DOI: 10.11817/j.issn.1672-7207.2017.11.001

烧结过程中碱金属脱除及在颗粒物中的富集行为

范晓慧,何向宁,甘敏,周阳,季志云,李强

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

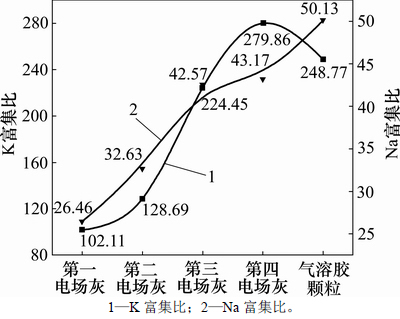

摘要:通过工业全流程采样分析烧结过程碱金属平衡,通过烧结杯实验研究K和Na的脱除行为及其影响因素,查明K和Na在不同粒径的颗粒物中的富集特性及赋存状态。研究结果表明:在烧结过程中,K和Na的脱除率分别为22.86%和8.70%,脱除的K和Na主要进入机头灰中,其次为机尾灰;燃料配比和碱度对碱金属脱除的影响最大,随着燃料配比和碱度提高,K和Na的脱除率增大,K和Na的脱除主要发生在料层中下部,烧结料层表层和底部的K和Na的脱除率低;K和Na随烟气进入颗粒物中,随着烟气颗粒物粒径减小,碱金属的质量分数和富集比增大,K和Na在第四电场灰中的富集比分别达279.86倍和43.17倍,在气溶胶颗粒中则分别达248.77倍和50.13倍; K和Na易与Cl元素汽化-凝结形成化合物,因而主要以氯化物存在于颗粒物中。

关键词:烧结;K;Na;脱除;赋存状态;富集特性

中图分类号:TF046 文献标志码:A 文章编号:1672-7207(2017)11-2843-08

Behavior of alkali metal removal and enrichment in particles during sintering process

FAN Xiaohui, HE Xiangning, GAN Min, ZHOU Yang, JI Zhiyun, LI Qiang

(School of Minerals Processing & Bioengineering, Central South University, Changsha 410083, China)

Abstract: Alkali balance in sintering process was investigated through analyzing the samples collected from the whole industrial process. Sinter pot tests were conducted to study the removal behaviors of K, Na and relevant influencing factors. The enrichment characteristics and occurrence states of K and Na in particles with different grain sizes were analyzed. The results show that the removal rates of K and Na are respectively 22.86% and 8.70% during the whole sintering process. Removed K and Na firstly go into the head ESP dust and then into the end ESP dust. Improving the ratio of fuel and basicity can increase the removal rates of K and Na. Additionally, the removal rates of K and Na are low in the upper layer and the lowest layer of the whole sintering bed, while the maximum removal rate is found in the middle-lower layer. K and Na go into particles along with gas flue. The content and enrichment ratios of K and Na in particles increase with the decrease of the particle size, and the enrichment ratios of K and Na reach 279.86 times and 43.17 times in the fourth electric field ash, and 248.77 times and 50.13 times in aerosol particle compared with those in raw materials. K and Na mostly exist in the form of chlorides in particles because they may form compounds with Cl element by vaporization- condensation.

Key words: sintering; potassium; sodium; removal; occurrence state; enrichment characteristics

