螺旋锥齿轮HFT法加工的反调修正方法

唐进元,聂金安,王智泉

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:针对高精度螺旋锥齿轮制造的机床调整参数反调修正计算问题,基于机床、刀具结构与螺旋锥齿轮刀倾法加工原理,建立刀倾法加工的螺旋锥齿轮理论齿面方程、误差齿面方程和齿面法向误差的数学模型,给出全齿面法向误差曲面表达式。研究机床调整参数与全齿面法向误差的变化规律,建立机床调整参数与齿面误差关联规律,给出全齿面敏感系数矩阵和理论齿面法向误差的计算公式,使用序列二次规划法求得机床调整参数修正量最优解,以一套HFT制造工艺参数验证了提出的齿面反调修正方法的正确有效性。

关键词:螺旋锥齿轮;刀倾法;机床调整参数;法向误差;齿面修正

中图分类号:TH132 文献标志码:A 文章编号:1672-7207(2012)06-2142-08

Reverse correction of spiral bevel gear HFT method

TANG Jin-yuan, NIE Jin-an, WANG Zhi-quan

(State Key Laboratory of High Performance Complex Manufacturing, School of Mechanical and Electrical Engineering,

Central South University, Changsha 410083, China)

Abstract: To calculate the machine setting parameters correction for high precision HFT spiral bevel gear manufacturing, based on the machine tool and tool structure and the spiral bevel gear tilt method manufacturing principle, HFT spiral bevel gear theoretical tooth surface equation and error tooth surface equations,tooth surface normal error model were derived, and the whole tooth surface error surface expression was given. The relationship between machine setting parameters and the spiral bevel tooth surface normal error variation was set up. The entire tooth surface sensitivity coefficient matrix and the theoretical tooth surface normal error formula were established. The optimal solution of the machine setting parameters correction values was obtained by using the sequential quadratic programming method, and a set of the HFT manufacturing process parameters were used to verify the correct validity of the tooth surface correction method.

Key words: spiral bevel gears; tilt method; machine setting parameters; normal errors; flank correction

螺旋锥齿轮是一种重要的动力传输部件,其齿面结构极其复杂。要实现高速、低噪音、低振动等工作性能,对其精度要求非常高。在实际加工过程中,由机床各轴的运动误差、机床弹性变形、受热变形等因素引起的齿面误差不可避免[1-2]。为减少齿面误差,使制造齿面接近理论设计齿面,通过机床的切齿调整参数微量反调对齿面误差进行补偿是提高螺旋锥齿轮制造精度的重要途径。Litvin等[3-5]分析了机床调整参数误差对齿面接触区位置、齿轮传动性能的影响,提出了最优机床调整参数的选择;王小椿等[6]基于三坐标测量机提出了利用差曲面特征参数修正齿面的方法,但没有分析各项机床调整参数对齿面的影响;李丽霞等[7]用数值法分析了机床调整误差对弧齿锥齿轮大轮齿面形状的影响规律,但没有分析加工更加复杂的小轮。采用刀倾法加工螺旋锥齿轮小轮时,机床调整计算最复杂,调整参数多达10多项,螺旋锥齿轮的齿面修正与高精度制造是螺旋锥齿轮制造中的瓶颈,关于刀倾法加工螺旋锥齿轮通过反调修正提高制造精度的问题至今没有得到解决。在此,本文作者基于齿轮啮合原理与刀倾法加工原理,根据机床结构模型,建立螺旋锥齿轮理论齿面和误差齿面方程,推导齿面法向误差的表达式。通过建立全齿面法向误差曲面,研究各项机床调整参数对齿面误差的变化规律,确定齿轮加工过程中对齿面影响较大的调整参数。通过建立齿面敏感系数矩阵,采用序列二次规划法,求得机床调整参数修正量最优解,以便实现刀倾法加工小轮的高精度齿面误差修正。

1 HFT加工方法下的螺旋锥齿轮齿面方程

以机床调整参数设置最为复杂的HFT(Hgpoid fomate tilt)加工方法为对象,基于包络制造原理,推导与建立螺旋锥齿轮齿面方程。

1.1 刀具方程的建立

GLEASON齿制刀盘形状简单,为圆锥状,刀具切削面如图1所示,圆弧和顶刃和侧刃的连接处是平滑相切的[8]。刀尖圆弧方程为:

(1)

(1)

刀尖圆弧的法矢为:

(2)

(2)

侧刃方程为:

(3)

(3)

侧刃的法矢为:

