Manufacturing techniques of armor strips excavated from Emperor Qin Shi Huang’s mausoleum, China

LIAO Ling-min(廖灵敏)1, PAN Chun-xu(潘春旭)1,2, MA Yu(马 宇)3

1. Department of Physics, Wuhan University, Wuhan 430072, China;

2. Center for Archaeometry, Wuhan University, Wuhan 430072, China;

3. Museum of the Terra-cotta Warriors and Horses of Qin Shi Huang, Xi’an 710600, China

Received 17 February 2009; accepted 17 June 2009

Abstract: The chemical compositions and microstructures of the armor strips excavated from the Emperor Qin Shi Huang’s mausoleum were examined systematically by using optical microscopy and electron microscopy. It was found that the armor strips were made of pure copper. Based on the morphology of α-Cu recrystal grain and copper sulphide (Cu2S) inclusions in the armor strips, the manufacturing techniques were proposed as follows: smelting pure copper, casting a lamellar plate, forming the cast ingots into sheets through repeated cold forging combined with annealing heat treatment, and finally cutting the sheets into filaments. Furthermore, through the deformation of copper sulphide (Cu2S) inclusions in the strips, the work rate during forging was evaluated and calculated to be close to 75%.

Key words: Qin Shi Huang’s mausoleum; armor strips; copper; manufacturing techniques; cold forging; annealing

1 Introduction

In 1998, the stone armors were excavated in the accessory pit K9801 of the Emperor Qin Shi Huang’s mausoleum[1]. The armors were composed of caesious limestone sheets which were jointed with metal wires. The wires all looked like filamentary with a length of dozens of centimeters, a width of about 4 mm and a thickness of 1 mm, which were similar with the modern metallic flat filaments or strips. Generally, the research work was concentrated upon the historical value of the stone armors from their types, texture and structures[2]. Some researchers explored the new methods for better restoration of the stone armors[3]. In addition, the production process of the stone armors was also proposed, including material selection, cutting, designing, drilling, grinding, polishing and weaving[4]. And the armor strips were the materials used in the last step for weaving the stone armors. However, its manufacturing technique is still not clear.

The modern fabrication of metal flat filaments approximately included the following technical processes: casting, press-working mixed with heat treating, and then wiredrawing[5], in which advanced machines and complex techniques were employed. However, the ancient technicians could not manufacture such slender armor strips with the same process in the productive condition over 2 000 years ago. As a matter of fact, following the flourishing period for bronze, Spring and Autumn Warring States period (472-221 years B. C.), the mature smelting and casting technologies for copper and bronze were well inherited in Qin dynasty (221-207 years B. C.), as well as the smelting of iron appeared and kept developing gradually[6-7]. In addition, the abundant material processing techniques such as cold or hot forging, welding, grinding, drilling and inlaying, were extensively utilized in the fabrication of metal products, which had been observed in the large quantity of gold, silver, bronze and iron relics excavated from Qin Shi Huang’s mausoleum[8-10]. Especially, various material processing techniques were skillfully combined to produce the bronze chariot and horse from the mausoleum, that is to say, the mechanical engineering for metal materials in Qin dynasty had developed to a quite high level. Hereby, the armor strips must be manufactured through a unique technological process which deserved much attention to explore it.

In the present work, the armor strips excavated from the K9801 accessory pit were examined systematically and comprehensively by using optical microscopy and electron microscopy, which aimed to make clear how did the Qin technicians produce such slender armor strips. It would be also helpful for further understanding the technological levels of material processing in Qin dynasty.

2 Materials and methods

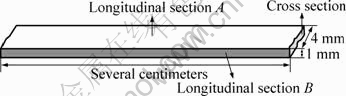

The fragments of the armor strips excavated from the K9801 accessory pit were provided by The Museum of the Terra-cotta Warriors and Horses of Qin Shi Huang, Xi’an, China. Approximately, the cross section of the several centimeters long wire exhibits a rectangle shape of 4 mm in width and 1 mm in thickness, as shown in Fig.1 and Fig.2. There is a thick cyan rust layer on the surface.

Fig.1 Typical photograph of armor strip

Fig.2 Sketch diagram of armor strip

Metallographic specimens for cross section and longitudinal sections (A and B) were prepared in a standard process: cutting samples, mounting, grinding, polishing and then etching by dipping into alcoholic ferric nitrate solution. The etching solution was made of 2 g ferric nitrate and 50 mL ethanol.

Microstructure observations and chemical composition analysis were carried out by using a OLYMPUS cover-018 optical microscope and a FEI Sirion field emission gun scanning electron microscope (SEM) system, equipped with an EDAX GENESIS 7 000 energy dispersive X-ray spectrometer (EDS) coupled to a Electron backscattering diffraction (EBSD) system.

