J. Cent. South Univ. Technol. (2011) 18: 704-710

DOI: 10.1007/s11771-011-0751-1

Development of twin wheel creep-feed grinding machine using continuous dressing for machining of aircraft rotary wing

KIM Jin-seob, HWANG Jong-dae, JUNG Yoon-gyo

School of Mechatronics, Changwon National University, Changwon 641-773, Korea

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract: The purpose of this study is to develop a twin wheel creep-feed grinding machine using continuous dressing to machine precise axisymmetric turbine blades that have been difficult to machine using a conventional creep-feed machine. In order to develop such a machine, 3D-modeling and machine simulations were performed and a twin wheel creep-feed grinding machine was manufactured. Furthermore, the axisymmetric precision of the machined workpieces through practical machining was evaluated and the quality of the continuous dressing effect of the developed machine was established. In addition, experimental considerations for a proper dresser-to-wheel speed ratio and proper feed rate of the dresser were carried out. As a result, a twin wheel creep-feed grinding machine with continuous dressing is developed through machine simulation, manufacturing and performance evaluation. Optimum condition for the dresser feed rate is 0.3 μm/rev. In cases of large dressor-to-wheel speed ratio, grinding efficiency can be enhanced, but the surface roughness shows a conflicting trend. Developed twin wheel creep-feed grinding machine has satisfactory appraisal with regard to surface roughness, flatness, and parallelism. Satisfactory surface roughness below 0.1 μm can be obtained for the blade of aircraft. However, in order to perform precise machining, it is necessary to improve the structure of the twin wheel creep- feed grinding machine.

Key words: creep-feed grinding; twin wheel; surface roughness; grinding force; continuous dressing; flatness; parallelism

1 Introduction

Creep-feed grinding is one of the most advantageous techniques of shaping that combines high efficiency and machining accuracy [1]. Recently, the efficiency of creep-feed grinding using continuous dressing has been proved in the profile grinding of high strength and hardness materials such as nickel-based alloys and ceramics [2-7], which easily incur grinding burns, cracks and thermal damage to the workpiece and increase the grinding force due to attritious wear of the grinding wheel grain as time passes [8-17]. This type of grinding is applied for the machining of aircraft rotary wing parts such as the blades of turbine engines. Such turbine blades have many machined parts that require precise symmetry on both sides, such as dovetails of the blade root part, the shank and the shroud plane of the Z-form. According to the developments in the aerospace industry, demand for machining of turbine blades has gradually increased. It is, therefore, necessary to suggest an efficient method of machining parts for which precise symmetry is required. The purpose of this study is to develop a twin wheel creep-feed grinding machine using continuous dressing to machine precisely axisymmetric turbine blades that have been difficult to machine using the conventional creep-feed machine. In order to develop such a machine, 3D-modeling and machine simulations were performed and a twin wheel creep-feed grinding machine was manufactured [18]. Furthermore, the axisymmetric precision of the machined workpieces through practical machining was evaluated and the quality of the continuous dressing effect of the developed machine was established. In addition, experimental considerations for a proper dresser-to- wheel speed ratio and proper feed rate of the dresser were carried out.

2 Principle of twin wheel creep-feed grinding using continuous dressing

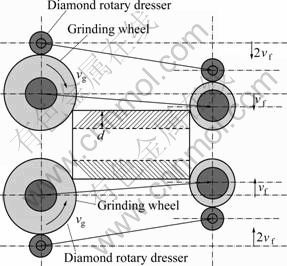

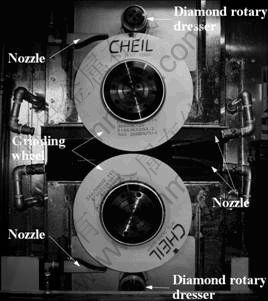

As shown in Fig.1, the twin wheel creep-feed using continuous dressing is a method to dress a grinding wheel continuously during the grinding with a diamond rotary dresser mounted on two grinding wheels on the upward and downward sides of the workpiece [19-21]. In the case of a symmetrical workpiece, this grinding method is able to grind efficiently on the upward side and the downward side of the workpiece in one pass. It is, however, necessary to adjust the radius of the wheel, because the radius is gradually decreased by dressing during the grinding. In other words, as shown in Fig.1, the dresser descends at a speed of 2vf, and then the axis of the wheel must be adjusted as much as vf. This adjustment motion is controlled by the NC.

