文章编号: 1004-0609(2005)04-0590-06

分级时效对Al-Cu-Li-Mg-Mn-Zr合金微/、观组织与性能的影响

范云强1 , 陈志国2 , 郑子樵2 , 李艳芬2

(1. 西南铝业(集团)有限责任公司 技术中心, 重庆 401326)

(2. 中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 通过合金室温力学性能测试及时效组织的透射电镜分析, 研究了分级时效对Al-Cu-Li-Mg-Mn-Zr合金显微组织与性能的影响。 结果表明, 经过先低温后高温的三级时效可使合金获得比T6处理更高的强度, 且随着第二级时效时间的延长, 合金抗拉强度和屈服强度逐渐提高。 采用先高温后低温二级时效, 可获得较先低温后高温三级时效更高的力学性能, 且其强度随第一级高温时效时间的延长而增加, 达到T8峰时效的强度水平。 合金在先低温后高温时效时, 在100℃低温预时效形成GP区, 在140℃析出弥散细小的δ′、 θ′和T1相并稳定下来, 然后在175℃进一步析出长大, 从而提高了合金强度。 当合金在先高温后低温二次时效时, 高温欠时效析出δ′和T1等强化相, 然后在140℃较低温度二次析出大量细小弥散的δ′相, 产生二次强化效果。

关键词: 铝锂合金; 时效; 微观结构; 力学性能 中图分类号: TG146.2

文献标识码: A

Effects of multi-stage ageing treatments on microstructure and

mechanical properties of Al-Cu-Li-Mg-Mn-Zr alloys

FAN Yun-qiang1 , CHEN Zhi-guo2 , ZHENG Zi-qiao2 , LI Yan-feng2

(1. Technology Centre, Southwest Aluminum Industry Ltd.Co., Chongqing 401326, China;

2. School of Materials Science and Engineering, Central South University,Changsha 410083, China)

Abstract: The effects of multi-stage ageing treatments on the microstructure and mechanical properties of Al-Cu-Li-Mg-Mn-Zr alloy were investigated.Compared with T6 treatment, higher mechanical properties can be obtained by multi-stage ageing treatments, especially the treatment of (175℃, 24h)+(140℃, 36h) leads to an excellent combination of strength and ductility. When the alloy is pre-aged at lower temperature(100℃), the GP zone is preferentially precipitated, and the fine and dispersed δ′, θ′ and T1 phases are precipitated at 140℃. These precipitates continue to grow at 175℃, which improves the strength of alloy. The combined effects of δ′, θ′ and T1 precipitates at the first age stage of 175℃ and the secondary-precipitation at the second stage of 140℃ can be aroused, which results in higher strength(close to that in T8 treatment) than that of the alloy pre-aged at lower temperature then at elevated temperature.

Key words: Al-Li alloy; ageing; microstructure; mechanical property

铝锂合金常用热处理为T6与T8工艺。 研究表明[1-3], 采用T6热处理可使合金具有较好的强度和塑性, 而T8工艺(预变形+时效)能在稍微损失塑性的情况下显著提高合金强度, 从而充分发挥合金效能。 但对于一些实际工业应用的铝锂合金制品, 如锻件或焊接件, 由于预变形使用不便而使得T8工艺难以实施, 因而寻求不需要预变形又能取得T8工艺强度水平的热处理制度成为当前铝锂合金研究的重要方向。 应用于7000系合金的先在较低温度时效, 接着在较高温度再次时效的热处理制度可大幅度调控合金的微观组织, 进而显著提高合金的综合性能[4]。 而在先低温后高温的分级时效前, 加入预变形, 可通过引入位错促进T1相形核来提高合金强度并改善塑性和韧性[5]。 普通时效后再迭加短时加热快冷的特殊分级时效, 则可改善铝锂合金的滑移特性并减少Li在晶界的偏聚, 从而提高合金横向断裂韧性[6]。 此外, 近些年对二次时效[7-11]现象的认识彻底改变了在高温时效后进行低温长时间时效其微观组织与性能不会发生改变的观点。 分级时效能否成为挖掘铝锂合金效能的有利手段将有待于进一步探讨。 本文作者研究了分级时效对铝锂合金力学性能与微观组织的影响, 并对其影响机理进行了较为深入的研究。