3 Results and discussion

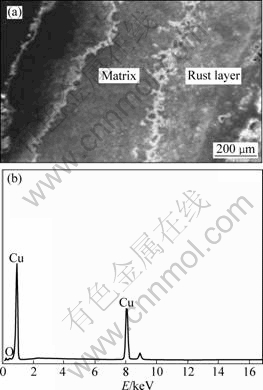

The EDS analysis confirms that the armor strip is only composed of copper (Cu) element, except a rust layer of about 300-400 μm containing small amount of tin (Sn) and oxygen (O), as shown in Fig.3. Obviously, selecting pure Cu for making flat wires due to its high toughness, ductility and malleability indicated that the ancient technicians at Qin dynasty had well-developed Cu smelting technique and fully understood the relationships between compositions and properties.

Fig.3 SEM image of cross section (a) and EDS result of matrix (b) in armor strip

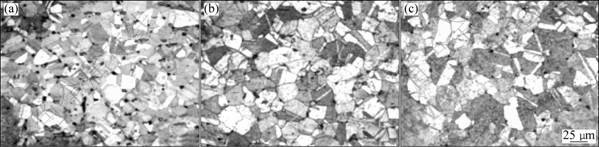

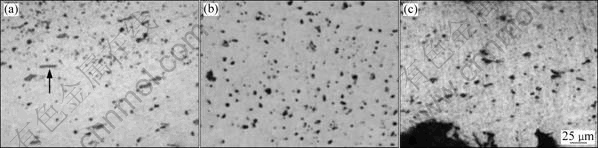

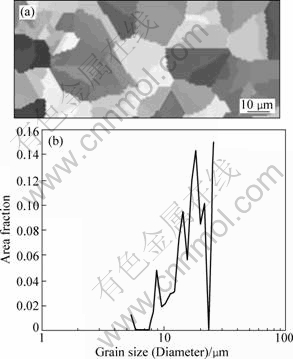

Fig.4 and Fig.5 show the etched and unetched microstructures of the longitudinal sections and the cross section, respectively, for revealing the grain size and inclusions in the strip. The results indicate that the microstructure of the armor strip consists of α-Cu recrystallized grains with annealing twins, porosity and copper sulphide (Cu2S) inclusions. Further EBSD analysis, as shown in Fig.6, reveals that the α-Cu phase presents the equiaxed grains without preferred crystal orientation in the strip, and the grain size ranges from 10 μm to 20 μm with an average diameter of 13.59 μm[11]. However, it is startling that the grain size is so small even compared with the modern grade standard of grain size for copper products[12]. Therefore, it could be inferred that the armor strip had been undergone a heat treatment process before it was applied to practical usage.

Fig.4 Optical images of etched sample: (a) Cross section; (b) Longitudinal section A; (c) Longitudinal section B

Fig.5 Optical images of unetched sample: (a) Cross section; (b) Longitudinal section A; (c) Longitudinal section B

Fig.6 EBSD analysis results of armor strip: (a) Orientation distribution map (B=[001]); (b) Corresponding profile of grain size

In addition, the morphologies of the inclusions on the cross section and longitudinal section B almost elongate parallel to the plane of the longitudinal section A, as shown in Fig.2 and Fig.5(a). However, the inclusions on the longitudinal section A exhibit a polygonal or approximately circular shapes without stretch deformation, which deform similarly as the malleated structure[13-15]. These results implied that the armor strip was manufactured through a large plastic deformation. Obviously, it could not be obtained as we do today by using a withdrawing process: casting, press-working, shaping, heat treatment, and wiredrawing[5]. Then, we need to evaluate the possible technological process for making the flat wire or strip before 2 200 years.

It is well known that during modern wire-drawing process, the grains and inclusions in a flat thread or wire are stretched along the shaping direction on axial sections and exhibit a polygonal morphology on cross section[16]. However, for the armor strip, the equiaxed grains are present in all sections, which means that its manufacturing technique is different from the modern wire-drawing process. In addition, the elongated inclusions in the armor strip hint that it has experienced a large plastic deformation. Hereby, the most probable manufacturing technique for making the armor strips is proposed as follows: smelting, casting, forming the copper ingots into sheets through repeated cold forging combined with heat treatment, and finally cutting the sheets into filaments.

