, 1.0, 0.75 and 0.5 mm were used, and the height-to-diameter ratio was 1.5.

The experiment was carried out at room temperature and strain rate of 0.033 s-1 with petroleum jelly on an axial static testing machine MTS-QTest/25 and the compression ratio was 60%.

Before experiment the specimens were annealed at 740 °C for 24 h. Grain images of specimens were captured by a scanning electronic microscope.

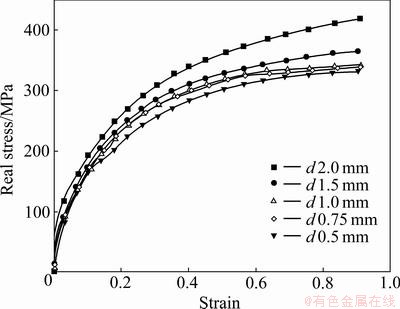

After heat treatment, the uniaxial tension experiments on the specimens with different dimensions were carried out. The true stress—strain data were recorded by computer. Figure 2 shows the true stress—strain curves of the specimens with different sizes.

Fig. 2 Strain—stress curves of specimen with different sizes

Fig. 3 Deformed shapes of specimens with different sizes

4 Results and discussion

The deformed shapes of the specimens with different sizes are shown in Fig. 3. From the results of micro-compression experiment, the strain and the drum value may be measured after deformation.

The grain images of the deformed specimens are shown in Fig. 4. It is clear from Fig. 4 that all the grains of the specimens were compressed and the deformation was very severely.

In order to verify the accuracy of the simulation results, the comparison of the simulated result to the experimental result of specimen with diameter about 2.0 mm is shown in Fig. 5. It shows that the simulated results agree well with the experimental values. The existing gap is mainly due to the randomness of grain orientation. With the increase of friction factor, the range of diameter of the specimen after compression increases. The range of the specimen diameter of experiment is close to the result of simulation when friction factor is 0.10. This is the same as the previous conclusions.

Therefore, the simulation results of this study can reflect truly the actual deformation of specimens.

Taking the specimen of d2.0 mm as an example, the initial height was 3.0 mm, after deformation the height of specimen was 1.2 mm. The logarithmic strain was 0.55. The maximal diameter after compression was 3.10 mm and the minimum diameter was 2.88 mm. The corresponding dump value was 0.048. The friction factor value in practical test was located between 0.1 and 0.2. The friction factor ms was identified as 0.13 by applying differential analysis method according to the regression equation as shown in Eq. (4).

Fig. 4 Grain images of deformed specimens

On the other hand, the friction factor was calculated using the deformation parameters measured in the experiment according to Eq. (8). So the friction factor mc of specimens of d2.0 mm was calculated as 0.19 in the experiment.

Fig. 5 Comparison of simulated result to experimental result

According to the methodology paradigm as shown in Fig. 1, the different friction factors and corresponding flow stresses were used as the input again in the CAE simulation, and the above process was repeated. When the deformation parameters in simulation were very close to the results after deformation in experiment, the friction factor was eventually identified as 0.142 in the experiment. So the real flow stress without friction was calculated to be 401 MPa by Eq. (10).

The curves of flow stress—strain under pre and post revising are shown in Fig. 6. The maximum stress value was 432 MPa before revising and it was 401 MPa after revising. This method decreased the maximum flow stress by 31 MPa, namely reduced 7.18%. The obtained value is more close to the true valued.

It can be seen from Fig. 6 that, the effect of friction on stress is very small in the initial stage of deformation; with the increase of strain, the contact surface between the punch and specimens increases, and the effect of friction also increases, which causes the decrease of flow stress relatively. Analogically, the friction factor of the remaining four specimens of d 1.5 mm, d 1.0 mm, d 0.75 mm and d 0.5 mm is determined to be 0.19, 0.11, 0.17 and 0.21, respectively, in the experiment by this method. The real flow stress is 349 MPa, 328 MPa, 320 MPa, 310 MPa, respectively.

Fig. 6 Curves of flow stress—strain under pre and post revising

Figure 7 shows the real strain—stress curves of specimens with different sizes. With the specimen size decreasing, the flow stress shows a gradually downward trend, that is, the flow stress at small scales associates with the specimen size. It appears the scale effect on decreasing flow stress.

Fig. 7 Real strain—stress curves of specimens with different sizes

According to the theory of surface layer, the grains located at the surface are less restricted than grains inside the material. Dislocations moving through the grains during deformation pile up at grain boundaries but not at the free surface. With decreasing the specimen size, the share of surface grains increases, which leads to lower flow stress.

5 Conclusions

Flow stress size effect occurred in scaled down micro-compression experiment and theory analysis. The real flow stress without friction can be confirmed using the method in micro-compression. Different specimen sizes of the flow stress were revised and the real stress—strain curves were obtained. The flow stress decreases with the decrease of specimen size.

