文章编号:1004-0609(2011)08-1887-06

Ni3Al基合金IC6与变形合金GH3030间

真空钎焊接头的组织与力学性能

王玉叶1,李树索1,于静静1,韩雅芳1, 2

(1. 北京航空航天大学 材料科学与工程学院,北京 100191;

2. 北京航空材料研究院,北京 100095)

摘 要:将两种Ni基钎料ВПР24和GHL-6-2用于IC6合金与变形高温合金GH3030之间的真空钎焊,分析接头钎缝和近缝区母材的微观组织,测试接头的900 ℃高温持久寿命,并对断口纵剖面微观组织进行分析。结果表明:ВПР24对近缝区母材组织没有明显的影响;GHL-6-2中降熔元素B含量较高,导致钎缝两侧近缝区母材析出大量针状硼化物相,严重影响了接头组织及性能,其900 ℃、22 MPa持久寿命仅73 h;而使用ВПР24的接头的900 ℃、22 MPa持久寿命为361 h,并最终断于母材GH3030,可见,使用ВПР24的接头钎缝处的持久性能比GH3030基体合金的更好。

关键词:IC6合金;GH3030;真空钎焊;接头;组织;持久寿命

中图分类号:TG457.19 文献标志码:A

Microstructure and mechanical properties of vacuum brazing joint between Ni3Al-based alloy IC6 and wrought superalloys GH3030

WANG Yu-ye1, LI Shu-suo1, YU Jing-jing1, HAN Ya-fang1, 2

(1. School of Materials Science and Engineering, Beihang University, Beijing 100191, China;

2. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: Two Ni-based filler metals ВПР24 and GHL-6-2 used to produce Ni-based superalloys blades and vanes were used on vacuum barzing between alloy IC6 and wrought superalloys GH3030. The microstructures of bonding seam and base metal nearby were observed, and endurance life at 900 ℃ was tested. The results show that ВПР24 has no significant effect on the microstructure of the base metal near the bonding seam. Due to a high borocic content in GHL-6-2, much acerose borides bring a bad effect on the properties of the joint precipitate in the base metal next to the bonding seam. The 900 ℃, 22 MPa stress rupture life of joint using GHL-6-2 is 73 h while that of the joint using ВПР24 is 361 h. The joint using ВПР24 finally breaks in the base metal GH3030. This indicates that the endurance of the joint is better than that of the base metal GH3030.

Key words: alloy IC6; GH3030; vacuum brazing; joints; microstructure; endurance life

Ni3Al基合金IC6成分简单、成本低廉、综合性能好,是一种理想的航空发动机叶片材料,适用于制作工作温度1 100 ℃左右的高温结构件,并用以制作航空发动机涡轮叶片[1-2]。在航空发动机涡轮叶片的制造过程中,真空钎焊因其低成本低、污染高、成品率等优点,已成为不可缺少的关键技术[3-4],对于焊接成型的叶片来说,焊缝组织及其性能对整个叶片的性能和使用寿命都非常重要[5]。目前,对高温合金焊接接头组织的研究较多,主要集中在焊缝的原始组织和性能上[6-11],也有研究专注于钎焊条件对钎缝组织的影 响[12-13],但针对IC6合金真空钎焊的研究报道较少, IC6合金与异种材料之间的钎焊接头组织和性能的研究需要进行更深入的研究[14]。本文作者研究了使用不同钎料钎焊时IC6合金与变形高温合金GH3030间接头的组织与力学性能,进一步探索IC6合金的钎焊工艺。

1 实验

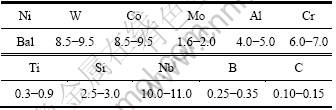

实验用母材为IC6母合金和GH3030合金,其中IC6成分(质量分数,%)为Ni-7.61Al-14.175Mo-0.024B- 0.01C,GH3030成分范围为Ni-(≤0.15)Al-(19-22)Cr- (0.15-0.35)Ti-(≤1.5)Fe-(≤0.12)C。采用定向凝固法制备IC6合金铸态试棒毛坯,然后经过1 260 ℃、10 h真空热处理并空冷,再进行喷砂处理,得到试验用试样。变形高温合金为直径20 mm的棒材。选用在高温合金钎焊中使用最为广泛的两种Ni基钎料ВПР24和GHL-6-2,其化学成分如表1和2所列。

表1 Ni基钎料ВПР24的化学成分

Table 1 Chemical compositions of filler metals used in experiments (mass fraction, %)

表2 GHL-6-2钎料的化学成分

Table 2 Chemical compositions of GHL-6-2 filler (mass fraction, %)