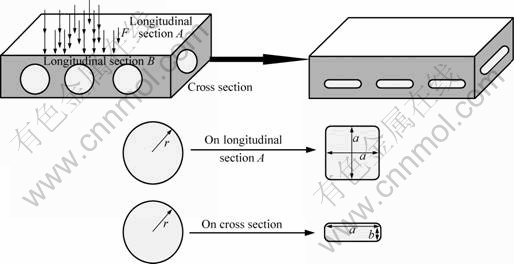

For the first step in the process, the well-developed copper smelting technology in Qin dynasty guaranteed high purity copper for manufacturing the armor strips[17-18], due to its excellent ductility. Though iron had appeared in Qin dynasty, it could not take the place of copper alloys for producing weaponry and arming owing to the limitation of immature iron smelting technology[19]. In the second step, the copper ingots were cast into a lamellar plate, which provided an easy way to obtain the ultimate flat filamentary shape of armor strips through forging technique. In fact, compared with the casting forming of the complex bronze chariots and horses, the shape of lamellar plate could be easily got through casting by the Qin technicians. Since the cast copper lamellar plate was forged into a sheet, the initial thickness of the lamellar plate could be approximately supposed through a simple simulative model, as shown in Fig.7.

Fig.7 Rough schematic simulative model on deformation process of Cu2S inclusions in armor strips

The model was based on the assumption that the initial Cu2S inclusions were spherical with a radius of r in the cast copper ingots. Then, corresponding to the pressure of forging, the shape of the inclusions changed from circles with a radius of r into almost squares with a side length of a observed on the longitudinal section A, while from circles with a radius of r to almost rectangle with a length of a and a width of b observed on the longitudinal section B and the cross section. As the volume of the inclusions was invariable, it could be described with Eq.(1):

(1)

(1)

In this case, the total work rate of forging, δ, could be calculated through the formula: δ=1-b/(2r). Thus, one of the Cu2S inclusions on the cross section was chosen for the calculation of δ, as shown in Fig.5(a). The length of a and width of b for it were measured, respectively, with the result of a=19.25 μm and b=3.43 μm. According to the Eq.(1), the value of r was obtained, i.e., r=6.72 μm. So, the total work rate of forging, δ, could be easily estimated to be about 75%, which was a large deformation degree. That is to say, the thickness of the initial cast copper lamellar plate might be approximately 4 mm.

Based on the production conditions in Qin dynasty, the forging technique was probably executed with a striking and forged tool, such as forging hammer manually. Owing to the mature bronze technology and the appearance of iron in Qin dynasty, the forged tool might be made of bronze or iron because of its higher hardness and strength. According to the modern forging theory of copper, due to its excellent plasticity, a pure copper could be plastically deformed by both cold and hot working[20]. Compared with cold forging, hot forging is easier to be performed and takes less force. And it will make the casting pores reduced in size or close completely[21]. However, as shown in Fig.4 and Fig.5, pores are visible in the microstructure of the armor strips. Therefore, it is more reasonable to consider that the armor strips were formed by a cold forging technique. That is to say, having realized it through summarizing the experience in the long-term copper processing, the Qin technicians successfully adopted cold forging technique to form the cast copper lamella into a sheet by using bronze or iron forging hammers.

It is well known that the copper lamella becomes harder and less ductile which intends to result in a fracture, if the forge is continuously performed. Thus, when the armor strips were produced, an intermediate annealing treatment must be used during cold forging for relieving the work-hardening and improving the plasticity. Based on the modern annealing technology, with the higher annealing temperature and longer duration, the larger recrystallization grain size will be obtained. This means that the annealing temperature and duration for Cu recrystallization should be precisely controlled in order to get the fine recrystal grains. For instance, the average recrystal grain size would be refined to 15 μm after annealing for 30 min at 450 ℃ for TP2 type industrial copper[22]. Thereby, the well- refined recrytallization grains less than 15 μm for armor strips represent that the ancient technicians had skillfully mastered the appropriate annealing technique to ameliorate the combination property of strength and toughness for them, which was very favorable for their utility in the jointing of stone armors.

Finally, as the copper sheets were cut into slender filaments, the armor strips were completely produced so as to commendably fulfill the usage of jointing the different parts of stone armors.

4 Conclusions

1) Different from the modern withdrawing process, the armor strips excavated from the Emperor Qin Shi Huang’s mausoleum, China, were made of pure copper with the following manufacturing processes: smelting, casting a lamellar plate, forming the cast ingots into sheets through repeated cold forging combined with intermediate annealing, and finally cutting the sheets into filaments, which further convinced the high level material processing technology in Qin dynasty.

2) According to the deformation of copper sulphide (Cu2S) inclusions in the armor strips, the work rate of forging during the process was evaluated to be close to 75%.

Acknowledgements

We would like to thank Museum of the Terra-cotta Warriors and Horses of Qin Shi Huang, China, for providing the samples.