1 实验

采用工业纯Al、 Mg、 Li和Al-49.35%Cu、 Al-3%Mn及Al-4.05%Zr(质量分数)中间合金为原料, 在熔剂保护下进行熔化和精炼, 在氩气保护下水冷铜模铸造成Al-2.8Cu-1.5Li-0.4Mg-0.3Mn-0.12Zr(质量分数, %)实验合金。 铸锭经均匀化之后热轧、 冷轧而成为厚2mm的板材。 经固溶处理、 水淬后进行以下两类时效处理: 1) 先低温后高温的分级时效: ①(100℃, 8h)+(140℃, t1)+(175℃, 24h), t1=4、 16、 24、 36、 48h; ②(100℃, 8h)+(175℃, 24h); ③(140℃, 48h)+(175℃, 24h)。 2) 先高温后低温的二次时效: (175℃, t2)+(140℃, t3), t2=8、 16、 24h, t3=0、 24、 36、 48h。 拉伸试样取自板材的纵向, 拉伸实验在Instron8019材料试验机上进行, 拉伸速度为2mm/min。 透射电镜样品经机械减薄后采用33%硝酸甲醇溶液在-40℃左右的条件下双喷穿孔, 显微组织观察在H-800透射电镜上进行, 加速电压为200kV。

2 结果与讨论

2.1 先低温后高温的分级时效

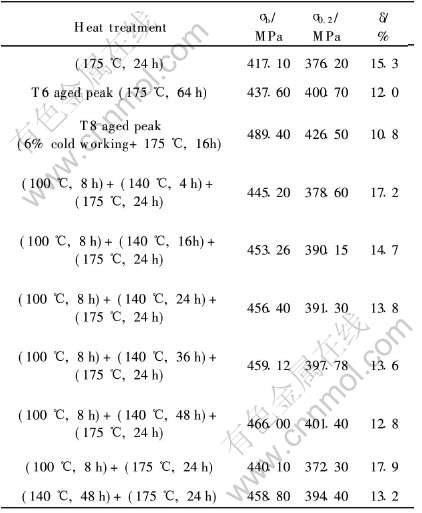

表1所列为合金在几种不同热处理制度下的力学性能实验数据。 由表1可知, 合金若不经过140℃第二级时效, 而直接进行(100℃, 8h)+(175℃, 24h)时效, 抗拉强度(σb)和屈服强度(σ0.2)比进行140℃第二级时效的要低, 说明合金经过140℃不同时间的第二级时效, 强度得到了提高, 但塑性有所下降。 随着第二级时效时间t1的延长, 合金抗拉强度和屈服强度逐渐得到提高, 时间达到48h时的抗拉强度比4h的提高了20.8MPa。 这说明延长第二级时效时间有利于合金强度的提高。 而从延伸率(δ)的规律来看, 变化趋势则相反, 随着时间t1的延长, 延伸率一直呈下降的趋势, t1从4h变化到48h, 延伸率则从17.2%下降到12.8%。 但总体来说, 合金仍然保持有较高的延伸率。 同样地, 合金不经过(100℃, 8h)的预时效, 即进行(140℃, 48h)+(175℃, 24h)时效, 与(100℃, 8h)+(140℃, 48h)+(175℃, 24h)的三级时效相比, 可知(100℃, 8h)预时效对合金的力学性能会产生一定的影响。

表1 不同热处理状态下合金的力学性能

Table 1 Tensile properties of alloy under different heat treatments

此外, 合金经过先低温后高温的三级时效, 强度要比单级时效高, 延伸率并没有下降。 特别是合金经过(100℃, 8h)+(140℃, 48h)+(175℃, 24h)时效, 与(175℃, 24h)单级时效相比, 合金抗拉强度要高出48.9MPa, 而延伸率只降低2.5%; 与(175℃, 64h)的峰值时效相比, 抗拉强度要高出28.4MPa, 而且延伸率并不比峰值时效低。 同样, 合金经过先低温后高温的二级时效, 强度也得到了一定的提高。 由此说明, 先低温后高温的多级时效能在一定程度上提高合金强度, 有利于合金综合性能的改善。

