文章编号:1004-0609(2011)09-2091-08

Ag-SnO2复合材料的热压缩变形行为

许灿辉1, 2, 易丹青1, 2, 曹适意1, 2, 刘会群1, 2, 吴春萍1, 2, 孙顺平1, 2, 刘润勇3

(1. 中南大学 材料科学与工程学院,长沙 410083;2. 中南大学 教育部有色金属重点实验室,长沙 410083;

3. 佛山通宝精密合金股份有限公司,佛山 528000)

摘 要:采用Gleeble-1500热模拟实验机对Ag-SnO2(10%,质量分数)复合材料进行高温压缩变形实验,分析该材料在变形温度为750~900 ℃、应变速率为0.01~1 s-1条件下的流变应力变化规律;采用透射电镜(TEM)观察Ag-SnO2(10%)复合材料热压缩变形后的显微组织。采用双曲正弦确定了该材料的变形激活能,建立了以Zener-Hollomon 参数描述的高温塑性变形本构模型,并验证了本构模型的准确性。结果表明:变形温度和应变速率均对流变应力有显著影响,流变应力随变形温度升高而减小,随应变速率的增加而增大。动态再结晶和孪晶共同作用是Ag-SnO2 复合材料热压缩变形的主要变形机制,随应变速率增加,孪晶数量增多,并形成了二次孪晶。

关键词:Ag-SnO2复合材料;热压缩变形;本构方程;显微组织

中图分类号:TM241 文献标志码:A

Hot compression behavior of Ag-SnO2 composite material

XU Can-hui1, YI Dan-qing1, CAO Shi-yi1, LIU Hui-qun1, WU Chun-ping1, SUN Shun-ping1, LIU Run-yong2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory for Nonferrous Metal, Education Ministry, Central South University, Changsha 410083, China;

3. Foshan Electrical Precision Alloy Co. Ltd., Foshan 528000, China)

Abstract: The flow stress behaviors of Ag-SnO2 (10%, mass fraction) composite material prepared by powder metallurgical method were investigated on Gleeble-1500 machine at temperatures of 750-900 ℃ and strain rates of 0.01-1 s-1. The microstructures of Ag-SnO2 (10%) composite materials after hot compression deformation were characterized by transmission electron microscopy (TEM). The deformation activation energy was calculated using the hyperbolic-sine mathematics model, and the flow stress constitutive equation of Ag-SnO2 composite during hot compression was represented by Zener-Hollomon parameter. The results indicate that the flow stress depends on the strain rate and deformation temperature. The flow stress increases with the strain rate increasing and decreases with deformation temperature increasing. The flow stress of Ag-SnO2 composite predicted by the proposed models well agrees with experimental results. The combined action of dynamic recrystallization and twins crystals is the main deformation mechanism in the hot compression of Ag-SnO2 composite. The quantity of twin crystals increases with the strain rates increasing and also the secondary twins are observed.

Key words: Ag-SnO2 composite; hot compression; constitutive equation; microstructures

银-氧化镉(Ag-CdO)触头材料因具有良好的抗熔焊性能、低而稳定的接触电阻被称为“万能触头”,但是镉元素具有毒性,西方发达国家已经禁止在家用电器和汽车电器中使用Ag-CdO触头材料[1]。因此,开发性能相当甚至更为优异的Ag-CdO替代材料成为电接触材料领域的研究热点。在众多研究体系中,Ag-SnO2是一种较为理想的替代材料[2-3]。早在20 世纪70 年代中期,日本学者在第七届国际电接触会议上公开了用合金内氧化法制备Ag-SnO2触点材料[4]。20世纪80年代,著名的德国Degussa公司采用先进的粉末冶金与挤压技术研制成功新型Ag-SnO2材料,解决了接触电阻和温升问题,成功地代替Ag-CdO应用于交直流接触器、继电器以及低压断路器等领域[5]。大量研究表明,Ag-SnO2不仅具有良好的抗电弧侵蚀性,而且还具有高抗熔焊和低材料转移特性[6-7]。这些优良性能完全可以与Ag-CdO相媲美,特别在汽车用大功率直流继电器领域,Ag-SnO2的抗材料转移特性要明显优于Ag-CdO 材料的[8-9]。