(4)

(4)

其中: ;sp为刀刃到刀尖的长度;λf为刀尖圆角;Rp,ρf和αp分别为刀尖半径、刀尖圆弧半径和刀具齿形角,其值由所选的刀具决定。切凹面时用外刀刃,Xf的计算公式取上面的符号;切凸面用内刀刃,Xf的计算公式取下面的符号。

;sp为刀刃到刀尖的长度;λf为刀尖圆角;Rp,ρf和αp分别为刀尖半径、刀尖圆弧半径和刀具齿形角,其值由所选的刀具决定。切凹面时用外刀刃,Xf的计算公式取上面的符号;切凸面用内刀刃,Xf的计算公式取下面的符号。

图1 刀刃几何图形

Fig.1 Geometric figures of blade

1.2 机械型机床结构下的螺旋锥齿轮齿面模型

根据机床设置和加工状况,建立如图2所示的一组坐标系[9]。其中:so(xo,yo,zo)为与床身固定连接的坐标系;sc(xc,yc,zc)为与摇台固定连接的坐标系,且原点在摇台中心;sb(xb,yb,zb)为与刀盘固定连接的坐标系;sp(xp,yp,zp)为与工件固定连接的坐标系;se(xe,ye,ze)为与工件箱固定连接的坐标系;sn(xn,yn,zn)为与床鞍固定连接的坐标系,其原点On在so中用坐标(0,-Em,Xb)来表示;sq(xq,yq,zq)是过渡坐标系,各轴与Sn的各轴平行,其原点Oq在sn中的坐标为(X1,0,0);加工时,sc绕zc轴转角度q,sp绕xp轴转角度fp,se绕ye轴转角度rm。

根据齐次坐标变换可求得 和

和 。其中:

。其中: 为标架St到Sp的旋转变换矩阵;

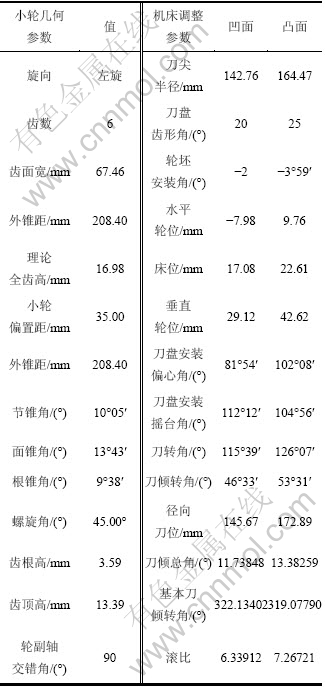

为标架St到Sp的旋转变换矩阵; 为轮坯轴交错点到刀盘中心在轮坯坐标系下的矢量长度;下标p和t分别代表轮坯和刀具坐标系;上标G代表传统机床;ζk为传统机床各调整参数,见表1。表1中:q为摇台旋转角;i为总刀倾角;j为基本刀转角;Em为垂直轮位;Sd为径向刀位;rm为安装根锥角;X1为水平轮位;Xb为床位;Rp为刀具半径;αp为刀具齿形角。

为轮坯轴交错点到刀盘中心在轮坯坐标系下的矢量长度;下标p和t分别代表轮坯和刀具坐标系;上标G代表传统机床;ζk为传统机床各调整参数,见表1。表1中:q为摇台旋转角;i为总刀倾角;j为基本刀转角;Em为垂直轮位;Sd为径向刀位;rm为安装根锥角;X1为水平轮位;Xb为床位;Rp为刀具半径;αp为刀具齿形角。

图2 螺旋锥齿轮机床加工坐标系

Fig.2 Coordinate of traditional spiral bevel gear machine tool

传统机械式机床由刀具到轮坯坐标系的转换矩阵如下:

(5)

(5)

其中: 为1个3阶旋转变换矩阵,矩阵的各个元素的表达式如式(6)所示;

为1个3阶旋转变换矩阵,矩阵的各个元素的表达式如式(6)所示; 为1个长度矢量,矢量的表达式如式(7)所示,它们的元素都包含机床调整参数,其中:cos=c;sin=s;q=θ0+wc·t;fp=i01·wc·t;θ0为初始摇台角;wc为摇台角速度;i01为滚比。

为1个长度矢量,矢量的表达式如式(7)所示,它们的元素都包含机床调整参数,其中:cos=c;sin=s;q=θ0+wc·t;fp=i01·wc·t;θ0为初始摇台角;wc为摇台角速度;i01为滚比。

