文章编号:1004-0609(2014)10-2594-07

湿化学法制备W-TiC复合粉体及其SPS烧结行为

丁孝禹1,罗来马1, 3,黄丽枚1,罗广南2,李 萍1, 3,朱晓勇1, 3,吴玉程1, 3

(1. 合肥工业大学 材料科学与工程学院, 合肥 230009;

2. 中国科学院 等离子体物理研究所,合肥230031;

3. 安徽省有色金属材料与加工工程实验室, 合肥 230009)

摘 要:采用湿化学法制备W-TiC复合粉体,然后采用放电等离子体烧结(SPS)技术制备超细晶W-TiC复合材料,并对其复合粉体形貌和烧结复合材料组织结构进行研究。结果表明,对原始TiC粉进行活化预处理,使TiC粉表面获得均匀分布的缺陷,提高TiC粉表面的的亲水性,通过化学还原获得第二相TiC颗粒,且均匀弥散分布于W基体晶界和晶粒内。采用SPS烧结技术获得的超细晶W-TiC复合材料晶粒尺寸为400 nm,致密度为95%,维氏显微硬度值HV0.2达到1280。

关键词:W-TiC复合粉体;湿化学法;放电等离子体烧结;活化预处理;缺陷

中图分类号:TG146.4 文献标志码:A

Synthesis of W-TiC composite powders by wet-chemical process and its sintering behavior by SPS

DING Xiao-yu1, LUO Lai-ma1, 3, HUANG Li-mei1, LUO Guang-nan2, LI Ping1, 3, ZHU Xiao-yong1, 3, WU Yu-cheng1, 3

(1. School of Material Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Institute of Plasma Physics, Chinese Academy of Sciences, Hefei 230031, China;

3. Laboratories of Nonferrous Metal Material and Processing Engineering of Anhui Province, Hefei 230009, China)

Abstract: W-TiC composite powders were prepared by wet-chemical process, and ultra-fine grained W-TiC composites were fabricated by spark plasma sintering (SPS). The surface morphologies of W-TiC composite powders and the microstructure of W-TiC composites were studied. The results show that TiC powders are subjected to chemical activation pretreatment to obtain uniform distribution of defects on the surface of TiC powder, thus increasing the hydrophilicity of the TiC surface. The second phase TiC particles are homogeneously and dispersively distribute in the grains and grain boundaries by chemical reduction. The grain size, relative density and the Vicker hardness HV0.2 of the ultra-fine grained W-TiC composites by SPS are 400 nm, 95% and 1280, respectively.

Key words: W-TiC composite powder; wet-chemical process; spark plasma sintering; activation pretreatment; defect

钨因具有高熔点、高导热率、高密度、低热膨胀系数、低蒸气压、低氚滞留、低溅射产额和高自溅射阀值等优异性能,被认为是核聚变装置最有前途的面对等离子体第一壁材料[1-10]。但是,W具有低温脆性、界面结合力小、韧脆转变温度(约400 ℃)高、再结晶温度(约1400 ℃)低和辐照脆化等应用缺陷,从而限制了在其核聚变装置中的应用[11-12]。为了克服纯W的上述脆性,改善W的高温力学性能,研究人员通过掺入少量的碳化物颗粒(如TiC、HfC和ZrC等)来弥散增强W,已取得很好的效果[13-16]。TiC 具有高熔点、低密度、良好的高温强度,以及与钨具有相似的热膨胀系数等性质,而且可以和W形成(Ti,W)C固溶体,是W合金的一种较好的增强相。

