DOI: 10.11817/j.issn.1672-7207.2017.07.003

含锌粉尘团块脱锌行为研究

陈子罗,张建良,刘征建,袁骧,王飞,刘依然,高斌

(北京科技大学 冶金与生态工程学院,北京,100083)

摘要:通过正交实验分析焙烧温度、碳氧物质的量比、水分质量分数、碱度和CO2体积分数5个关键因素对含锌粉尘的脱锌过程的影响,利用热力学软件Factsage计算分析实验温度范围内锌、铁的还原优势,并且通过扫描电镜(SEM)和X线衍射分析(XRD)Zn和Fe元素在焙烧过程中的还原行为。研究结果表明:温度是影响脱锌率最主要的因素,脱锌率随着温度的升高而显著增加。达到1 200 ℃时Zn单质几乎能和Fe单质同时被还原出来。脱锌的最佳工艺参数如下:温度为1 200 ℃,碳氧物质的量为1.0,水分质量分数为10%,碱度为2.0,CO2体积分数为65%,在此最佳工艺条件下团块脱锌率达到82.66%。

关键词:含锌粉尘;脱锌;正交实验;还原;热力学

中图分类号:TF556 文献标志码:A 文章编号:1672-7207(2017)07-1704-08

Research on dezincification of zinc-bearing dusts composite briquettes

CHEN Ziluo, ZHANG Jianliang, LIU Zhengjian, YUAN Xiang, WANG Fei, LIU Yiran, GAO Bin

(School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Based on the orthogonal experiment, the effects of roasting temperature, molar ratio of carbon to oxygen, mass fraction of water, binary basicity and CO2 volume fraction on the dezincification of zinc-bearing dusts briquettes were studied. The predominancearea of Zn and Fe were calculated by Factsage. The reduction behavior of Zn and Fe was analyzed by scanning electron microscope (SEM) and X-Ray Diffraction (XRD). The results show that roasting temperature is the most important factor of the dezincification, and the higher temperature, the higher dezincification rate. At 1 200 ℃, Zn and Fe can be reduced at the same time. The optimal parameters are roasting temperature of 1 200 ℃, molar ratio of C to O of 1.0, mass fraction of water of 10%, binary basicity of 2.0 and CO2 volume fraction of 65%, and under this condition the dezincification ratio reaches 82.66%.

Key words: zinc-bearing dusts; dezincification; orthogonal experiment; reduction; thermodymanics

作为钢铁工业主要污染源和二次资源之一,粉尘主要产生于烧结、炼铁、炼钢以及轧制等工序,具有粒度细小、成分复杂等特点[1-3]。据国际钢铁协会统计,2015年中国粉尘产出量约为8 000万t,钢铁厂的环保压力日益增加。而且粉尘中的碳、铁和锌等有价元素未能得到有效利用等问题使得综合回收及有效利用粉尘显得尤为迫切。钢铁企业一般采用火法工艺处理粉尘,该工艺具有较高的生产效率和较低的环境代价[4-6]。目前,我国主要采用返回烧结的方法,但配加细粒级、高含锌量的粉尘会降低烧结料层透气性,且锌在高炉中的循环富集会引发煤气流阻塞,进而影响烧结和高炉生产的经济技术指标[7-8],因此,冶金工作者对含锌粉尘脱锌预处理进行了大量的研究。张建良等[9]通过能谱、差热及热重等分析手段验证了用还原焙烧的方法脱除高炉含锌粉尘中锌的可行性。高金涛等[10]采用“非熔态还原-磁选分离-Zn的回收、富集”方法对典型高炉粉尘进行Fe和Zn非熔态分离研究。胡晓军等[11]对含锌粉尘中重要成分ZnFe2O4在CO-CO2气体还原过程中的热力学行为进行了计算和分析。为充分利用钢铁厂的热能,采用含碳球团还原脱锌工艺[12-15]可以在锌元素沸点之上将锌彻底脱除。而前人的研究多数基于单因素实验,单因素实验能很好地分析某因素对粉尘脱锌的作用规律,但是工作量较大,所以,这些研究考察的因素较少,不能同时进行多因素对粉尘脱锌影响规律的对比,且在各因素水平的选取上也不尽相同,因此,本文作者通过正交实验获得各种因素在不同水平下的脱锌率,旨在明晰各因素对粉尘脱锌的作用机制。本文作者采用正交实验考察焙烧温度、碳氧物质的量比、水分质量分数、碱度(即CaO与SiO2质量分数之比)和CO2体积分数(即CO2在还原气中的体积占比)对含锌粉尘脱锌率的影响,并分析各因素对脱锌的影响机制。利用热力学软件Factsage计算分析实验温度范围内锌、铁的还原优势,使用扫描电镜和X线衍射对含锌粉尘复合团块脱锌过程的微观机理进行分析。

