Trans. Nonferrous Met. Soc. China 22(2012) 1407-1411

Effect of surface roughness on plasticity of Zr52.5Cu17.9Ni14.6Al10Ti5 bulk metallic glass

LIN Tao, HU Yong, KONG Ling-ti, LI Jin-fu

State Key Laboratory of Metal Matrix Composites, School of Materials Science and Engineering,

Shanghai Jiao Tong University, Shanghai 200240, China

Received 17 June 2011; accepted 28 July 2011

Abstract: Zr52.5Cu17.9Ni14.6Al10 Ti5 (Vit105) bulk metallic glass (BMG) rods were abraded to different surface roughnesses using different types of waterproof abrasive papers and sometimes polishing pastes, and the compressive deformation behavior was examined. The results show that the yield strength of the BMG is hardly affected while the compressive plasticity increases from 2.3% to 4.5% with decreasing the surface roughness. Observation of the fractured samples under a scanning electron microscope indicates that the rise in plasticity is accompanied with an increase in shear band density. The results suggest that it is necessary to reduce the surface roughness of BMGs for achieving a large plasticity.

Key words: bulk metallic glass; surface roughness; compressive plasticity; stress concentration

1 Introduction

Bulk metallic glasses (BMGs) have a variety of unique properties, such as high strength, large elastic limit and good corrosion resistance, and therefore represent a promising class of materials for structural and functional applications [1-3]. However, the localized and inhomogenieous deformation at the ambient temperature leads to rapid propagation of shear bands and subsequent premature catastrophic fracture [4]. A widespread application of BMGs as structural materials therefore needs to improve their plasticity substantially. In this regard, intensive efforts have been made and two promising approaches have been developed. The first approach is intrinsic, focusing on modifying the structure of BMGs. For example, the plasticity can be improved by physically introducing a second phase to the molten alloy, [5] designing a proper alloy composition [6] or adopting an effective heat treatment scheme [7]. The other approach is extrinsic, dedicated to modifying the structure of BMGS by means of mechanical working, during which excess free volume is created in the BMGs and consequently improves the plasticity. The related techniques include cold rolling [8], neutron irradiation [9], and/or pre-compressing [10].

In general, the plasticity of BMGs is dominated by many factors, such as sample size [11], sample geometry [12,13], sample alignment [14], oxygen concentration [15], casting temperature [16,17], applied temperature/ strain rate [18,19] and structural states [20,21]. Surface treatment is known for improving the mechanical properties of metallic alloys without introducing internal structural changes [22]. However, to our knowledge, its effect on the performance of BMGs has rarely been examined. Among a few studies reported, ZHANG et al [23] found that the plasticity of Zr-Ti-Cu-Ni-Be (Vit1) amorphous alloy was improved after shot-peening in uniaxial compression test. CHOI and HONG [24] also reported an enhanced plasticity of partially crystallized Vit1 BMG after surface modification and electro-plating. These findings suggest that the surface modification might be promising in improving the mechanical properties of BMG as well. In this work, the effect of surface roughness on the compressive plasticity of Zr52.5Cu17.9Ni14.6Al10 Ti5 (Vit105) bulk metallic glass is investigated.

2 Experimental

Master alloy ingots of Zr52.5Cu17.9Ni14.6Al10 Ti5 (mole fraction, %) were prepared by arc melting a mixture of pure Zr(99.9%), Cu(99.98%), Ni(99.98%), Al(99.99%), and Ti(99.9%) metals in a water-cooled copper crucible with a Ti-gettered argon atmosphere. Each ingot was remelted 4 times so as to achieve chemical homogeneity. The master alloy ingots were subsequently suction cast into a water-cooled copper mold to form cylindrical rods of 2 mm in diameter, whose structure was confirmed to be amorphous by X-ray diffraction measurement. The electric current of the arc for suction casting kept the same for all samples so as to insure the same casting conditions. The as-cast rods were then subjected to surface treatment. The rods denoted by S180 were only abraded by 180# waterproof abrasive paper (WAP). Those denoted by S800 were abraded by 180#, 400#, and 800# WAPs sequentially. Those denoted by S2000 were abraded by 180#, 400#, 800#, 1200#, 1500#, and 2000# WAPs sequentially. Those denoted by SP were further polished by W5 and W1 diamond pastes. In order to exclude the effect of sample size, a same thickness of surface layer was removed for each rod subjected to abrading/polishing. After that, a compressive specimen with an aspect ratio of 2:1 was cut from the middle part of the rod according to the ASTM standards. The two ends of each specimen were exactly parallel and perpendicular to the longitudinal axis.