机械合金化法是目前制备超细W-TiC复合粉体应用最广泛的一种方法,然而,因磨球和球磨罐的磨损,易引入大量杂质,进而引起成分的微量变化。同时,球磨过程中引入大量的机械能,使粉末处于高能活化状态,加速了烧结过程中晶粒长大,并且由于高的内应力,烧坯易萌生裂纹。因此,亟需寻找新的复合粉体制备方法。其中,湿化学法作为一种制备超细粉的制备方法,具有成分精确可控、制得的粉末纯度高且均匀性好等优点[17-20]。由于W具有熔点高、自扩散系数低等特点,采用传统的烧结方法来制备全致密W需要在2000~2500 ℃保温很长时间,晶粒存在着强烈的长大倾向。放电等离子体烧结(SPS)融等离子活化、热压、电阻加热为一体,具有升温速度快、烧结时间短、晶粒均匀、有利于控制烧结体的细微结构、获得的材料致密度高、性能好等特点,在纳米材料、复合材料等的制备中显示出极大的优越性,现已应用于金属、陶瓷、复合材料以及纳米块体材料、非晶块体材料、梯度材料等功能材料的制备[20-24]。谈军等[24]采用SPS技术于1700℃制备了晶粒细小的氧化物弥散强化W 基复合材料,有效提高了 W 的力学性能。本文作者通过湿化学法制备W-TiC复合粉体,然后采用SPS烧结技术制备W-TiC复合材料,对其复合粉体形貌和烧结复合材料组织结构进行了研究。

1 实验

实验所用的TiC粉(上海超尔纳米科技有限公司生产)平均粒径为50 nm,纯度为99.9%。试验所用化学试剂有氢氟酸(分析纯,含量≥40%,国药集团化学试剂有限公司生产)和氟化铵(分析纯,含量≥96.0%,国药集团化学试剂有限公司生产)。所用的超声波清洗器型号为JK-450B,功率为450 W,频率为40 kHz。将1~2 g氟化铵溶于500 mL去离子水中,在完全溶解的氟化铵中加入浓度约40%的氢氟酸20~40 mL,搅拌均匀,将5 g TiC粉加入上述溶液中,室温下超声处理30 min,静置至粉体沉降后,分离粗化液,再用去离子水清洗粉体3次,最后放在烘箱里60 ℃烘干。采用场发射扫描电镜(FE-SEM)观察化学活化前后粉末的表面形貌。将化学处理后的5.0%TiC粉加入由无水乙醇、氯化钨(WCl6)、乳酸(C3H6O3)、水合肼(H4N2.H2O)和2, 2-联吡啶混合搅拌的溶液中,80 ℃超声加搅拌3 h,通过加入氨水调节pH保持9~10,静置至粉体沉降后,再用无水乙醇清洗粉体3次,最后放在烘箱里60 ℃烘干。由于还原得到的W粉在溶液中易氧化,故将复合粉体放置管式炉中于800 ℃通氢气还原2 h。采用SU8020型FE-SEM和JEF-2100F型透射电子显微镜(TEM)观察复合粉体形貌,利用EDX和D/MAX 2500V型X射线衍射仪(XRD)分析粉末的成分和物相。

将粉体装填在直径20 mm的石墨模具内,采用放电等离子烧结技术,烧结设备为德国的SE-607。SPS烧结工艺曲线如图1所示。烧结过程开始以50 ℃/min的加热速度升温到600 ℃,同时压制压力缓慢增加到18 kN(约57 MPa),保温1 min后,充氩气保护。然后以100℃/min的加热速度升温到900 ℃,保温5 min,紧接着升温到1800 ℃烧结1 min,最后以100 ℃/min的冷却速度冷却到室温,得到直径20 mm、厚度2~3 mm的试样。极快地加热速度和极短的高温停留时间避免了晶粒长大。为了在SEM观察中能清晰地分析表面形貌,采用氨水、双氧水浸蚀剂(氨水50 mL,双氧水50 mL)对抛光后的样品表面进行了浸蚀。采用阿基米德排水法测定样品的密度。在维氏显微硬度计(MH-3L)上测试材料的显微硬度,载荷为2 N,保压时间为20 s。在SU8020型场发射扫描电子显微镜上对材料的表面和断口形貌进行观察。用透射电子显微镜对复合材料微观组织结构进行分析表征。