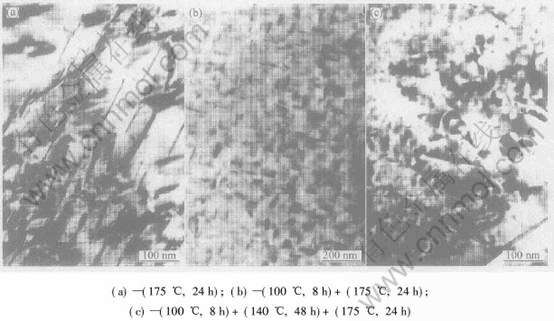

图1所示为合金在不同时效制度下的微观组织。 由图1可见, 合金经过(175℃, 24h)单级时效, 晶内主要析出物为T1相(见图1(a))。 而合金在(175℃, 24h)时效之前, 经过(100℃, 8h)的低温预时效, 析出数量较多、 弥散分布的δ′、 θ′和T1相, 且主要强化相为相互垂直的θ′相(见图1(b))。 合金经过三级时效(100℃, 8h)+(140℃, 48h)+(175℃, 24h)后, 仍然析出弥散分布的δ′、 θ′和T1相(图1(c))。 但与(100℃, 8h)+(175℃, 24h)时效相比, 强化相析出密度有所加大、 尺寸稍增大, 且T1相增多, 而θ′相数量减少。 说明在时效过程中, T1相的析出长大伴随θ′相的溶解, 即T1相长大所需的Cu原子以消耗θ′相而获取。 此时, 由于T1相增多, 尺寸加大, 且强化相析出较充分, 因此该时效制度下合金强度较高。

图1 合金在不同时效状态下的显微组织

Fig.1 Microstructures of alloy under different heat treatments

2.2 先高温后低温的二次时效

图2所示为合金在(175℃, t2)+(140℃, t3)(t2=8、 16、 24h; t3=0、 24、 36、 48h)热处理制度下, 力学性能随t2和t3的变化曲线。 由图2可见, 当t3=0h时, 也就是进行175℃单级时效时, 合金强度比相应的二次时效要低得多。

图2 合金力学性能与时效时间的关系

Fig.2 Relationship between tensile properties and ageing time

当预时效时间t2一定时, 第二级时效时间t3 从24、 36变化到48h, 合金强度和延伸率变化很小, 在图2上几乎表现为平行线。 也就是说, 在本研究的条件下, t3超过24h后, 时效时间对合金力学性能影响不大。 这与James等[12]在AF/C-458合金中的二次时效实验结果一致。

而当第二级时效时间t3一定时, 从图2可以看到, 随着预时效时间t2的延长, 合金抗拉强度和屈服强度也相应增长, 延伸率则呈下降趋势。 说明预时效时间t2对合金力学性能有一定的影响, 延长预时效时间, 能在一定程度上提高合金的强度, 同时造成一定的延伸率损失。 此外, 与该合金的T6处理与T8处理比较, 经过先高温后低温的二次时效后, 合金强度较T6峰值强度显著提高, 达到T8的峰值强度, 而延伸率与T8峰值的相当, 其中强度与塑性达到最佳的双级时效制度为(175℃, 24h)+(140℃, 36h)。 同时, 与前面的先低温后高温的多级时效相比, 平均强度也提高了20MPa左右, 而延伸率相差无几。 由此可见, 采用这种比较简单的二次时效工艺, 可使合金性能得到显著提高, 远远超过T6处理的强度, 达到T8处理的强度水平。

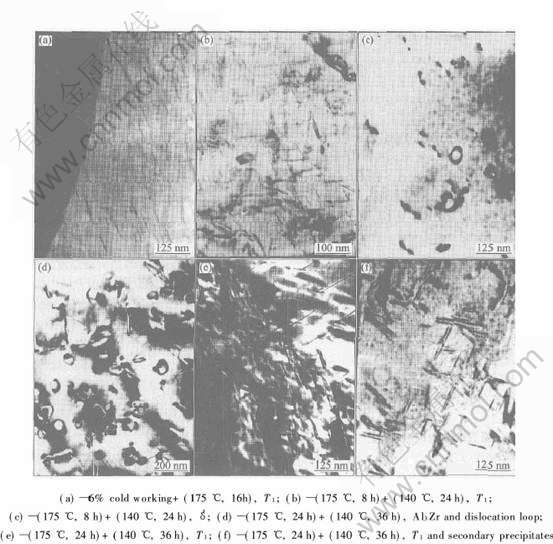

图3所示为合金在不同时效制度下的微观组织。 由图3可知, 合金在T8峰值时效时, 合金析出非常密集、 尺寸较大的T1相, 几乎观察不到δ′相(图3(a))。 当合金进行(175℃, 8h)+(140℃, 24h)时效时, 析出较多的T1和δ′相。 研究表明, 时效前的预变形[13]或低温预时效[14]能在Al3Zr粒子周围形成位错环, 以补偿β′与基体间的晶格错配度。 在本研究的时效制度中也观察到β′周围位错环的存在(如图3(d)所示), 而这种位错环可以成为T1相的形核位置, 有利于T1相的析出, 从而有利于提高合金强度。 同时, T1相析出虽然不如T8峰值时效密集, 但数量也较多, 如图3(e)所示。 此外, 更重要的是, 从图3(f)中可以看到, 合金中除了在(175℃, 24h)析出的δ′、 T1相之外, 还在基体上二次析出大量细小弥散的δ′相。 正是由于这种大量弥散析出二次相δ′相的存在, 导致了强度的进一步提高。 这与Lumley等[15, 16]的研究结果相一致。