Fig.1 Mechanism of continuous dressing for twin wheel

Because this type of grinding using continuous dressing is one in which the grinding wheel surface right after dressing is maintained uniformly, an improvement of grinding efficiency is anticipated. Also, the grinding burning is decreased and the supply of grinding fluid can be accomplished in a more convenient way. In addition, it is not necessary to consider the variation due to the passing of time on the wheel surface. Consequently, because the creep-feed grinding is possibly regardless of workpiece length, this grinding method is able to maintain the quality of the machined product constantly. Besides, there is the advantage that this system is able to affect efficient grinding because of the twin wheel structure. However, in order to maintain a stable grinding quality, a discussion is essential for the proper dresser feed rate and proper dresser-to-wheel speed ratio during the continuous dressing and performance evaluation for the twin wheel structure.

3 Machine simulation of twin wheel creep- feed grinding machine

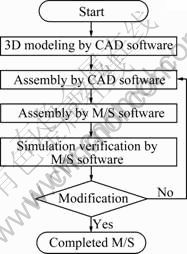

First, in order to perform the machine simulation, 3D-modeling for each part of the twin wheel grinding machine by CAD software has to be carried out and the entire system shape has to be composed through the assembly of the modeled parts. Second, in order to operate the modeled machine with the machine simulation software, after the location information of each part is saved in the axis of standard coordinates for the assembly of the CAD system, the machine simulation results have to be verified again through an assembling process by the machine simulation software for the files of this part. Figure 2 shows the machine simulation steps. The software used is NCSIMUL8 (Spring Tech. France).

Fig.2 Flow chart for machine simulation process

In this study, in order to identify the reliability for collision and interference phenomena during the operation of the grinding machine before manufacture of a trial product, 218 components in each part are integrated into 17 components for the designed main components and 3D-modeling and assembly were performed for these 17 components. On the basis of these results, the machine simulation was performed. Figure 3 shows a part of the progress of the machine simulation. As a result of the machine simulation, because the slot part of the backboard is designed to be shorter than the up-down movement distance, interference was found to occur. The design was changed and a satisfactory result was able to be obtained as a result of the second machine simulation.

Fig.3 Machine simulation of twin wheel creep-feed machine

4 Manufacture of twin wheel creep-feed grinding machine

To make the maximum use of the characteristics of the process of twin creep-feed grinding using continuous dressing, the following particular functions and performance are required. First, because the grinding power is very large in the creep-feed grinding, to prepare a large capacity motor for the grinding wheel driving is essential. The main spindle must have a sufficient stiffness to endure the large grinding force. The driving table must enable a very low speed without stick slip. On the other hand, it must retain the extensive speed range in order to drive the table at a high speed. Also, the dresser feeding must be controlled with high accuracy and a great quantity of grinding fluid must be supplied to interrupt the scattering of the grinding wheel grains by continuous dressing. In this study, the development of a twin wheel creep-feed grinding machine to coincide with the above mentioned characteristics was attempted.