真空钎焊接头采用对接接头。待焊试样接边处开两面施焊的45°坡口,以便较容易地送入钎料,钎缝选取0.1 mm,在待焊的两试样之间垫厚度为0.1 mm的钢板以保证间隙,并用氩弧点焊定位后取出钢板,将钎料置于坡口处。为防止钎料熔化后流失,在钎缝两侧涂以Al2O3阻流剂。

使用日本JEOL的JSM-5600HV/LV型扫描电镜、JXA-8100型电子探针(EPMA)及其能谱(EDS)、波谱(WDS)对钎焊接头组织进行分析;使用GWT304高温持久试验机测试接头的持久寿命。

2 钎焊接头组织

2.1 使用钎料ВПР24的钎缝组织

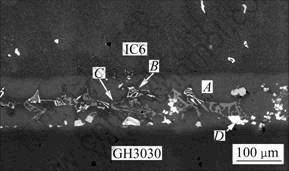

使用钎料ВПР24时IC6与GH3030间接头组织如图1所示。由图1可知,钎缝组织由钎缝两侧靠近母材的灰色钎缝基体(见图1中A)、在钎缝中央不连续分布的白色骨架状相(见图1中B)和连续分布的灰色骨架状相(见图1中C)、以及一些块状的白亮相(见图1中D)组成,各相的EDS成分分析结果如表3所列。可以判定灰色的钎缝基体为Ni基固溶体;M3B2硼化物相形态常呈骨架状或羽毛状,白色骨架状相的能谱分析表明x(Ni)/x(Mo)=1:2,结合EDS分析结果(见图2)认为该相为硼化物相;灰色骨架相为富含Nb的Ni3Si相;白色块状相为富含W和Ni 的高温初生相,判断为含硅的硼化物或碳化物(MC或M6C) 相或者硼碳化物相。

图1 使用ВПР24真空钎焊时IC6合金与GH3030间对接头的微观组织形貌

Fig.1 Back scattered electron (BSE) image of vacuum brazed joint between IC6 and GH3030 with ВПР24 filler

表3 图1所示钎缝中各相成分的EDS分析结果

Table 3 EDS analysis results of phases component in bonding seam shown in Fig.1

2.2 使用钎料GHL-6-2的钎缝组织

使用GHL-6-2钎焊料时IC6合金与GH3030间接头的微观组织如图3所示。由图3可知,钎缝与GH3030界面不明显,对图3(b)中的相A,B,C,D,E的EDS成分分析如表4所列,结合EDS分析(见图4)可知,钎缝两侧为Ni基固溶体(见图3(b)中的A相),钎缝中央出现大块葵花状Ni3B-Ni3Si共晶(见图3(b)中的B相),共晶Ni3Si被丝状的Ni3B分割成大块状,共晶内的成分分布不均匀,在Ni3B-Ni3Si共晶边缘出现初熔区(见图3(b)中的C相),并且Ni3B-Ni3Si共晶边缘出现的黑色相D和E是两种Ni、Mo含量不同的富Cr相。

2.3 近缝区母材组织

使用不同钎焊料时试样钎缝两侧近缝区的母材组织如图5所示。从图5(a)和(b)可以看出,使用ВПР24钎焊料的GH3030/IC6试样中,IC6一侧近缝区组织与IC6母材原始组织无明显差异,没有出现明显的过渡区;GH3030一侧近缝区也没有出现明显的过渡区。从图5(c)可以看出,使用GHL-6-2钎焊料的GH3030/IC6试样中,IC6一侧近缝区存在宽度约30 μm的影响区,由钎缝向母材的方向依次为宽度约10 μm的连续的絮状硼化物,宽度约20 μm的针状和棒状硼化物相富集层,这些密集分布的针状硼化物相的析出具有一定的取向性,沿垂直于钎缝方向的夹角约为30°。元素面扫描结果显示絮状硼化物富集层的Al含量低于针状硼化物富集区域的,这是由于在连接温度下,GHL-6-2中Al元素含量很低,连接过程中,母材中的Al元素向钎缝溶解扩散,靠近钎缝的母材出现贫Al的区域。靠近钎缝形成的呈细针状或小棒状交叉有序排列的硼化物主要为(Ni21Mo2)(B,C)6。由于母材的溶解扩散,在连接界面上的细针或小棒状的硼化物逐渐溶解消失,形成絮状。由于GHL-6-2中B含量较高,近缝区部位的枝晶干B含量已超过其溶解度,因此,在枝晶间和枝晶干部位均有硼化物形成。图5(d)显示GH3030一侧近缝区存在宽度为15~20 μm的影响区,影响区中黑色富铬相呈不规则富集。

