文章编号:1004-0609(2008)05-0923-06

Pb/Zn冶炼废渣中有价金属生物浸出条件优化

郭朝晖1, 2,程 义2,邱冠周1,刘学端1,潘凤开2

(1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 中南大学 冶金科学与工程学院,长沙 410083)

摘 要:为提高生物浸出Pb/Zn冶炼废渣中有价金属的浸出率,利用正交设计,通过摇瓶实验,研究微生物浸出某Pb/Zn冶炼废渣过程中温度、pH值、废渣浓度及浸出时间等对废渣中Cu,Zn,In,Ga,Pb和Ag等有价金属浸出的影响。结果表明,在pH值为1.5、废渣浓度为5%、温度为65 ℃的优化浸出条件下生物浸出4d,Pb/Zn冶炼废渣中有价金属Cu,Zn,In和Ga的浸出率分别达到95.5%,93.5%,85.0%和80.2%,而Pb和Ag则主要以硫酸铅、黄钾铁矾类物质或硫化银形式富集在余渣中。

关键词:Pb/Zn冶炼废渣;有价金属;生物浸出;浸出条件优化

中图分类号:TF 18; X 705 文献标识码:A

Optimization on bioleaching of metal values from

Pb/Zn smelting slag

GUO Zhao-hui1, 2, CHENG Yi2, QIU Guan-zhou1, LIU Xue-duan1, PAN Feng-kai2

(1. School of Resources Processing and Bio-engineering, Central South University, Changsha 410083, China;

2. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: In this study, the main variables involved in the bioleaching process include temperature, pH, pulp density and leaching time. These variables were studied through a shaking flask experiment by orthogonal design in order to improve the leaching rate of metal values, including Cu, Zn, In, Ga, Pb and Ag, from the Pb/Zn smelting slag. The results show that bioleaching rate of Cu, Zn, In and Ga in the Pb/Zn smelting slag under optimized conditions (pH 1.5, temperature 65 ℃, 5% pulp density and a leaching time of 4 d) is 95.5%, 93.5%, 85.0% and 80.2% respectively. Lead and silver, however, are mostly deposited in the leached residues with the forms of lead sulfate, argentojarosite-type or silver sulfide compounds, respectively.

Key words: Pb/Zn smelting slag; metal values; bioleaching; optimization of bioleaching variables

随着国民经济的快速发展,有色冶炼行业发展迅猛[1]。我国有色冶炼技术主要以火法为主,在有色冶炼过程中产生了大量的冶炼废渣。由于缺乏高效、经济、环境友好的有价金属回收技术,导致大量有色冶炼废渣堆置。这些堆置的有色冶炼废渣中含有大量As,Cd,Cr,Cu,Ni,Pb和Zn等具有高度迁移性的重金属和有毒元素,长期堆置不仅导致大量有价金属的流失,而且对土壤、地下水等生态环境造成潜在污染和危害[2]。传统的有色冶炼废渣处理方法主要有填埋、堆置储存和做建筑材料等[3],而利用磁选、浮选、湿法浸提和焙烧等技术回收有色冶炼废渣中有价金属主要集中在那些含有较高品位的Al,Co,Cu,Ni,Pb和Zn等金属和含Au,Ag,In,Nb,Pt和Ta等贵金属的冶炼废渣[4],且这些工艺存在经济效益低、易产生二次污染物等缺点。因此,研究和应用经济合理、环境友好并能处理低品位有色冶炼废渣的处理工艺不仅有利于保护生态环境,而且有利于提高有价金属的综合回收率和利用率。

