DOI: 10.11817/j.ysxb.1004.0609.2021-39699

高速冲击载荷下预变形AZ31镁合金的流变行为及本构模型

刘 筱1,杨 辉1,朱必武2,胡铭月1,唐昌平1,刘文辉1

(1. 湖南科技大学 材料科学与工程学院,湘潭 411201;

2. 湖南科技大学 机电工程学院,湘潭 411201)

摘 要:为了研究高速冲击载荷下预变形AZ31镁合金的高温流变行为和组织演变过程以及构建能够准确预测高温流变行为的本构模型,采用霍普金森压杆技术,对预变形AZ31镁合金进行应变速率分别为2150 s-1、3430 s-1、4160 s-1,变形温度分别为150 ℃、200 ℃、250 ℃、300 ℃、350 ℃的高温冲击试验。结果表明:在相同应变速率下某些温度区间内,由于孪晶强化、细晶强化和升温软化三者共同作用,流变应力出现随温度升高下降幅度不明显的现象;随着变形温度的升高,其组织呈现交叉孪晶、变形剪切带、转变剪切带、完全再结晶的转变;引入孪晶强化项修正Johnson-Cook本构模型,修正后的Johnson-Cook本构模型可以准确地预测出孪晶对流变行为的影响,同时通过计算得到相关系数(R)为0.9744,平均相对误差(E)为4.51%,表明所修正的模型能够较好地描述预变形AZ31镁合金的高温流变行为。

关键词:AZ31镁合金;高速冲击;孪晶;流变行为;Johnson-Cook本构模型

文章编号:1004-0609(2021)-03-0659-10 中图分类号:TG146.22 文献标志码:A

引文格式:刘 筱, 杨 辉, 朱必武, 等. 高速冲击载荷下预变形AZ31镁合金的流变行为及本构模型[J]. 中国有色金属学报, 2021, 31(3): 659-668. DOI: 10.11817/j.ysxb.1004.0609.2021-39699

LIU Xiao, YANG Hui, ZHU Bi-wu, et al. Flow behavior and constitutive model for pre-deformed AZ31 magnesium alloy under high-speed impact loading[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 659-668. DOI: 10.11817/j.ysxb.1004.0609.2021-39699

镁合金作为最轻的金属结构材料,因其高比强度、高比刚度等特点,广泛应用于武器、航空航天及交通运输等领域[1-5]。而镁合金的低屈服强度阻碍了其在武器、航空航天及交通运输等领域的应 用[6-10],因此,提高镁合金的屈服强度具有重要意义,镁合金中引入孪晶是实现合金屈服强度提升的一种常用方式。同时镁合金应用在这些领域内不可避免的要承受高速冲击载荷[11-15]。随着镁合金广泛应用在苛刻的工作环境,如何提高镁合金抗冲击性能受到学者的广泛关注,同时对镁合金在冲击载荷下力学本构的研究也越发重视。

通过预变形引入孪晶,可有效提高镁合金强度。ZHANG等[16]采用室温横向(TD)预压的方法,在AZ31镁合金热轧板中引入了拉伸孪晶,发现引入的拉伸孪晶显著提高了AZ31镁合金板材的屈服强度。李祎等[17]采用室温压缩预变形引入孪晶,发现预变形试样的强度比无预变形试样的强度略有提升,且塑性提升明显。XIN等[18]对AZ31镁合金沿轧制方向进行室温预压缩引入拉伸孪晶,有效地增强了预变形样品的屈服强度和抗拉强度。

Johnson-Cook本构模型简称J-C本构模型,形式上简单并且包含了应变率和温度效应的影响,可以很好地预测金属材料的应力响应[19]。徐绍勇等[20]研究了应变速率对挤压变形AZ31镁合金力学行为的影响,建立了J-C本构模型,其拟合结果和实验结果基本相吻合。刘筱等[21]研究了高速冲击载荷下LZ91镁合金的动态变形行为并构建了相应的力学本构,所建立的J-C本构模型能够很好的预测冲击载荷下的流变应力。

目前,大部分学者都着重于研究预变形对静态压缩的影响,对预变形镁合金在高速冲击载荷下的研究还相对较少。本文作者对预变形AZ31镁合金在不同应变速率和不同温度下进行高速冲击试验,研究了高速冲击载荷下预变形AZ31镁合金的变形行为及力学性能;且引入孪晶强化项建立一个适用于预变形镁合金在冲击载荷下的本构模型。

