DOI: 10.11817/j.issn.1672-7207.2018.09.020

掘进工作面通风布置对粉尘分布规律的影响

周智勇1, 2, 3,胡培1,韩章程1,陈建宏1

(1. 中南大学 资源与安全工程学院,湖南 长沙,410083;

2. 中南大学 矿业工程博士后科研流动站,湖南 长沙,410083;

3. 湖南辰州矿业博士后协作研发中心,湖南 怀化,419607)

摘要:针对深部通风面临的粉尘污染问题,结合气固两相流理论,采用长压短抽-前压后抽式通风方式,建立掘进巷道混合式通风三维模型。以湖南辰州矿业沃溪坑口为研究对象,选取4种通风布置参数即压风口与掘进面之间的距离、抽风口与掘进面之间的距离、抽压风量比、风筒高度,每种参数设置3种模拟方案,利用Fluent软件对不同方案下巷道内的粉尘浓度进行模拟研究,通过分析比较不同布置参数下的排尘效果,得出该混合式通风布置参数的最优值。研究结果表明:当压风口与掘进面之间的距离 =10.0 m,抽风口与掘进面之间的距离

=10.0 m,抽风口与掘进面之间的距离 =35.0 m,抽压比K=1.5,双风筒高度H=1.5 m时,通风排尘效果最理想。

=35.0 m,抽压比K=1.5,双风筒高度H=1.5 m时,通风排尘效果最理想。

关键词:矿井通风;掘进巷道;数值模拟;粉尘

中图分类号:TD72 文献标志码:A 文章编号:1672-7207(2018)09-2264-08

Effect of heading face ventilation arrangement on regulation of dust distribution

ZHOU Zhiyong1, 2, 3, HU Pei1, HAN Zhangcheng1, CHEN Jianhong1

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. Center for Post-doctoral Studies of Mineral Engineering, Central South University, Changsha 410083, China;

3. Collaborative Research and Development Center for Postdoctor, Hunan Chenzhou Mining Group Co. Ltd., Huaihua 419607, China)

Abstract: Aiming at the problem of dust pollution in the deep ventilation, the theory of gas-solid two-phase flow and combined ventilation systems in excavation roadway were used, and the three-dimensional numerical model of hybrid ventilation was established. Taking Woxi pithead of Chenzhou Mining as the research object, Fluent software was used to study the optimized ventilation method. The four layout parameters, i.e. the distance between the pressure vent and the heading surface, the distance between the suction and the heading surface, the suction pressure ratio of air volume and the height of fan drum, were selected. The effect of exhaust dust of the ventilation method in different setting parameters was analyzed, and the optimal value of the ventilation layout parameter was obtained. The results show that when the distance between the pressure vents and the heading surface is 10.0 m, the distance between the suction and the heading surface is 35.0 m, the suction pressure ratio of air volume is 1.5 and the height of fan drum is 1.5 m, the effect of dust exhaust is the most ideal.

Key words: mine ventilation; excavation roadway; numerical simulation; dust

随着矿山地下开采深度的下延以及采掘机械化的普遍应用,井下生产面临的粉尘污染问题也越来越严峻[1]。对此,许多矿山采取了多种方法和手段来降低掘进巷道内爆破开凿产生的粉尘,主要包括采用混合式局部通风、加大掘进面供风量、大量延长掘进巷道通风降尘时间等。这些措施虽然在实际降尘应用中取得了一定效果,但由于缺乏对掘进巷道通风及粉尘运移规律的理论研究,导致通风成本显著提高,并且除尘效率较低。人们利用CFD(computational fluid dynamics)理论对矿井通风风流及粉尘运动规律进行了研究,取得了一定研究成果,如:蒋仲安等[2]在气固两相流的基础上,分析了掘进巷道的特征,利用DPM离散相模型对掘进巷道的风流进行模拟研究,得到了抽出式局部通风情况下巷道的粉尘运移规律;王海桥等[3-4]对独头巷道受限贴附射流特征参数进行了分析计算,得到了独头巷道受限贴附射流流场的一些规律;秦跃平等[5]针对掘进面煤尘含量高、通风除尘效果不理想的状况,利用数值模拟软件研究了长压短抽型局部通风方式在不同通风参数时的除尘效果;张朝波[6]采用正交实验设计和数值模拟这2种方法分别对备选的独头巷道通风布置方案进行了研究,最后将2种方法得到的优化方案进行了对比分析,优选出最佳方案;LEE[7]使用“空气年龄”的概念,研究了风筒直径和空间位置对掘进面通风除尘的影响。目前,人们对关于深部金属矿山混合式通风方案的多参数优化研究较少。为此,本文作者结合气固两相流理论,以湖南辰州矿业沃溪坑口为研究对象,利用计算流体软件Fluent对混合式通风的风流场以及不同通风布置参数下的除尘效果进行数值模拟,以期为金属矿山深部通风降尘提供参考。