References

[1] WANG Wang-sheng. Trial excavation of the stone armor accessory pit in the Qin Shi Huang Mausoleum [J]. Relics and Museolgy, 1999(6): 12-17. (in Chinese)

[2] JIANG Wen-xiao. A new study on the armor of the Qin dynasty [J]. Relics and Museolgy, 2002(6): 62-65. (in Chinese)

[3] XIA Yan, WEICHER M, ZHANG Zhi-jun, ZHOU Tie, MA Sheng-tao. Application of cyclododecane on one stone armour set excavation and restoration [J]. Sciences of Conservation and Archaeology, 2005, 17(2): 31-35. (in Chinese)

[4] JIANG Wen-xiao. The study on the Qin stone armours of pit K9801 [D]. Xi’an: Northwest University, 2007. (in Chinese)

[5] LI Zhong-he. Copper wires and meshes [M]. Beijing: China Light Industry Press, 1987: 150-200. (in Chinese)

[6] CHASE W T. Ancient Chinese bronze art: Casting the precious sacral vessel [M]. New York: China House Gallery, 1991: 250-269.

[7] LI Yang, LI Zu-de. Bloomery iron process in ancient china [J]. Materials Science and Engineering of Powder Metallurgy, 1999, 4 (1): 1-9. (in Chinese)

[8] ZHANG Tao. The unearthed arms out of the warrior figure pits of the Qin dynasty [J]. The Silk Road, 1999(1): 20-24. (in Chinese)

[9] YUAN Zhong-yi, CHENG Xue-hua. The structure and manufacturing technology of bronze chariots and horses from Qingshihuang’s Tomb [J]. Acta Univ Agric Boreali-occidentalis, 1995, 23(supplement): 59-65. (in Chinese)

[10] HOU Jie-ren. A practical study on the drilling technology adopted in bronze chariots and horses building in Qin dynasty [J]. Acta Univ Agric Boreali-occidentalis, 1995, 23(supplement): 81-84. (in Chinese)

[11] ARTIOLI G. Crystallographic texture analysis of archaeological metals: Interpretation of manufacturing techniques [J]. Applied Physics A, 2007, 89 (4): 899-908.

[12] ZUO Shen-ao, LIU Huai-he. Measurement and application of the grain size of α single-phase Cu alloys [J]. Materials for Mechanical Engineering, 2005, 29(9): 69-70. (in Chinese)

[13] KIENLIN T L, BISCHOFF E, OPIELKA H. Copper and bronze during the eneolithic and early bronze age: A metallographic examination of axes from the northalpine region [J]. Archaeometry, 2006, 48(3): 453-468.

[14] GORDON R, KNOPF R. Metallurgy of bronze used in tools from Machu Picchu, Peru [J]. Archaeometry, 2006, 48(1): 57-76.

[15] GUO Ming-xing, WANG Ming-pu, SHEN Kun, CAO Ling-fei, LEI Ruo-shan, LI Shu-mei. Effect of cold rolling on properties and microstructures of dispersion strengthened copper alloys [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 333-339.

[16] The Metallographic Examination Group of Luoyang Copper Working Factory. The atlas copper and copper alloy [M]. Beijing: Metallurgical Industry Press, 1983: 22-25. (in Chinese)

[17] SU Rong-yu, HUA Jue-ming, LI Ke-ming, LU Ben-shan. The metal technology of early ancient China [M]. Ji’nan: Shandong Science & Technology Press, 1995: 40. (in Chinese)

[18] PIGOTT V C. Old world archaeometallurgy[J]. Journal of Metals, 1988, 40(2): 36-37.

[19] HAN R, WATTS G, KENNON N. The development of iron and steel technology in ancient China [J]. Materials Australasia, 1986, 18(9): 12-16.

[20] GUO Hong-zhen. Alloy steel and nonferrous alloys forging [M]. Xi’an: Northwestern Polytechnical University Press, 1999: 158-172. (in Chinese)

[21] DOUGLAS R, KUHLMANN D. Guidelines for precision hot forging with applications [J]. Journal of Materials Processing Technology, 2000, 98: 182-188.

[22] KOO J B, YOON D Y. Abnormal grain growth in bulk Cu: The dependence on initial grain size and annealing temperature [J]. Metallurgical and Materials Transactions A, 2001, 32(8): 1911-1926.

Corresponding author: PAN Chun-xu; Tel: +86-27-62367023; Fax: +86-27-68752569; E-mail: cxpan@whu.edu.cn

DOI: 10.1016/S1003-6326(09)60152-7

(Edited by YANG Bing)