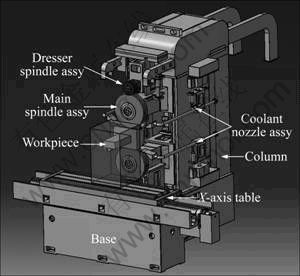

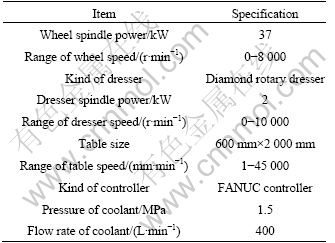

The main spindle of the grinding machine developed in this study was designed considering the high stiffness for creep-feed grinding. The main spindle and the dresser spindle were designed in a structure of waterproof type that cannot be infiltrated by a large quantity of grinding fluid during the spray of high pressure. The power of the spindle motor was ensured by installing a 37 kW heavy capacity motor in order to endure the grinding power. The transfer mission devices for adjusting the movement of the main spindle, an up-down feeding axis unit of the main spindle, an up-down feeding axis unit for the dresser spindle and an up-down feeding axis unit for the coolant nozzle to cool the workpiece and grinding wheel were designed considering the positional control precision and the optimal load. In order to enable the creep-feed grinding, the driving table was manufactured in such a way that the table speed retains an extensive speed range, from a minimum speed of 1 mm/min to a maximum speed of 45 000 mm/min. X-axis, Y-axis, Z-axis, V-axis (axis of dresser spindle) and C-axis (axis of coolant nozzle) were controlled by the NC, and the value of the minimum set-up unit was 0.1 μm. Table 1 lists the specifications of the developed creep-feed grinding machine and Fig.4 shows a photograph of the whole developed machine.

5 Decision of continuous dressing conditions

5.1 Experimental device and method

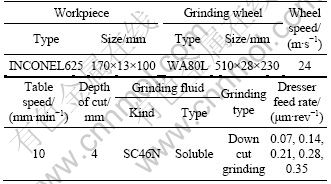

An experiment was carried out for down cut grinding using the grinding machine developed in this study. The workpiece used was an INCONEL625 of a nickel-based alloy, which is known as a difficult-to-cut material for which the surface roughness of the ground surface is measured by a stylus type surface tester (Mytutoyo Company). The observation of the ground surface was done by tool microscope (MF-1020TH).

Table 1 Specifications of CNC creep-feed grinding machine with continuous dressing device

Fig.4 Photograph of developed twin wheel creep-feed grinding wheel

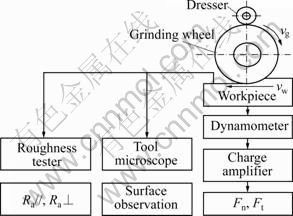

The grinding forces measured were the horizontal grinding force (Fh) and the vertical grinding force (Fv), with measurements taken with a piezoelectric type tool dynamometer (KISTLER company 9257B). Figure 5 shows the flow chart of the experiment set-up. In cases in which a diamond rotary dresser is used, it is important to set the rotational direction and the speeds of dresser and the grinding wheel, because these factors decide the shape of the grain edge during dressing. The speed ratio qd can be presented by the following formula, qd=±vd/vg, where vd (r/min) is the dresser speed and vg (r/min) is the grinding wheel speed. In this study, in cases in which the velocity vector of the grinding wheel speed and the dresser speed on the dressing point are in the same directions, it is defined as the positive direction; in cases in which these values are in different directions, it is defined as the negative direction. This experiment was, however, performed only for the positive velocity (qd=+0.2, +0.4, +0.6, +0.8) because of the structural problems of the grinding machine. Table 2 lists the experimental conditions in this study.

Fig.5 Experimental set-up

Table 2 Experimental conditions

5.2 Effect of continuous dressing

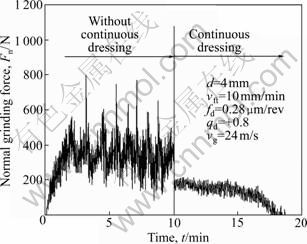

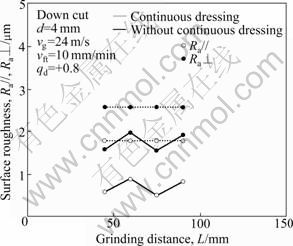

Figure 6 shows an example in which the effect of continuous dressing can be expressed directly.