1 粉尘扩散理论

井下掘进巷道的粉尘扩散是多种外界因素联合作用的结果。在初始条件下,爆破开凿生成的粉尘在机械力作用下脱离岩体获得初速度,运动至巷道中后在通风气流推动下开始沿风流方向运动,期间所受作用力主要包括流体的阻力、浮力以及自身重力[8-9]。为了便于理论分析,将粉尘沿掘进巷道的扩散简化为等强度源一维纵向扩散,从t= 0 s开始,在某处加入粉尘扩散质,扩散方程为[10-12]

(1)

(1)

式中:K为综合扩散系数;ρ为平均粉尘质量浓度,mg/m3;v为平均流速,m/s;t为扩散时间,s。

一般地,粒径大的粉尘沉降时间较短,而粒径小的粉尘将持续漂浮在巷道中,有赖于风流将其稀释排出。依据牛顿力学定律,可列出尘粒在空气中的运动方程为

(2)

(2)

式中:mp为粉尘质量,kg;v为尘粒与气体间的相对速度,m/s;t为时间,s;dP为尘粒的直径,m; 为尘粒密度,kg/m3;

为尘粒密度,kg/m3; 为气体密度,kg/m3;g为重力加速度,m/s2;Cp为阻力系数。

为气体密度,kg/m3;g为重力加速度,m/s2;Cp为阻力系数。

2 通风优化模型的建立

2.1 模型建立与网格划分

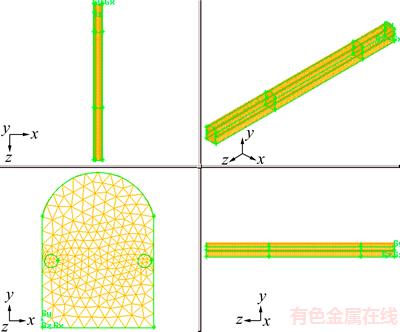

本文进行模拟计算的对象为湖南辰州沃溪坑口井下42中段西部某掘进巷道,巷道净断面形状为三心拱,面积为5.9 m2,宽为2.5 m,侧壁高为2.5 m,长为161.0 m。根据实际生产情况,高浓度粉尘主要分布于离掘进面约40.0 m的范围内,故计算模型的长度取为45.0 m。通风采用长压短抽(前压后抽)双风筒,双风筒直径均为300.0 mm。利用前处理器GAMBIT绘制巷道的立体模型并进行网格划分,网格的划分采用四面体非结构化网格,如图1所示。

图1 巷道非结构化网格划分

Fig. 1 Unstructured grid division of roadway

2.2 设定优化模拟方案

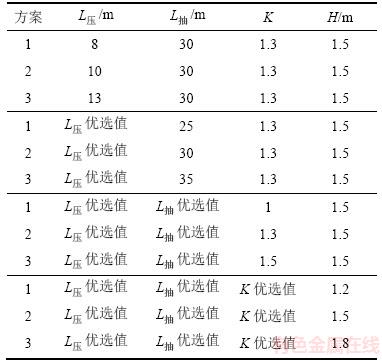

影响掘进巷道通风控尘效果的因素众多,本文针对沃溪坑口深部开采巷道的实际情况,并据文献[13-15],选取4项参数即压入风筒出口到迎头距离 、抽出风筒入口到迎头距离

、抽出风筒入口到迎头距离 、抽压比K、双风筒的高度H研究其对掘进面除尘效果的影响。通风参数优化模拟方案如表1所示,每项参数设计3个方案,对各参数依次进行模拟,并将上一个参数的最佳值作为下一个参数的模拟设定值,最终优选出所有参数。

、抽压比K、双风筒的高度H研究其对掘进面除尘效果的影响。通风参数优化模拟方案如表1所示,每项参数设计3个方案,对各参数依次进行模拟,并将上一个参数的最佳值作为下一个参数的模拟设定值,最终优选出所有参数。

表1 通风参数优化模拟方案

Table 1 Simulation projects of ventilation parameter optimization

2.2.1  和

和 的取值

的取值

根据通风理论和已有研究成果[16],为了有效排出掘进工作面的粉尘和炮烟,同时确保采掘爆破过程中风筒不被破坏,综合考虑 和

和 需满足以下条件:

需满足以下条件:

5≤

=12.1 m

=12.1 m

30≤ ≤40 m

≤40 m

其中:Ls为有效射程,m;S为巷道断面面积,m2。

2.2.2 抽压比K取值

抽压比过大会导致已经落在地面的粉尘再次扬起,加大风流中的粉尘含量;若抽压比过小,则新鲜风流不足以使工作面产生的粉尘和炮烟及时排走。据文献[17],合理的抽压风量比应保持在1.2~1.5。

