文章编号:1004-0609(2007)04-0505-06

反向凝固法生产H90-钢-H90复合带

李宝绵,许光明,崔建忠

(东北大学 材料电磁过程研究教育部重点实验室, 沈阳 110004)

摘 要:研究H90-钢-H90反向凝固复合过程中复合层厚度的变化规律以及复合带的组织和性能,探讨界面结合机理。结果表明:随着浸渍时间的增加,复合层的厚度变化经历了凝固生长、平衡相持和回熔3个阶段,钢带的预热温度越低,获得的最大复合层厚度越厚;H90复合层的组织为等轴晶粒,复合界面处Cu和Fe发生了扩散,而Zn未发生明显扩散,扩散层较薄,约为4 μm;复合带的界面结合牢固;不同复合层厚度的复合带,其力学性能略有差异,但均达到GB5213—85所规定的F级深冲钢板的力学性能要求。

关键词:反向凝固;复合带;复合层;界面;结合强度

中图分类号:TB 331 文献标识码:A

Production of H90-steel-H90 clad coil by inversion solidification

LI Bao-mian, XU Guang-ming, CUI Jian-zhong

(The Key Laboratory of Electromagnetic Processing of Materials,

Ministry of Education, Northeastern University, Shenyang 110004, China)

Abstract: The variation law of cladding thickness, the structures and properties of the clad strip produced by inversion solidification were studied. The interface bonding mechanism was approached. The results show that the thickness of H90 cladding goes sequentially through solidification growth stage, holding stage and remelting stage with the increase of immersion time. The higher the preheating temperature of steel coil, the thicker the maximum cladding thickness obtained. The microstructure of H90 clad layer is equiaxed grains. There is inter-diffusion of Cu and Fe near the interface but there is not obvious diffusion of Zn. The diffusion layer is very thin and about 4 μm. The interface is firmly bonded, and the mechanical properties of the as-clad coils can reach the requirements of GB5213—85 for F-grade deep-drawing steel plate though there is slight difference of mechanical properties among the clad strips with different cladding thickness.

Key words: inversion solidification; clad coil; clad layer; interface; bond strength

铜-钢复合材料由于具有强度高、耐腐蚀、抗磨损、导电导热、成本低等优点,在军工、电子、造币、炊具、冶金及建筑装饰等领域有着广阔的应用前景,尤其是使用H90-08Al-H90复合材料代替黄铜做弹头外壳,不仅经济,且其弹道性能更优越,近年来已引起广泛关注[1-3]。目前,国内外生产铜-钢复合板带材的方法主要有热轧法、冷轧法和爆炸法[4-7]。热轧法和爆炸法的工艺复杂、成本高、不能实现连续生产;冷轧法虽然能实现连续生产且在实际生产中获得了广泛应用,但在应用于铜-钢复合材料的生产时却未获得理想的效果[8-9]。其原因是:铜及其合金的基体和氧化膜都具有良好的塑性,冷轧复合时,坯料虽经钢丝刷清理且首道次变形量达到70%,其表面也不出现裂口,但结果还是坯料带着氧化膜被挤入钢的裂口中,故复合界面的结合强度低且不稳定,这限制了铜-钢复合材料的进一步推广和应用。因此,开发新的、高效率的铜-钢复合材料制备技术具有实际意义。

反向凝固工艺是德国Mannesmann集团和Aachen技术大学在1989年联合开发的一种具有独特概念的近终形薄带连铸技术[10-11],从原理上看也可用于生产凝固层与母带不同的复合材料,而与目前广泛采用的爆炸复合、轧制复合技术相比,又具有高效率、低能耗、连续化和短流程的特点,因此一经提出即引起关注[12-16]。但目前还没有见到将此工艺应用于铜-钢复合带生产的研究报道,同时现有的研究还缺乏对界面结合机理的探讨。因此,本文作者对反向凝固法生产H90-08Al-H90复合带的工艺进行了探索,研究了钢带预热温度和浸渍复合时间对复合层厚度的影响规律以及复合带的组织和性能,探讨了界面结合机理。