1 实验

1.1 实验原料

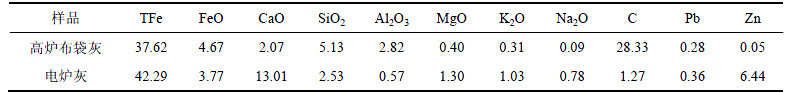

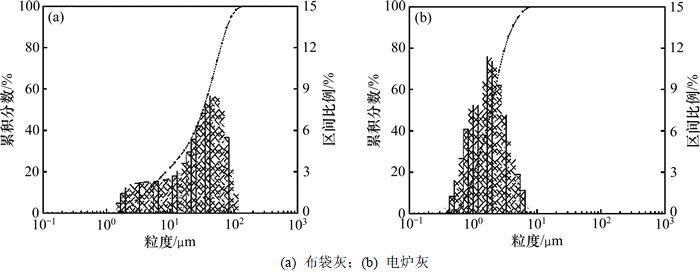

实验所用2种含锌粉尘分别取自宝钢炼铁工序和炼钢工序中的高炉布袋灰和电炉灰,其化学成分分析和粒度组成分别如表1和图1所示。

从表1可以看出:高炉布袋灰和电炉灰的总铁(TFe)质量分数较高具有很大的回收价值,布袋灰的C质量分数高达28.33%,在自还原团块中可以替代部分还原剂,减少外配焦粉的使用量。电炉灰中的Zn含量较高,回收后可作为炼锌的原料。此外,电炉灰中CaO质量分数达到13.01%,可以减少调节碱度时CaO的配加量。

从图1可以看出:高炉布袋灰和电炉灰在粒径分布上存在差异,高炉布袋灰的粒径较大,大部分分布在10~100 μm,而电炉灰的粒径非常小,均小于10 μm。这种粒径上的差异可以使2种粉尘在成球过程中具有一定的互补性,粒径较大的布袋灰充当骨架,电炉灰填充在布袋灰颗粒间的缝隙中,混合粉尘的成球效果良好。

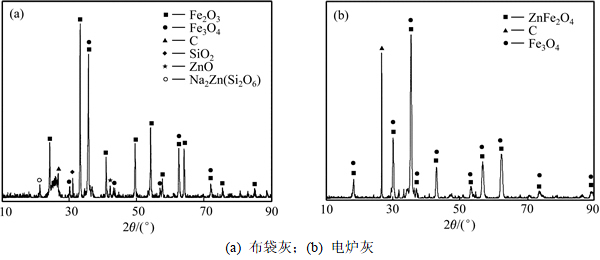

为明晰Zn和Fe等元素在粉尘中的赋存状态,对2种粉尘进行了X线衍射分析,如图2所示。

表1 粉尘成分(质量分数)

Table 1 Composition of dusts %

图1 粉尘粒度分布

Fig. 1 Particle size distribution of dusts

图2 2种粉尘的XRD物相分析

Fig. 2 XRD patterns of two dusts

从图2可以看出:高炉布袋灰中的Fe元素以Fe2O3和Fe3O4形式存在,Zn元素以ZnO和Na2Zn(Si2O6)形式存在。而电炉灰中Fe元素主要存在形式为Fe3O4,Zn元素主要存在于ZnFe2O4中。