1 实验

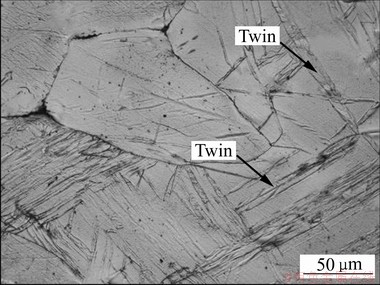

本实验采用10 mm厚商用AZ31镁合金连铸板坯,其主要成分为3.19%Al、0.81%Zn、0.33%Mn,其余为Mg(质量分数)。采用到温入炉的方式,将镁合金板坯放至420 ℃的电阻炉中固溶处理12 h,然后取出水冷。将固溶处理后的镁合金板坯加工成123 mm×50 mm×10 mm的轧制坯料,在d 200 mm×d 200 mm的轧机上对AZ31镁合金进行预变形,变形工艺为:预变形温度300 ℃,保温15 min,轧辊转速20 r/min、变形量为10%。其预变形后的组织如图1所示。最后,将预变形后的镁合金沿着法向(ND)方向切割圆柱压缩试样,高速冲击的压缩尺寸为d 8 mm×4 mm。

高速冲击实验采用分离式霍普金森压杆(Split Hopkinson pressure bar, SHPB),加载应变速率分别为2150 s-1、3430 s-1、4160 s-1,变形温度分别为150 ℃、200 ℃、250 ℃、300 ℃、350 ℃。为了避免误差,每次冲击实验进行了2~3次。冲击实验后,沿着圆柱面中心切取样品进行金相观察。

图1 预变形后AZ31镁合金的组织

Fig. 1 Microstructure of AZ31 magnesium alloy after pre-deformation

2 结果与讨论

2.1 流变行为

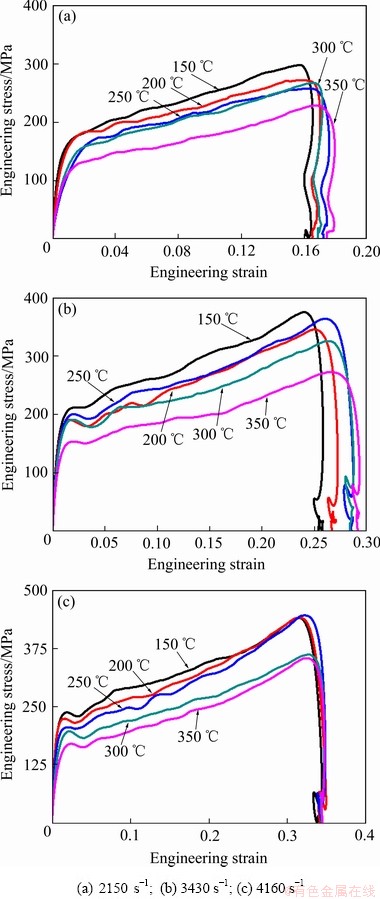

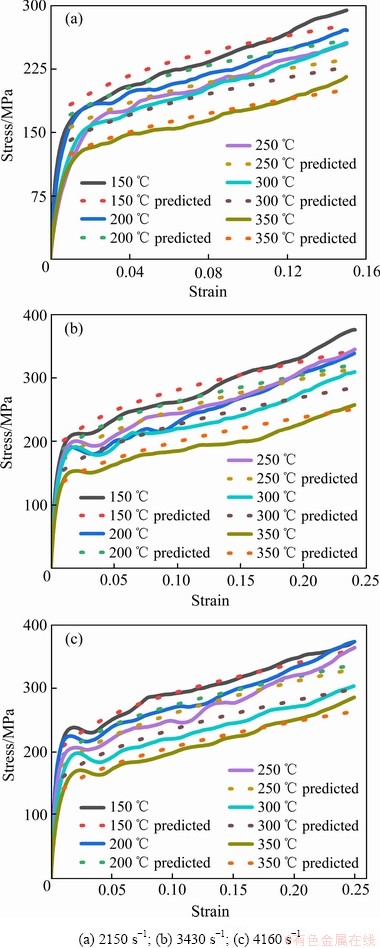

图2 不同变形条件下预变形AZ31镁合金的流变应力

Fig. 2 Flow stresses of pre-deformed AZ31 magnesium alloy under different deformation conditions

图2所示为高速冲击载荷下预变形AZ31镁合金的流变应力。由图2可知,在相同应变速率下,随着温度的升高,由于晶间黏性流动作用随变形温度的增加而增加,同时高温也增强了动态再结晶的软化作用,使得变形过程发生了更多的位错滑移,降低了材料变形抗力[22],所以在整体上流变应力呈现逐渐降低的趋势。但是,应变速率为2150 s-1、温度为250 ℃和300 ℃时,以及应变速率为3430 s-1、温度为200 ℃和250 ℃时,流变应力下降幅度不明显;应变速率为4160 s-1、温度为150 ℃、200 ℃和250 ℃时也存在同样的情况。