1 实验

以市售的08Al钢带作母带,其宽度为120 mm,厚度为1.2 mm;复合层材料H90黄铜由1号电解铜和1号锌在中频感应炉中熔炼而成,熔炼时用硼砂保护、用Cu-13.5%P(质量分数)的中间合金脱氧。实验装置主要由50 kg中频感应炉、打磨机、超音频快速加热设备、反向凝固器和开、卷取设备组成。H90合金液由反向凝固器的上端浇入,其设备示意图如图1所示。钢带经脱脂除油、打磨除锈、喷涂助焊剂和经超音频快速加热到一定温度后,以一定的速度通过H90合金液。钢带的表面预处理(除油、打磨和涂助焊剂)与反向凝固复合分开进行。为防止复合层H90合金氧化,在反向凝固器前端喷Ar气保护。H90合金液的温度用Pt-Rh热电偶测量;钢带的温度用手持非接触式红外测温仪测量;复合层的厚度用Leica MPS30显微镜在放大50倍下测量,测量时在复合带的两边及中部分别取样,每个试样测量3个点,取平均值作为测量结果。由数值模拟结果[17]可知,H90合金液的温度变化对复合层的厚度及其开始凝固的时间影响不大,因此实验中将H90合金液的温度固定不变。参考H90合金的液相线温度及考虑到合金液的流动性,将其定为1 100 ℃。钢带的预热温度参照浸渍复合实验结果[17]分别定为600和800 ℃。调整钢带的运行速度以改变钢带与H90合金液的接触(复合)时间。

图1 反向凝固复合设备示意图

Fig.1 Schematic diagram of inversion solidification clad apparatus

2 结果与分析

2.1 H90复合层厚度的变化规律

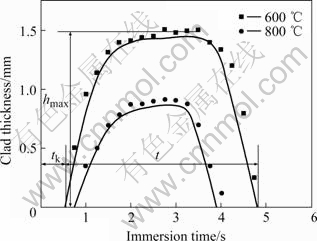

图2所示为H90合金液温度为1 100 ℃,钢带预热温度分别为600和800 ℃时,复合时间对复合层厚度的影响。为便于比较,图中同时给出了相应条件下的数值模拟结果[17] (连续曲线)。由图2可见,随着钢带在铜液中浸入时间的延长,凝固复合层的厚度变化经历了快速生长(变厚)、平衡相持(厚度基本不变)和迅速回熔(厚度变薄) 3个有特征的阶段(超过第三阶段即进入通常所说的热浸镀阶段),钢带预热温度的高低只影响复合层开始凝固的时间tk、可获得的最大复合层厚度hmax以及复合层完全重熔所需要的时间t,对复合层厚度变化的“三阶段”模式没有影响。

图2 复合时间对复合层厚度的影响

Fig.2 Effect of clad time on thickness of clad layer

2.2 H90复合层的组织

图3所示为H90合金液温度为1 100 ℃,钢带预热温度为600 ℃,钢带运行速度为1.8 m/min(复合时间为3 s)时,H90复合层组织的金相照片。从图中可以看出,复合界面规整、平直、无孔洞缺陷,证明复合界面结合良好。复合层的组织为等轴晶且晶粒的生长方向与复合界面成一定的角度。这是因为钢带较薄且预热温度较高,与H90合金液接触后瞬间即可达到较高的温度(模拟结果[17]表明,钢带与铜液接触约1.5 s后,其温度就达850 ℃),故凝固前沿的温度梯度较小,复合层的组织为等轴晶。同时,反向凝固复合时,复合层的结晶是在动态(钢带与铜合金液间有相对运动)条件下完成的,晶粒的生长不仅受热流方向的支配,同时也受钢带与铜合金液间相对运动速度的影响,因此,其晶粒生长方向与复合界面成一定角度。