图1 SPS烧结工艺曲线

Fig. 1 Temperature profile of SPS process

2 结果与讨论

2.1 TiC粉末预处理前后表面形貌

图2(a)和2(b)所示为一步活化预处理前TiC粉的表面形貌。由高倍图2(b)可以看出,原始TiC粉表面光滑、平整,无明显台阶缺陷。图2(c)和2(d)所示为经过氢氟酸和氟化铵按一定比例混合超声活化处理后的TiC粉表面形貌。可见,经过活化预处理后粉末的尺寸没有明显变化。从高放大倍数形貌可以看出,经过化学处理后TiC粉表面形成均匀分布的表面缺陷,对于固体材料,表面活性就意味着单位面积缺陷的数量,一般为表面缺陷,比如边缘、台阶以及吸附质岛的边缘等某些配位不饱和的表面原子或原子基团,这些部位易于吸附外来物质成键。常规化学镀包覆表面没有催化活性的陶瓷粉体,采用敏化、活化等预处理,目的就是在不具备催化活性表面附着Pd元素微颗粒,使表面易于吸附外来物质成键,实现化学镀沉积过程。本实验中的简化预处理工艺思路即为使碳化物粉体表面产生缺陷,即大量纳米级条状凸起物,直接成为W元素微颗粒吸附中心,W颗粒依附这些条状凸起,发生吸附、形核和长大。与原始TiC粉相比,经过活化预处理后的TiC粉表面形成均匀分布的缺陷,使粉末表面呈微观粗糙不平的状态,增大了材料的比表面积,提高了TiC粉表面的的亲水性,便于后续还原W粉沉积到活化TiC表面,形成包覆粉结构。

2.2 W-TiC复合粉体的表征

图3(a)所示为W-TiC复合粉体的形貌。由SEM像可以看出,复合粉体呈准球形,尺寸均匀,平均粒径约为300 nm,从形貌上已无法区分 W 和 TiC 颗粒,颗粒表面没有发现明显的第二相,证明形成了W-TiC包覆粉结构。图3(b)所示为复合粉体的TEM像,从图中可以看出明显的核壳包覆结构。图3(c)所示为图3(b)选定区域的能谱图。由EDS谱分析表明,选定区域主要由W、Ti、C和O元素组成,Cu元素由于用的铜网被去掉。为了鉴定复合粉末在活化预处理前后物相是否发生变化,对复合粉体进行XRD分析,分析结果如图4(a)所示。从图中可以看出,预处理后粉末的XRD谱主要是W的衍射峰,TiC的衍射峰很弱,可能是由于TiC含量较低和XRD仪器扫描速度过快。这说明通过化学合成的W-TiC粉体纯度很高,中间过程没有引入杂质相。同时可以看到W的衍射峰峰值很强,峰的宽度很窄很尖锐,证明具有很好的晶体结晶度。说明相比机械合金化法因磨球和球磨罐的磨损易引入大量杂质,湿化学法成分精确可控、制得的粉末纯度高且均匀性好。