Friction effect has big difference in micro- deformation compared to the traditional plastic forming. The relationship curves between the bulging and friction factor, deformation degree were obtained. With the increase of friction factor and deformation degree, the bulging value increases.

References

[1] GEIGER M, KLEINER M, ECKSTEIN R. Microforming [J]. Annals of the CIRP, 2001, 52(2): 452-462.

[2] MESSNER A. Cold massive forming on metallic material behaviors and effect flat friction in process interpretation [M]. Bamberg, Germany: Meisenbach Publishing Company, 1998:74-76.

[3] GEERS M G D, BREKELMANS W A M, JANSSEN P J M. Size effects in miniaturized polycrystalline FCC samples: Strengthening versus weakening [J]. International Journal of Solids and Structures, 2006, 43: 7304-7321.

[4] EVERS L P, BREKELMANS W A M, GEERS M G D. Scale dependent crystal plasticity framework with dislocation density and grain boundary effects [J]. International Journal of Solids and Structures, 2004, 41(18-19): 5209-5230.

[5] JEON J, BRAMLEY A N. Afriction model for microforming [J]. International Journal of Advanced Manufacture Technology, 2007, 33: 125-129.

[6] WANG C J, SHAN D B, ZHOU J. Size effects of the cavity dimension on the microforming ability during coining process [J]. Journal of Materials Processing Technology, 2007, 187-188: 256-259.

[7] KRISHNAN N, CAO J, DOHDA K. Microforming: Study of friction conditions and the impact of low friction/high-strength die coatings on the extrusion of micropins [C]// ASME International Mechanical Engineering Conference and Exposition. Orlando, FL, USA, 2005: 234-239.

[8] MORI L F, KRISHNAN N, CAO J. Study of the size effects and friction conditions in microextrusion—Part II: Size effect in dynamic friction for brass-steel pairs [J]. Journal of Manufacturing Science and Engineering, 2007, 129: 677-689.

[9] GEIDRFER S, ENGEL U, GEIGER M. FE simulation of microforming processes applying a mesoscopic model [J]. Internation Journal of Machine Tools and Manufacture, 2006, 46: 1122-1126.

[10] JUSTINGER H, HIRT G. Estimation of grain size and grain orientation influence in microforming processes by Taylor factor considerations [J]. Journal of Materials Processing Technology, 2009, 21: 111-121.

[11] EBRAHIMI R, NAJAFIZADEH A. A new method for evaluation of friction in bulk metal forming [J]. Journal of Materials Processing Technology, 2004, 152: 136-143.

[12] MICHEL J F, PICART P. Modelling the constitutive behavior of thin metal sheet using strain gradient theory [J]. Journal of Materials Processing Technology, 2002, 125-126: 164-169.

[13] DONG Xiang-huai, MA Ning. A study on size effects on process design of micro deep drawing [C]//Proceedings of the 8th International Conference on Technology of Plasticity. Italy, 2005: 97-103.

[14] ENGEL U, MESSNER A, TIESLER N. Cold forging of microparts—Effect of miniaturization on friction [C]// CHENOT J L, AGASSANT I F, MONTMITONNET P, et al. Proceedings of the First ESAFORM Conference on Materials Forming. Sophia Antipolis, France, 1998: 77-80.

[15] ENGEL U, ECKSTEIN R. Microforming-from basic research to its realization [J]. Journal of Materials Processing Technology, 2002, 35: 125-126.

[16] GONG Feng, GUO Bin, ZHOU Jian. Size effects on flow stress of C3602 in cylinder compression with different lubricants [J]. Rare Metals, 2009, 28(5): 528-532.

[17] VOLLERTSEN F, NIEHOFF S H, HU Z. State of the art in micro forming [J]. International Journal of Machine Tools and Manufacture, 2006, 46: 1172-1179.

林俊峰1,李 峰2,张晋锋1

1. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

2. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150001

摘 要:不同于传统的常规成形,摩擦效应在微成形过程中非常重要。提出了一个采用微挤压实验中的摩擦因子来评估材料真实流动应力的方法。应用理论分析、数值模拟和实验研究对微挤压过程中的摩擦行为和流动应力进行研究。研究不同的试件尺寸对流动应力的影响,确定出真实的摩擦因子。结果表明,随着试件尺寸的变小,流动应力也随之减少,鼓度值随着摩擦因子的增加而增加,并获得到了纯铜的真实应力—应变曲线。

关键词:微成形;流动应力;摩擦;挤压

(Edited by YUAN Sai-qian)

Foundation item: Project (51175111) supported by the National Natural Science Foundation of China

Corresponding author: LIN Jun-feng; Tel: +86-451-86413917; E-mail: jflin@hit.edu.cn

DOI: 10.1016/S1003-6326(12)61713-0