(6)

(6)

(7)

(7)

1.3 齿面方程建立

机床坐标系如图2所示。切削过程的计算可以转变为求产形轮方程及确定刀具与轮坯的相对位置和相对运动[10]。可以推导得刀具切削面在轮坯运行坐标系下的方程为:

(8)

(8)

在轮坯坐标系下,2个运动坐标系在P点的相对速度为:

(9)

(9)

切削点的法矢在轮坯坐标系下表示为:

(10)

(10)

其中:i为1和2,分别表示侧刃和刀尖的法矢。则齿面加工过程中各点啮合方程为:

(11)

(11)

求解上式可得:

(12)

(12)

将式(12)代入式(8)得:

(13)

(13)

式(13)为2个参变量表示的理论齿面表达式,通过离散θ和t的取值便可计算出齿面的点矢量。

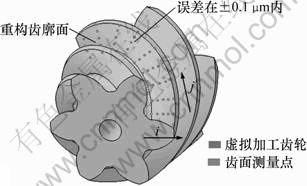

以表1所示的齿轮与机床参数,求得小轮齿面方程。在MATLAB中编制程序[11],计算齿面上的离散点,导入三维软件中,拟合出齿面[12],并建立三维几何模型,结果如图3所示。按照格里森测量全齿面误差方法[13],选取如图3所示的45个点,与GLEASON公司计算的理论齿面在齿面法矢方向的偏差在±1×10-4 mm以内,结果表明采用本文方法所得齿面与GLEASON公司理论齿面相吻合。

表1 轮坯设计与机床调整参数(HFT调整卡)

Table 1 Wheel blank design and machine setting parameters (a set of HFT)

图3 小轮几何模型

Fig.3 Geometric model of pinion

2 齿面法向误差求解

齿面误差的实际来源是加工过程中刀盘的形位误差以及机床各个轴的空间误差[14]。由以上齿面方程的建立过程可知:齿面上的点矢量是关于机床调整参数的函数,齿面上任一点的误差可以看作是该点矢量函数的微分增量在该理论点法矢方向的投影。

2.1 误差齿面方程的建立

当机床调整参数存在误差时,它偏离了理论设计值,设为 ,有误差的各机床调整参数可用下面方程表示:

,有误差的各机床调整参数可用下面方程表示:

(14)

(14)

其中:ΔRp,ΔEm,ΔIx,ΔJ,ΔXb,ΔX1,Δi01,Δrm,Δαp,Δbt和ΔQ为偏离理论设计值的各机床调整参数误差量,用符号∑i表示;i01为滚比;bt为安装偏角;Q为安装摇台角;Ix为刀倾转角;J为刀转角。则在包含误差的情况下,转换矩阵为M′pt,其中参数为包含有误差的机床调整参数,则小轮误差齿面方程为:

(15)

(15)

2.2 差曲面的建立

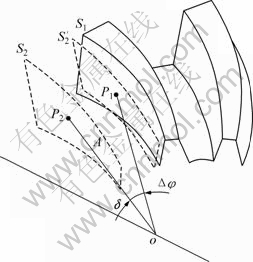

齿面误差分解示意图如图4所示。其中:S1表示理论齿面;S2表示各项机床误差综合影响得到的实际齿面;齿面S1与齿面S2间的偏差为齿面整体误差。在齿面误差分解过程中,将齿面S2绕其轴线旋转适当角度Δφ得到齿面S2′。设S2′节点与理论齿面S1节点P1重合,则齿面S2与齿面S2′间的误差可以理解为由齿轮加工中分度误差引起的齿距误差Δφ,齿面S2′与理论齿面S1间的误差为齿形误差,用δR表示[14]。

图4 齿面误差分解示意图

Fig.4 Decomposition of tooth-surface error

在实际加工过程中对齿面误差实施修正时,三坐标测量机所测得的就是齿形误差δR。因此,在计算法向误差过程中,必须对所设理论齿面进行适当调整使得实际齿面节点与理论齿面节点位置重合,使所求法向误差为齿形误差。

设齿轮轴向为X轴,OP1方向为Y轴,Z轴符合右手法则。以节点P1为齿面测量的中点,对整个齿面进行测量规划,确定测量范围和测量步长,可计算出对应测量点的锥距A和锥角δ。通过式(16)求出与之对应的理论齿面点P1(TPx,TPy,TPz)及其所对应的参数Sp1,θ1和t1。

(16)

(16)