2.3 复合材料的微观组织结构

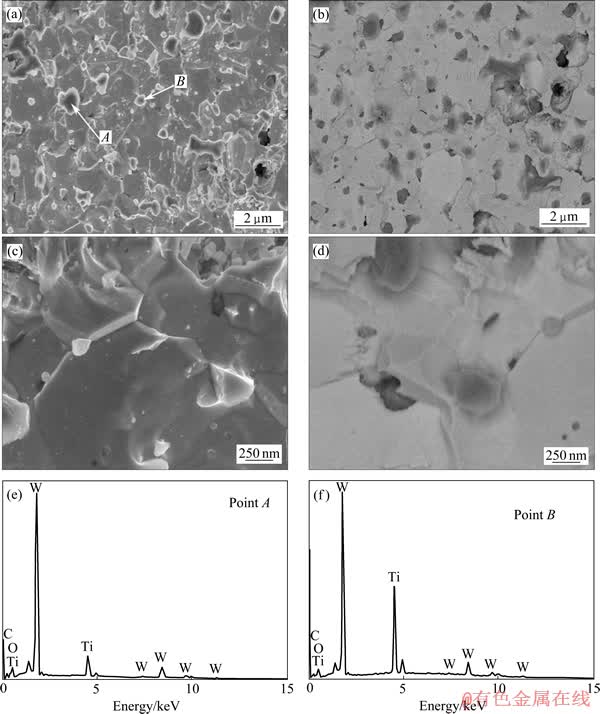

经SPS烧结W-TiC复合材料再经抛光、用氨水和双氧水浸蚀剂(氨水50 mL,双氧水50 mL)对抛光后的样品表面进行浸蚀,其表面的二次电子像(SEM)和背散射电子像(BSE)及其能谱如图5所示。从低倍SEM-BSE像(见图5(a)和5(b))可以看出,第二相TiC颗粒均匀弥散分布在三角晶界和W晶粒内,没有明显的团聚发生。BSE像(见5(b)和5(d))中白色的为W基体,黑色为可能是由于磨样抛光过程中TiC脱落留下的凹坑,灰色部分主要是第二相。EDS结果表明,第二相颗粒的化学成分为 W-Ti-C-O固溶物,因氧及其钛含量的不同而使得第二相颗粒在显微电镜下呈现出不同的颜色。能谱中氧的少量存在主要是由原始粉末中的O和烧结过程所引入的O所造成。从高倍BSE像(见图5(d))可以看出,超细TiC颗粒主要分布在单个W晶粒内,晶粒内部细小弥散分布的第二相颗粒在拉伸过程中可有效的积累位错进而提高材料拉伸过程中的加工硬化能力,避免过早出现局部软化。W-TiC复合材料的XRD结果如图4(b)所示。从XRD谱可以看出,SPS烧结过程中没有引入杂质相。

图2 活化预处理前后TiC粉的表面形貌

Fig. 2 Surface morphologies of TiC powder before and after pretreatment

图3 W-TiC复合粉体的显微组织及其能谱图

Fig. 3 Microstructures and EDS spectrum of W-TiC composite powder

图4 W-TiC复合粉体活化预处理前后XRD谱

Fig. 4 XRD patterns of W-TiC composite powder before(a) and after(b) pretreatment

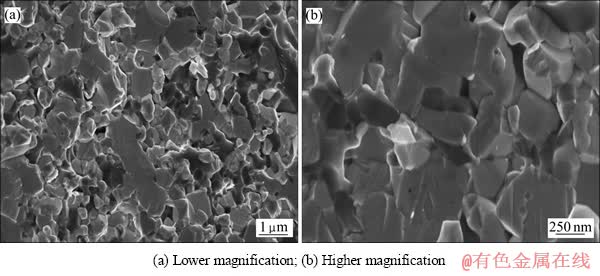

图6所示为W-TiC复合材料的断口形貌。从图6中可以看出,烧结体晶粒平均为400nm,说明在烧结过程中W颗粒没出现明显的长大现象。主要原因如下:1) 由于采用了SPS烧结技术,升温速度快,烧结时间短,烧结全程保持较大的压制压力;2) 由于TiC颗粒在 W 晶界及晶粒内的聚集和钉扎,降低了 W 的界面能,使钨晶粒长大的驱动力减小;同时起到钉扎原始钨晶界、增大晶界迁移阻力和有效地阻碍原始钨晶粒间聚集长大的作用。从高倍SEM像(见图6(b))可以看出,W颗粒之间及TiC与W基体结合强度较好,孔隙很少。通过阿基米德排水法测得W-TiC复合材料的相对密度为95%。通过维氏显微硬度计(MH-3L)测得W-TiC复合材料的显微硬度值HV0.2达到1280,这主要是由于烧结样品的致密度较高,且其晶粒尺寸较细。由Hall-Petch关系可知,晶粒尺寸越小,强度越大,硬度也相应增加。