碱金属(K和Na)对高炉炼铁的危害一直是钢铁生产关注的重点。碱金属在高炉内循环富集,会导致高炉结瘤、炉衬被侵蚀,且K和Na沉积在炉料表面会加剧烧结矿低温还原粉化和焦炭溶损,进一步影响高炉透气性和高炉顺行。近年来,不少钢铁企业因有害元素的问题导致高炉事故频发,甚至严重影响到炼铁生产[1-4]。我国高炉炼铁是以烧结矿为主、配加部分球团矿和块矿的炉料结构,其中烧结矿配比高达75%以上。铁矿烧结过程原料种类繁杂,在生产过程中,为控制生产成本,不可避免地会配加K和Na等有害元素含量较高的劣质矿石,以回收含铁粉尘。已有研究表明,K和Na在烧结过程中经过复杂的氧化还原反应,除有一部分以蒸汽状态进入烧结烟气外,质量分数超过80%的K和Na会随着烧结矿进入高炉[5-7]。由此可见,控制烧结矿K和Na质量分数是降低其对高炉冶炼危害性的关键。采用氯化烧结工艺有助于K和Na的脱除,该方法利用KCl,NaCl和金属氯化物如CaCl2(MgCl2)之间化学稳定性的差异,Ca2+将烧结矿和球团矿中的K+和Na+置换出来,新生成的KCl和NaCl与CaCl2相比有较低的熔点、较高的挥发性及更容易还原等性质,在高温条件下挥发并被废气流带走。但氯化烧结会降低烧结矿的冷强度[8-10],且K和Na进入烟气之后,凝结成细小颗粒附着于除尘灰,易堵塞和腐蚀设备[11-12]。关于K和Na如何随烧结料层迁移、K和Na在烧结过程中的流向未见详细报道。为此,本文作者对国内某烧结生产周期的原料及产物进行系统采样,分析样品中K和Na元素的质量分数及其赋存形式,并结合烧结试验,探究K和Na在烧结过程中的脱除行为及其在烟气颗粒物中的富集规律。

1 原料性能与试验方法

1.1 原料性能

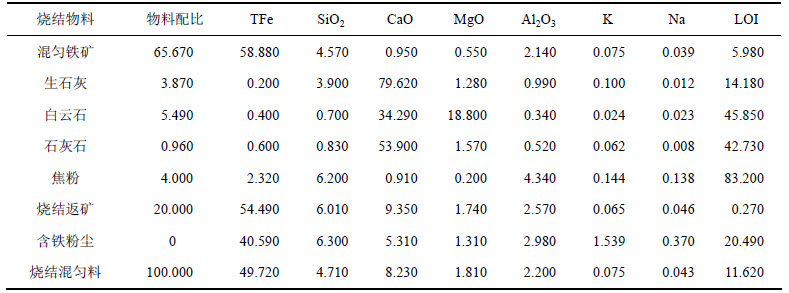

烧结试验所用原料包括铁矿、熔剂、返矿及燃料,其化学成分及配比见表1。烧结混合料中燃料质量分数为5%,返矿外配质量分数为25%,水分质量分数为8.0%,生产的烧结矿碱度R以及SiO2和MgO质量分数分别控制在1.72,5.21%和2.03%。由表1可以看出:铁矿、熔剂、燃料及返矿中均含有一定质量分数的K和Na,烧结混匀料中K和Na质量分数分别为0.075%和0.043%。在改变烧结工艺条件下配入的含铁粉尘中,K和Na质量分数分别高达1.539%和0.370%。

1.2 试验方法

1.2.1 采样方法

本研究采集的样品主要来源于烧结现场,包括烧结混匀料、烧结矿、电场除尘灰以及外排烟气颗粒物样品。混匀料在烧结给料圆辊处取样,取样时用取样铲沿圆辊宽度方向均匀接取下料(约10 kg);烧结矿在成品皮带处取样,用取样铲沿垂直皮带运行方向截取1个断面(约20 kg);电除尘灰在各电场卸灰阀接取,取样时需暂停输灰设备,打开卸灰阀用取样铲铲取灰样(约10 kg);固体物料取样后,均经缩分取1 kg样品供制样分析用;外排烟气中的颗粒物采用WY型冲击式粉尘分级仪进行采集。

烧结杯试验采用直径为180 mm的烧结杯,料层高度为700 mm,采用天然气点火及保温,在负压为-5 kPa、温度为(1 100±50)℃条件下点火1.5 min。在烧结过程中,抽风负压为-10 kPa,到达烧结终点时,抽风负压调低至-5 kPa,冷却3 min后卸料。在烧结杯试验中,布料前的混合料及成品烧结矿均需取样检测有害元素质量分数。其中,烧结矿取样分2类:一类为将单杯烧结矿全部破碎,缩分后取样1 kg;另一类为将单杯烧结矿由表层至底部均分为5层,每层厚度约为140 mm,逐层分别取样。

表1 烧结原料化学成分(质量分数)