2.2 微观组织

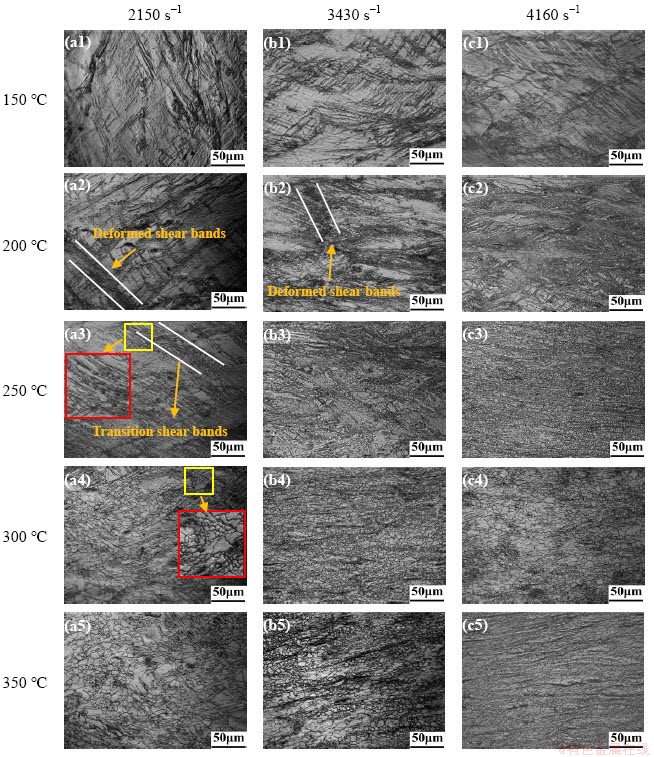

图3所示为预变形AZ31镁合金在不同应变速率、不同温度下的微观组织。由图3(a1)~(a5)可知,在应变速率为2150 s-1、变形温度为150 ℃时,组织中存在大量相互交错的孪晶;当变形温度升高到200 ℃时,可以看到大量孪晶聚集,形成变形剪切带(见图3(a2)中白色平行线);当变形温度升高到250 ℃时,除了存在孪晶外,在组织中也观察到了剪切带(见图3(a3)中白色平行线),通过观察剪切带内部组织(见图3(a3)中黄色框),发现剪切带内部有细小的动态再结晶晶粒(见图3(a3)中红色框),这种现象叫做转变剪切带[23];当变形温度为300 ℃时,组织出现大量的动态再结晶晶粒(见图3(a4)中红色框),只存在少部分孪晶;当变形温度为350 ℃时,观察到组织中已经全部发生动态再结晶。

图3 预变形AZ31镁合金在不同应变速率、不同温度下变形的微观组织

Fig. 3 Microstructures of pre-deformed AZ31 magnesium alloy deformed at different strain rates and different temperatures

图3(b1)~(b5)、图3(c1)~(c5)所示分别为应变速率为3430 s-1和4160 s-1时不同温度下变形后的微观组织。在较低变形温度下,组织以大量的交叉孪晶为主,随着变形温度的升高,组织中出现变形剪切带,当变形温度再升高时开始发生动态再结晶,直到完全再结晶。此外,应变速率为2150 s-1时,变形温度达到250 ℃才出现极少量的动态再结晶(见图3(a3));当应变速率为3430 s-1时,变形温度达到250 ℃已经出现了大量的再结晶(见图3(b3));而应变速率为4160 s-1、温度为200 ℃时,已经出现了大量的再结晶(见图3(c2))。因此,应变速率的增加降低了动态再结晶的临界温度。

材料的强度不仅与晶粒尺寸减少引起的强化有关,而且研究表明孪晶的存在也具有强化作用[16, 24]。ZHANG等[16]发现拉伸孪晶提高了AZ31镁合金板材的屈服强度。XIN等[18]研究发现AZ31镁合金中拉伸孪晶有效地增强了合金的屈服强度和抗拉强度。在本实验中应变速率为2150 s-1、温度为250 ℃时微观组织为孪晶,此时孪晶强化占主导地位,而温度升高到300 ℃时微观组织以再结晶晶粒为主,细晶强化作用弥补了由于温度升高带来的软化作用,同时孪晶数量急剧减低,细晶强化作用大于孪晶强化。因此,孪晶强化、细晶强化和温升软化相互竞争作用,导致图2(a)中当温度从250 ℃升高到300 ℃时,流变应力下降幅度不明显。同样,在应变速率为3430 s-1、温度为200 ℃和250 ℃时,组织从以孪晶为主转变为以再结晶为主。由于组织转变导致的孪晶强化和细晶强化、以及温升软化三者共同作用,最终导致图2(b)中200 ℃和250 ℃时的流变应力下降幅度不明显。同样的现象也发生在应变速率为4160 s-1、温度为150 ℃、200 ℃和250 ℃时。可见,孪生、再结晶等微结构的形成会影响动态力学行为。