Ag-SnO2作为一种典型的氧化物颗粒增强银基复合材料,由于SnO2的高硬度导致Ag-SnO2材料的塑性和韧性降低,材料加工成型异常困难,其中丝材拉拔,铆钉墩制过程表现尤其突出,严重影响了该材料的广泛应用。因此,如何改善Ag-SnO2材料加工性能对提高生产效率、加快Ag-SnO2材料的推广应用具有重要意义。Ag-SnO2材料的加工性能受SnO2的尺寸、含量、分布等多种因素的影响。HERINGHAUS等[10]研究认为,Ag-SnO2材料的抗拉强度随SnO2颗粒间距减小而显著增加,而采用超细SnO2颗粒则不利于提高材料加工性能。张志伟等[11]研究发现,在大塑性变形条件下,SnO2颗粒分布弥散均匀,且材料伸长率得到较大改善。张国庆等[12]研究了Ag-SnO2材料变形过程的断裂机制,发现通过调整SnO2颗粒尺寸及分布状况能有效防止Ag-SnO2复合材料在变形过程中形成微裂纹。由于硬脆相SnO2颗粒难变形,因此在Ag-SnO2复合材料中起到强化基体和阻碍变形的作用。目前,关于Ag-SnO2复合材料变形机理的研究报道很少。刘满门等[13]研究了Ag-SnO2(8%)复合材料的热压缩变形行为,并建立了其流变应力本构方程,但对其变形机制没有进行深入研究。为此,本文作者利用Gleeble-1500热力模拟试验机对粉末冶金法制备的Ag-SnO2(10%)复合材料进行高温压缩变形实验,分析Ag-SnO2(10%)复合材料高温变形过程流变应力与变形温度、应变速率间的关系,建立材料热变形过程的本构方程并验证了该模型的准确性,结合显微组织分析探讨Ag-SnO2(10%)复合材料的塑性变形机制。

1 实验

本实验所用的Ag-SnO2(10%,质量分数)复合材料由佛山精密电工合金有限公司提供。材料制备过程如下:将粒径小于0.44 μm的纯银粉和粒径小于1 μm 的SnO2粉末充分混合,经冷等静压、烧结工序制成 Ag-SnO2(10%)复合材料锭坯。加工后的热压缩实验样品的尺寸为d 6 mm×10 mm,两端带有d 5 mm×0.2 mm凹槽。高温压缩实验在Gleeble-1500材料热模拟试验机上进行。高温压缩实验变形温度为750、800、850和900 ℃;应变速率为0.01、0.1和1 s-1;总压缩变形量约为0.6 (真应变)。样品采用热模拟机电阻加热,升温速度约为5 ℃/s,保温时间3 min,试样两端的凹槽内填充润滑剂(75%石墨+20%机油+5%硝酸三甲苯脂),以减少摩擦对变形的影响。压缩后的样品迅速水冷到室温以保留热变形时的组织。

采用FEI TECNAIG2 20(200 kV)型透射电镜对热压缩后的样品进行显微组织分析。热压缩后样品先进行机械预磨减薄成d 3×0.08 mm的圆片,并利用Gatan凹坑仪进行凹坑处理,然后在Gatan离子减薄仪上进行离子减薄制成透射样品进行显微组织分析。