将Sp1,θ1和t1代入式(15),可得到误差齿面S2对应点P2,其点矢量为:

(17)

(17)

设理论齿面与实际齿面的齿距误差为Δφ,将实际齿面绕轴线x轴旋转Δφ,实际齿面上节点与理论齿面节点重合,因此,有:

(18)

(18)

求解式(18),计算出实际误差齿面与理论齿面的齿距误差Δφ。实际齿面绕其轴线旋转角度Δφ后得到误差齿面S2′,其齿面方程为:

(19)

(19)

齿面误差分解后的齿形误差为S2′与理论齿面S1间的法向误差。设理论齿面上1点的法矢为N,沿其法向到实际补偿齿面S2′距离为δR,则下式成立:

(20)

(20)

依次代入理论齿面上规划测量点处对应参数Sp,θ和t,即可求解出齿面测量点的齿形误差δR。

将理论齿面向过齿轮轴线的某一平面旋转投影,形成1个拓扑平面。在该拓扑平面上取齿宽和齿高方向分别为X轴和Y轴,其上任一点对应齿面点的法向误差值为该点的Z坐标值,则形成1个新的曲面,称为理论齿面与实际齿面之间的差曲面。根据工程实际测量规则一般沿齿宽方向取9排齿面点,每排取5个数据点,在齿面上均匀取45个点,分别求得对应点的法向误差δR,建立全齿面的差曲面[15]。

3 调整参数对齿面误差的影响

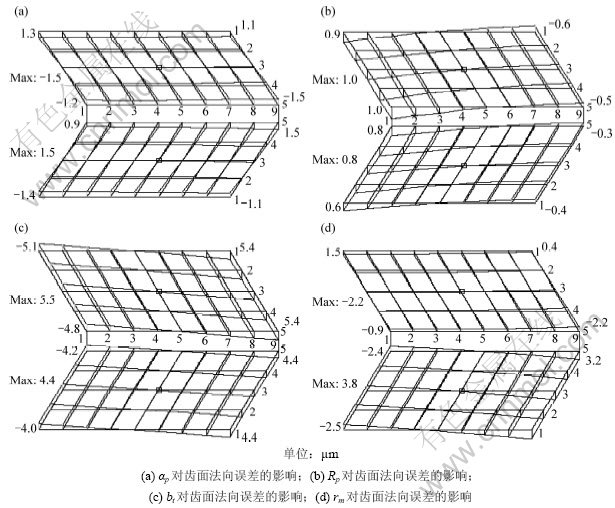

研究认为齿面误差可以用机床调整参数的微变量来表示,并建立对应的函数关系。研究过程中依次对各项机床调整参数进行微调[15],设其中位移调整参数的扰动为+0.01 mm,角度调整参数扰动为+1 s,无量纲调整参数扰动为+0.01。观察各项齿面误差的变化情况,从而找到对齿形误差影响较明显的机床调整参数。

本文以表2所示调整参数为例,分析各个调整参数的变化对齿面误差的影响,以便为齿面高精度反调修正提供参考初值。调整参数误差对齿面误差的影响规律如图5所示。

图5表明:不同调整参数误差对齿面误差的影响不同,对齿面不同部位的误差的贡献有大小和正负之分。在齿轮的实际加工过程中,可以通过分析实际齿面与理论齿面的法向误差的变化趋势,结合图5所示影响规律和幅值,得到对齿轮加工参数进行反调修正的初值整。

图5 调整参数误差对齿面法向误差的影响规律

Fig.5 Sensitivity of tooth flank to change of machine settings coefficients

4 基于序列二次规划法的齿面误差反调修正方法

由于各项调整参数对齿面误差的影响相互关联,其中耦合关系复杂,所以,本文所采用齿面修正方法并不考虑各项调整参数之间的关系,而是直接根据齿面测量点处的法向误差,根据已建立的机床调整参数变化量与齿面法向误差的关系模型,求出对应的齿面误差敏感系数矩阵,采用序列二次规划法求出调整参数修正量最优解。

4.1 敏感系数矩阵计算

理论齿面上任意1点的齿面误差可以认为是各项机床调整参数微小变化引起的齿面误差的叠加。

(21)

(21)

其在理论齿面法向方向的投影即法向误差为:

(22)

(22)

则全齿面测量点处的法向误差用矩阵形式表示为:

(23)

(23)

其中:Ti为理论齿面在第i点的表达式;δRi为理论齿面第i点的法向误差;δζj为第j项机床调整参数的微小变化;[Sij]为齿面第i点法向误差随第j项机床调整参数变化的敏感系数矩阵。