Table 1 Chemical compositions of raw materials %

1.2.2 分析方法

碱金属K和Na质量分数采用 ICP-AES测定。测定前样品需要经过消解,具体流程如下:将采集到的样品经过制样处理使其粒度小于0.074 mm;称取0.2 g样品分别置于聚四氟乙烯的坩埚之内,加入9 mL HCL,3 mL HNO3和3 mL HF(所用酸均为GR等级),然后将坩埚盖好,放置在温控加热平台上,控制温度在250 ℃,加热3 h至样品完全消解。然后,将溶液转移至100 mL容量瓶中,使用去离子水定容,摇匀即得待测的试样溶液。

K和Na在烧结过程中的脱除率计算式为

(1)

(1)

式中:η为元素的烧结过程脱除效率,%; 为元素在烧结矿中的质量分数,%;

为元素在烧结矿中的质量分数,%; 为元素在混匀料中的质量分数,%;

为元素在混匀料中的质量分数,%; 为采样期间烧结矿总产量,t;

为采样期间烧结矿总产量,t; 为采样期间混匀料总量,t。对于颗粒物,使用精度为1/(10万) g的电子天平称量捕集板上的采样滤膜前后的质量差,可以得到采集到的颗粒物质量,结合采样流量即可得到颗粒物浓度。固体颗粒物的形貌及其元素组成采用扫描电镜-能谱(SEM-EDS)进行分析。K和Na在颗粒物中的富集比计算公式为

为采样期间混匀料总量,t。对于颗粒物,使用精度为1/(10万) g的电子天平称量捕集板上的采样滤膜前后的质量差,可以得到采集到的颗粒物质量,结合采样流量即可得到颗粒物浓度。固体颗粒物的形貌及其元素组成采用扫描电镜-能谱(SEM-EDS)进行分析。K和Na在颗粒物中的富集比计算公式为

(2)

(2)

式中:i为元素在颗粒物中的富集比;w1为元素在混匀料中的质量分数,%;w2为元素在颗粒物中的质量分数,%。对于碱金属在混合料与烧结矿中的物相,采用逐级化学提取方法进行检测,将其物相分为可溶于水的氯化物、硫酸盐、碳酸盐、硅酸盐,难溶解的霞石、榴石,以及更难以消解的长石、云母。

2 实验结果及分析

2.1 烧结过程中K和Na的平衡分析

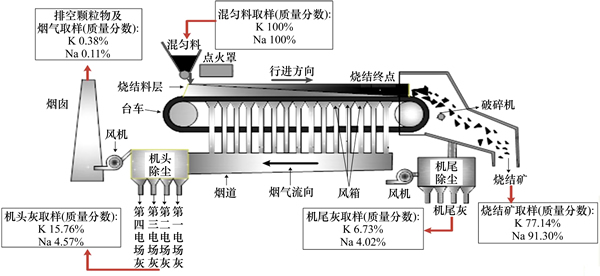

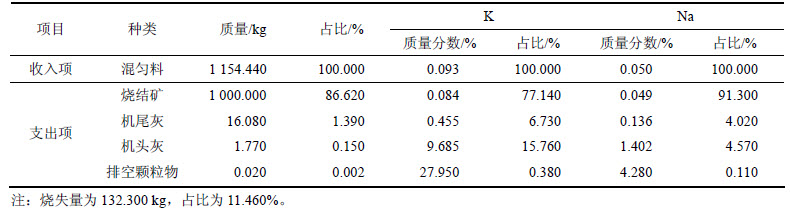

图1所示为烧结现场采样流程图。通过全流程采样及其有害元素分析,得到现场烧结生产过程物料及碱金属的收支平衡关系,如表2所示。分析图1可知:在烧结过程中,质量分数为77.14%的K和91.30%的Na保留在烧结矿中。K和Na在烧结过程中脱除部分主要进入各类粉尘及颗粒物中,机头灰中K、Na含量较高,有15.76% K和4.75% Na分布于其中;机尾灰中K和Na所占质量分数分别为6.73%和4.02%,而排空的颗粒物和烟气中的K和Na质量分数不高。烧结试验也证实:K和Na在烧结过程中有一些被脱除,钾的脱除率达23.77%;钠的脱除率较低,为14.71%。