图2 使用ВПР24钎焊时IC6与GH3030间接头组织的EDS元素线分布

Fig.2 EDS elements line distribution of joint between IC6 and GH3030 with ВПР24 filler

表4 图3(b)钎缝中各相成分的EDS分析结果

Table 4 EDS analysis results of phases component in bonding seam shown in Fig.3(b)

图3 使用GHL-6-2真空钎焊时IC6合金与GH3030对接接头的微观组织形貌

Fig.3 BSE images of vacuum brazed joint between IC6 and GH3030 with GHL-6-2: (a) Whole zone; (b) Magnified image of Fig.3(a)

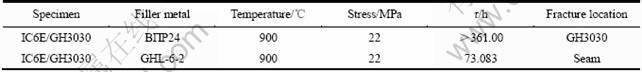

3 钎焊接头的高温持久性能

由于IC6 合金本身的高温持久性能远优于GH3030的[15],选用IC6系列合金中性能较差的等轴晶IC6E与GH3030进行900 ℃较低应力条件下的高温持久试验,GH3030/IC6E试样接头组织与GH3030/IC6试样的一致,IC6合金的晶型改变并没有对钎缝组织产生影响。根据GH3030冷轧钢板标准热处理状态的持久应力—寿命曲线[1],选用900 ℃下50 h持久寿命对应的应力22 MPa作为试验应力。持久试验结果如表5所列,在900 ℃、22 MPa条件下,ВПР24钎焊接头的持久强度已经远高于GH3030母材的,试样断裂于GH3030母材上,持久寿命高于361 h;而GHL-6-2钎焊接头断于钎缝处,接头持久寿命只有73 h。使用GHL-6-2钎焊料的GH3030/IC6E接头试样,在高温持久试验中裂纹产生并沿钎缝中央的Ni3B-Ni3Si共晶晶界扩展断裂,IC6E一侧钎缝基体和近缝区母材组织没有明显变化,靠近GH3030一侧钎缝基体出现二次裂纹并扩展,近缝区GH3030母材发生明显的塑性变形,部分富铬相聚集长大并偏聚于晶界和母材与钎缝的界面上。

图4 使用GHL-6-2钎焊时IC6与GH3030间接头组织EDS元素线分布

Fig.4 EDS elements line distribution of joint between IC6 and GH3030 with GHL-6-2 filler

图5 使用不同钎料时近缝区母材的微观组织形貌

Fig.5 BES image of base metal next to bonding seam with different filler metals: (a), (b)ВПР24; (c), (d) GHL-6-2

表5 接头900 ℃、22 MPa高温持久性能数据

Table 5 Stress rupture properties data of joint under 900 ℃ and 22 MPa

4 结论

1) IC6E/GH3030使用钎料ВПР24的钎焊接头钎缝主要由Ni基固溶体、M3B2硼化物Mo2NiB2、富含Nb的Ni3Si相、白色块状富含W 和Ni 且含Si的硼化物或碳化物或者硼碳化物相组成。

2) IC6E/GH3030使用钎料GHL-6-2的钎焊接头钎缝主要由Ni基固溶体、Ni3B-Ni3Si共晶、Ni3B-Ni3Si共晶边缘的初熔区以及一些其他化合物相组成。

3) ВПР24对近缝区母材组织没有明显的影响;GHL-6-2由于降熔元素B含量较高,导致钎缝两侧近缝区母材析出大量针状硼化物相,严重影响了接头组织及性能。

4) GHL-6-2接头900 ℃、22 MPa持久寿命仅为73 h,并且接头均断于钎缝;ВПР24接头900 ℃、22 MPa持久寿命达361 h,并且断于变形高温合金母材,可见,ВПР24接头具有足够的强度,并且现有工艺已可以满足IC6合金钎焊应用要求。

REFERENCES

[1] ABDELFATAH M M, OJO O A. On the extension of processing time with increase in temperature during transient-liquid phase bonding[J]. Metallurgical and Materials Transaction A, 2009, 40: 377-380.

[2] 周瑞发, 韩雅芳, 李树索. 高温结构材料[M]. 北京: 国防工业出版社, 2006: 165-168.

ZHOU Rui-fa, HAN Ya-fang, LI Shu-suo. High temperature structure materials[M]. Beijing: National Defense Industry Press, 2006: 165-168.