生物浸矿技术因其具有处理对象范围广、过程简单、能耗低、环境友好等优点得到了广泛关注。目前,该技术不仅成功地应用于从低品位矿和尾矿中回收Au,Cu,Co[5-6]和U[7]]等有价金属,而且从低品位矿中回收Ag,Cd,Ga,Mo,Ni,Pb,Pd,Pt,Rh,Ru,Sb和Zn等金属也具有一定的前景[5]。近年来,利用微生物浸矿技术解毒含有重金属的污泥[8-9]、土壤[10]、生活垃圾焚化炉飞灰[11]等受到了环境工作者的关注。有色冶炼废渣成分复杂,但渣中通常含有大量铁和金属硫化物,为利用具有氧化低价硫、铁的嗜酸菌回收废渣中有价金属,实现废渣资源化和无害化提供了可能[12]。目前,利用微生物技术对有色冶炼废渣进行资源化和无害化的研究报道并不多。GUPTA等[13]研究了氧化亚铁硫杆菌(Thiobacillus ferrooxidans)处理经焙烧—浸出—电积工艺冶炼锌过程中产生的浸出渣(含Zn 11%~18%,Pb 4%~6%,Fe 18%~29%,Ag 200~ 500 mg/kg,Cu 0.15%~0.3%,Cd 0.12%~0.25%,Ni 100~140 mg/kg,Co 80~100 mg/kg),在pH值为1.2,温度为35 ℃,矿浆浓度为1%的条件下浸出30 d,Zn的浸出率可高达27.5%,表明氧化亚铁硫杆菌能促进渣中Zn的浸出,但由于浸出率低、浸出时间长,目前难以对渣中其他有价金属进行综合回收。利用高温下具有高生物活性和抗毒性的中等嗜热菌则可大大提高金属的浸出率[14],但不同温度[9, 13]、pH值[13]、矿浆浓度[13, 15]和浸出时间[16]等对其中金属的浸出率影响明显。因此,寻找合适的资源化和无害化工艺条件,是采用微生物浸出技术处理有色冶炼废渣亟待解决的关键问题。本研究采用正交设计,通过摇瓶试验,研究了温度、pH值、废渣浓度及浸出时间对中等嗜热菌浸出有色冶炼废渣中有价金属浸出规律的影响,为选用生物浸矿技术对有色冶炼废渣进行资源化和选定无害化处理的高效浸出工艺参数提供科学依据。

1 实验

1.1 废渣和菌种

实验所用废渣采自某大型铅锌冶炼厂废渣堆场,经自然风干,球磨机磨细,过0.1 mm筛后在105 ℃烘干,渣中含铁量约35%。为回收渣中的部分铁资源,磨细后的废渣经磁铁除铁后,装袋,供实验用。除Fe后废渣中主要有价金属元素为Zn,Cu,Pb,Ag,In和Ga等,其含量分别为2.57%,1.03%,0.41%,92 g/t,100 g/t和916 g/t;主要有害元素为As,Cd和Pb等,As和Cd含量分别为0.42%和24 g/t。

本研究采用本课题组驯化的中等嗜热混合菌群,以球菌为主,革兰氏阳性。耐高温,在55~65 ℃活性很强。实验所采用菌种通过8 000 r/min离心分离后弃去上清液,余下的菌球用蒸馏水漂洗后离心,重复2次后用pH值为2.0的嗜热培养基溶液稀释至2×107个细胞/mL待用。

1.2 正交实验设计

采取正交实验设计,利用摇瓶(锥形瓶容积为250 mL)实验考察pH值、温度、废渣(矿浆)浓度及浸出时间对废渣中有价金属浸出率的影响。正交表采用L9(34)[17],每个处理重复3次。其中,pH值设为0.5,1.5和2.5,温度设为45、55和65 ℃,废渣浓度设为5%,10%和15%,浸出时间设为4 d,8 d和12 d。为使浸出体系pH值保持稳定,废渣经1.5 mol/L硫酸溶液预浸1 d以消耗其中的脉石。于锥形瓶中加入90 mL嗜热培养基溶液,严格调节pH值至设定值,按体积比1?10接种上述菌种后置于恒温水浴摇床中,转速为120 r/min,按正交表中设定温度下培养,分别于第4 d,8 d和12 d取样。浸出体系pH值采用pH计(420 A台式pH/mV)每隔24 h测定1次,测定后滴加2 mol/L稀硫酸控制其为实验设定pH值,采用恒量法用蒸馏水补充浸出过程中的水分损失。同时,在正交实验设计基础上,根据优化条件进行验证实验。