Fig.6 Comparison between continuous dressing and non- continuous dressing from viewpoint of grinding force

In Fig.6, the horizontal grinding force during creep-feed grinding was measured and continuous dressing was performed in the middle of the grinding. The cutting depth d, workpiece speed vft and wheel speed vg were established at 4 mm, 10 mm/min and 24 m/s, respectively. As shown in Fig.6, it was confirmed that the fluctuation of the grinding force appeared to be violent during non-continuous dressing, but steady grinding was achieved during continuous dressing.

In order to confirm the effect of continuous dressing indirectly, Fig.7 shows the behavior of the measured grinding surface roughness before and after continuous dressing. In Fig.7, the surface roughness of the grinding direction (Ra//) and the grinding perpendicular direction (Ra⊥) were plotted simultaneously. Due to the effect of continuous dressing, it was confirmed that a uniform surface roughness was obtained in the case of continuous dressing.

Fig.7 Comparison between continuous dressing and non- continuous dressing from viewpoint of surface roughness

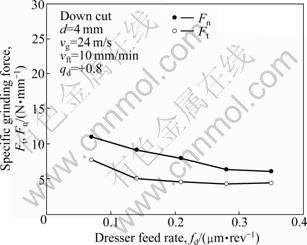

5.3 Decision of dresser feed rate

In dressing conditions, dresser feed rate (fd) is an important factor to consider from an economical aspect for this grinding wheel. In other words, the effect of dressing decreases in cases in which the dresser feed rate is small, and it is difficult to grind stably; also, in cases in which the dresser feed rate is large, the grinding wheel is excessively wasted.

Figure 8 shows the change of normal and tangential grinding forces according to the change of dresser feed rate. Experimental conditions are the same as those shown in Fig.6. As shown in Fig.8, when the dresser feed rate becomes large, the grinding force decreases gradually. Namely, the improvement of the dressing effect is confirmed. However, in cases that the feed rate exceeds 0.3 μm/rev in the experimental conditions of this study, the improvement of the dressing effect cannot be expected.

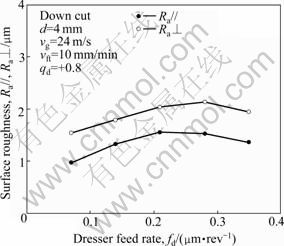

Figure 9 shows the change of Ra// and Ra⊥ according to the change of the dresser feed rate in the same grinding conditions with those shown in Fig.8. As the cutting edge of the wheel becomes sharper with the increase of the dresser feed rate, it can be confirmed that the increase of the dresser feed rate brings about a deterioration of the ground surface.

Fig.8 Behavior of specific grinding force according to dresser feed rate

Fig.9 Behavior of surface roughness according to dresser feed rate

And in keeping with the results shown in Fig.8, changes of the surface roughness become gradual in the vicinity of the feed rate of 0.3 μm/rev. It can be said that this phenomenon verifies the reliability of the experimental results.

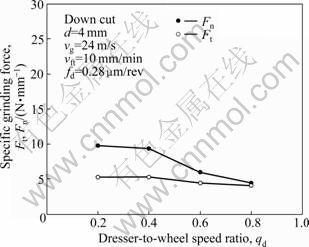

5.4 Decision of speed ratio

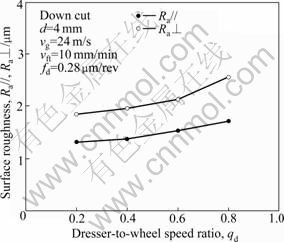

Dresser-to-wheel speed ratio is an important factor in controlling the shape of the cutting edge.

Namely, in cases in which the speed ratio is small, because micro unevenness on the cutting edge during dressing can be generated, an improvement of the surface roughness is anticipated. On the other hand, in cases in which the speed ratio is large, because macro unevenness on the cutting edge during dressing can occur, an increase in the grinding efficiency is supposed.