同时动态变化的应力实际上是位错密度分布情况的综合反应,而位错密度的分布会决定局部应力应变的分布,局部应力应变为晶粒内部和边界、孪晶内部和边界的再结晶形核提供所需能量,从而影响组织演变。综上所述,孪生和再结晶等微结构的形成与动态力学行为之间存在交互作用。

3 本构模型的建立

Johnson-Cook(J-C)本构模型是一个经验模型,可以对金属材料的流变应力进行很好的预测,该模型考虑了应变硬化、应变率敏感性和热软化作为耦合形式。J-C本构模型的一般形式如下所示:

(1)

(1)

式中: 为应力;

为应力; 为应变;A为在参考温度和参考应变速率下的屈服应力;B是应变硬化系数;n为应变硬化指数;C和m分别为应变速率硬化系数和温度软化指数;

为应变;A为在参考温度和参考应变速率下的屈服应力;B是应变硬化系数;n为应变硬化指数;C和m分别为应变速率硬化系数和温度软化指数; 和

和 分别为无量纲应变速率和变形温度;

分别为无量纲应变速率和变形温度; 和T分别为应变速率和变形温度;

和T分别为应变速率和变形温度; 和T0分别为参考应变速率和参考变形温度;Tm为材料熔点。

和T0分别为参考应变速率和参考变形温度;Tm为材料熔点。

原始J-C本构模型只考虑了应变硬化,应变率敏感性和热软化,没有考虑孪晶的作用;因为在材料的变形过程中,孪生边界对位错运动有很强的阻碍作用也会提高材料的强度[24],所以基于原始J-C本构模型,充分考虑了AZ31镁合金孪晶强化的特征,引入孪晶强化项。

PROUS等[25]用式(2)来描述孪生的强化作用:

(2)

(2)

式中: 和

和 表示孪晶的临界剪切应力和初始临界剪切应力;

表示孪晶的临界剪切应力和初始临界剪切应力; 和

和 表示各种变形模式(M)的临界剪切应力和硬化率,结合其论文中的数据,可以得到孪晶强化的应力(

表示各种变形模式(M)的临界剪切应力和硬化率,结合其论文中的数据,可以得到孪晶强化的应力( )为

)为

(3)

(3)

综上所述可知,为了预测孪晶对流变应力的影响,提出如下修正的J-C模型:

(4)

(4)

本文中参数的求解通过拟合求得[26],且参考应变速率和参考温度的选取要适当[27-28],所以在本研究中,取参考应变速率为4160 s-1,参考温度为150 ℃。在该条件下,屈服应力(A)为160.55 MPa,AZ31镁合金的熔点为650 ℃[29]。

3.1 参数n、B的求解

在参考温度和参考应变速率下,修正的J-C本构模型可以简化成:

(5)

(5)

把两个等式通过移项,再两边取对数,得到

(6)

(6)

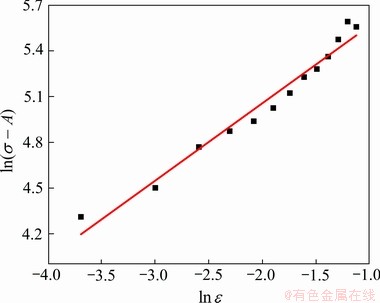

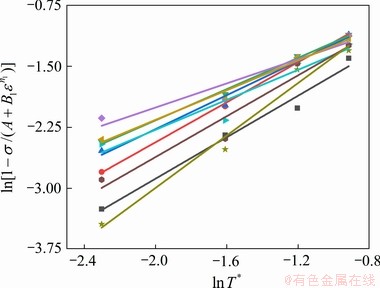

通过 和

和 拟合线的斜率可以确定n1、n2,根据其截距可以确定B1、B2。拟合的数据是从参考应变速率和参考温度的应力应变曲线上均匀选取,其拟合结果如图4和5所示。由此可以确定n1为0.509,n2为1.159,B1为434.971 MPa,B2为476.492 MPa。