1.3 测试与方法

将样品全部转移至100 mL离心管中于5 000 r/min下离心5 min,取上清液2.5 mL,加入2.5 mL硝酸后用二次去离子水定容至50 mL,过滤后移至100 mL聚乙烯瓶中于4 ℃冷藏。取优化条件下浸后余渣于105 ℃烘干后进行X射线衍射分析(SIMENS2500X型X衍射仪)。浸出液中Cu,Zn,Pb,Ag,In和Ga的浓度采用电感耦合等离子体发射光谱仪(美国热电元素公司IntrepidⅡXSP型)测定。实验所用器皿在清洗后用12%以上的硝酸溶液浸泡24 h,再用二次去离子水清洗后烘干备用。

2 结果与讨论

2.1 微生物浸出有价金属条件优化分析

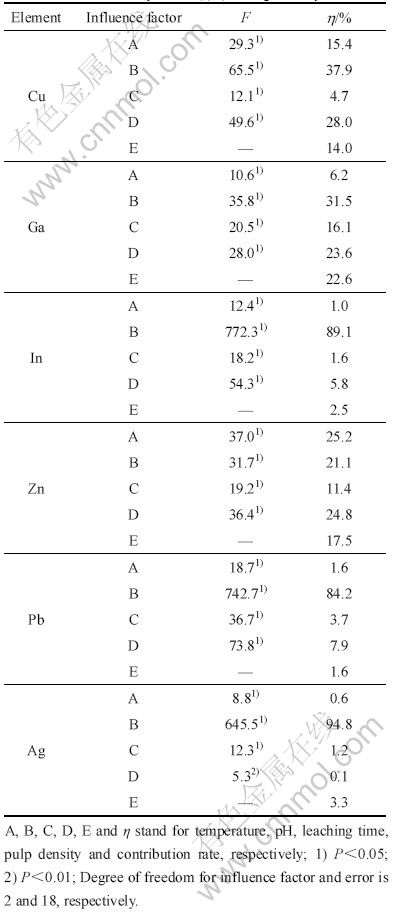

2.1.1 pH值

从表1所示正交分析结果可以看出,pH值是影响微生物浸出最重要的因素之一。PH值对废渣中Cu,Zn,Ag和In有极显著影响(F>F0.01),其对废渣中Cu,Zn,Ag和In浸出率影响的贡献率分别为37.9%,21.1%,94.8%和89.1%。因此,pH值对废渣中Ag和In的浸出起决定性作用,同时是影响废渣中Cu和Zn浸出的主要影响因素之一(ηB>ηE)。

表1 L9(34)正交实验方差分析

Table 1 Variance analysis of L9(34) orthogonal experiments

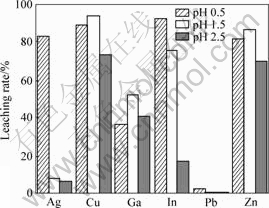

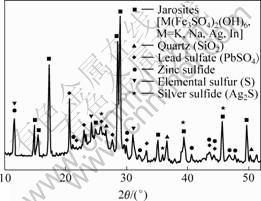

Cu,Ga和Zn的浸出率在pH值为1.5时最高(图1)。研究表明,当浸出体系pH值为1.5时,中等嗜热菌具有较高活性,能加快Fe2+与Fe3+之间相互转化与循环[18],比体系pH值为0.5和2.5时更有利于废渣中Cu和Zn硫化物的氧化浸出[18]。废渣中Ag和In主要以类质同相形式镶嵌在铁、锌和铜等金属硫化矿物的晶格中[12],因此,当Fe,Zn和Cu等金属硫化物被微生物氧化后,Ag和In才能被浸出。然而,Ag和In在浸出体系pH值大于1.5时浸出率都非常低(图1)。在生物浸出体系中,当pH值超过1.5时,体系中浸出的大量铁离子开始水解,产生黄钾铁矾类物质(图5)[18],阻碍铁离子与矿物之间的传质,并吸附和沉淀已浸出的金属离子,严重影响金属矿物的进一步浸 出[18]。Ag+比较容易聚集于黄钾铁矾晶格中而生成银铁矾[19]重新沉淀到渣中,因此,废渣中Ag在浸出体系pH值高于1.5时浸出率低于10%。此外,部分Ag+还能取代硫化矿中金属元素生成Ag2S(图5)(Ksp = 5.5× 10-51)沉淀到废渣矿物的表面,与其他金属硫化物组成大量微小的原电池,从而促进其他金属的浸出[6]。溶液中In也能与黄钾铁矾一起沉淀到浸出渣中[20],当浸出体系pH值高于1.5时,In浸出率也明显降低。因此,综合考虑废渣中主要有价金属元素Cu和Zn的浸出率以及Ag能富积于黄钾铁矾中等因素,选定细菌浸出此废渣的优化pH值为1.5。