Figure 10 shows the changes of normal and tangential grinding forces according to the speed ratio. As supposed, an increase of the speed ratio induces a decrease of the grinding force, which results in an increase of the grinding efficiency. Figure 11 shows the change of Ra// and Ra⊥ according to the change of the speed ratio under the same grinding conditions. From this result, it can be confirmed that the tendency of grinding efficiency and surface roughness have to be contrary to each other.

Fig.10 Behavior of specific grinding force according to dresser- to-wheel speed ratio

Fig.11 Behavior of surface roughness according to dresser-to- wheel speed ratio

6 Performance evaluation of twin wheel creep-feed grinding machine

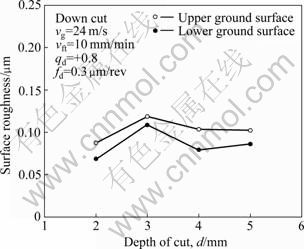

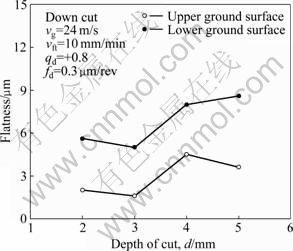

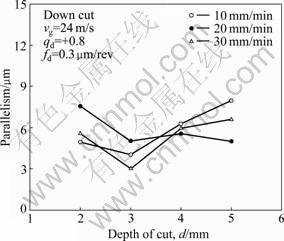

Under the dressing conditions decided, the performance of the developed twin wheel creep-feed grinding machine was evaluated in view of flatness, parallelism and surface roughness of each workpiece ground by upper and lower grinding wheels.

Figures 12-14 are given to show the changes of the surface roughness Ra//, flatness and parallelism according to the change of depth of the cut, for the surface ground by the lower grinding wheel and the surface ground by the upper grinding wheel. The surface roughness of the upper ground surface is slightly rough compared with that of the lower surface. But, it is estimated to be at a satisfactory level for surface roughness of a turbine blade, because it is less than 0.1 μm overall. On the other hand, the flatness shows a remarkable difference between the upper ground surface and the lower ground surface. Hence, it is necessary to improve the structure of the twin wheel because the measured flatness value is above 9 μm. The parallelism between the upper and lower ground surfaces is also measured at about 9 μm.

Fig.12 Comparison of roughness according to depth of cut between upper ground surface and lower ground surface

Fig.13 Comparison of flatness according to depth of cut between upper ground surface and lower ground surface

Fig.14 Comparison of parallelism according to depth of cut between upper ground surface and lower ground surface

7 Conclusions

1) A twin wheel creep-feed grinding machine with continuous dressing was developed by machine simulation process and performance evaluation.

2) The optimum condition for the dresser feed rate is 0.3 μm/rev. When the speed ratio is large, the grinding efficiency can be improved. However, the surface roughness shows a conflicting tendency.

3) The performance of developed machine is satisfactory overall from the view of surface roughness, flatness and parallelism.

References

[1] NOSENKO A V, ZOTOVA S A, NOSENKO S V. Run and cutting power of a conical-camber disk under creep feed grinding of a horizontal face [J]. Machinery Manufacture and Reliability, 2009, 38(4): 373-378.

[2] AI K, KISHIMOTO Y. Creep feed grinding of ceramics [J]. JSPE, 1992, 58(4): 607-609.

[3] WAIDA T, SUTO T, NOGUCHI H, INOUE H. Creep feed grinding of ceramic-matrix composites with slotted & perforated wheel [J]. JSPE, 1991, 57(2): 324-329.

[4] HOOD R, ASPINWALL D K, VOICE W. Creep feed grinding of a gamma titanium aluminide intermetallic alloy using SiC abrasives [J]. Journal of Materials Processing Technology, 2007, 191(1/3): 210- 214.