拟合线的斜率可以确定n1、n2,根据其截距可以确定B1、B2。拟合的数据是从参考应变速率和参考温度的应力应变曲线上均匀选取,其拟合结果如图4和5所示。由此可以确定n1为0.509,n2为1.159,B1为434.971 MPa,B2为476.492 MPa。

3.2 参数C的求解

在参考温度(150 ℃)下,式(4)可以简化为

(7)

(7)

通过移项,式(7)可以转换成:

(8)

(8)

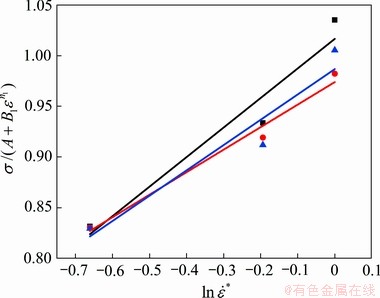

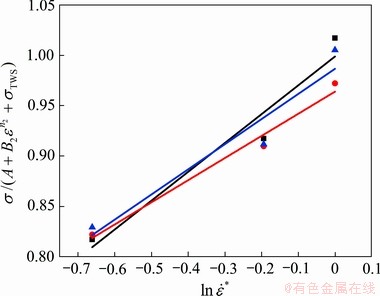

图6所示为 与

与 关系图。由此可以确定C1为0.190,

关系图。由此可以确定C1为0.190, 的拟合线如图7所示。通过拟合线的斜率可以确定C2值为0.190。

的拟合线如图7所示。通过拟合线的斜率可以确定C2值为0.190。

图4  与

与 关系图

关系图

Fig. 4 Relationship curve between  and

and

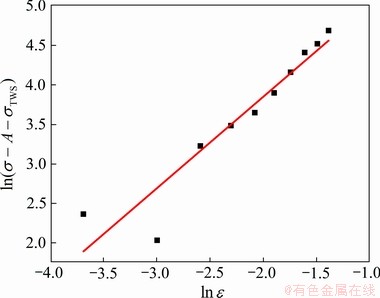

图5  与

与 关系图

关系图

Fig. 5 Relationship curve between  and

and

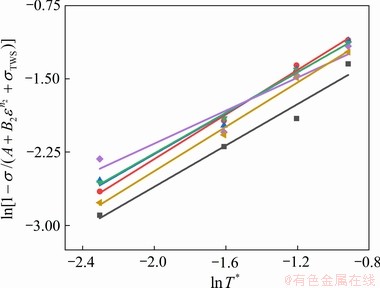

3.3 参数m的求解

在参考应变速率(4160 s-1)下,式(4)可以简化为

(9)

(9)

式(9)通过变形,可以得到:

(10)

(10)

通过 拟合线的斜率可以确定m1值,拟合结果如图8所示,可以确定m1值为1.322。图9所示为

拟合线的斜率可以确定m1值,拟合结果如图8所示,可以确定m1值为1.322。图9所示为 与

与 关系图,由此可以确定m2为1.191。

关系图,由此可以确定m2为1.191。

图6  与

与 关系图

关系图

Fig. 6 Relationship curves between  and

and

图7  与

与 关系图

关系图

Fig. 7 Relationship curves between  and

and

最终,修正的J-C本构模型如下:

(11)

(11)

图8

和

和 的关系图

的关系图

Fig. 8 Relationship between  and

and

图9  与

与 关系图

关系图

Fig. 9 Relationship between  and

and

3.4 模型精度评价

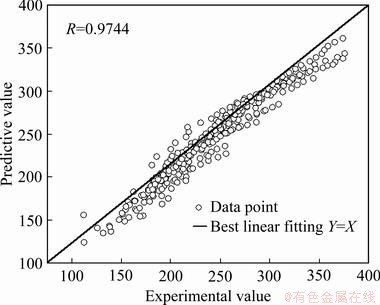

修正的J-C本构模型获得的流变应力预测值与实验值的对比如图10所示,发现预测结果与实验结果吻合良好,并且也能较好地预测出孪晶对流变应力的影响。

为了进一步评价修正后的J-C本构模型的流变应力预测能力,预测精度可以由相关系数(R)和平均相对误差(E)来衡量;R值表示预测值和实验值之间的线性相关性,平均相对误差是衡量数学模型准确性的常用参数[30]:

(12)

(12)

(13)

(13)

式中: 为预测的流变应力;

为预测的流变应力; 为实测的流变应力;

为实测的流变应力; 为预测的流变应力的平均值;

为预测的流变应力的平均值; 为实测的流变应力的平均值;N为数据点的总数。

为实测的流变应力的平均值;N为数据点的总数。

图10 采用修正J-C模型的预测值与实验值对比图

Fig. 10 Comparison chart of predicted and experimental values using modified J-C model