2.2.3 H取值

确定风筒的离地高度时既要考虑通风排尘效果,也要考虑吊挂施工和更换维修便利以及节省空间等因素,因此,风筒距离底板的高度一般处于侧壁面中部至侧壁面顶部的位置,即H=1.25~2.50 m。

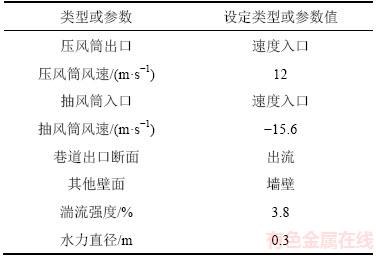

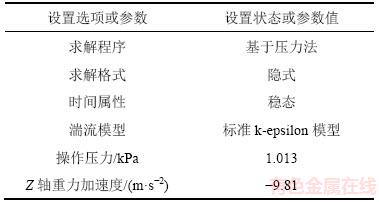

2.3 数值模拟条件的设置

巷道除尘模拟为典型的气固两相流,粉尘体积率在10%之内,故采用离散相模型[18-19]。数值模拟过程是先计算连续相,当连续相稳定收敛后再利用离散相方程加入粉尘颗粒进行迭代计算,直至收敛。根据矿山现场测试结果以及工程经验,并参考现有研究成果对边界条件、连续相计算模型、离散相计算模型、粉尘源参数进行设置,如表2~5所示。

表2 边界条件设定

Table 2 Boundary conditions

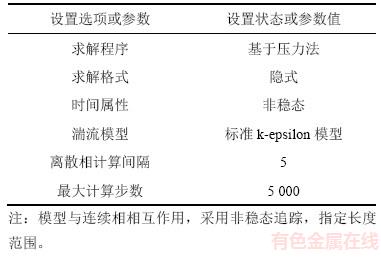

表3 连续相计算模型设置

Table 3 Setting of continuous phase calculation model

表4 离散相计算模型设置

Table 4 Setting of discrete phase model

表5 粉尘源参数设置

Table 5 Setting of dust parameters

3 数值模拟结果与分析

3.1 掘进工作面风流场分布模拟

以优化模拟方案中的第1个方案为例,对混合式通风的风流场进行模拟计算,分析其风流场分布规律。设定压风筒射流出口与迎头断面的距离为 =8.0 m,风速

=8.0 m,风速 =12.0 m/s;抽风筒吸口与迎头断面的距离

=12.0 m/s;抽风筒吸口与迎头断面的距离 =30.0 m;风速

=30.0 m;风速 =15.6 m/s;抽压风筒中心离地高度H=1.5 m。

=15.6 m/s;抽压风筒中心离地高度H=1.5 m。

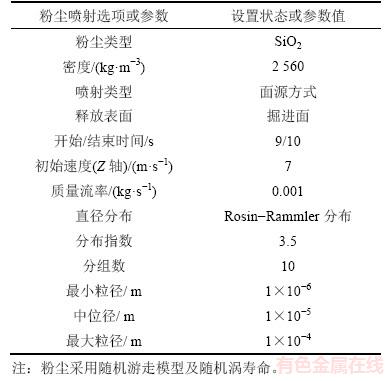

为了清晰、直观地了解压抽风筒流场的相互作用,截取Y=1.5 m平面作巷道风流场的速度云图和流线图,见图2。

从图2可以看到:新风流经压风筒出口以较高的速度射出,紧贴赋着巷道侧壁面向掘进面冲击,形成典型的贴壁射流;随着射流的向前运动,射流断面也逐渐扩大,当到达掘进面时,射流体与其发生碰撞致使风向发生改变,风流附壁回转,形成冲击射流;回转风流一部分沿抽风筒侧壁面向巷道断面出口方向运动,到达抽风筒附近被吸走排出巷道;一部分被射流卷吸,在压风筒出口附近区域产生涡流。而在逐渐远离压抽风筒出口的巷道空间内,由于风流速度降低,流场相对趋于稳定。另外还可看出混合式长压短抽(前压后抽)式通风流场的分区:在距离掘进面8 m内的空间区域,压风筒一侧射流为主要风流运动形式;而在距离掘进面8~30 m空间区域,抽风筒一侧回流为主要风流运动形式。