[3] ZHANG Qiu-ming, HE Xiao-dong. Microstructural evolution and mechanical properties of a nickel-based honeycomb sandwich[J]. Materials Characterization, 2009, 60(3): 178-182.

[4] 高 磊. 真空钎焊工艺应用与研究[J]. 科技创新导报, 2008, 27: 72.

GAO Lei. Application and research of vacuum brazing process[J]. Science and Technology Innovation Herald, 2008, 27: 72.

[5] GHONEIM A, OJO O A. On the influence of boron-addition on TLP bonding time in a Ni3Al-based intermetallic[J]. Intermetallics, 2010, 18: 582-586.

[6] 梁 海, 毛 唯, 孙计生. K465铸造高温合金高温钎焊接头的显微组织[J]. 材料工程, 2005, 9: 7-10.

LIANG Hai, MAO Wei, SUN Ji-sheng. Microstructures of high temperature brazed joints of cast superalloy K465[J]. Materials Engineering, 2005, 9: 7-10.

[7] 刘秀波, 虞 钢, 庞 铭, 张振国, 范积伟. K418高温合金和42CrMo合金钢的激光焊接[J]. 中国有色金属学报, 2008, 18(3): 444-448.

LIU Xiu-bo, YU Gang, PANG Ming, ZHANG Zhen-guo, FAN Ji-wei. Laser welding of superalloy K418 to 42CrMo steel[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 444-448.

[8] 毛 唯, 周 媛, 叶 雷, 梁 海. 不同钎料钎焊K465高温合金接头的组织和性能[J]. 电焊机, 2008, 38(9): 65-68.

MAO Wei, ZHOU Yuan, YE Lei, LIANG Hai. Microstructures and properties of K465 superalloy joints brazed with different filler metals[J]. Electric Welding Machine, 2008, 38(9): 65-68.

[9] 毛 唯, 李晓红, 叶 雷. 定向凝固Ni3Al基高温合金IC6A的真空钎焊[J]. 航空材料学报, 2006, 26(3): 103-106.

MAO Wei, LI Xiao-hong, YE Lei. Vacuum brazing of a directionally solidified Ni3Al-based high-temperature alloys IC6A[J]. Journal of Aeronautical Materials, 2006, 26(3): 103-106.

[10] 张丽霞, 冯吉才. GH3044镍基合金钎焊接头的界面组织和强度分析[J]. 材料科学与工艺, 2009, 17(6): 770-773.

ZHANG Li-xia, FENG Ji-cai. Interface structure and strength analysis of brazed GH3044 nickel-based alloy joint[J]. Materials Science and Technology, 2009, 17(6): 770-773.

[11] POURANVARI M, EKRAMI A, KOKABI A H. Microstructure development during transient liquid phase bonding of GTD-111 nickel-based superalloy[J]. Journal of Alloys and Compounds, 2008, 461(1/2): 641-647.

[12] 于治水, 石 昆, 李瑞峰. 钎焊温度对镍基合金真空钎焊接头组织及硬度的影响[J]. 金属铸锻焊技术, 2009, 17(6): 116-119.

YU Zhi-shui, SHI Kun, LI Rui-feng. Effects of brazing temperature on vacuum joint microstructure and microhardness of inconel superalloy[J]. Casting?Forging?Welding, 2009, 17(6): 116-119.

[13] 石 昆, 于治水, 李 军, 李瑞峰. 钎焊保温时间对GH738与GH4169镍基合金真空钎焊接头组织性能的影响[J].金属铸锻焊技术, 2010, 18(1): 112-115.

SHI Kun, YU Zhi-shui, LI Jun, LI Rui-feng. Effect of brazing holding time on microstructure and property of GH738/GH4169 vacuum brazing joint[J]. Casting?Forging?Welding, 2010, 18(1): 112-115.

[14] 刘庆瑔. Ni3Al基IC6高温合金工程应用研究[J]. 航空材料学报, 2003, 23(增刊): 209-214.

LIU Qing-quan. Engineering application research of Ni3Al-based high temperature alloy IC6[J]. Journal of Aeronautical Materials, 2003, 23(Supplement): 209-214.

[15] 刘 艳. GH3030合金成分组织与性能的研究[D]. 武汉: 武汉大学, 2001: 31-38.

LIU Yan. Research of composition, microstructure and properties of alloy GH3030[D]. Wuhan: Wuhan University, 2001: 31-38.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50971005)

收稿日期:2010-09-03;修订日期:2010-11-24

通信作者:李树索,副教授,博士;电话:010-82314488;E-mail: lishs@buaa.edu.cn