图3 H90复合层的组织照片

Fig.3 Micrograph of H90 clad layer

2.3 复合界面

为了确认复合界面是否产生了冶金结合,对复合界面进行了线扫描。图4所示为H90合金液温度为 1 100 ℃,钢带预热温度为600 ℃,钢带运行速度为1.8 m/min(复合时间为3 s)时,复合界面的线扫描照片。由图4可见,在复合过程中, Cu和Fe之间发生了相互扩散,未观察到Zn的明显扩散,没有化合物层形成;Cu和Fe之间相互扩散的距离大致相等,形成的扩散层较薄,约为4 μm。由此可以看出,在反向凝固复合中,尽管复合时间较短,但Cu和Fe之间发生了相互扩散且未形成化合物,因此能保证复合界面形成良好的冶金结合。

图4 复合界面的线扫描照片

Fig.4 Line-scan micrograph of clad interface

2.4 界面结合强度

复合带的界面结合强度反映了钢带与复合层间接合的牢固程度,是判断复合带品质的重要指标。由于反向凝固时的复合层较薄,不能采用GB6396—86中复合板剪切强度的测试方法来测量结合强度,因而采用小变形量多道次冷轧和反复弯曲来间接衡量界面的结合强度。

将复合带送入轧机进行多道次冷轧,每道次的变形量约为5%,观察复合带在多道次冷轧过程中是否有边裂、分层等现象发生。轧制实验表明,将厚度为2.44 mm的复合带(单面复合层厚度为0.62 mm)经10道次冷轧到1.21 mm(总变形量为50.41%)时,复合带结合依然良好,没有边裂和分层现象发生。为了进一步检查复合界面是否有微裂纹产生,对复合界面进行了金相观察,如图5所示。从图5可以看出,冷轧后的复合界面平直、完整,无显微裂纹产生。

图5 复合带冷轧后的组织照片(总变形量为50.41%)

Fig.5 Micrograph of cold-rolled clad-strip (50.41% deformation)

将复合带按照GB235—82截取160 mm×10 mm的板状弯曲试样(试样的长度方向与钢带的纵向一致),将试样垂直夹紧于弯曲计夹口中,沿左右方向分别做90?反复弯曲,直到界面开裂或弯断为止。实验结果表明,不同工艺参数所获得的复合带试样,弯断前的弯曲次数相差不大,均在15~18次之间,且在弯断前没有分层现象产生,在弯断断面处也无法将界面剥开,说明界面结合牢固。

2.5 复合带的力学性能

将具有不同复合层厚度的复合带按照GB228—76制成标准试样(试样的长度方向与钢带的纵向一致),在Instron4206型电动材力实验机上进行拉伸实验,测量复合带的屈服强度σs、抗拉强度σb和伸长率δ。测量时,每种复合层厚度的复合带取3个试样数据的平均值,结果如表1所示。由表1可见,尽管不同复合层厚度的复合带其力学性能略有差异,但均能达到GB5213—85所规定的F级深冲钢板的力学性能指标(σs≤216 MPa;σb=255~343 MPa;δ≥39%)。这表明,经反向凝固复合工艺所生产的复合带,不经任何后处理即可用于深冲成型。

表1 复合带的力学性能

Table 1 Mechanical properties of as-clad strip

3 讨论

3.1 复合层厚度的控制

由图2可知,在H90合金液的温度不变时,复合层的厚度随钢带的预热温度以及复合时间(由反向凝固器的长度和钢带的运行速度决定)而变化。这意味着,为了获得某一厚度复层的复合带,可以通过控制钢带的预热温度或控制复合时间来实现,如为了生产复合层厚度为0.75 mm的复合带(见图2),可以采取以下工艺参数:

1) 钢带预热温度为800 ℃,复合时间控制在1.5~3.5 s以内。

2) 钢带预热温度为600 ℃,复合时间控制为约 1 s或4.5 s。

当然,在600~800 ℃钢带预热温度范围内,还有许多可采用的工艺参数。实验中发现,处于不同凝固阶段的复合层,其表面品质是有差异的,处于第一阶段即快速凝固阶段的复合层,表面平整光洁,表面品质好;处于第二阶段即平衡相持阶段的复合层,表面平整但常有轻微划痕,表面品质较好;处于第三阶段即重熔阶段的复合层,表面不光洁,划痕严重,表面品质不好。可见,从保证制品表面品质的角度来看,所确定的工艺参数应使复合层处于快速凝固阶段或平衡相持阶段。

在快速凝固阶段,复合层的凝固速度快,复合层的厚度对复合时间非常敏感,即复合时间的微小波动(如钢带速度的波动)会造成复合层厚度的剧烈波动,故工艺控制难度大;而在平衡相持阶段,复合层的厚度对复合时间不敏感,复合时间的微小波动不会造成复合层厚度的显著变化,工艺控制难度小。因此,综合考虑复合带的表面品质和工艺控制的难易程度,合理的工艺参数应使复合层处于平衡相持阶段,从这个意义上看,复合层的厚度与钢带预热温度之间的关系是一一对应的。

3.2 界面结合机理

一般认为,反向凝固复合属于液-固相复合范畴,但从图2可知,界面的结合过程分为两个阶段:一是液态合金与固态钢带的液-固相相互作用阶段,即复合时间为tk的阶段;二是已凝固的复合层与固态钢带的固-固相相互作用阶段,即复合时间>tk的阶段。由于反向凝固复合时的复合时间较短,加之固-固相相互作用时界面间元素的扩散较慢,因此第二阶段对界面间冶金结合的形成不起作用,第一阶段才是界面间能否形成冶金结合的决定性关键阶段。

在液-固相相互作用阶段,合金液对钢带的润湿、原子之间的相互扩散以及界面能否形成冶金结合起着至关重要的作用。对于H90合金和08Al钢所构成的液-固体系而言,当界面温度为1 100 ℃时,H90合金液是完全能润湿钢带的[18],H90合金液对钢带的完全润湿会在瞬间内与钢带形成大面积的物理接触,这为H90-钢接触界面的快速激活以及被激活原子之间的相互扩散奠定了基础。又由Cu-Fe相图可知,Cu和Fe相互扩散时只形成有限溶解度的固溶体,不形成脆性金属化合物,而Zn的存在不会明显地改变Cu-Fe相图的上述特性,只是使Cu和Fe之间的相互溶解度稍微降低[19]。从相图的这些特点可知,当Cu(Zn)、Fe相互作用时,在接触界面处不形成脆性金属化合物,只形成浓度不同的两个固溶体区:一个是Fe向 Cu(Zn)中扩散所形成的Cu(Zn,Fe)固溶体,另一个是Cu、Zn向Fe中扩散所形成的Fe (Cu,Zn)固溶体。两个固溶体区域的宽度取决于Cu(Zn)和Fe之间相互作用的温度和时间,相互作用的温度越高、时间越长,所形成的两个固溶体区域的宽度越宽。

可见,对于反向凝固复合工艺而言,欲实现界面的冶金结合,需有一定的液-固接触时间来实现界面的物理接触、接触表面的激活以及适当的扩散。若工艺参数控制不当,如钢带预热温度太低,则可能由于液-固接触时间太短而不能实现界面冶金结合。因此,在反向凝固复合工艺中应有最小液-固接触时间(tk)的概念。

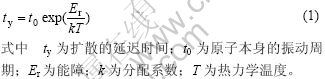

对于液-固接触界面,只要液态金属能润湿固态金属表面,则界面的物理接触在瞬间内即可实现,实际中可忽略其完成的时间,但接触表面的激活过程却不是在瞬间内完成的,只有当表面层原子获得了足以克服相间能障的能量时才能实现。由此可以想象,原子从一种状态向另一种状态过渡的扩散运动会因此而延迟。通常,可以把延迟扩散的时间看作是克服能障前自由原子的存在时间,并可用下式计算[20]:

因此,在反向凝固复合过程中,欲实现界面的冶金结合,应保证tk>ty,即可应用式(1)来计算所需的最小液-固接触时间。遗憾的是,目前还不能对两相之间的能量Er进行精确计算,还只能依靠实验确定。图4所示的界面线扫描分析结果和数值模拟结果[17]表明,对于H90-钢反向凝固复合过程而言,只要保证H90合金液与钢带约有0.5 s以上的接触,即可实现界面的冶金结合,这在H90合金液的温度为1 100 ℃时,只要钢带的预热温度高于600 ℃即可实现。

应该指出的是,如果仅仅将反向凝固复合工艺作为实现界面物理接触的一种手段,而接触界面的激活以及原子的相互扩散通过后序工艺如退火来实现,则在反向凝固复合工艺中也可没有最小液-固接触时间的概念。

4 结论

1) 随着浸渍复合时间的延长,复合层的厚度变化经历了凝固生长、平衡相持和回熔3个阶段。平衡相持阶段因持续时间相对较长、复合层的厚度变化不大且复合带表面品质较好,是实际生产中控制复合层厚度的最佳阶段。

2) 反向凝固复合时,界面的结合过程可分为液-固接触和固-固接触两个阶段,液-固接触阶段持续的时间是界面能否实现冶金结合的关键因素。

3) 当H90合金液的温度为1 100 ℃,钢带的预热温度高于600 ℃时,界面处Cu和Fe发生了相互扩散且扩散距离大约相等,未观察到Zn的明显扩散,没有脆性金属化合物生成,扩散层较薄,约为4 μm。

4)复合层厚度不同时,复合带的力学性能略有差异,但均能达到GB5213—85所规定的F级深冲钢板的力学性能要求,可直接用于深冲成型。

REFERENCES

[1] 李宝绵,李兴刚,许光明,崔建忠. 铜/钢复合材料的研究及应用[J]. 材料导报,2002, 16(2): 22-24.

LI Bao-mian, LI Xing-gang, XU Guang-ming, CUI Jian-zhong. Study and application of Cu/steel clad metal[J]. Materials Review, 2002, 16(2): 22-24.

[2] Rasgado M T A, Davey K, Clark L D. Bi-metallic dies for rapid die casting[J]. Journal of Materials Processing Technology, 2006, 175: 109-116.

[3] 吕战竹,刘顺福,赵福令. 铜/钢爆炸复合材料在电火花加工中的应用[J]. 电加工与模具, 2002, 37(5): 9-11.

LU Zhan-zhu, LIU Shun-fu, ZHAO Fu-ling. Application of explosively welded copper/steel clad material in EDM[J]. Electromachining & Mould, 2002, 37(5): 9-11.

[4] YAN Hong-zhi, Lenard J G. A study of warm and cold roll-bonding of an aluminum alloy [J]. Materials Science and Engineering A, 2004, 385: 419-428.

[5] Raghukandan K. Analysis of the explosive cladding of Cu-low carbon steel plates[J]. Journal of Materials Processing Technology, 2003, 139: 573-577.

[6] 田雅琴,秦建平,李小红. 金属复合板的工艺研究现状与发展[J]. 材料开发与应用, 2006, 21(1): 40-43.

TIAN Ya-qin, QIN Jian-ping, LI Xiao-hong. Current state and trend of metal clad sheet manufacture technology[J]. Development and Application of Materials, 2006, 21(1): 40-43.

[7] Manesha H D, Taherib A K. Theoretical and experimental investigation of cold rolling of tri-layer strip[J]. Journal of Materials Processing Technology, 2005, 166: 163-172.