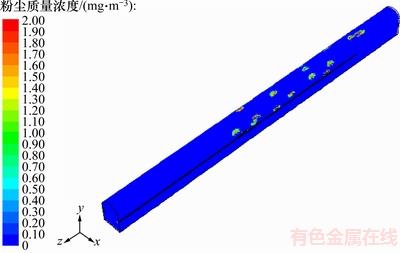

3.2 混合式通风方案优化模拟

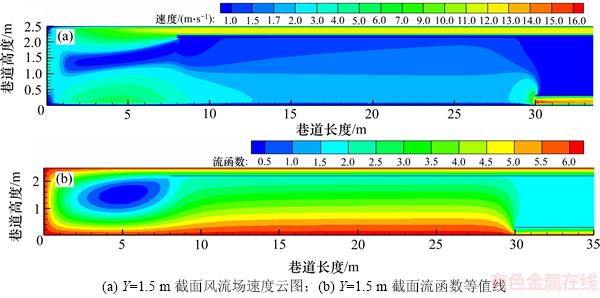

根据表1所示优化模拟方案,利用Fluent软件对各方案进行模拟计算。首先对各方案的风流场进行迭代计算,待风流场收敛之后在掘进面加入瞬态粉尘源,然后对粉尘进行迭代计算。统一观察通风5 min后巷道内粉尘质量浓度分布。根据地下矿山生产要求[20-21],矿山短时期接触烟尘的安全标准为2×10-6 kg/m3,以此为参考依据选择通风优化参数。

3.2.1 压风距离对粉尘质量浓度的影响分析

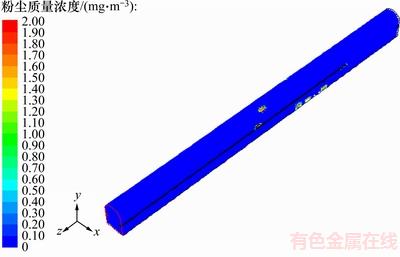

首先固定其他因素不变,将 作为变量进行模拟分析,通过改变其取值,对巷道内粉尘在混合式通风流场下的扩散及质量浓度分布规律进行数值模拟,从而确定压风口合理位置。

作为变量进行模拟分析,通过改变其取值,对巷道内粉尘在混合式通风流场下的扩散及质量浓度分布规律进行数值模拟,从而确定压风口合理位置。 为8.0,10.0和13.0 m时的模拟结果分别如图 3~5所示(由于将粉尘质量浓度显示范围设定在2×10-6 kg/m3以下,所以,图3~5中高质量浓度粉尘呈团状且不连续分布)。

为8.0,10.0和13.0 m时的模拟结果分别如图 3~5所示(由于将粉尘质量浓度显示范围设定在2×10-6 kg/m3以下,所以,图3~5中高质量浓度粉尘呈团状且不连续分布)。

图2 巷道风流场分布

Fig. 2 Distribution of wind flow field

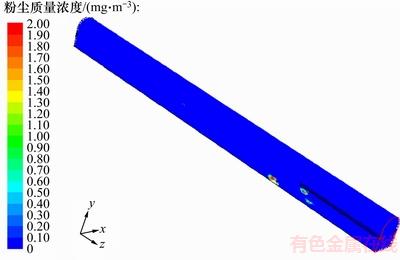

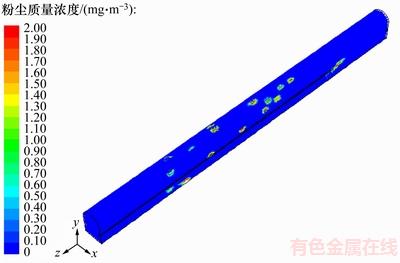

图3压风口 =8.0 m,通风5 min时粉尘质量浓度分布云图

=8.0 m,通风5 min时粉尘质量浓度分布云图

Fig. 3 Distribution nephogram of dust mass concentration when Lpressure is 8.0 m and time is 5 min

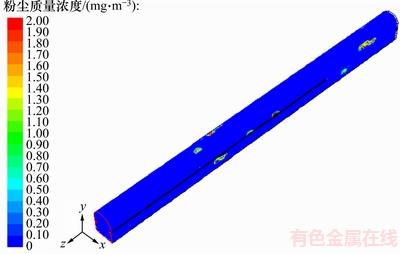

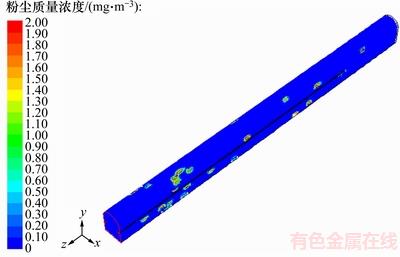

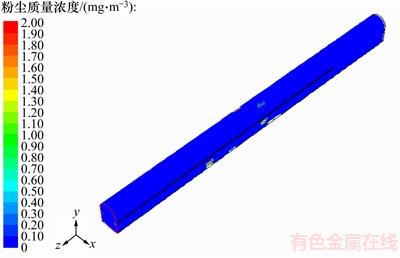

图4 压风口 =10.0 m,通风 5 min时粉尘质量浓度分布云图

=10.0 m,通风 5 min时粉尘质量浓度分布云图

Fig. 4 Distribution nephogram of dust mass concentration when Lpressure is 10.0 m and time is 5 min