The surface roughness of the abraded/polished rods was characterized by the roughness parameter Ra measured with a surface roughness tester TR220. Uniaxial compression tests were carried out using a Sans CMT 5105 testing machine at room temperature at a constant engineering strain rate of 5×10-4 s-1. The fracture appearance was examined by a Jeol JSM-6460 scanning electron microscope (SEM).

3 Results and discussion

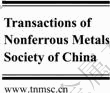

Figure 1 shows the surface profiles of a set of samples. Based on three independent measurements for each type of rods, the Ra (the arithmetical mean roughness) is determined to be (1.343±0.114) μm, (0.178±0.008) μm, (0.040±0.002) μm and (0.014± 0.004) μm for S180, S800, S2000 and SP samples, respectively.

Fig. 1 Surface profiles of rod samples after different surface treatments

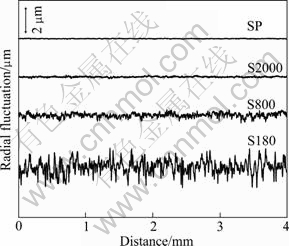

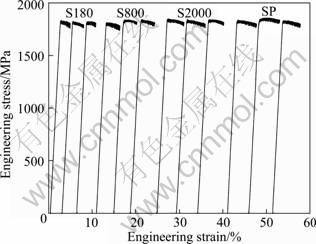

Compression test with a strain rate of 5×10-4 s-1 was performed with three specimens for each type of rods. Figure 2 shows the engineering stress—strain curves of samples. One can find that the same type of specimens nearly coincides with each other in the curves. The yield strengths for all specimens are essentially the same, being (1815±13) MPa and showing no dependence on the surface roughness. The compressive plasticity, however, increases gradually with decreasing the surface roughness. When the surface roughness decreases from 1.343 mm for S180 to 0.014 mm for SP, the plastic strain increases from 2.3% to 4.5% (see Fig. 3), which suggests an enhanced plasticity for the samples with small surface roughness.

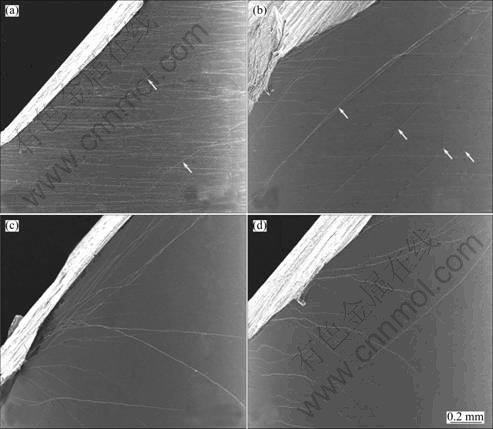

The fractured specimens were observed under SEM so as to discern the origin of the plasticity enhancement. Figure 4 shows the SEM images viewed from one side. For sample S180, many coarse horizontal scratches caused by the abrasive paper are clearly seen, together with only two primary shear bands within the area of view (Fig. 4(a)). For S800, however, the scratches become finer and less significantly than in S180. Meanwhile, more primary shear bands form, as seen in Fig. 4(b). On the surfaces of S2000 and SP, the deep scratches are hardly seen, while more primary shear bands are observed. In addition, in contrast to S180 and S800, there are a lot of secondary shear bands developed beside the primary ones, as evidenced in Figs. 4(c) and (d). That is to say, the plasticity is dominated by only one or two primary shear bands for S180 and S800, but by multiple shear bands for S2000 and SP.

Fig. 2 Engineering stress—strain curves for Vit105 samples under uniaxial compression

Fig. 3 Surface roughness dependence of plastic strain in Vit105 BMG

Fig. 4 SEM images showing side surfaces of fractured Vit105 specimens of S180 (a), S800 (b), S2000 (c) and SP (d)