[8] 魏 伟,史庆南. 铜/钢双金属板异步轧制复合机理研究[J]. 稀有金属, 2001, 25(4): 307-311.

WEI Wei, SHI Qing-nan. Bonding mechanism of Cu/steel clad sheet in asymmetrical rolling of bimetal[J]. Chinese Journal of Rare Metals, 2001, 25(4): 307-311.

[9] 李英宏,齐克敏,朱 泉. 钢与黄铜双金属冷轧固相复合的研究[J]. 钢铁,1997, 32(4): 46-50.

LI Ying-hong, QI Ke-min, ZHU Quan. Study on cold-roll bonding of steel/brass bi-metal[J]. Iron & Steel, 1997, 32(4): 46-50.

[10] Pleschiutschigg F P. Inversion casting—a new method for producing near-net-shape cast strips[J]. Stahl und Eisen, 1994, 114(2): 47-53.

[11] Pleschiutschigg F P. Inversion casting of steel strip[J]. Steel Times, 1995, 223(6): 228-229.

[12] 倪红卫,陈 浩. 反向凝固复合不锈钢带界面结合和凝固组织特征[J]. 武汉理工大学学报:交通科学与工程出版, 2002, 25(1): 35-38.

NI Hong-wei, CHEN Hao. Inversion casting stainless steel composite strip: its characters of bonding and solidification microstructure on interface[J]. Journal of Wuhan University of Technology: Transportation Science & Engineering, 2002, 25(1): 35-38.

[13] LI Na, CHEN Yan-bo, MENG Xian-yun. Preparation of composite aluminum automobile radiator by inversion casting[J]. Trans Nonferrous Met Soc China, 2001, 11(1): 138-140.

[14] 孙跃军,仲伟深,高顺利. 反向凝固铜/钢电车线的研究[J]. 铸造技术, 2004, 25(8): 607-609.

SUN Yue-jun, ZHONG Wei-shen, GAO Shun-li. Research on reversing solidification copper/steel electrical train wire[J]. Foundry Technology, 2004, 25(8): 607-609.

[15] 方晓英,张艳莉,吴法宇. 包铜钢线液固相反向凝固过程的数值模拟[J]. 热加工工艺, 2004, 33(1): 27-29.

FANG Xiao-ying, ZHANG Yan-li, WU Fa-yu. Numerical simulation on process of liquid and solid inverted solidification of Cu/Fe in copper clad steel [J]. Hot Working Technology, 2004, 33(1): 27-29.

[16] LI Na, GUO Shou-ren, LU De-zhong. Technique of aluminum alloy composite by inversion casting[J]. Journal of Materials Science and Technology, 2002, 18(2): 187-188.

[17] 李宝绵. H90-钢反向凝固复合工艺及理论研究[D]. 沈阳: 东北大学, 2004.

LI Bao-mian. Process and Theory Study on Inversion-cast Cladding of H90-Steel Strip[D]. Shenyang: Northeastern University, 2004.

[18] Ishida T. Spreading kinetics of liquid metals on mild steel[J]. Mater Sci Tech, 1988, 4(9): 830-835.

[19] 田荣璋,王祝堂. 铜合金及其加工手册[M]. 长沙:中南大学出版社,2002: 44.

TIAN Rong-zhang, WANG Zhu-tong. Handbook of Copper and Copper Alloy[M]. Changsha: Central South University Press, 2002: 44.

[20] 何康生,曹雄夫. 异种金属焊接[M]. 北京:机械工业出版社,1986: 106-142.

HE Kang-sheng, CAO Xiong-fu. Welding of Dissimilar Metals[M]. Beijing: China Machine Press, 1986: 106-142.

基金项目:国家高技术研究发展计划资助项目(2002AA334060)

收稿日期:2006-10-24;修订日期:2006-12-26

通讯作者:李宝绵,副教授,博士;电话:024-83681735;E-mail:bmlee@epm.neu.edu.cn

(编辑 杨幼平)