图1 pH值对废渣中有价金属浸出率的影响

Fig.1 Influences of pH value of solution on leaching rate of metal values from smelting slag

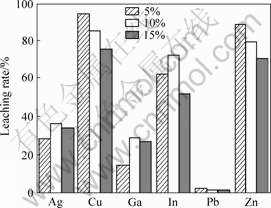

2.1.2 废渣浓度

从表1所示正交分析结果可以看出,废渣浓度对废渣中Cu,Zn和In的浸出有极显著影响(F>F0.01),对Ag有显著影响(F>F0.05)。在正交实验条件下,废渣浓度对废渣中Cu,Zn和In浸出率的贡献率分别为28.0%,24.8%和5.8%,表明废渣浓度也是影响废渣中Cu和Zn浸出的主要因素之一(ηD>ηE),废渣中Cu和Zn浸出率随着废渣浓度的升高而呈下降趋势(图2)。废渣浓度对Ag和In浸出率影响较小(ηD<ηE)。有研究表明,搅拌浸出时矿浆浓度在5%以内并不会影响氧和二氧化碳的传递速度,但矿浆浓度过高,微生物和亚铁氧化的耗氧速率将高于气液传质速率,从而造成浸出体系缺氧[21],同时,矿浆浓度的升高将加剧固体颗粒之间的摩擦和液体的剪切力,从而造成微生物细胞的机械损伤[22],严重影响废渣中有价金属的微生物浸出。此外,矿浆浓度增加后,浸出液中Fe3+浓度大大加快有利于黄钾铁矾的生成[18, 23],这也将导致Cu,Zn,Ag和In浸出率降低。因此,废渣浓度为5%应是废渣浸出的优化浓度。

图2 废渣浓度对废渣中有价金属浸出率的影响

Fig.2 Influence of pulp density on leaching rate of metal values from smelting slag

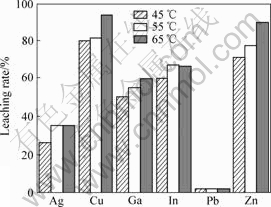

2.1.3 温度

从表1所示正交分析结果可以看出,温度对Cu,Zn,In和Ag的浸出有着极显著的影响(F>F0.01)。温度对废渣中Cu,Zn,Ag和In浸出率影响的贡献率分别为15.4%,25.2%,0.6% 和1.0%,因此,温度也是影响废渣中Cu和 Zn浸出的主要因素之一(ηA>ηE)。由图3可以看出,温度为65 ℃时Cu,Ga和Zn浸出率最高,而Ag和In浸出率也较高。在微生物生长的活性温度范围内,在较高温度下不仅能有效提高传质效率,显著缩短浸出时间[14],加速废渣中部分难浸出金属矿物的浸出[12],而且还可以有效控制钝化层(黄钾铁矾类物质 等)的形成[14]。因此,利用中等嗜热菌浸出废渣中有价金属的优化温度为65 ℃。