在3个应变速率、5个温度下,均匀地在实验值和修正后的本构模型预测值中各选取了320个应变对应的屈服强度进行计算。

通过计算获得修正J-C本构模型的相关系数(R)为0.9744(如图11所示)这表明本文考虑孪晶强化修正的J-C本构模型预测精度较好。同时计算出修正后的J-C本构模型的平均相对误差(E)为4.51%,进一步证实了本文修正的J-C本构模型具有良好的预测能力。因此,该模型可以用来预测预变形AZ31镁合金在高温高速冲击过程中的流变行为。

图11 本构模型预测值与实验值的相关性

Fig. 11 Correlation between predicted value and experimental value of constitutive model

4 结论

1) 预变形AZ31镁合金在应变速率为2150 s-1、3430 s-1、4160 s-1变形时,因为存在孪晶强化、细晶强化和升温软化三者相互竞争,导致流变应力随温度的升高出现下降幅度不明显的现象。

2) 预变形AZ31镁合金在高速冲击载荷下,变形温度较低时,其组织以交叉孪晶为主,随着变形温度的升高,其组织呈现由交叉孪晶向变形剪切带、转变剪切带、完全再结晶的转变。

3) 修正的Johnson-Cook本构模型如下:

该模型能够较好地预测流变应力,同时也能预测出孪晶对流变应力的影响,修正后的Johnson-Cook本构模型的相关系数为0.9744,平均相对误差仅为4.75%。

REFERENCES

[1] 毛萍莉, 刘 正, 王长义, 等. 镁合金高速冲击载荷下的变形行为研究进展[J]. 材料导报, 2012, 26(7): 95-101.

MAO Ping-li, LIU Zheng, WANG Chang-yi, et al. Review of the dynamic deformation behavior of magnesium alloys under high strain rates[J]. Materials Reports, 2012, 26(7): 95-101.

[2] LIU X, WANG Y Y, ZHU B W, et al. Effect of microstructures and textures on the anisotropy of mechanical properties of AZ31 magnesium alloy sheets subjected to high strain rate rolling[J]. Materials Research Express, 2019, 6(10): 106591.

[3] ZHU B W, LIU X, XIE C, et al. Unveiling the underlying mechanism of forming edge cracks upon high strain-rate rolling of magnesium alloy[J]. Journal of Materials Science and Technology, 2020, 50: 59-65.

[4] 李旭东, 毛萍莉, 刘晏宇, 等. 高应变速率下Mg-3Zn-1Y镁合金的各向异性及变形机制[J]. 金属学报, 2018, 54(4): 557-565.

LI Xu-dong, MAO Ping-li, LIU Yan-yu, et al. Anisotropy and deformation mechanisms of as-extruded Mg-3Zn-1Y magnesium alloy under high strain rates[J]. Acta Metallurgica Sinica, 2018, 54(4): 557-565.

[5] 穆 桐, 石国梁, 张 奎, 等. T6态ZM51变形镁合金的高周疲劳行为[J]. 中国有色金属学报, 2020, 30(8): 1770-1780.

MU Tong, SHI Guo-liang, ZHANG Kui, et al. High cycle fatigue behavior of T6-treated ZM51 alloy extrusion[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(8): 1770-1780.

[6] 丁文江, 付彭怀, 彭立明, 等. 先进镁合金材料及其在航空航天领域中的应用[J]. 航天器环境工程, 2011, 28(2): 103-109.

DING Wen-jiang, FU Peng-huai, PENG Li-ming, et al. Advanced magnesium alloys and their applications in aerospace[J]. Spacecraft Environment Engineering, 2011, 28(2): 103-109.

[7] 蒋 斌, 刘文君, 肖 旅, 等. 航空航天用镁合金的研究进展[J]. 上海航天, 2019, 36(2): 22-30.

JIANG Bin, LIU Wen-jun, XIAO Lü, et al. Development of magnesium alloys for aerospace application[J]. Aerospace Shanghai, 2019, 36(2): 22-30.

[8] 付丽丽, 邱克强, 任英磊, 等. 长周期结构增强镁合金的研究进展[J]. 材料导报, 2016, 30(17): 152-157.

FU Li-li, QIU Ke-qiang, REN Ying-lei, et al. Research progress of long period stacking ordered structure reinforced mg alloys[J]. Materials Reports, 2016, 30(17): 152-157.

[9] 汝金明. 基于剧烈变形的高强度镁合金(AZ31)制备技术与性能[D]. 镇江: 江苏大学, 2009.