图3 合金在不同热处理态下的显微组织

Fig.3 Microstructures of alloy under different heat treatments

3 分析与讨论

3.1 先低温后高温的分级时效

采用先低温后高温的三级时效, 第一级时效温度选择在100℃(低于GP区的溶解温度[17]), 使合金中形成大量弥散分布的GP区; 然后将温度提高到140℃进行第二级时效, 这样能使合金析出弥散细小的δ′、 θ′和T1相, 并在此温度保持一段时间稳定下来; 最后进一步提高时效温度到175℃, 使强化相进一步析出并长大, 并逐渐转化为强化效果更大的T1相, 以此来实现合金强度的提高。

当合金不进行140℃中间时效, 而直接进行(100℃, 8h)+(175℃, 24h)时效时, 合金在(100℃, 8h)的低温预时效处理时, 已形成均匀分布的GP区, 作为强化相弥散形核的核心, 然后在175℃时效, 合金形成尺寸较细、 分布非常弥散的δ′、 θ′和T1相。 正是由于这些强化相的细小弥散分布提高了合金强度, 使强度远远超过(175℃, 24h)时效的强度, 但由于T1相的数量没有T6峰值时效多, 因此其强度只比T6峰值强度略高。

合金进行三级时效时, 第二级时效时间t1的长短对合金析出相有一定影响。 t1较短时, 析出的δ′、 θ′和T1数量较少, 也不能较好的稳定下来, 进一步提高温度时效时, 部分小于临界尺寸的δ′相会回溶, 大于临界尺寸的会继续长大, 因此, 时效强化主要来自于后来形成的T1相。 随时效时间t1的延长, 尺寸增大的δ′相数量增多, 阻碍位错运动的作用增强, 但此时α中过饱和的Li已较多的消耗于δ′相的析出, 致使析出的T1相数量减少, 即在δ′相对时效强化贡献增加的同时, T1相的贡献却下降, 但由于前者作用大于后者, 因此, 合金强度仍然增长, t1的延长有利于合金强度的提高。

3.2 先高温后低温的二次时效

在高温欠时效(175℃, 8h)时, 合金中析出了少量的δ′、 θ′和T1相, 此时其尺寸较细小, 在随后进行140℃不同时间的时效中, 已析出相将继续长大, 但其速度较慢, 同时还在基体上进一步析出细小弥散的δ′相等。 正是由于这些二次析出的细小弥散相造成的强化使得合金强度能超过相同时间单级时效的强度。

当高温175℃欠时效时间t2一定时, 140℃第二级时效时间t3延长时, 出现两种相反的作用: 一方面弥散析出相增多, 尺寸增大, 强化作用增加; 另一方面初次析出相粗大, 强化作用减弱。 因此, 虽然在不同第二级时效时间t3下, 各强化相尺寸、 数量和分布发生不同的变化, 但这些变化均存在对时效强化作用利弊共存的两方面, 综合效果表现为t3超过24h后对拉伸性能影响不明显。 但James 等[12]研究表明, 此时对合金性能的影响表现为对断裂韧性的提高。

当140℃第二级时效时间t3一定, 175℃预时效时间t2延长时, 析出强化相的数量增多, 尺寸长大, 强化作用增强。 而进行随后140℃时效时, 由于预时效析出强化相数量多, 强化相在140℃时效时长大所带来的强化效果也越大。 因此, 当低温140℃时效时间t3相同时, 延长高温预时效时间t2有利于合金强度的提高。

4 结论

1) 经过先低温后高温的三级时效可使合金获得比T6处理更高的强度, 且随着第二级时效时间的延长, 合金抗拉强度和屈服强度逐渐提高, 但延伸率有所下降。

2) 采用先高温后低温的双级时效处理, 可获得较先低温后高温的三级时效更高的力学性能, 且其强度随第一级高温时效时间的延长而增加, 其中以(175℃, 24h)+(140℃, 36h)时效制度的强度和塑性最佳, 达到T8峰值时效强度水平。

3) 合金在先低温后高温时效时, 在100℃低温预时效形成GP区, 接着在140℃析出细小弥散的δ′、 θ′和T1相, 并稳定下来, 然后在175℃进一步析出长大, 从而提高了合金强度。

4) 当合金在先高温后低温时效时, 合金在高温欠时效析出强化相δ′和T1, 然后在140℃较低温度二次析出大量细小弥散的δ′相, 产生二次强化效果。

REFERENCES

[1] Kim J D, Park J K. Effect of stretching on the precipitation kinetics of an Al-2.0Li-2.8Cu-0.5Mg(0.13Zr) alloy[J]. Metall Trans, 1993, 24A: 2613-2621.