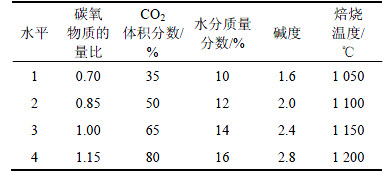

1.2 实验方案

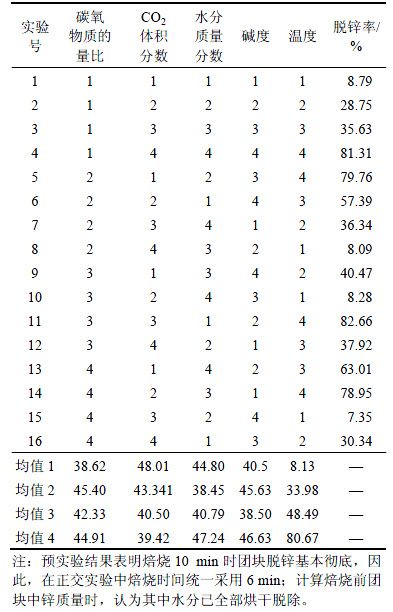

正交实验考察焙烧温度、碳氧物质的量比、水分质量分数、碱度和CO2体积分数5个因素对脱锌率的影响,每个因素设置4个水平,实验所用正交表为L16(45),实验方案如表2所示。并在正交实验得出的最佳工艺参数条件下,研究脱锌过程的微观形貌变化和物相转变过程。

表2 脱锌正交实验方案

Table 2 Orthogonal experiment scheme of dezincification

粉尘团块中高炉布袋灰和电炉灰以3:7质量比混合,使用水泥作为黏结剂且配加量为10%(质量分数),焦粉作为还原剂,并通过添加分析纯SiO2或CaO粉末以调节团块碱度。首先将原料按比例混和后加水充分混匀,每10.00 g混匀料装入直径为20 mm模具中压制成块,压强为50 MPa。然后将团块放入温度为25 ℃、湿度为95%的养护箱中养护72 h。将养护好的团块在105 ℃的电热鼓风干燥箱中干燥24 h。实验使用高温硅钼竖式电阻炉,加热元件为U型硅钼棒,分布于炉膛四周。当设备温度升温至预设温度时,使用刚玉坩埚将团块放入恒温区进行脱锌实验,实验中除通有还原气外全程还通有高纯氩气Ar(总流量为4 L/min)保护。实验结束后,取出样品在高纯氩气Ar(1 L/min)保护迅速降温至室温,并对产物进行脱锌率计算、微观形貌及物相分析。

2 结果与讨论

还原脱锌后的团块具有一定金属化率,由于还原时间较短,金属化率最高的团块仅为36.7%,可进一步还原用于生产金属化球团。

2.1 脱锌正交实验

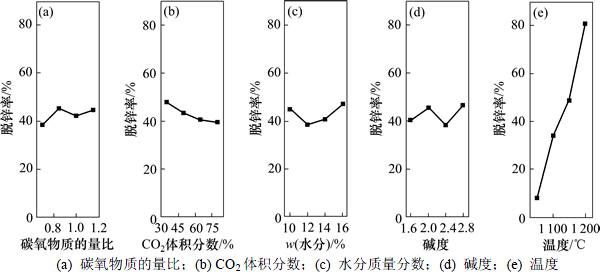

按照实验方案共进行16组实验,每组实验重复3次,焙烧后分析团块中的锌含量以计算脱锌率,取平均值作为该工艺条件下的脱锌率。计算各因素的均值以绘制各因素对脱锌率的影响曲线,分别如表3和图3所示。

从图3可以看出:碳氧物质的量比和碱度的提高,团块脱锌率呈现先上升后下降的趋势,但整体脱锌率均维持在38.50%和46.63%之间。提高CO2体积分数,团块的脱锌率从48.01%降低到39.42%。脱锌率随着团块的配水量的增加而先从44.80%降低至38.45%后上升至40.79%。而温度极大程度地影响到团块脱锌率,1 050 ℃时脱锌率为8.13%;随着温度升高,脱锌率急剧升高,1 200 ℃时脱锌率达到82.66%。

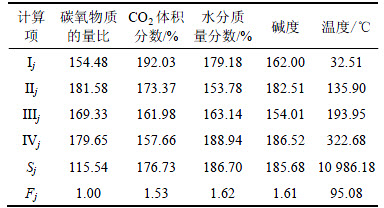

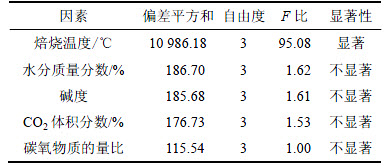

采用方差分析各因素对脱锌率影响是否显著对还原效果进行判断,并得出各因素的主次顺序。正交实验的方差分析结果如表4和表5所示。

表4中Ⅰj,Ⅱj,Ⅲj和Ⅳj分别表示因子j下相对于水平1,2,3和4的数据之和;Sj为因子j的偏差平方和,其计算方法为[16-17]