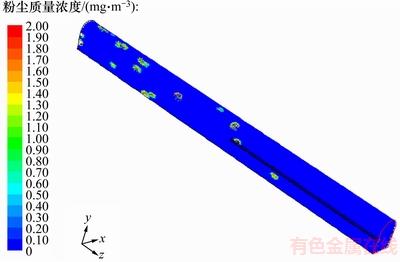

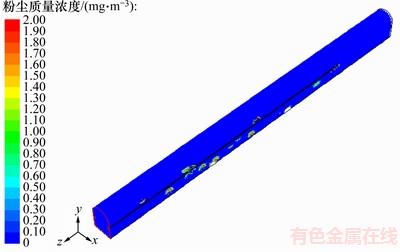

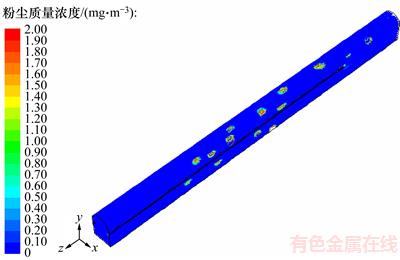

图5 压风口 =13.0 m,通风5 min时粉尘质量浓度分布云图

=13.0 m,通风5 min时粉尘质量浓度分布云图

Fig. 5 Distribution nephogram of dust mass concentration when Lpressure is 13.0 m and time is 5 min

从图3可看出巷道空间内的粉尘较多,除尘效果差。其原因在于当 =8 m时,压风口离掘进面太近,高速风流从风筒口流出后激射在掘进面,并在掘进面铺散开来,粉尘在压入射流和抽风筒负压联合作用下流动过快,导致粉尘无法形成有效回流,同时卷吸地面粉尘,从而使巷道内的空间粉尘增多;当

=8 m时,压风口离掘进面太近,高速风流从风筒口流出后激射在掘进面,并在掘进面铺散开来,粉尘在压入射流和抽风筒负压联合作用下流动过快,导致粉尘无法形成有效回流,同时卷吸地面粉尘,从而使巷道内的空间粉尘增多;当 =13.0 m时,

=13.0 m时, 在压风筒有效射程之外,压风口喷射出的新风无法抵达掘进面,导致射流拐点的后方形成涡流,迎头产尘受涡流的作用难以被彻底清洗,通风排尘效果不好;当

在压风筒有效射程之外,压风口喷射出的新风无法抵达掘进面,导致射流拐点的后方形成涡流,迎头产尘受涡流的作用难以被彻底清洗,通风排尘效果不好;当 =10.0 m时,

=10.0 m时, 恰好在射流的有效射程范围内,压风口喷射出的新风可以将迎头产生的粉尘稀释并有效清除,之后被抽风筒抽出,排尘效果较好。故

恰好在射流的有效射程范围内,压风口喷射出的新风可以将迎头产生的粉尘稀释并有效清除,之后被抽风筒抽出,排尘效果较好。故 =10.0 m为合理的压风口位置。

=10.0 m为合理的压风口位置。

3.2.2 抽风距离对粉尘浓度影响分析

将优选的 =10 m作为压风口合理布置地点,固定其他因素不变,将

=10 m作为压风口合理布置地点,固定其他因素不变,将 作为变量进行模拟分析,通过改变其取值,对巷道内粉尘在混合式通风流场下的扩散及质量浓度分布规律进行数值模拟,从而确定抽风口的合理位置。

作为变量进行模拟分析,通过改变其取值,对巷道内粉尘在混合式通风流场下的扩散及质量浓度分布规律进行数值模拟,从而确定抽风口的合理位置。 为25.0,30.0和35.0 m时的模拟结果分别如图6~8所示。

为25.0,30.0和35.0 m时的模拟结果分别如图6~8所示。

图6 抽风口 =25.0 m,通风5 min时粉尘质量浓度分布云图

=25.0 m,通风5 min时粉尘质量浓度分布云图

Fig. 6 Distribution nephogram of dust mass concentration when Lexhaus is 25.0 m and time is 5 min

图7 抽风口 =30.0 m,通风5 min时粉尘质量浓度分布云图

=30.0 m,通风5 min时粉尘质量浓度分布云图

Fig. 7 Distribution nephogram of dust mass concentration when Lexhaus is 30.0 m and time is 5 min