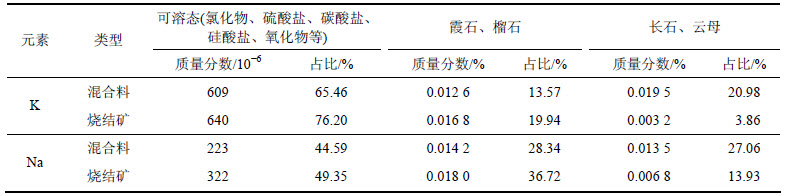

2.2 烧结过程碱金属的物相变化

利用逐级化学提取方法分析碱金属在混合料与烧结矿中的物相,结果如表3所示。从表3可知:这2类碱金属的物相分布有差异;在烧结矿中,K和Na以可溶于水的KCl,NaCl,K2SO4,Na2SO4,K2CO3和Na2CO3等形式存在的质量分数比混合料的高,而难溶解的铝硅酸盐类(长石、云母)质量分数减小。与混合料和烧结矿相比,烧结之后以复杂铝硅酸盐形式存在的碱金属相减少,简单的铝硅酸盐及水溶态物相增多,在烧结过程中复杂的碱金属化合物可被分解或还原。

图1 烧结现场采样流程图

Fig. 1 Flow diagram of sampling system in sintering process

表2 现场烧结过程物料及碱金属收支平衡(按每吨烧结矿)

Table 2 Material and Alkali metal balance in sintering process

表3 碱金属在混合料与烧结矿中的物相

Table 3 Phase composition of alkali metal in mixture and sinter

2.3 工艺条件对K和Na脱除的影响

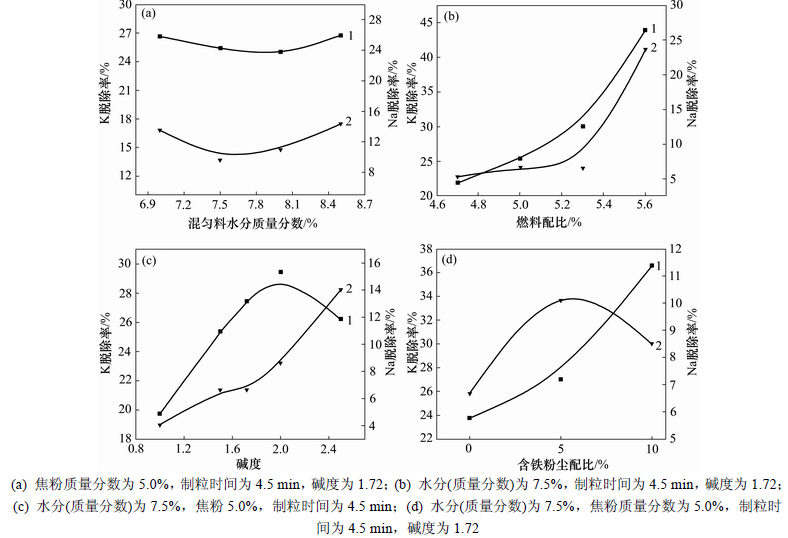

采用烧结杯试验,分别研究烧结混合料制粒水分、燃料配比、碱度以及含铁粉尘配比等因素对K和Na脱除的影响,结果如图2所示。

从图2可见:随着混合料水分增加,碱金属脱除率先降低后升高,当混合料水分为7.5%时,水分为适宜值(实际检测此时透气性最佳),K和Na的脱除率最低。其主要原因可能是透气性被改善,烧结过程氧化性气氛增强,不利于碱金属的脱除。