表3 脱锌正交实验结果

Table 3 Results of orthogonal experiment

(1)

(1)

其中:N为各水平重复数;Yi为第i组脱锌率。

由于本实验所用正交表不存在空列,所以误差平方和Se取偏差平方和Sj的最小值Smin,因此,统计量的计算式为

(2)

(2)

式中:a为样本个数。

表4 不同因素下的计算项

Table 4 Calculation under different factors

表5 各因素对脱锌率影响的方差分析

Table 5 Variance analysis of impact of each factor on dezincification rate

图3 各因素对脱锌率的影响

Fig. 3 Effects of each factor on the dezincification rate

由表5可知:对脱锌率影响最为显著的是焙烧温度,而水分质量分数、碱度、碳氧物质的量比以及CO2体积分数对脱锌率的影响比较小。因此,在对含锌粉尘进行脱锌处理首先需要考虑的是温度,温度的提高能大幅度提高脱锌率,并且得出脱锌的最佳工艺参数如下:温度为1 200 ℃,碳氧物质的量比为1.0,水分质量分数为10%,碱度为2.0,CO2体积分数为65%。

2.2 焙烧温度对脱锌的影响分析

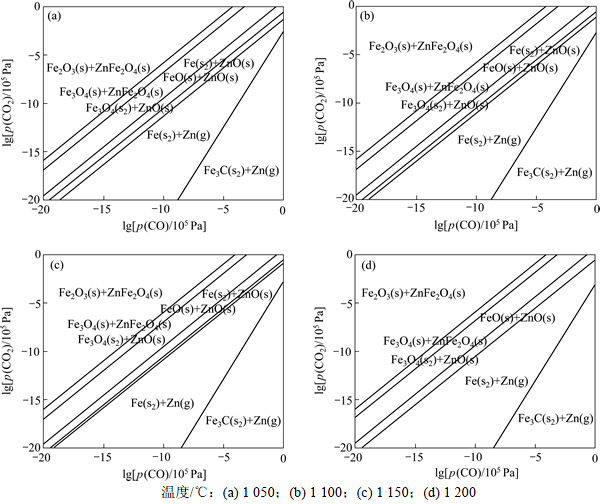

使用Factsage热力学软件计算实验焙烧温度范围内Fe-Zn-C-O体系在等压条件下还原的优势区域图,如图4所示。

从图4可以看出:铁氧化物和锌氧化物的还原 过程分别按照Fe2O3→Fe3O4→FeO→Fe→Fe3C和ZnFe2O4→ZnO→Zn的还原顺序逐级还原。1 050 ℃时Fe单质要先于Zn单质被还原出来。升高温度,更利于锌氧化物的还原,当温度达到1 200 ℃时,Zn单质几乎和Fe单质同时被还原出来。并且温度越高,还原所需的还原气氛越弱。因而,提高温度有利于Zn和Fe元素的还原,即有利于Zn被彻底脱除。而且温度升高能大幅度提高脱锌率也是因为ZnO的直接还原和碳气化反应是强吸热反应,温度升高有利于ZnO还原,降低ZnFe2O4和ZnO还原反应的活化能[18]。