[2] Cassada W A, Shiflet G J, Starke E A Jr. The effect of plastic deformation on Al2CuLi(T1) precipitation[J]. Metallurgical Transaction A, 1991, 22A(2): 299-306.

[3] Huang J C, Ardell A J. Addition rules and the contribution of δ′ precipitates to strengthening of aged Al-Li-Cu alloys[J]. Acta Metall, 1988, 36(11): 2995-3006.

[4] Park J K, Ardell A J. Microchemical analysis of precipitate free zones in 7075-A1 in the T6, T7 and RRA tempers[J]. Acta Metallurgica et Materialia, 1991, 39(4): 591-598.

[5] Acosta E, Garcia O, Dakessian A. On the effect of thermomechanical processing on the mechanical properties of 2197 plates[J]. Mater Sci Forum, 2002, 396-402: 1157-1162.

[6] Blankenship C P, Starke E A. Mechanical behavior of double-aged AA8090[J]. Metall Trans A, 1993, 24(4): 833-841.

[7] Peel C J. Applications and developments for aluminium-lithium alloys[A]. Peters M. Proceeding of the 6th Aluminium-Lithium Alloy Conference[C]. Germany: Garmisch-Partenkirchen, 1991. 1259-1270.

[8] Lynch S P. Fracture of 8090 Al-Li plate I. Short transverse fracture toughness[J]. Mater Sci Eng A, 1991, 136: 25-43.

[9] Pitcher P D, Stewart R J, Gupta S. A study of reversion behaviour in 8090 alloys using small angle neutron scattering and transmission electron microscopy[J]. Scripta Metall, 1992, 26(4): 511-516.

[10] Kerr M J, Sweet E D, Bennett C G, et al. Effect of alkali metal impurities on the low temperature thermal stability of 2090 Al-Cu-Li alloys[J]. Mater Forum, 1996, 217-222: 1079.

[11] Lumley R N, Morton A J, Polmear I J. Enhanced creep performance in an Al-Cu-Mg-Ag alloy through underageing[J]. Acta Mater, 2002, 50(14): 3597-3608.

[12] Fragomen J M, Wheeler R. The strengthening and microstructure of precipitation hardened Al-Li-Cu alloys[J]. Mater Sci Forum, 2003, 426-432: 309-314.

[13] 赵志龙, 韩 栋, 王永欣, 等. 2090铝锂合金中T1相与β′(Al3Zr)相间的交互作用[J]. 有色金属, 1999, 51(3): 83-86.

ZHAO Zhi-long, HAN Dong, WANG Yong-xin, et al. Interaction between T1 phase and β′(Al3Zr) phase in 2090 aluminium-lithium alloys[J]. Nonferrous Metals, 1999, 51(3): 83-86.

[14] Tite C N J, Gregson P J, Pitcher P D. Further precipitation reactions associated with β′( Al3Zr) particles in Al-Li-Cu-Mg-Zr alloys[J]. Scripta Metallurgica, 1988, 22(7): 1005-1010.

[15] Lumley R N, Polmear I J, Morton A J. Development of properties during secondary ageing of aluminium alloys[J]. Mater Sci Forum, 2003, 426-432: 303-308.

[16] Lumley R N, Polmear I J, Morton A J. Interrupted aging and secondary precipitation in aluminium alloys[J]. Mater Sci and Tech, 2003, 19(11): 1483-1490.

[17] Garcia J, Haboshi M, Galland J. Differential scanning calorimetric studies and stress-corrosion cracking in Al-Li alloys[A]. Sanders T H Jr, Starke E A Jr. Proceeding of the 5th International Aluminum-Lithium Conference[C]. Birmingham: Materials and Component Engineering Publication Ltd, 1989. 1293-1308.

收稿日期: 2004-09-21; 修订日期: 2004-12-22

作者简介: 范云强(1968-), 男, 高级工程师.

通讯作者: 范云强, 电话: 023-65808225; E-mail: fanyunq@163.net

(编辑 李艳红)