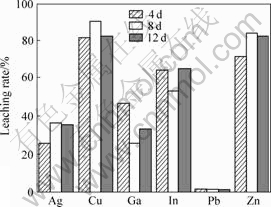

2.1.4 浸出时间

从表1所示正交分析结果可以看出,浸出时间对废渣中Cu,Zn,Ag和In的浸出有极显著影响(F>F0.01),但浸出时间对废渣中Cu,Zn,Ag和In浸出率的影响贡献率较小,仅为4.7%,11.4%,1.2%和1.6%。由图4可知,废渣中有价金属在前4 d就能达到很高的浸出率,而随浸出时间进一步延长,废渣中有价金属浸出率并无显著的提高。由于浸出时间取决于浸出速率,影响浸出速率的因素包括矿物组成及结构[5]、不同种类菌种及浸出条件等,因此,在废渣成分和细菌性质确定条件下,浸出体系各参数(pH值、温度和废渣浓度等)的优化很大程度地提高有价金属的浸出速率。根据正交方差分析结果,在优化的pH值、温度和废渣浓度的浸出条件下,浸出4d后,废渣中Cu,Zn,Ag,In,Ga和Pb的浸出率理论上可以分别达到(92.6±5.2)%,(88.6±6.0)%,(6.8±0.6)%,(74.3±5.0)%,(87.6±7.0)%和(1.1±0.1)%,而浸出8 d时,Cu,Zn,Ag,In,Ga和Pb的浸出率理论上可以分别达(93±5.3)%,(89±5.8)%,(15±6.2)%,(64.2±5.0)%,(73±6.5)%和(1±0.1)%。这说明,若浸出体系经过优化后,废渣中有价金属经4 d浸出后可以达到很高的浸出率,可以作为比较理想的浸出时间。

图3 温度对废渣中有价金属浸出率的影响

Fig.3 Influence of temperature on leaching rate of metal values from smelting slag

图4 浸出时间对废渣中有价金属浸出率的影响

Fig.4 Influence of leaching time on leaching rate of metal values from smelting slag

上述研究表明,pH值、废渣浓度、温度均对Cu和Zn浸出有着非常显著的影响。pH值是影响废渣中Cu浸出的最重要因素,其次是废渣浓度,再次是温度,而浸出时间对废渣中Cu的浸出影响相对较小。温度、pH值及废渣浓度是影响废渣中Zn浸出的主要因素(ηA,ηB和ηD均大于ηE),三者对Zn的浸出影响相当 (ηA,ηB和ηD分别为25.2%,21.1%和24.8%)。由正交分析结果可知,生物浸出废渣中Cu和Zn的优化浸出条件应为:pH值为1.5,温度为65 ℃,矿浆浓度为5%,在此条件下浸出4 d。废渣中Ag和In的浸出则主要决定于pH(η分别为94.8%和89.1%),温度、废渣浓度及浸出时间则影响比较小,In在pH值为1.5、温度为65 ℃、废渣浓度为5%的浸出体系中,浸出率可以达到74.3%,而Ag浸出率很低,主要以黄钾铁矾类物质和硫化银(图5)的形式富积在浸后余渣中[19]。pH值、废渣浓度、温度及浸出时间对废渣中Pb浸出率均有极显著的影响(F>F0.01),但因硫酸铅溶解度(Ksp=1.62×10-8)低而大部分以沉积(图5)在余渣中[24],因此,废渣中铅浸出率很低(<5%)。pH、温度、废渣浓度及浸出时间均对Ga浸出有极显著影响,pH和废渣浓度是影响废渣中Ga浸出的主要因素(η分别为31.5%和23.6%),而温度和浸出时间的贡献率较 小。正交方差分析结果表明,在pH值为1.5左右、废渣浓度为5%、温度为65 ℃的条件下浸出4 d浸出率也可达到87.6%左右。但Ga在废渣中的存在形态复杂,主要以氧化物、硫化物甚至以类质同象形式镶嵌等在黄铁矿晶格中[12],目前对Ga的生物浸出机理研究很少[5],Ga在废渣中的浸出规律及其机理还有待进一步研究。综上所述,废渣生物浸出工艺的优化条件选取如下:pH值为1.5,废渣浓度为5%,温度为65 ℃,浸出时间为4 d。在优化浸出条件下,通过方差分析 (表1),废渣中Cu和Zn的浸出率理论上可分别达到(92.6±5.2)%和(88.6±6.0)%,In和Ga分别达到(74.3±5.0)%和(87.6±7.0)%,Ag和Pb的浸出率很低,为(6.8±0.6)%和(1.1±0.1)%。