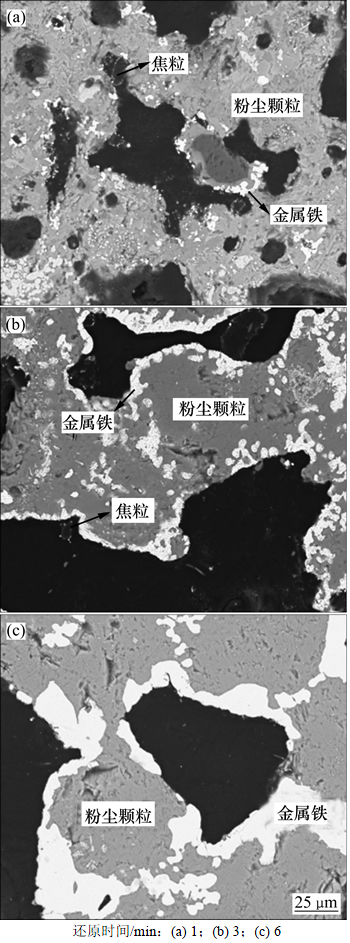

2.3 脱锌过程微观形貌变化

通过扫描电镜分析(SEM,Quanta250环境扫描电子显微镜)对1 200 ℃下还原不同时间的含锌粉尘团块进行显微形貌分析,如图5所示。

由图5可知:反应开始时(图5(a))团块中的还原反应是由团块内部的含碳颗粒和锌铁氧化物颗粒在接触点上的直接还原反应。随着反应进行(如图5(b)所示),团块内部粉尘颗粒与石墨颗粒的接触点逐渐减少,此时主要依赖直接还原产生的CO向未反应的氧化物扩散,进而以间接还原的方式还原锌铁氧化物。当时间进一步延长至6 min时(图5(c)),生成的金属铁颗粒在外层扩散聚集,产物层进一步增厚,使得CO气体间接还原氧化物成为还原脱锌的主要方式。

图4 Fe-Zn-C-O体系的还原优势区域图

Fig. 4 Predominance area diagram of Fe-Zn-C-O system

图5 不同还原时间脱锌产物扫描电镜图

Fig. 5 SEM pictures of dezincification products of different reduction time

2.4 脱锌过程物相转变过程

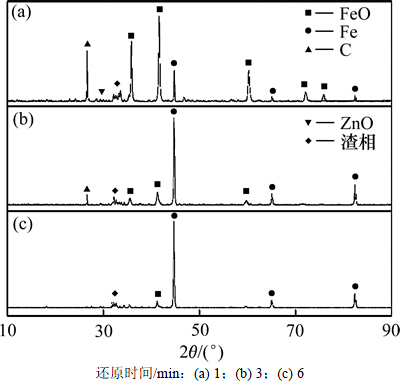

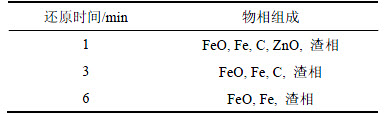

通过X线衍射分析(XRD,Ultima-IV X线衍射仪)对1 200 ℃下还原不同时间的含锌粉尘团块进行物相分析,如图6所示。

从图6和表6可以看出:当还原脱锌1 min时,有少量金属Fe生成,团块内主要物相为FeO,C,ZnO,Fe和脉石成分。

图6 不同还原时间脱锌产物的XRD谱

Fig. 6 XRD patterns of dezincification products of different reduction time

表6 不同还原时间的脱锌产物物相组成

Table 6 Phase compositions of dezincification products of different reduction time

当还原脱锌3 min时,XRD图谱中金属Fe的衍射峰强显著增高,FeO的衍射峰强降低,而且几乎没有ZnO特征衍射峰,说明在1 200 ℃时ZnO的还原速度非常快。这是因为锌的沸点仅为908 ℃,在1 200 ℃时,还原出的单质Zn以气态形式存在。在高纯氩气(4 L/min)保护下,团块内气态锌的分压非常低,有利于提高ZnO还原的动力学条件。

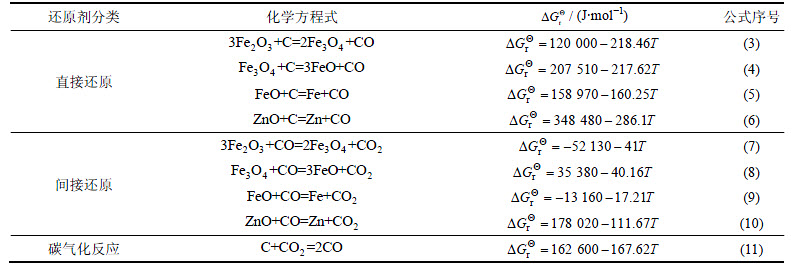

当还原脱锌达到6 min时,金属Fe峰成为主相,此时脱锌过程基本结束。FeO在高温下会与CaO和SiO2形成钙铁辉石,阻碍了FeO的还原,因而6 min中仍有微量未反应的FeO。XRD图谱中没有检测到C的衍射峰。而随着反应进行,焦粒不可能与粉尘颗粒一直保持良好接触而仅通过直接还原将焦粉消耗殆尽,这就意味着还原过程有间接还原作用。根据二步还原理论[19-20],实验条件下氧化物的还原过程中的直接还原(表7中方程式(3)~(6))起到间接还原(表7中方程式(7)~(10))的启动作用,直接还原产生的气体产物CO继续还原氧化物,反应产物CO2通过与碳的熔损反应(表7中方程式(11))不断地提供气体还原剂CO,不断推进还原反应进行,直至焦粉消耗完毕。