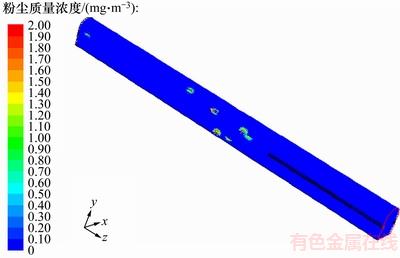

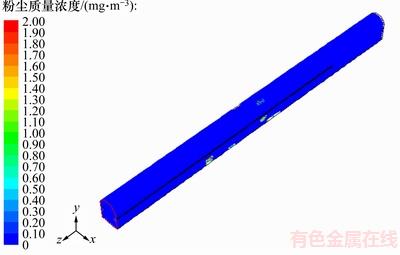

图8 抽风口 =35.0 m,通风5 min时粉尘质量浓度分布云图

=35.0 m,通风5 min时粉尘质量浓度分布云图

Fig. 8 Distribution nephogram of dust mass concentration when Lexhaus is 35.0 m and time is 5 min

从图6和图7可知:当抽风口与掘进面的距离 为25.0 m和30.0 m时,均有部分粉尘逃逸至压抽风筒重叠段,其中

为25.0 m和30.0 m时,均有部分粉尘逃逸至压抽风筒重叠段,其中 =25.0 m时巷道中聚集的粉尘量最多,这主要是因为抽压风口相距太近,抽压风筒之间无法形成有效的吹吸风流场,这部分粉尘将在此处聚集沉降且难以随风流排出;当

=25.0 m时巷道中聚集的粉尘量最多,这主要是因为抽压风口相距太近,抽压风筒之间无法形成有效的吹吸风流场,这部分粉尘将在此处聚集沉降且难以随风流排出;当 =35.0 m时,大部分粉尘都由抽风筒吸走,未吸走的粉尘也基本沉降于巷道地面,除尘效果良好,故

=35.0 m时,大部分粉尘都由抽风筒吸走,未吸走的粉尘也基本沉降于巷道地面,除尘效果良好,故 =35.0 m为合理的抽风口位置。

=35.0 m为合理的抽风口位置。

3.2.3 抽压比对粉尘质量浓度影响分析

将优选的 =10.0 m和

=10.0 m和 =35.0 m分别作为压风口和抽风口合理布置地点,固定其他因素,将抽压比作为变量进行模拟分析。由沃溪矿区井下局部风机实测结果v压=12.0 m/s,根据抽压比可得v抽的取值分别为12.0,15.6和18.0 m/s,模拟结果分别如图9~11所示。

=35.0 m分别作为压风口和抽风口合理布置地点,固定其他因素,将抽压比作为变量进行模拟分析。由沃溪矿区井下局部风机实测结果v压=12.0 m/s,根据抽压比可得v抽的取值分别为12.0,15.6和18.0 m/s,模拟结果分别如图9~11所示。

图9 抽压比K为1.0,通风5 min时粉尘质量浓度分布云图

Fig. 9 Distribution nephogram of dust mass concentration when K is 1 and time is 5 min

图10 抽压比K为1.3,通风5 min时粉尘质量浓度分布云图

Fig. 10 Distribution nephogram of dust mass concentration when K is 1.3 and time is 5 min

图11 抽压比为1.5,通风5 min时粉尘质量浓度分布云图

Fig. 11 Distribution nephogram of dust mass concentration when K is 1.5 and time is 5 min

从图9可以得知:当抽压比为1即抽风量等于压风量时,压口、抽口之间的区域残留了大量粉尘。其原因主要为抽压风量相等,当从压风出流的空气经掘进面折返至抽风口附近时,只有一部分风流被抽风筒吸走,另一部分则继续向巷道出口运动,污染其他区域的空气,通风排尘的效果不好;当抽压比为1.3时,工作面附近处的粉尘基本被排出,只有很少量粉尘越过抽风口向巷道断面出口运动,相比抽压比为1.0的参数布置,除尘效果已经有所改善;当抽风量进一步提高时,除尘效果也明显增强;当抽压比为1.5时,由工作面产生的粉尘几乎完全被压、抽风筒联合作用吸走排出,除尘效果良好。故选取抽压比1.5作为合理的混合式通风布置参数。

3.2.4 风筒高度对粉尘浓度的影响

将优选的 =10.0 m,

=10.0 m, =35.0 m,抽压比1.5作为固定参数,压抽风筒高度H作为变量进行模拟分析。H为1.2,1.5和1.8 m的模拟结果分别如图12~14所示。

=35.0 m,抽压比1.5作为固定参数,压抽风筒高度H作为变量进行模拟分析。H为1.2,1.5和1.8 m的模拟结果分别如图12~14所示。

图12 风筒高度H=1.2 m,通风5 min时粉尘质量浓度分布云图

Fig. 12 Distribution nephogram of dust mass concentration when H is 1.2 m and time is 5 min

图13 风筒高度H=1.5 m,通风5 min时粉尘质量浓度分布云图

Fig. 13 Distribution nephogram of dust mass concentration when H is 1.5 m and time is 5 min

图14 风筒高度H=1.8 m,通风5 min时粉尘质量浓度分布云图

Fig. 14 Distribution nephogram of dust mass concentration when H is 1.8 m and time is 5 min