It is well known that decreasing the surface roughness helps to promote the plasticity of a polycrystalline alloy [25]. The observations described above suggest that the same effect can also be expected for bulk metallic glass like Vit105 as well. Similar to the case of polycrystalline alloy, the mechanism underlying such a plasticity enhancement in BMGs can be attributed to the alleviation of local stress concentration by the reduced surface roughness. Inhomogeneous deformation of metallic glasses is localized in narrow shear bands and accompanied with creation of free volume at the ambient temperature [4]. The creation of free volume is a stress-driven process, and will initiate at locations where stress concentration exists. For sample S180, the abrasion with 180# WAP introduced many deep uneven scratches on the surface. Upon compression, the deepest scratches serve as stress concentration centers and facilitate the formation of a few of primary shear bands, leading to the rapid fracture and consequently the smallest plastic strain. When abraded with finer WAPs, the resultant scratches on the specimen surface become more and shallower, due to which the degree of local stress concentration is alleviated and more scratches serve as surface imperfections [26] for shear banding. As a result, more shear bands develop and a larger fracture strain is observed for samples S2000 and SP. In other words, with decreasing the surface roughness, the possibility of local stress concentration is reduced, which promotes the multiplication and branching of primary shear bands and improves the plasticity. The increase in plasticity of polycrystalline alloys is attributed to the removal of the surface layer containing mobile dislocations and stress concentration [27]. In this sence, the mechanism of promoting plasticity by decreasing the surface roughness is the same for metallic glasses and polycrystalline alloys.

While analyzing the shot-peening induced plasticity improvement of Zr-Ti-Cu-Ni-Be (Vit1) BMG, ZHANG et al [23] attributed it to the introduction of residual compressive stress into the sample surface layer and the rise of the surface roughness. They thought that a rough surface is favorable for the uniform deformation induced by a high population of pre-existing shear bands. But the present work clearly indicates that a rougher surface may deteriorate the plasticity. The reason is that plasticity behavior is also controlled by the morphology of the surface defect rather than merely by the magnitude of roughness. A deep sharp groove may lead to a severe stress concentration and early formation of cracks on the sample surface, as found in S180.

4 Conclusions

The effect of surface roughness on compressive plasticity was investigated. It is found that a smaller surface roughness generally corresponds to a higher fracture strain and therefore a better plasticity. The plasticity enhancement originates from the fact that a reduced surface roughness reduces the chances of stress concentration, while helps to enhance shear band multiplication and branching. The result indicates that one should pay attention to the surface roughness while they machine bulk metallic glasses.

References

[1] JOHNSON W L. Bulk glass-forming metallic alloys: Science and Technology [J]. MRS Bull, 1999, 24: 42-56.

[2] INOUE A. Stabilization of metallic supercooled liquid and bulk amorphous alloys [J]. Acta Mater, 2000, 48: 279-306.

[3] ASHBY M F, GREER A L. Metallic glasses as structural materials [J]. Scripta Mater, 2006, 54: 321-326.

[4] SPAEPEN F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses [J]. Acta Metall, 1977, 25: 407-415.

[5] CHOI-YIM H, CONNER R D, SZUECS F, JOHNSON W L. Processing, microstructure and properties of ductile metal particulate reinforced Zr57Nb5Al10Cu15.4Ni12.6 bulk metallic glass composites [J]. Acta Mater, 2002, 50: 2737-2745.

[6] KATO H, HIRANO T, MATSUO A, KAWAMURA Y, INOUE A. High strength and good ductility of Zr55Al10Ni5Cu30 bulk glass containing ZRC particles [J]. Scripta Mater, 2000, 43: 503-507.

[7] FAN C, INOUE A. Ductility of bulk nanocrystalline composites and metallic glasses at room temperature [J]. Appl Phys Lett, 2000, 77: 46-48.

[8] CAO Q P, LI J F, ZHOU Y H, HORSEWELL A, JIANG J Z. Effect of rolling deformation on the microstructure of bulk Cu60Zr20Ti20 metallic glass and its crystallization [J]. Acta Mater, 2006, 54: 4373-4383.

[9] SKORVANEK I, GERLING R, GRAF T, FRICKE M, HESSE J. Neutron irradiation effects on the structural, magnetic and mechanical properties of amorphous and nanocrystalline Fe73.5Cu1Nb3Si13.5B9 [J]. IEEE Trans Magn, 1994, 30: 548-551.

[10] LEE S C, LEE C M, YANG J W, LEE J C. Microstructural evolution of an elastostatically compressed amorphous alloy and its influence on the mechanical properties [J]. Scripta Mater, 2008, 58: 591-594.

[11] HUANG Y J, SHEN J, SUN J F. Bulk metallic glasses: Smaller is softer [J]. Appl Phys Lett, 2007, 90: 081919.

[12] BEI H, XIE S, GEORGE E P. Softening caused by profuse shear banding in a bulk metallic glass [J]. Phys Rev Lett, 2006, 96: 105503.

[13] ZHANG Z F, ZHANG H, PAN X F, DAS J, ECKERT J. Effect of aspect ratio on the compressive deformation and fracture behaviour of Zr-based bulk metallic glass [J]. Philos Mag Lett, 2005, 85: 513-521.