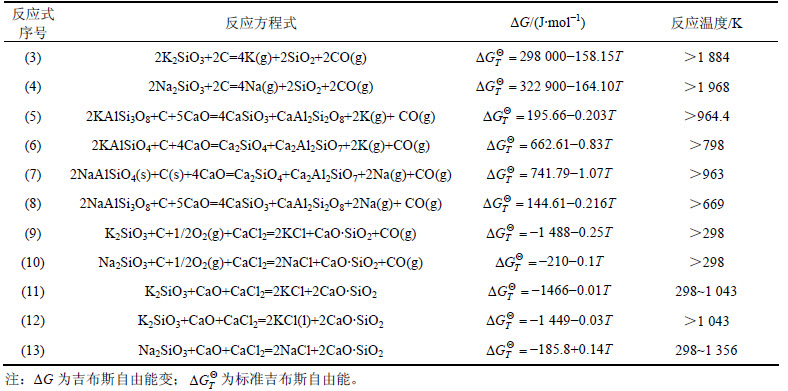

K和Na的脱除率随着焦粉配比提高而升高,表明增加燃料用量有利于碱金属的脱除。碱金属及其化合物在烧结过程中可能发生的部分反应如表4所示。碱金属的硅酸盐被C直接还原,反应式见表4中式(3)和(4),这2个反应发生的温度在1 550 ℃以上,在烧结过程中很难达到,故以简单硅酸盐形态存在的碱金属基本上不能被C直接还原脱除[13-14]。在烧结原料时,由于有熔剂存在,在燃料、熔剂附近的钾钠长石、霞石等铝硅酸盐则可发生如式(5)~(8)所示的反应,此类反应一般在500~700 ℃即可发生。当复杂的碱金属铝硅酸盐与氯化物及燃料临近时,可发生如表4中式(9)和(10)所示的反应,使得碱金属大量以氯化物的形态被脱除。所以,燃料用量增加,更有利于碱金属以氯化物的形式脱除,因反应(9)的△G比反应(10)的△G小,故其更容易发生,所以,K的脱除率要大于Na的脱除率。随着碱度提高,K和Na的脱除率总体呈升高趋势。以自由状态存在的CaO及氯化物可与碱金属的硅酸盐发生反应,生成碱金属的氯化物,促使其脱除。当碱度增大时,CaO与碱金属硅酸盐中的SiO2部分结合,更有利于碱金属的脱除,反应式如表4中式(11)~(13)所示。

在混合料中配入含铁粉尘(主要为钢铁厂的回收粉尘),随着随着含铁粉尘配比增加,K的脱除率也随之上升,Na的脱除率呈现先升高后降低的趋势。含铁粉尘中的K和Na主要以简单氯化物的形式存在,脱除较容易。

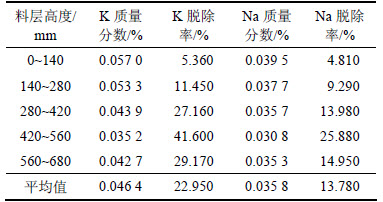

在烧结杯试验中,将烧结料层分为5层,研究K和Na在不同高度料层中的质量分数及脱除率的变化,结果如表5所示。从表5可知:K和Na在烧结料层上部质量分数较高,这可能是由于烧结初始阶段料层温度低,还原性气氛弱,K和Na的脱除并不明显;随着料层向下,K和Na质量分数持续降低,在料层中下部两者质量分数达到最低,随后又增高直至烧结终点;K和Na脱除率在烧结料层中下部达到最大,分别为41.60%和25.88%,其原因可能是在料层中下部,料层蓄热作用而使得料层温度升高,促使碱金属脱除加剧,进入烟气的碱金属化合物也增多;而在烧结末期,在高温燃烧带生成的挥发性,碱金属化合物随气流向烧结料层下部迁移,在此过程中会被湿料层捕获、吸附,累积于料层的下部,加之烧结快结束前气体中氧分压增大,对碱金属的脱除不利,所以,脱除率下降。

图2 不同因素对K和Na脱除的影响

Fig. 2 Effect of different factors on removal ratio of K and Na

表4 烧结过程中碱金属发生的部分反应及反应的△G-T的关系

Table 4 Reaction of alkali metal and relationship of △G-T in sintering process

表5 K和Na在不同料层中的质量分数及脱除率

Table 5 Mass fraction and removal rate of K and Na in different beds

2.4 K和Na随烟气的迁移行为

由于K和Na的挥发性,在烧结过程中容易进入烟气。这部分K和Na会以化合物的形态冷凝成单个固态晶体,或附着在颗粒物上[15]。本研究收集现场自烧结机头第一、二、三、四电场灰以及除尘后的气溶胶颗粒,这4种电场灰的平均粒径分别为47.855,40.777,27.963和20.980 μm,气溶胶颗粒粒径为0.7~20 μm。针对不同粒级的颗粒物,测定其K和Na质量分数及其赋存状态。