图5 W-TiC复合材料的显微照片及EDS谱

Fig. 5 SEM images((a), (c)) and BSE images((b), (d)) of W-TiC composites and EDS spectra ((e), (f)) of selected points in Fig. (a)

图6 W-TiC复合材料的断口形貌

Fig. 6 Fracture morphologies of W-TiC composites

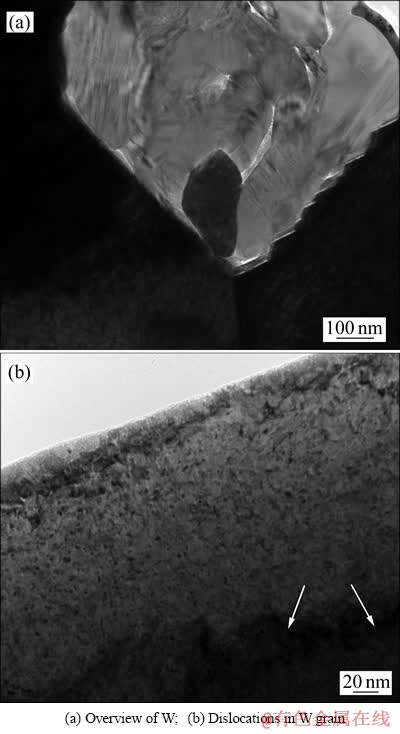

图7所示为W-TiC复合材料的TEM像。由图7(a)可以明显看到超细的第二相TiC颗粒分布在单个W晶粒内。从图7(b)可以看出W晶粒内部出现了位错(如图中箭头所示)。这些位错和在大变形材料中观察到的位错很相似,表明在SPS烧结过程中,极高的压制压力使粉末颗粒发生了变形。产生高密度的位错主要是因为粉末在烧结过程中高温停留时间短(仅1min),没有足够的时间达到热平衡来消除这些缺陷。这些高密度的位错可能会提高复合材料的强度和硬度。

图7 W-TiC复合材料的TEM像

Fig. 7 TEM images of W-TiC composites

3 结论

1) 通过氟化铵和氢氟酸混合液为活化液的常温超声波辅助活化处理,使TiC粉表面获得均匀分布的缺陷,提高了TiC粉表面的的亲水性,便于后续还原W粉沉积到活化TiC表面,形成核壳结构。

2) 采用化学还原和放电等离子烧结技术制备了高致密度超细晶TiC颗粒增强W-TiC复合材料。采用湿化学法可获得第二相TiC颗粒均匀弥散分布于W基体晶界和晶粒内。

3) TiC的加入促进了W的烧结致密化,抑制了W晶粒的长大,由于SPS工艺的加热速度极快,保温时间极短,采用该工艺可获得晶粒尺寸约为400 nm、相对密度为95%、维氏显微硬度值HV0.2达到1280的超细晶W-TiC复合材料。

REFERENCES

[1] HAN Y, FAN J L, LIU T, CHENG H C, TIAN J M. The effects of ball-milling treatment on the densification behavior of ultra-fine tungsten powder[J]. International Journal of Refractory Metals and Hard Materials, 2011, 29: 743-750.

[2] MONDAL A, UPADHYAYA A, AGRAWAL D. Effect of heating mode on sintering of tungsten[J]. International Journal of Refractory Metals and Hard Materials, 2010, 28: 597-600.

[3] KURISHITA H, MATSUO S, ARAKAWA H, NARUI M, YAMAZAKI M, SAKAMOTO T, KOBAYASHI S, NAKAI K, TAKIDA T, TAKEBE K, KAWAI M, YOSHIDA N. High temperature tensile properties and their application to toughness enhancement in ultra-fine grained W-(0-1.5)wt% TiC[J]. Journal of Nuclear Materials, 2009, 386/388: 579-582.