2.2 优化条件下废渣中有价金属的浸出分析

根据正交实验优化浸出条件(pH值为1.5,温度为65 ℃,废渣浓度为5%,浸出时间为4 d),开展实验论证。结果表明,Cu,Zn,In和Ga浸出率实际分别达到95.5%,93.5%,85.0%和80.2%,而Ag和Pb的浸出率仅为7.2%和0.8%。其结果与正交实验方差分析结果吻合。因此,废渣中有价金属元素Cu,Zn,In,Ga,Ag和Pb可以分为两大类:一类是废渣中的Cu,Zn,In和Ga具有较高的浸出率,可以通过生物浸出到浸出液中,再通过萃取—电解等工艺回收;而另一类为Ag和Pb等经细菌浸出后,则主要以黄钾铁矾类物质、硫化银和硫酸铅的形式富集在余渣中(图5),需要寻找其他途径从生物浸出后余渣中回收Pb和Ag[25-26]。

图5 优化条件下生物浸出后余渣的XRD谱

Fig.5 XRD pattern of residues from bioleaching process under optimization variables

3 结论

1) 正交实验研究结果表明,浸出体系中pH值、废渣浓度、浸出温度和时间对Pb/Zn冶炼废渣中有价金属浸出影响非常明显。废渣中有价金属微生物浸出的优化条件为:pH 1.5,矿浆浓度5%,温度65 ℃,浸出时间4 d。

2) 在此优化条件下,废渣中的Cu,Zn,In和Ga的实际浸出率分别可以达到95.5%,93.5%,85%和80.2%,可以通过生物浸出从浸出液中回收废渣中的Zn,Cu,In和Ga;Ag和Pb则主要以黄钾铁矾类物质、硫化银和硫酸铅等形式富积在余渣中。

REFERENCES

[1] 刘业翔. 有色金属冶金基础研究的现状及对今后的建议[J]. 中国有色金属学报, 2004, 14(1): 21-24.

LIU Ye-xiang. Current status and future proposals of fundamental research in nonferrous metallurgy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 21-24.

[2] MANZ M, CASTRO L J. The environmental hazard caused by smelter slags from the STA. Maria De La PAZ mining district in mexico[J]. Environmental Pollution, 1997, 98(1): 7-13.

[3] AGRAWAL A, SAHU K K, PANDEY B D. Solid waste management in non-ferrous industries in India[J]. Resources Conservation and Recycling, 2004, 42(2): 99-120.

[4] GBOR P K, HOQUE S, JIA C Q. Dissolution behavior of Fe, Co, and Ni from non-ferrous smelter slag in aqueous sulphur dioxide[J]. Hydrometallurgy, 2006, 81(2): 130-141.

[5] 杨显万, 沈庆峰, 郭玉霞. 微生物湿法冶金[M]. 北京: 冶金工业出版社, 2003: 106-244.

YANG Xian-wan, SHEN Qing-feng, GUO Yu-xia. Bio-hydrometallurgy[M]. Beijing: Metallurgical Industry Press, 2003: 106-244.

[6] 杨松荣, 邱冠周, 胡岳华, 谢纪元. 含砷难处理金矿石生物生物氧化工艺及应用[M]. 北京: 冶金工业出版社, 2006: 133-137.

YANG Song-rong, QIU Guan-zhou, HU Yue-hua, XIE Ji-yuan. The application of biooxidation of arsenic-bearing refractory gold ore[M]. Beijing: Metallurgical Industry Press, 2006: 133-137.

[7] MUFIOZ J A, GONZBLEZ F, BLIZQUEZ M L, BALLESTER A. A study of the bioleaching of a Spanish uranium ore, Part I: A review of the bacterial leaching in the treatment of uranium ores[J]. Hydrometallurgy, 1995, 38(1): 39-57.

[8] CHEN S Y, LIN J G. Bioleaching of heavy metals from sediment significance of pH[J]. Chemosphere, 2001, 44(5): 1093-1102.

[9] TSAIA L J, YU K C, CHEN S F, KUNG P Y. Effect of temperature on removal of heavy metals from contaminated river sediments via bioleaching[J]. Water Research, 2003, 37(10): 2449-2457.

[10] BABEL S, DACERA M D. Heavy metal removal from contaminated sludge for land application: A review[J]. Waste Management, 2006, 26(9): 988-1004.

[11] ISHIGAKI T, NAKANISHI A, TATEDA M, IKE M, FUJITA M. Bioleaching of metal from municipal waste incineration fly ash using a mixed culture of sulfur-oxidizing and iron-oxidizing bacteria[J]. Chemosphere, 2005, 60(8): 1087-1094.