RU Jin-ming. Preparation and properties of magnesium alloy (AZ31) based on severe plastic deformation[D]. Zhenjiang: Jiangsu University, 2009.

[10] 张 真. AZ31B镁合金塑性变形行为的相关基础研究[D]. 长沙: 中南大学, 2011.

ZHANG Zhen. Basic research on the plastic deformation behavior of AZ31B mg alloy[D]. Changsha: Central South University, 2011.

[11] GUO P C, LI L X, LIU X, et al. Compressive deformation behavior and microstructure evolution of AM80 magnesium alloy under quasi-static and dynamic loading[J]. International Journal of Impact Engineering, 2017, 109: 112-120.

[12] FENG F, HUANG S Y, MENG Z H, et al. Experimental study on tensile property of AZ31B magnesium alloy at different high strain rates and temperatures[J]. Materials and Design, 2014, 57: 10-20.

[13] 谢奇峻. AZ31B镁合金冲击动态力学行为的实验和本构模型研究[D]. 成都: 西南交通大学, 2018.

XIE Qi-jun. Experimental and constitutive model study on impact dynamic mechanical behavior of AZ31B magnesium alloy[D]. Chengdu: Southwest Jiaotong University, 2018.

[14] 王长义, 刘 正, 毛萍莉. AZ31B镁合金动态力学行为及变形机制[J]. 沈阳工业大学学报, 2012, 34(5): 509-514.

WANG Chang-yi, LIU Zheng, MAO Ping-li. Dynamic mechanical behavior and deformation mechanism of AZ31B magnesium alloy[J]. Journal of Shenyang University of Technology, 2012, 34(5): 509-514.

[15] 王瑞峰. 预制孪晶对AZ31镁合金板材高速变形行为的影响[D]. 沈阳: 沈阳工业大学, 2019.

WANG Rui-feng. Influence of pre-twinning on high strain rate deformation behavior of AZ31 mg-alloys sheet[D]. Shenyang: Shenyang University of Technology, 2019.

[16] ZHANG H, BAI X Q, HOU M J, et al. Enhancing compressive mechanical properties of rolled AZ31 Mg alloy plates by pre-compression[J]. Materials Science and Engineering A, 2020, 772: 138686.

[17] 李 祎, 蒋莉萍, 肖振宇. 预变形对AZ80镁合金组织与力学性能的影响[J]. 铝加工, 2016(6): 12-16.

LI Wei, JIANG Li-ping, XIAO Zhen-yu. Effect of pre-deformation on microstructures and mechanical properties of AZ80 magnesium alloys[J]. Aluminium Fabrication, 2016(6): 12-16.

[18] XIN Y C, WANG M Y, ZENG Z, et al. Strengthening and toughening of magnesium alloy by {10-12} extension twins[J]. Scripta Materialia, 2012, 66(1): 25-28.

[19] 郭鹏程, 曹淑芬, 叶 拓, 等. 高速冲击载荷下AM80镁合金的力学本构及仿真模拟[J]. 中国有色金属学报, 2017, 27(6): 1075-1082.

GUO Peng-cheng, CAO Shu-fen, YE Tuo, et al. Mechanical constitutive equation and simulation of AM80 magnesium alloy under high speed impact load[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1075-1082.

[20] 徐绍勇, 龙思远, 廖慧敏, 等. 应变速率对AZ31挤压变形镁合金力学行为的影响[J]. 材料热处理学报, 2010, 31(5): 44-48.

XU Shao-yong, LONG Si-yuan, LIAO Hui-min, et al. Influence of strain-rate on mechanical behavior of as-extruded AZ31 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2010, 31(5): 44-48.

[21] 刘 筱, 易宏翔, 朱必武, 等. 高速冲击载荷下LZ91镁合金的动态变形行为及力学本构[J]. 稀有金属材料与工程, 2019, 48(7): 2171-2178.

LIU Xiao, YI Hong-xiang, ZHU Bi-wu, et al. Dynamic deformation behavior and mechanical constitutive of LZ91 magnesium alloy under high speed impacting[J]. Rare Metal Materials and Engineering, 2019, 48(7): 2171-2178.

[22] 陈幼筠, 陈忠家, 王雪英, 等. ZK60镁合金的热变形流变行为与本构方程[J]. 金属功能材料, 2017, 24(1): 25-31.

CHEN You-yun, CHEN Zhong-jia, WANG Xue-ying, et al. Flow behavior and constitutive equations of ZK60 magnesium alloy during isothermal compression[J]. Metallic Functional Materials, 2017, 24(1): 25-31.