表7 脱锌过程化学反应方程式

Table 7 Chemical equations occurred in dezincification

3 结论

1) 通过脱锌正交实验得到影响团块脱锌的主要因素是温度,温度提高能大幅度地提高团块的脱锌率。最佳工艺条件如下:温度为1 200 ℃,碳氧物质的量比为1.0,水分质量分数为10%,碱度为2.0,CO2体积分数为65%。在此最佳工艺条件下,团块脱锌率达到82.66%。

2) 在1 050 ℃时,Fe单质要先于Zn单质被还原出来。随着温度升高,ZnO的还原逐渐变得易于进行;当温度达到1 200 ℃时,Zn单质几乎和Fe单质同时被还原出来。因此,温度升高有利于脱锌反应进行。

3) 在1 200 ℃时脱锌过程非常快,6 min时则脱锌过程基本结束。脱锌过程遵循二步还原理论,由直接还原和间接还原组成。团块内较低的Zn蒸气分压使得脱锌反应动力学条件良好,有利于锌的脱除。

参考文献:

[1] XIA Leige, MAO Rui, ZHANG Jianliang, et al. Reduction process and zinc removal from composite briquettes composed of dust and sludge from a steel enterprise[J]. International Journal of Minerals Metallurgy and Materials, 2015(2): 122-131.

[2] 刘洋, 张延玲, 郭文明, 等. Fe-Cr-Ni-O体系碳还原产物热力学计算及实验分析[J]. 中南大学学报(自然科学版), 2015, 46(6): 1989-1998.

LIU Yang, ZHANG Yanling, GUO Wenming, et al. Thermodynamic calculation and experimental analysis of the carbothermal reduction products of Fe-Cr-Ni-O system[J]. Journal of Central South University (Science and Technology), 2015, 46(6): 1989-1998.

[3]  T, E SOUZA B V, BERNARDES A M, et al. Hydrometallurgical processing of carbon steel EAF dust[J]. Journal of Hazardous Materials, 2006, 135(1): 311-318.

T, E SOUZA B V, BERNARDES A M, et al. Hydrometallurgical processing of carbon steel EAF dust[J]. Journal of Hazardous Materials, 2006, 135(1): 311-318.

[4] 佘雪峰, 薛庆国, 董杰吉, 等. 钢铁厂典型粉尘的基本物性与利用途径分析[J]. 过程工程学报, 2009, 9(S1): 7-12.

SHE Xuefeng, XUE Qingguo, DONG Jieji, et al. Study on basic properties of typical industrial dust from iron and steel plant and analysis of its utilization[J]. The Chinese Journal of Process Engineering, 2009, 9(S1): 7-12.

[5] 丁银贵, 王静松, 曾晖, 等. 转炉尘泥含碳球团还原动力学研究[J]. 过程工程学报, 2010, 10(S1): 73-77.

DING Yingui, WANG Jingsong, ZEN Hui, et al. Research on reduction kinetics of caron-cearing pellets of BOF dust and sludge[J]. The Chinese Journal of Process Engineering, 2010, 10(S1): 73-77.

[6] SHAWABKEH R A. Hydrometallurgical extraction of zinc from Jordanian electric arc furnace dust[J]. Hydrometallurgy, 2010, 104(1): 61-65.

[7] 党要均. 高炉粉尘还原脱锌实验研究[D]. 西安: 西安建筑科技大学冶金工程学院, 2014: 13-15.

DANG Yaojun. The experimental study of reduction dezincification on blast furnace dust[D]. Xi’an: Xi’an University of Architecture and Technology. School of Metallurgical Engineering, 2014: 13-15.

[8] 周云, 彭开玉, 李辽沙, 等. 电炉含锌粉尘在微波场下脱锌的试验研究[J]. 金属矿山, 2006(2): 82-84.

ZHOU Yun, PENG Kaiyu, LI Liaosha, et al. Experimental research of zinc removal from dust of EAF in microwave field[J]. Metal Mine, 2006(2): 82-84.

[9] 张建良, 闫永芳, 徐萌, 等. 高炉含锌粉尘的脱锌处理[J]. 钢铁, 2006, 41(10): 78-81.

ZHANG Jianliang, YAN Yongfang, XU Meng, et al. Research on removal of Zn from blast furnace dust[J]. Iron and Steel, 2006, 41(10): 78-81.