[5] ABDULLAH A, PAK A, FARAHI M, BARZEGARI M. Profile wear of resin-bonded nickel-coated diamond wheel and roughness in creep-feed grinding of cemented tungsten carbide [J]. Journal of Materials Processing Technology, 2007, 183(2/3): 165-168.

[6] SPUR G, NIEWELT W. Creep feed grinding of nickel-based alloys with advanced corundum and with CBN-grinding wheels [J]. JSPE, 1994(1): 321-326.

[7] TUFFY K, NAILER S, O SULLIVAN M. Creep feed grinding Inconel 718 with ABN 800 in vitrified bond grinding wheels an assessment of the impact of different dressing conditions for grinding Inconel 718 with vitrified bond CBN wheels [J]. Industrial Diamond Review, 2008(3): 44-50.

[8] HARA S, SAITOU T. Study on grinding cracks in creep feed grinding [J]. JSPE, 1993, 59(2): 252-256.

[9] FURUKAWA Y, OHISHI S, KITAMURA J. Adaptive control of workpiece burn in creep feed grinding [J]. JSPE, 1985, 51(3): 614- 619.

[10] MAYSUI S, SYOJI K, KURIYAGAWA T. Loading on soft grade wheel and effects of removal of loading chips [J]. JSPE, 1988, 54(4): 743-748.

[11] WAIDA T, SUTO T, NOGUCHI H, INOUE H. Development of slotted and perforated wheels for creep feed grinding and their grinding performance [J]. JSPE, 1991, 57(7): 1223-1228.

[12] ICHIDA Y, KISHI K, SUYAMA Y, OKUBO J. Study on creep feed grinding with CBN wheels [J]. JSPE, 1989, 55(8): 1468-1474.

[13] KIM N K, GUO C, MALKIN S. Heat flux distribution and energy partition in creep-feed grinding [J]. CIRP Annals, 1997, 46(1): 227- 232.

[14] ZHENG J X, XU J W, LIU C S. Studies on the grinding properties of ultrasonic assisted creep feed grinding using grinding wheel with small diameter [J]. Key Engineering Materials, 2009, 416: 23-27.

[15] STEFFEN J, BAUER R, WARKENTIN A, BECZE E. Performance of a coherent jet coolant system in non-continuous dress creep-feed grinding of Inconel 718 [J]. Advanced Manufacturing Systems, 2005, 4(2): 117-130.

[16] WANG S B, WU C F. Selections of working conditions for creep feed grinding. Part III: Avoidance of the workpiece burning by using improved BP neural network [J]. International Journal of Advanced Manufacturing Technology, 2006, 28(1/2): 31-37.

[17] WANG S B, KOU H S. Selections of working conditions for creep feed grinding. Part II: Workpiece temperature and critical grinding energy for burning [J]. International Journal of Advanced Manufacturing Technology, 2006, 28(1/2): 38-44.

[18] DIEYE M D, ACUNTO A, MARTIN P. Modelling and simulation creep feed grinding process [J]. Courses and Lectures, International Centre for Mechanical Sciences, 2005, 486: 235-246.

[19] SEKINE S, INASAKI I, KOBAYASHI S. Creep feed grinding of inconel 718 with continuous dressing [J]. JSPE, 1985, 52(8): 2558- 2562.

[20] ARAKI Y, INASAKI I, KOBAYASHI S, AOYAMA T. Creep feed grinding with continuous dressing [J]. JSPE, 1985, 51(8): 1851- 1856.

[21] LEE Young-wook, KIM Jong-kwan, JUNG Yoon-gyo. Development of CNC creep-feed grinding machine and determination of dressing conditions using continuous dressing [J]. KSPE, 2007, 24(6): 51-57.

(Edited by YANG Bing)

Foundation item: Work supported by the Second Stage of Brain Korea 21 Project

Received date: 2010-04-29; Accepted date: 2010-06-24

Corresponding author: JUNG Yoon-gyo, Professor, PhD; Tel: +82-55-213-3604; E-mail: ygjung@changwon.ac.kr