[14] WU W F, LI Y, SCHUH C A. Strength, plasticity and brittleness of bulk metallic glasses under compression: Statistical and geometric effects [J]. Philos Mag, 2008, 88: 71-89.

[15] LU Z P, BEI H, WU Y, CHEN G L, GEORGE E P, LIU C T. Oxygen effects on plastic deformation of a Zr-based bulk metallic glass [J]. Appl Phys Lett, 2008, 92: 011915.

[16] KUMAR G, OHKUBO T, HONO K. Effect of melt temperature on the mechanical properties of bulk metallic glasses [J]. J Mater Res, 2009, 24: 2353-2360.

[17] ZHU Z W, ZHENG S J, ZHANG H F, DING B Z, HU Z Q, LIAW P K, WANG Y D, REN Y. Plasticity of bulk metallic glasses improved by controlling the solidification condition [J]. J Mater Res, 2008, 23: 941-948.

[18] MUKAI T, NIEH T G, KAWAMURA Y, INOUE A, HIGASHI K. Effect of strain rate on compressive behavior of a Pd40Ni40P20 bulk metallic glass [J]. Intermetallics, 2002, 10: 1071-1077.

[19] KAWAMURA Y, SHIBATA T, INOUE A, MASUMOTO T. Deformation behavior of Zr65Al10Ni10Cu15 glassy alloy with wide supercooled liquid region [J]. Appl Phys Lett, 1996, 69: 1208-1210.

[20] PARK E S, KIM D H. Phase separation and enhancement of plasticity in Cu-Zr-Al-Y bulk metallic glasses [J]. Acta Mater, 2006, 54: 2597-2604.

[21] FAN C, LI C, INOUE A. Nanocrystal composites in Zr-Nb-Cu-Al metallic glasses [J]. Journal of Non-Cryst Solids, 2000, 270: 28-33.

[22] DRITS M E, KADANER E S, KOPEV I M, TOROPOVA L S. Effect of surface roughness on mechanical properties of aluminum foil under static and cyclic loads [J]. Soviet Mater Sci, 1973, 6: 522-523.

[23] ZHANG Y, WANG W H, GREER A L. Making metallic glasses plastic by control of residual stress [J]. Nat Mater, 2006, 5: 857-860.

[24] CHOI Y C, HONG S I. Effect of crystallization and surface treatment on deformation and fracture of Zr-Ti-Cu-Ni-Be bulk metallic glass [J]. Int J Mod Phys B, 2009, 23: 1270-1275.

[25] NOVIKOV N V, GORODYSKILL N I, ZASIMCHUK E E, MAIDICH O D. Influence of surface machining operations on mechanical properties of chromium-nickel steels at low temperatures [J]. Strength Mater, 1974, 6: 436-443.

[26] ARGON A S. Plastic deformation in metallic glasses [J]. Acta Metall, 1979, 27: 47-58.

[27] KOVALEVA V N, MOSKALENKO V A. Quality of surface treatment and plastic deformation of titanium alloys at 2.5 to 293 K [J]. Cryogenics, 1989, 29: 1002-1005.

表面粗糙度对Zr52.5Cu17.9Ni14.6Al10Ti5块体非晶合金塑性的影响

林 涛,胡 勇,孔令体,李金富

上海交通大学 材料科学与工程学院,金属基复合材料国家重点实验室,上海 200240

摘 要:将Zr52.5Cu17.9Ni14.6Al10 Ti5 (Vit105)块体非晶合金棒用水砂纸和抛光膏打磨到不同粗糙度,研究表面粗糙度对试样压缩变形行为的影响。结果表明,随着试样表面粗糙度的降低,屈服强度并没有明显变化,但压缩塑性从2.3%提高到4.5%。在扫描电镜下观察断裂试样的侧面发现,塑性越大的试样,剪切带的密度越大。因此,对于非晶合金,要得到较大的塑性,降低表面粗糙度是必要的。

关键词:块体非晶合金;表面粗糙度;压缩塑性;应力集中

(Edited by LI Xiang-qun)

Foundation item: Projects (50771064, 50831003) supported by the National Natural Science Foundation of China; Project (10PJ1405900) supported by Shanghai Pujiang Program, China

Corresponding author: LI Jin-fu; Tel: +86-21-54748530; Fax: +86-21-54748530; E-mail: jfli@sjtu.edu.cn

DOI: 10.1016/S1003-6326(11)61333-2