4.2二次规划求解调整参数修正量

在实际齿面修正过程中由于齿面取点数目比机床调整参数数目多,即p>>q,则式(23)方程组为超定方程组,通过常规方程求解是无法求得正确解的。本文研究过程采用序列二次规划方法(SQP)求得一组最优解[16],得到调整参数修正量。由式(24)确定优化函数如下:

(24)

(24)

即通过计算选择最优Δζj,使得代入齿面45个计算点参数后,式(24)计算结果的最大值最小化。在计算之前,还需要添加以下约束条件:

(25)

(25)

(26)

(26)

据式(25)可确定Δζk的搜索范围,据式(26)可确定迭代计算过程中各调整参数微变量的初值。

将通过人为设定调整参数误差计算出的齿面45点处的法向误差或者通过三坐标测量机测量的45点的法向误差代入式(24),得到机床调整参数修正量最优解使得齿面上各点最大法向误差最小。

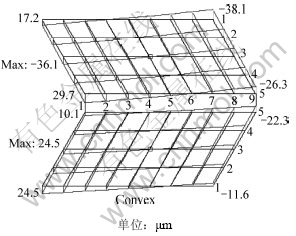

5 实例分析

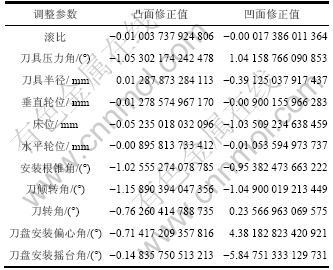

以表1所示轮坯设计参数和调整参数为例,设位移调整参数的扰动为+0.01 mm,角度调整参数扰动为+1 s,无量纲调整参数扰动为0.01,得到包含全部机床调整参数误差的差曲面如图6所示。其凸面最大法向误差为30 μm,凹面最大法向误差为-40 μm。采用以上述方法对该齿轮进行机床加工参数反调,得到调整参数的变化量如表2所示。

图6 最大法向误差修正前的差曲面

Fig.6 Flank form errors before correction

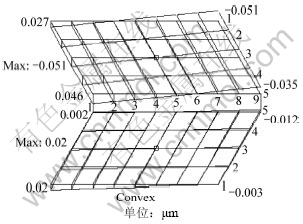

根据机床调整参数修正后的差曲面如图7所示。从图7可见:凸面最大法向误差为0.02 μm,凹面最大法向误差为0.05 μm,表明修正效果很好。

图7 机床调整参数修正后的差曲面

Fig.7 Flank form errors after correction

表2 调整参数的修正值

Table 2 Correction of machine setting parameters

6 结论

(1) 通过建立最为复杂的刀倾法加工螺旋锥齿轮的齿面数学模型,研究得到各项机床调整参数误差对齿面误差的影响规律。该规律为螺旋锥齿轮加工参数反调修正提供了正确的初值。

(2) 通过序列二次规划法,可求出满足高精度加工要求的调整参数反调量的最优解。由所提出的螺旋锥齿轮齿面高精度制造的反调修正方法正确可行,可用于螺旋锥齿轮高精度制造。

(3) 采用所提出的齿面反调修正方法实现任意螺旋锥齿轮高精度加工,为螺旋锥齿轮的制造提供了科学方法。

参考文献:

[1] 罗筱英, 唐进元. 结构参数对砂轮主轴系统动态性能的影响 [J]. 机械工程学报, 2007, 43(3): 128-134.

LUO Xiao-ying TANG Jin-yuan. Effect of structure parameters on dynamic properties of spindle system[J]. Chinese Journal of Mechanical Engineering, 2007, 43(3): 128-134.

[2] 曾韬. 螺旋锥齿轮设计与加工[M]. 哈尔滨: 哈尔滨工业大学出版社, 1989: 91-94.

ZENG Tao. Design and processing of the spiral bevel gear[M]. Harbin: Press of Harbin Institute of Technology, 1989: 91-94.

[3] Litvin F L, Tsung W, Coy J, et al. Generated spiral bevel gears: Optimal machine-tool settings and tooth contact analysis[J]. SAE Transactions, 1985, 94(5): 877-884.

[4] 唐进元, 卢延峰, 周超. 有误差的螺旋锥齿轮传动接触分析 [J]. 机械工程学报, 2008, 44(7): 16-23.