2.4.1 K和Na在颗粒物中的分布特点

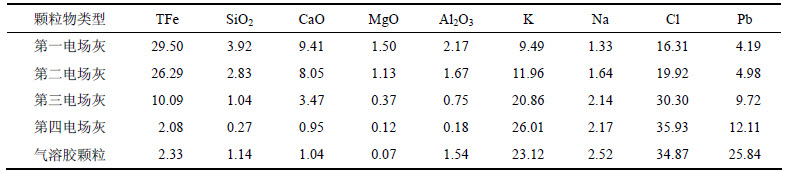

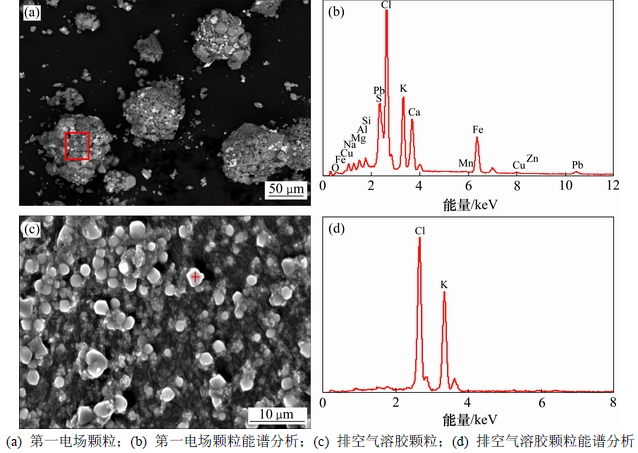

不同粒级颗粒物的化学成分如表6所示。从表6可知:随着颗粒物粒径减小,颗粒物中Fe,Si,Ca,Mg和Al等元素的质量分数降低,而K,Na,Cl和Pb等挥发性元素在颗粒物中显著富集,气溶胶颗粒中K和Na的质量分数分别高达23.12%和2.52%。K和Na在5种颗粒物中的富集比见图3。从图3可知:与混合料相比,颗粒物中K和Na的富集非常明显,K和Na在第四电场灰中的富集比分别达279.86倍和43.17倍,在气溶胶颗粒中的富集比分别达248.77倍和50.13倍。在各粒级颗粒物中,K的富集程度比Na的高。

图3 不同粒级颗粒物中K和Na的富集比

Fig. 3 Enrichment ratio of K and Na in different particles

2.4.2 K和Na在颗粒物中的赋存状态

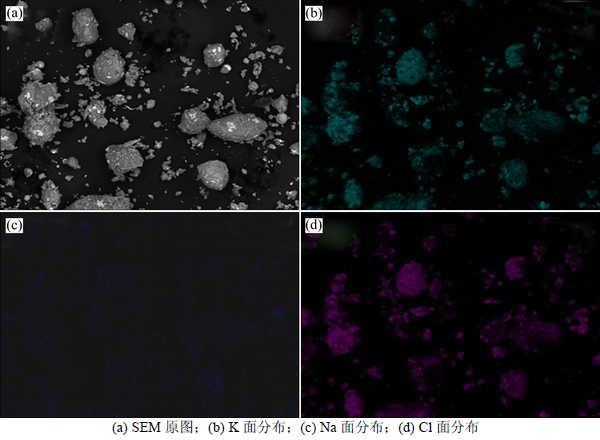

针对粒度较粗的第一电场灰和细粒级的气溶胶颗粒进行SEM-EDS分析,结果如图4所示。分析图4可知:第一电场灰的颗粒形貌复杂,形态差异明显,颗粒表面高低不平,呈现团聚状,为细小的不规则颗粒物聚集在一起形成;气溶胶颗粒主要由规则的球形颗粒和板片状颗粒组成,边缘清晰,轮廓分明,表面光滑,主要为单体存在。能谱分析显示2种颗粒物中K和Na的质量分数与Cl元素的质量分数变化趋势一致,说明K和Na主要与Cl结合。根据颗粒物形成机理[16-17],粗粒级颗粒物的主要来源是:在烧结过程中,由于温度升高,物料颗粒中内应力增大,从而发生破碎及爆裂,所以,Fe和Al等元素质量分数较高。气溶胶颗粒主要来源于烧结原料的汽化-凝结,在高温和还原性气氛条件下,K,Na与易于挥发的Cl元素结合,形成微米及亚微米颗粒。