[12] 郭朝晖, 程 义, 柴立元, 宋 杰. 有色冶炼废渣的矿物学特征及其环境活性研究[J]. 中南大学学报: 自然科学版, 2007, 38(6): 1100-1105.

GUO Zhao-hui, CHENG Yi, CHAI Li-yuan, SONG Jie. Mineralogical characteristics and environmental availability of the non-ferrous slag[J]. Journal of Central South University: Natural Sciences, 2007, 38(6): 1100-1105.

[13] GUPTA A, BIRENDRA K, MISHRA R. Study on the recovery of zinc from Moore cake: a biotechnological approach[J]. Minerals Engineering, 2003, 16(1): 41-43.

[14] ROD?GUEZ Y, BALLESTER A, BL?ZQUEZ M L, GONZ?LEZ F, MU?OZ J A. New information on the chalcopyrite bioleaching mechanism at low and high temperature[J]. Hydrometallurgy, 2003, 71(1/2): 47-56.

[15] LIU Yun-guo, ZHOU Ming, ZENG Guang-ming, LI Xin, XU Wei-hua, FAN Ting. Effect of solids concentration on removal of heavy metals from mine tailings via bioleaching[J]. Journal of Hazardous Materials, 2007, 141(1): 202-208.

[16] POWELL N, JORDAN M A. Batch Leaching data analysis: Eradication of time dependency prior to statistical analysis[J]. Minerals Engineering,1997, 10(8): 859-870.

[17] 李云雁, 胡传荣. 试验设计与数据处理[M]. 北京: 化学工业出版社, 2005. 208-215.

LI Yun-yan, HU Chuan-rong. Experiment design and analysis[M]. Beijing: Chemical Industry Press, 2005: 208-215.

[18] DAOUD J, KARAMANEV D. Formation of jarosite during Fe2+ oxidation by Acidithiobacillus ferrooxidans[J]. Minerals Engineering, 2006, 19(9): 960-967.

[19] BOLORUNDURO S A, DREISINGER D B, WEERT V G. Zinc and silver recoveries from zinc-lead-iron complex sulphides by pressure oxidation[J]. Minerals Engineering, 2003, 16(4): 375-389.

[20] 王树楷. 铟冶金[M]. 北京: 冶金工业出版社, 2006: 82-88.

WANG Shu-kai. Indium metallurgy[M]. Beijing: Metallurgical Industry Press, 2006: 82-88.

[21] TIPRE D R, DAVE S R. Bioleaching process for Cu-Pb-Zn bulk concentrate at high pulp density[J]. Hydrometallurgy, 2004, 75(1/4): 37-43.

[22] DEVECI H. Effect of solids on viability of acidophilic bacteria[J]. Minerals Engineering, 2002, 15(15): 1181-1189.

[23] 张招崇, 毛景文, 杨建民, 王志良. 甘肃寒山金矿区黄钾铁矾的形成机制及其地质意义[J]. 地质地球化学, 1999, 27(1): 33-37.

ZHANG Zhao-chong, MAO Jing-wen, YANG Jian-min, WANG Zhi-liang. Genesis of jarosite in the Hanshan gold mine of Gansu province and its geological significance[J]. Geology- Geochemistry, 1999, 27(1): 33-37.

[24] SILVA D G. Kinetics and mechanism of the bacterial and ferric sulphate oxidation of galena[J]. Hydrometallurgy, 2004, 75(1/4): 99-110.

[25] LIAO M X, DENG T L. Zinc and lead extraction from complex raw sulfides by sequential bioleaching and acidic brine leach[J]. Minerals Engineering, 2004, 17(1): 17-22.

[26] FR?AS C, D?AZ G, OCA?A N, LOZANO J I. Silver, gold and lead recovery from bioleaching residues using the PLINT process[J]. Minerals Engineering, 2002, 15(11): 877-878.

基金项目:国家自然科学基金资助项目(20507022);中南大学博士后基金资助项目(1339-811640000)

收稿日期:2007-08-10;修订日期:2008-03-04

通讯作者:郭朝晖,副教授,博士;电话:0731-8836442;传真:0731-8710171;E-mail: zhguo@mail.csu.edu.cn

(编辑 陈爱华)