[4] CHANTHAPAN S, KULKARNI A, SINGH J, HAINES C, KAPOOR D. Sintering of tungsten powder with and without tungsten carbide additive by field assisted sintering technology[J]. International Journal of Refractory Metals and Hard Materials, 2012, 31: 114-120.

[5] 王 超, 贺跃辉, 彭超群, 王世良, 刘新利. 一维W纳米材料的场发射性能及其可控制备的研究发展[J]. 中国有色金属学报, 2012, 22(6): 1632-1641.

WANG Chao, HE Yue-hui, PENG Chao-qun, WANG Shi-liang, LIU Xin-li. Research progress in field emission properties and controllable preparation of one-dimensional W nano-materials[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1632-1641.

[6] 陈 勇, 吴玉程, 于福文, 陈俊凌. La2O3 弥散强化钨合金的组织性能研究究[J]. 稀有金属材料与工程, 2007, 36(5): 822-824.

CHEN Yong, WU Yu-cheng, YU Fu-wen, CHEN Jun-ling. Study on structure and property of tungsten alloy strengthened with dispersed La2O3[J]. Rare Metal Materials and Engineering, 2007, 36(5): 822-824.

[7] 种法力, 于福文, 陈俊凌. W-TiC合金面对等离子体材料及其电子束热负荷实验研究[J]. 稀有金属材料与工程, 2010, 39(4): 429-433.

ZHONG Fa-li, YU Fu-wen, CHEN Jun-ling. W-TiC alloy plasma facing materials and heat flux performance test under electron beam facility[J]. Rare Metal Materials and Engineering, 2010, 39(4): 429-433.

[8] 朱玲旭, 燕青芝, 郎少庭, 徐 磊, 葛昌纯. 钨基面向等离子体材料的研究进展[J]. 中国有色金属学报, 2012, 22(12): 3522-3528.

ZHU Ling-xu, YAN Qing-zhi, LANG Shao-ting, XU Lei, GE Chang-chun. Research progress of tungsten-base materials as plasma facing materials[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3522-3528.

[9] TAN Jun, ZHOU Zhang-jian, ZHU Xiao-peng, GUO Shuang-quan, QU Dan-dan, LEI Ming-kai, GE Chang-chun. Evaluation of ultra-fine grained tungsten under transient high heat flux by high-intensity pulsed ion beam[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1081-1085.

[10] 范景莲, 龚 星, 祁美贵, 刘 涛, 黄伯云. 细晶钨合金的制备与动态失效行为[J]. 中国有色金属学报, 2009, 19(12): 2143-2148.

FAN Jing-lian, GONG Xing, QI Mei-gui, LIU Tao, HUANG Bai-yun. Fabrication of fine-grain tungsten heavy alloy and its dynamic failure behavior[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(12): 2143-2148.

[11] KAJIOKA M, SAKAMOTO T, NAKAI K, KOBAYASHI S, KURISHITA H, MATSUO S, ARAKAWA H. Effects of plastic working and MA atmosphere on microstructures of recrystallized W-1.1%TiC[J]. Journal of Nuclear Materials, 2011, 417: 512-515.

[12] CUI K, SHEN Y Z, YU J, JI B. Microstructural characteristics of commercial purity W and W-1%La2O3 alloy[J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 143-151.

[13] LEE D, UMER M A, RYU H J, HONG S H. The effect of HfC content on mechanical properties HfC-W composites[J]. International Journal of Refractory Metals and Hard Materials, 2014, 44: 49-53.

[14] LEE D, UMER M A, RYU H J, HONG S H. Elevated temperature ablation resistance of HfC particle-reinforced tungsten composites[J]. International Journal of Refractory Metals and Hard Materials, 2014, 43: 89-93.