表6 不同粒级颗粒物的化学成分(质量分数)对比

Table 6 Comparison of the chemical composition of different particles %

图5所示为颗粒物表面K,Na和Cl这3种元素的面扫描分析结果。从图5可知:这3种元素在颗粒物上分布较均匀,没有局部富集现象,这3种元素具有相同的分布,可推断K和Na主要以氯化物的形式附着在颗粒物表面。

图4 2种粒径颗粒物的SEM-EDS

Fig. 4 SEM-EDS image of two different particles

图5 颗粒物表面能谱分析

Fig. 5 SEM-EDS mapping of particles

3 结论

1) 在烧结过程中,大部分K和Na保留在烧结矿中,少部分进入粉尘及颗粒物被脱除,其中粉尘里的机头灰和机尾灰的K和Na含量高,而排空的颗粒物和烟气中K和Na质量分数不高。

2) 燃料配比和碱度对K和Na的脱除有较大影响。随着燃料配比和碱度提高,K和Na的脱除率增大,K和Na在烧结过程中的脱除主要发生在烧结中后期。在烧结初始及末期,K和Na的脱除率低。

3) 烧结脱除的K和Na主要富集在排出的粉尘和气溶胶颗粒物上,其在4种除尘灰和气溶胶颗粒物中的质量分数和富集程度随着颗粒粒径减小而增大,在颗粒中以氯化物为主要存在形态。

参考文献:

[1] 欧阳坤, 孔延厂, 孙艳芹, 等. 高炉中碱金属的研究进展[J]. 河北理工大学学报(自然科学版), 2011, 33(1): 37-41, 118.

OUYANG Kung, KONG Yanguang, SUN Yanqin, et al. The research progress of alkali metals in blast furnace[J]. Journal of Hebei Polytechnic University (Natural Science Edition), 2011, 33(1): 37-41, 118.

[2] 项钟庸, 王筱留. 高炉设计: 炼铁工艺设计理论与实践[M]. 2版. 北京: 冶金工业出版社, 2014: 139-142.

XIANG Zhongyong, WANG Xiaoliu. Blast furnace design: theory and application of ironmaking process[M]. 2nd ed. Beijing: PressofMetallurgyIndustry, 2014: 139-142.

[3] 王成立, 吕庆, 顾林娜, 等. 碱金属在高炉内的反应及分配[J]. 钢铁研究学报, 2006, 18(6): 6-10, 13.

WANG Chengli, L Qing, GU Linna, et al. Reaction and distribution ofalkali metalsinblast furnace[J]. Journal of Iron and Steel Research, 2006, 18(6): 6-10, 13.

Qing, GU Linna, et al. Reaction and distribution ofalkali metalsinblast furnace[J]. Journal of Iron and Steel Research, 2006, 18(6): 6-10, 13.

[4] 余松, 赵宏博, 程树森, 等. 高炉内碱金属和碱金属氯化物对焦炭的影响[J]. 钢铁研究学报, 2011, 23(5): 20-23.

YU Song, ZHAO Hongbo, CHENG Shusen, et al. Influence of alkali and alkali chloride on coke in the blast furnace[J]. Journal of Iron and Steel Research, 2011, 23(5): 20-23.

[5] KOBAYASHI K, 邱硕. 碱金属在烧结过程中的特性[J]. 烧结球团, 1982, 7(2): 72-81.

KOBAYASHI K, QIU Shuo. Property of alkali metals in sintering process[J]. Sintering and Pelletizing, 1982, 7(2): 72-81.

[6] 张世忠, 张芳, 罗果萍. 碱金属在烧结过程中的行为规律[J]. 内蒙古科技大学学报, 2010, 29(2): 108-111.

ZHANG Shizhong, ZHANG Fang, LUO Guoping. Influence of alkali metal on the process of sintering[J]. Journal of Inner Mongolia University of Science & Technology, 2010, 29(2): 108-111.

[7] 庞真丽, 颜芳, 王沧. 唐钢烧结碱金属和锌平衡的研究[J]. 南方金属, 2012, 19(2): 25-27.