[23] ZHEN L, ZOU D L, XU C Y, et al. Microstructure evolution of adiabatic shear bands in AM60B magnesium alloy under ballistic impact[J]. Materials Science and Engineering A, 2010, 527(21/22): 5728-5733.

[24] 刘 筱, 朱必武, 吴远志, 等. 中高应变速率轧制AZ31镁合金的边裂、组织与性能[J]. 中国有色金属学报, 2019, 29(2): 232-240.

LIU Xiao, ZHU Bi-wu, WU Yuan-zhi, et al. Edge crack, microstructure and mechanical property of AZ31 magnesium alloy sheets rolled by medium-high strain rate[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(2): 232-240.

[25] PROUST G, TOME C N, JAIN A, et al. Modeling the effect of twinning and detwinning during strain-path changes of magnesium alloy AZ31[J]. International Journal of Plasticity, 2009, 25(5): 861-880.

[26] LIN Y C, CHEN X M, LIU G. A modified Johnson–Cook model for tensile behaviors of typical high-strength alloy steel[J]. Materials Science and Engineering A, 2010, 527(26): 6980-6986.

[27] LIN Y C, CHEN X M. A combined Johnson-Cook and Zerilli-Armstrong model for hot compressed typical high-strength alloy steel[J]. Computational Materials Science, 2010, 49(3): 628-633.

[28] ZHANG F, LIU Z, YANG M M, et al. Microscopic mechanism exploration and constitutive equation construction for compression characteristics of AZ31-TD magnesium alloy at high strain rate[J]. Materials Science and Engineering A, 2020, 771: 138571.

[29] 张 峰. AZ31镁合金动态压缩变形机制与数值模拟[D]. 沈阳: 沈阳工业大学, 2019.

ZHANG Feng. Dynamic compression deformation mechanism and numerical simulation of AZ31 magnesium alloy[D]. Shenyang: Shenyang University of Technology, 2019.

[30] TRIMBLE D, O'DONNELL G E. Flow stress prediction for hot deformation processing of 2024Al-T3 alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1232-1250.

Flow behavior and constitutive model for pre-deformed AZ31 magnesium alloy under high-speed impact loading

LIU Xiao1, YANG Hui1, ZHU Bi-wu2, HU Ming-yue1, TANG Chang-ping1, LIU Wen-hui1

(1. School of Materials Science and Engineering, Hunan University of Science and Technology, Xiangtan 411201, China;

2. School of Mechanical Engineering, Hunan University of Science and Technology, Xiangtan 411201, China)

Abstract: In order to investigate the high-temperature flow behavior and microstructure evolution of the pre-deformed AZ31 magnesium alloy under high-speed impact loading and establish a constitutive model to accurately predict the high-temperature flow behavior, high-temperature impact tests at deformation temperatures of 150 ℃, 200 ℃, 250 ℃, 300 ℃, and 350 ℃ with strain rates of 2150 s-1, 3430 s-1, and 4160 s-1 were carried out on the pre-deformed AZ31 magnesium alloys using the Hopkinson pressure bar technology. The results show that, under certain temperature range with the same strain rate, due to the effects of twin strengthening, fine grain strengthening and heating softening, the flow stresses do not obviously decrease with increasing the temperature. With the increase of deformation temperature, the microstructures transform from cross twinning, deformed shear bands, transition shear bands to complete recrystallization. The twinning strengthening is introduced to modify the Johnson-Cook constitutive model. The modified Johnson-Cook constitutive model can accurately predict the effect of twinning on the flow behavior. The correlation coefficient (R) is 0.9744 and the average relative error (AARE) is 4.51%, indicating that the modified Johnson-Cook constitutive model can well forecast the high-temperature flow behavior of the pre-deformed AZ31 magnesium alloy.

Key words: AZ31 magnesium alloy; high-speed impact; twinning; flow behavior; Johnson-Cook constitutive model

Foundation item: Projects(52071139, 51905166) supported by the National Natural Science Foundation of China; Project(2020JJ5198) supported by the Natural Science Foundation of Hunan Province, China; Project(18B198) supported by the Research Foundation of Education Bureau of Hunan Province, China

Received date: 2020-05-20; Accepted date: 2021-01-05

Corresponding author: LIU Xiao; Tel: +86-18674355539; E-mail: liuxiao0105@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(52071139,51905166);湖南省自然科学基金资助项目(2020JJ5198);湖南省教育厅优秀青年资助项目(18B198)

收稿日期:2020-05-20;修订日期:2021-01-05

通信作者:刘 筱,副教授,博士;电话:18674355539;E-mail:liuxiao0105@163.com