[15] ZHANG T Q, WANG Y J, ZHOU Y, SONG G M. High temperature electrical resistivities of ZrC particle-reinforced tungsten-matrix composites[J]. International Journal of Refractory Metals and Hard Materials, 2010, 28: 498-502.

[16] MATSUO S, KURISHITA H, ARAKAWA H, OGAWA T, HASEGAWA A, ABE K, ARAKAWA H, MATSUO S, TAKIDA T, TAKEBE K, KAWAI M, YOSHIDA N. Deformability enhancement in ultra-fine grained, Ar-contained W compacts by TiC additions up to 1.1%[J]. Materials Science and Engineering: A, 2008, 492: 475-480.

[17] XIA M, YAN Q Z, XU L, GUO H Y, ZHU L X, GE C C. Bulk tungsten with uniformly dispersed La2O3 nanoparticles sintered from co-precipitated La2O3/W nanoparticles[J]. Journal of Nuclear Materials, 2013, 434: 85-89.

[18] XIA M, YAN Q Z, XU L, ZHU L X,GUO H Y, GE C C. Synthesis of TiC/W core-shell nanoparticles by precipitate-coating process[J]. Journal of Nuclear Materials, 2012, 430: 216-220.

[19] WAHLBERG S, YAR M A, ABUELNAGA M O, SALEM H G, JOHNSSON M, MUHAMMED M. Fabrication of nanostructured W-Y2O3 materials by chemical methods[J]. Journal of Materials Chemistry, 2012, 22: 12622-12628.

[20] YAR M A, WAHLBERG S, BERGQVIST H, SALEM H G, JOHNSSON M, MUHAMMED M. Chemically produced nanostructured ODS–lanthanum oxide–tungsten composites sintered by spark plasma[J]. Journal of Nuclear Materials, 2011, 408: 129-135.

[21] 崔教林, 杨 炜, 赵伟敏, 徐雪波. SPS法制备p-型四元Al-Bi-Sb-Te合金的微结构与热电性能[J]. 中国有色金属学报, 2005, 15(10): 1526-1531.

CUI Jiao-lin, YANG Wei, ZHAO Wei-min, XU Xue-bo. Microstructures and thermoelectric properties of p-type quaternary Al-Bi-Sb-Te alloys prepared by spark plasma sintering[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(10): 1526-1531.

[22] XIAO Shu-long, XU Li-juan, YU Hong-bao, TIAN Jing, CHEN Yu-yong. Microstructure and mechanical properties of Ti-45Al-5.5(Cr,Nb,B,Ta) alloy sintered at different SPS temperatures[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2960-2964.

[23] ZHANG Zhao-hui, SHEN Xiang-bo, WANG Fu-chi, WEI Sai, LI Shu-kui, CAI Hong-nian. Microstructure characteristics and mechanical properties of TiB/Ti-1.5Fe-2.25Mo composites synthesized in situ using SPS process[J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2598-2604.

[24] 谈 军, 周张健, 屈丹丹, 马 垚, 李 明. 放电等离子烧结制备超细晶粒W-TiC复合材料[J]. 稀有金属材料与工程, 2011, 40(11): 1990-1993.

TAN Jun, ZHOU Zhang-jian, QU Dan-dan, MA Yao, LI Ming. Fabrication of Ultra Fine Grained W-TiC Composites by Spark Plasma Sintering[J]. Rare Metal Materials and Engineering, 2011, 40(11): 1990-1993.

(编辑 龙怀中)

基金项目:国际热核聚变实验堆(ITER)计划专项资助项目(2014GB121001,2010GB109004);中央高校基本科研业务费专项资金资助项目(2013HGCH0011)

收稿日期:2014-03-20;修订日期:2014-07-14

通信作者:吴玉程,教授,博士;电话:0551-62901012;E-mail: luolaima@126.com