[10] 高金涛, 李士琦, 张延玲, 等. 高炉粉尘Fe和Zn非熔态分离工艺[J]. 北京科技大学学报, 2012, 34(11): 1268-1274.

GAO Jintao, LI Shiqi, ZHANG Yanling, et al. Separation technology of Fe and Zn from blast furnace dust at non-molten state[J]. Journal of University of Science and Technology Beijing, 2012, 34(11): 1268-1274.

[11] 胡晓军, 刘俊宝,郭培民, 等. 铁酸锌气体还原的热力学分析[J]. 工程科学学报, 2015, 37(4): 429-435.

HU Xiaojun, LIU Junbao, GUO Peimin, et al. Thermodynamic analysis of the reduction of zinc ferrite with CO-CO2[J]. Chinese Journal of Engineering, 2015, 37(4): 429-435.

[12] WU C C, CHANG F C, CHEN W S, et al. Reduction behavior of zinc ferrite in EAF-dust recycling with CO gas as a reducing agent[J]. Journal of Environmental Management, 2014, 143: 208-213.

[13] SHE Xuefeng, WANG Jingsong, WANG Guang, et al. Removal mechanism of Zn, Pb and alkalis from metallurgical dusts in direct reduction process[J]. Journal of Iron and Steel Research (International), 2014(5): 488-495.

[14] 巨建涛, 党要均, 赵忠宇. 高炉粉尘和转炉尘泥的还原脱锌试验[J]. 钢铁钒钛, 2013(4): 36-40, 46.

JU Jiantao, DANG Yaojun, ZHAO Zhongyu. Experimental study on using BF dust and converter sludge for reduction of dezincification[J]. Iron Steel Vandium Titanium, 2013(4): 36-40, 46.

[15] 王强, 龙世刚, 占莉. 含锌粉尘脱锌处理的实验室研究[J]. 安徽工业大学学报(自然科学版), 2007, 24(4): 351-353.

WANG Qiang, LONG Shigang, ZHAN Li. Study on dezincification of dust contained zinc in lab[J]. Journal of Anhui University of Technology (Science and Technology), 2007, 24(4): 351-353.

[16] 秦明达. 统计与优化[M]. 北京: 冶金工业出版社, 1998: 101-105.

QIN Mingda. Statistical and optimization[M]. Beijing: Metallurgical Industry Press, 1998: 101-105.

[17] 魏效玲, 薛冰军, 赵强. 基于正交试验设计的多指标优化方法研究[J]. 河北工程大学学报(自然科学版), 2010, 27(3): 95-99.

WEI Xiaoling, XUE Bingjun, ZHAO Qiang. Optimization design of the stability for the plunger assembly of oil pumps based on multi-target orthogonal test design[J]. Journal of Hebei University of Engineering (Natural Science Edition), 2010, 27(3): 95-99.

[18] 彭兵, 张传福, 彭及, 等. 不锈钢冶炼粉尘中锌还原的研究[J]. 中南工业大学学报(自然科学版), 2002, 33(3): 242-246.

PENG Bing, ZHANG Chuanfu, PENG Ji, et al. Reduction of zinc oxide in EAF dust by carbon monoxide[J]. Journal of Central South University of Technology (Natural Science), 2002, 33(3): 242-246.

[19] 安秀伟, 王静松, 佘雪峰, 等. 含锌粉尘内配碳球团还原模型[J]. 北京科技大学学报, 2013, 35(2): 155-160.

AN Xiuwei, WANG Jingsong, SHE Xuefeng, et al. Reduction model of carbon-containing pellets made of zinc-bearing dust[J] Journal of University of Science and Technology Beijing, 2013, 35(2): 155-160.

[20] LIU Ying, SU Fuyong, WEN Zhi, et al. Mathematical simulation of direct reduction process in zinc-bearing pellets[J]. International Journal of Minerals Metallurgy and Materials, 2013, 11: 1042-1049.

(编辑 杨幼平)

收稿日期:2016-07-28;修回日期:2016-09-15

基金项目(Foundation item):国家自然科学基金资助项目(U1260202) (Project(U1260202) supported by the National Natural Science Foundation of China)

通信作者:张建良,教授,博士生导师,从事炼铁新技术研究;E-mail: zhang.jianliang@hotmail.com