PANG Zhenli, YAN Fang, WANG Cang. An investigation of the alkali-zinc balance in the sintered ores at Tang Steel[J]. Southern Metals, 2012, 19(2): 25-27.

[8] 杨永清, 鲁素萍, 段祥光. K2O和Na2O在烧结过程行为机理分析[J]. 包钢科技, 2012, 38(6): 33-36.

YANG Yongqing, LU Suping, DUAN Xiangguang. Analysis on behavior mechanism of K2O and Na2O in sintering[J]. Science & Technology of Baotou Steel, 2012, 38(6): 33-36.

[9] 张贺顺, 马洪斌. 首钢高炉锌及碱金属负荷的研究[J]. 钢铁研究, 2010, 38(6): 51-55.

ZHANG Heshun, MA Hongbin. Study on zinc load and alkalis load in blast furnaces of Shougang Corporation[J]. Research on Iron and Steel, 2010, 38(6): 51-55.

[10] ROBREDO R, GERLACH W, 刘韬. 铁矿石烧结时添加氯化钙降低碱金属的含量[J]. 烧结球团, 1980, 5(3): 66-79.

ROBREDO R, GERLACH W, LIU Tao. Adding calcium chloride to lower alkali content in iron ore sintering[J]. Sintering and Pelletizing, 1980, 5(3): 66-79.

[11] 马燕生. 氯化烧结脱除碱金属的试验研究[J]. 烧结球团, 1983, 8(6): 30-36.

MA Yansheng. Experimental study on removal of alkali metal in chloride sintering[J]. Sintering and Pelletizing, 1983, 8(6): 30-36.

[12] PENG Cui, GUO Zhancheng, ZHANG Fuli. Existing state of potassium chloride in agglomerated sintering dust and its water leaching kinetics[J]. Trans Nonferrous Met Soc China, 2011, 21(8): 1847-1854.

[13] 佘雪峰, 薛庆国, 董杰吉, 等. 钢铁厂典型粉尘的基本物性与利用途径分析[J]. 过程工程学报, 2009, 9(6): 7-12.

SHE Xuefeng, XUE Qingguo, DONG Jieji, et al. Analysis on basic physical properties and utilization of typical dust from steel plant[J]. The Chinese Journal of Process Engineering, 2009, 9(6): 7-12.

[14] 李久. 使用高、低碱度烧结矿抑制碱金属对高炉危害的探讨[J]. 钢铁, 1986, 21(5): 66-69.

LI Jiu. Discussion on the controlling of alkalis in BF by charging high and low both basicity sinters[J]. Journal of Iron and Steel, 1986, 21(5): 66-69.

[15] CURRIER J W, EHLERT T C. New perspectives on the behavior of alkalis under blast furnace conditions[J]. Proceedings Ironmaking Conference, ISS-AIME. Toronto, America, 1988, 47(1): 579-587.

[16] DACOMBE P J, HAMPARTSOUMIAN E, POURKASHANIAN M. Fragmentation of large coal particles in a drop-tube furnace[J]. Fuel, 1994, 73(8): 1365-1367.

[17] BAXTER L L. Char fragmentation and fly ash formation during pulverized-coal combustion[J]. Combustion and Flame, 1992, 90(2): 174-184.

(编辑 陈灿华)

收稿日期:2016-12-11;修回日期:2017-01-28

基金项目(Foundation item):国家自然科学基金重点资助项目(U1660206);中南大学“创新驱动计划”项目(2015CX005);湖南省战略金属矿产资源清洁高效利用协同创新中心资助项目(2015);国家重金属污染防治工程技术研究中心开放基金资助项目(2015CNERC-CTHMP-14) (Project(U1660206) supported by the National Natural Science Foundation of China; Project(2015CX005) supported by the Innovation Driven Plan of Central South University; Project(2015) supported by the Co-Innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources of Hunan Province; Project(2015CNERC-CTHMP-14) supported by the Opening Foundation of the Chinese National Engineering Research Center for Control and Treatment of Heavy Metal Pollution)

通信作者:甘敏,副教授,从事矿产资源综合利用研究;E-mail: csuganmin@126.com