从图12和图14可以看出:当压抽风筒离地高度H为1.2 m和1.8 m时,压风口至抽风口段巷道粉尘较多;而当H =1.5 m时,通风除尘效果较理想,能够达到生产要求。故确定H =1.5 m为最合适的风筒高度。

4 结论

1) 在本次研究中,长压短抽(前压后抽)式通风流场的分区为:在距离掘进面8.0 m以内的空间区域,压风筒一侧射流为主要风流运动形式;而在距离掘进面8.0~30.0 m的空间区域,抽风筒一侧回流为主要风流运动形式。

2) 建立了掘进巷道长压短抽(前压后抽)混合式通风数值模型。通过模拟得到风流场的分布,主要包含射流区、涡流区、回流区、压抽风流联合作用区4个区域。其中合理的压抽风流联合作用区能够形成阻止粉尘逃逸的风流屏障,对提高巷道排尘效率起着重要作用。

3) 根据通风模拟方案对4种通风参数进行调节,模拟各布置参数下混合式通风的除尘效果,得出该巷道通风布置参数的最优值: =10.0 m,

=10.0 m, =35.0 m,抽压比K=1.5,H =1.5 m。在此最优参数下,粉尘质量浓度能够在规定时间内降至矿山安全标准。

=35.0 m,抽压比K=1.5,H =1.5 m。在此最优参数下,粉尘质量浓度能够在规定时间内降至矿山安全标准。

参考文献:

[1] 黄寿元, 蔡建华, 李刚. 沃溪坑口千米深井降温技术研究与实践[J]. 黄金科学技术, 2016, 24(3): 81-86.

HUANG Shouyuan, CAI Jianhua, LI Gang. Research and practice of cooling technology in Woxi Pithead kilometer deep mine[J]. Gold Science and Technology, 2016, 24(3): 81-86.

[2] 蒋仲安, 金龙哲, 袁绪忠, 等. 掘进巷道中粉尘分布规律的实验研究[J]. 煤炭科学技术, 2001, 29(3): 43-45.

JIANG Zhongan, JIN Longzhe, YUAN Xuzhong, et al. Experimental research on the distribution of dust in roadway[J]. Coal Science and Technology, 2001, 29(3): 43-45.

[3] 王海桥, 陈世强, 李轶群. 独头巷道受限贴附射流有效射程的理论研究与数值计算[J]. 中国安全生产科学技术, 2015, 11(11): 41-45.

WANG Haiqiao, CHEN Shiqiang, LI Yiqun. Theoretical research and numerical calculation of effective range for restrained wall-attached jet flow in heading face[J]. Journal of Safety Science and Technology, 2015, 11(11): 41-45.

[4] 昝军, 刘祖德, 赵云胜. 独头巷道受限贴附射流特征参数对流场的影响研究[J]. 中国安全科学学报, 2010, 20(3): 24-28.

ZAN Jun, LIU Zude, ZHAO Yunsheng. Influence of characteristic parameters of restricted attachment jet on flow field in blind drift[J]. China Safety Science Journal, 2010, 20(3): 24-28.

[5] 秦跃平, 张苗苗, 崔丽洁, 等. 综掘工作面粉尘运移的数值模拟及压风分流降尘方式研究[J]. 北京科技大学学报, 2011, 33(7): 790-794.

QIN Yueping, ZHANG Miaomiao, CUI Lijie, et al. Numerical simulation of dust migration and study on dust removal modes with the forced ventilation shunt in a fully mechanized workface[J]. Journal of University of Science and Technology Beijing, 2011, 33(7): 790-794.

[6] 张朝波. 独头巷道掘进风流场分析及通风优化[D]. 长沙: 中南大学资源与安全工程学院, 2014: 8-9.

ZHANG Chaobo. Study of air flow field analysis and ventilation optimization in heading face roadway excavation[D]. Changsha: Central South University. School of Resources and Safety Engineering, 2014: 8-9.

[7] LEE D K. A Computational flow analysis for choosing the diameter and position of an air duct in a working face[J]. Journal of Mining Science, 2011, 47(5): 664-674.

[8] 赵恩彪. 采煤工作面粉尘浓度分布及传感器的部署[J]. 中国安全生产科学技术, 2012, 8(11): 85-89.

ZHAO Enbiao. Study on concentration of dust distribution and deployment of sensor in coal mining face[J]. Journal of Safety Science and Technology, 2012, 8(11): 85-89.

[9] 陈举师, 王毅, 蒋仲安. 采场爆破烟尘浓度分布及扩散规律的数值模拟[J]. 煤炭学报, 2013, 38(Zl): 147-152.

CHEN Jushi, WANG Yi, JIANG Zhongan. Numerical simulation of blasting dust concentration distribution and diffusion regularities in stope[J]. Journal of China Coal Society, 2013, 38(Zl): 147-152.