TANG Jin-yuan, LU Yan-feng, ZHOU Chao. Error tooth contact of analysis of spiral bevel gears transmission[J]. Chinese Journal of Mechanical Engineering, 2008, 44(7): 16-23.

[5] 唐进元, 卢延峰, 周超. 调整参数误差对齿面接触质量的影响[J]. 航空动力学报, 2008, 23(9): 1718-1723.

TANG Jin-yuan, LU Yan-feng, ZHOU Chao. Effect of machine tool adjustment parameter errors on spiral bevel gears tooth contact quality[J]. Journal of Aerospace Power, 2008, 23(9): 1718-1723.

[6] 王小椿, 王军, 姜虹, 等. 螺旋锥齿轮的齿面测量及机床加工参数修正[J]. 机械工程学报, 2003, 39(8): 125-128.

WANG Xiao-chun, WANG Jun, JIANG Hong, et al. Tooth surface measurement and machine-settings correction of spiral bevel gear[J]. Chinese Journal of Mechanical Engineering, 2003, 39(8): 125-128.

[7] 李丽霞, 李培军, 刘新状. 机床调整误差对弧齿锥齿轮大轮齿面形状影响规律的研究[J]. 机械传动, 2006, 30(4): 13-15.

LI Li-xia, LI Pei-jun, LIU Xin-zhuang. Research on the influence of the gear tooth surface shape of spiral bevel gear by adjustment error of machine tool[J]. Journal of Mechanical Transmission, 2006, 30(4): 13-15.

[8] Litvin F L, Fuentes A. Gear geometry and applied theory[M]. London: Cambridge University Press, 2004: 83-150.

[9] Kawasaki K. Effect of cutting edge profile on meshing and contact of spiral bevel gears in cyclo-palloid system[J]. Mechanics Based Design of Structures and Machines, 2005, 33(3/4): 343-357.

[10] Lin C, Tsay C, Fong Z. Computer-aided manufacturing of spiral bevel and hypoid gears by applying optimization techniques[J]. Journal of Materials Processing Tech, 2001, 114(1): 22-35.

[11] 唐进元, 曹康, 杜晋, 等. 含过渡曲面的弧齿锥齿轮齿面精确建模[J]. 机械科学与技术, 2009, 28(3): 317-321.

TANG Jin-yuan, CAO Kang, DU Jin, et al. Method of accurate modeling of hypoid gear with fillet[J]. Mechanical Science and Technology, 2009, 28(3): 317-321.

[12] 蒲太平, 唐进元. 基于 CATIA V5 的圆柱齿轮虚拟加工研究[J]. 系统仿真学报, 2008, 20(16): 4339-4343.

PU Tai-ping, TANG Jin-yuan. Virtual machining process research of spur-gear based on CATIA V5[J]. Journal of System Simulation, 2008, 20(16): 4339-4343.

[13] Simon V. Computer simulation of tooth contact analysis of mismatched spiral bevel gears[J]. Mechanism and Machine Theory, 2007, 42(3): 365-381.

[14] 周超, 唐进元, 曾韬, 等. 螺旋锥齿轮磨齿机砂轮位置误差与齿轮齿面误差的关系[J]. 机械工程学报, 2008, 44(2): 94-101.

ZHOU Chao, TANG Jin-Yuan, ZENG Tao, et al. Relationship between grinding wheel and tooth surface error[J]. Chinese Journal of Mechanical Engineering, 2008, 44(2): 94-101.

[15] 唐进元, 曹康, 周超, 等. 小轮齿面误差与调整参数误差敏感性研究[J]. 航空动力学报, 2009, 24(9): 20-30.

TANG Jin-yuan, CAO Kang, ZHOU Chao, et al. Research on the sensitivity between the machine setting parameter errors and the spiral bevel gears surface errors[J]. Journal of Aerospace Power, 2009, 24(9): 20-30.

[16] WANG Yong-li, CHEN Li-feng, HE Guo-ping. Sequential systems of linear equations method for general constrained optimization without strict complementarity[J]. Journal of Computational and Applied Mathematics, 2005, 182(2): 447-471.

(编辑 陈灿华)

收稿日期:2011-07-10;修回日期:2011-09-27

基金项目:国家重点基础研究发展规划(“973”计划)项目(2005CB724100);国家自然科学基金资助项目(50875263)

通信作者:唐进元(1962-),男,湖南永州人,博士研究生,教授,从事数字化制造、齿轮动力学的研究;电话:0731-88876350;E-mail:jytangcsu@163.com