[10] 聂文, 马骁, 程卫民, 等. 通风条件影响长压短抽掘进面粉尘扩散的仿真实验[J]. 中南大学学报(自然科学版), 2015, 46(9): 3346-3353.

NIE Wen, MA Xiao, CHENG Weimin, et al. Simulation experiment on effects of ventilation conditions on dust diffusion of the forced with long duct fan accompanied with short duct exhaustor in heading face[J]. Journal of Central South University(Science and Technology), 2015, 46(9): 3346-3353.

[11] SERAFIN J, BEBCAK A, BERNATIK A, et al. The influence of air flow on maximum explosion characteristics of dust-air mixtures[J]. Journal of Loss Prevention in the Process Industries, 2013, 26(1): 209-214.

[12] SILVESTER S A, LOWNDES I S, HARGREAVES D M. A computational study of particulate emissions from an open pit quarry under neutral atmospheric conditions[J]. Atmospheric Environment, 2009, 43(40): 6415-6424.

[13] 杜翠凤, 王辉, 蒋仲安, 等. 长压短抽式通风综掘工作面粉尘分布规律的数值模拟[J]. 北京科技大学学报, 2010, 32(8): 957-961.

DU Cuifeng, WANG Hui, JIANG Zhongan, et al. Numerical simulations of dust distribution in a fully mechanized excavation face with far-pressing-near-absorption ventilation[J]. Journal of University of Science and Technology Beijing, 2010, 32(8): 957-961.

[14] 朱红青, 朱帅虎, 贾国伟. 大断面掘进压入式风筒最佳高度的数值模拟[J]. 安全与环境学报, 2014, 14(1): 25-28.

ZHU Hongqing, ZHU Shuaihu, JIA Guowei. Numerical simulation for the optimal driving duct height in a large-scale cross-section of driving face[J]. Journal of Safety and Environment, 2014, 14(1): 25-28.

[15] 幸大学. 掘进混合式通风合理抽压风筒口位置的探讨[J]. 矿业安全与环保, 2005, 32(4): 25-27.

XING Daxue. The discussion on the reasonable position of airduct mouth of mixed ventilation[J]. Mining Safety & Environmental Protection, 2005, 32(4): 25-27.

[16] 金波. 长距离掘巷前压后抽混合式通风数值模拟研究[D]. 赣州:江西理工大学资源与环境工程学院, 2015: 41-45.

JIN Bo. Numerical simulation research on front pressing back pumping mixed ventilation for long distance excavation roadways[D]. Ganzhou: Jiangxi University of Science and Technology. School of Resources and Environmental Engineering, 2015: 41-45.

[17] 赵书田. 抽压混合式通风除尘系统布置方式的选择和技术参数的确定[J]. 中国安全科学学报, 1993, 3(1): 32-38.

ZHAO Shutian. The choice of layout and the determination of technical parameters for mixed system with exhaust and blow[J]. China Safety Science Journal, 1993, 3(1): 32-38.

[18] 袁竹林, 朱立平, 耿凡, 等. 气固两相流动与数值模拟[M]. 南京:东南大学出版社, 2013: 62-63.

YUAN Zhulin, ZHU Liping, GENG Fan, et al. Gas-solid two-phase flow and numerical simulation[M]. Nanjing: Southeast University Press, 2013: 62-63.

[19] 张珅榕, 蔡卫军, 闵景新. 基于欧拉多相流模型的空泡数值模拟[J]. 船海工程, 2015, 44(1): 103-106, 111.

ZHANG Shenrong, CAI Weijun, MIN Jingxin. Numerical simulation of cavity based on eulerian multiphase model[J]. Ship & Ocean Engineering, 2015, 44(1): 103-106, 111.

[20] GB 16423—2006, 金属非金属矿山安全规程[S].

GB 16423—2006, Safety regulations for metal and nonmetal mines[S].

[21] 国家安全生产监督管理总局. 煤矿安全规程[M]. 北京:煤炭工业出版社, 2016: 65-67.

State Administration of Work Safety. Safety regulations for coal mines[M]. Beijing: China Coal Industry Publishing House, 2016: 65-67.

(编辑 陈灿华)

收稿日期:2017-10-12;修回日期:2017-12-07

基金项目(Foundation item):国家自然科学基金资助项目(51504286,51374242);中国博士后科学基金资助项目(2015M572270);湖南省科技计划项目(2015RS4004) (Projects(51504286, 51374242) supported by the National Natural Science Foundation of China; Project(2015M572270) supported by China Postdoctoral Science Foundation; Project(2015RS4004) supported by the Science and Technology Plan of Hunan Province)

通信作者:周智勇,博士,讲师,从事矿业系统工程及矿山安全研究;E-mail: csuzzy@126.com