2 结果与分析

2.1 真应力—真应变曲线

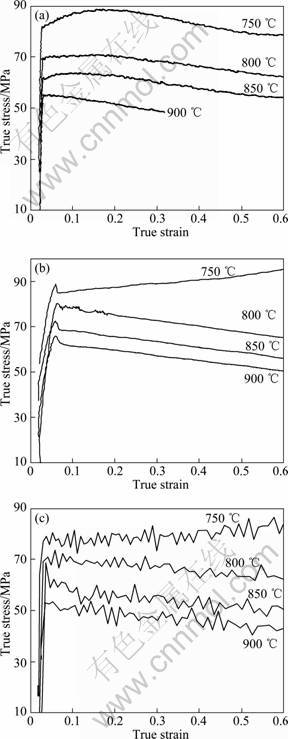

图1所示为Ag-SnO2(10%)复合材料热压缩变形过程的真应力—真应变关系曲线。由图1可以看出,在变形温度为750~900 ℃、应变速率为0.01~1 s-1的变形条件下,Ag-SnO2复合材料存在较明显的稳态流变特征,即在弹性变形阶段,应力呈线性迅速增加;当应力超过材料屈服强度时开始发生塑性变形。峰值应力之前,虽然发生部分动态回复或动态再结晶,但位错密度增加所导致的硬化作用占主导地位,因此,应力随应变增加而缓慢上升。应力达到峰值后逐渐下降并趋于稳定,此时加工硬化与动态再结晶软化作用相互竞争,达到平衡状态。对比分析图1(a),(b)和(c)可发现,变形温度为750 ℃时,应力达到稳态流变状态后缓慢上升;当变形温度在750 ℃以上时,随着变形温度的增加,稳态流变应力均缓慢降低,表明材料的动态再结晶软化作用随变形温度升高而增强。分析发现,在同一应变速率下,流变应力随着变形温度的升高而降低;在同一变形温度下,流变应力随着应变速率的增大而增大。这说明在该实验条件下,Ag-SnO2复合材料具有正的应变速率敏感指数[14],即应变速率越大,变形温度越低,材料越难达到稳态变形。当应变速率为1 s-1时,真应力—真应变曲线呈明显的锯齿状特征(见图1(c)),分析认为,这种应力波动一方面是受变形过程中硬化与软化交替作用的影响,另一个原因则是孪晶造成的。孪晶容易在层错能较低的晶体中形成(如银),且通常在高应力集中处形核,孪晶“形核”所需应力远比孪晶长大的大。在Ag-SnO2复合材料热变形过程中,SnO2颗粒的存在对位错运动具有显著的钉扎作用,位错在SnO2颗粒周围的塞积产生应力集中。当滑移受到阻碍时,才在应力集中处萌发孪晶。一旦孪晶成核,应力迅速释放,因此,其应力—应变曲线会有突然下降。随着应变的进一步增加,在SnO2颗粒周围又会产生新的应力集中和新的孪晶形核,从而导致其应力—应变曲线呈锯齿状特征,这一点在材料的微观组织分析中也得到了证实。

图1 Ag-SnO2(10%)材料真应力—真应变曲线

Fig.1 True stress—true strain curves of Ag-SnO2(10%) composites under different deformation conditions: (a)  =0.01 s-1; (b)

=0.01 s-1; (b)  =0.1 s-1; (c)

=0.1 s-1; (c)  =1 s-1

=1 s-1

2.2 流变应力本构方程的建立

由材料的真应力—真应变曲线可知,材料的流变应力与变形温度及应变速率有着密切的关系。SELLARS和TEGART等[15-16]提出了一种包含变形激活能Q和温度T的双曲正弦形式的流变应力模型,材料变形温度T、应变速率 与流变应力σ的关系可表示如下:

与流变应力σ的关系可表示如下:

在低应力水平时,

(1)

(1)

在高应力水平时,

(2)

(2)

在所有应力状态时,

(3)

(3)

式中: 为应变速率,s-1;σ为峰值应力或稳态流变应力,MPa;Q为变形激活能,J/mol;R为气体常数,8.314 J/(mol·K);T为热力学温度,K;A、α、β和n为常数,且满足:

为应变速率,s-1;σ为峰值应力或稳态流变应力,MPa;Q为变形激活能,J/mol;R为气体常数,8.314 J/(mol·K);T为热力学温度,K;A、α、β和n为常数,且满足: 。

。

ZENER和HOLLOMON[17]的研究表明,材料的高温塑性变形是一个受热激活控制的过程,应变速率与温度之间的关系可用Zener-Hollomon参数表示:

(4)

(4)

Z参数的物理意义是温度补偿的变形速率因子。

对式(1)、(2)和(3)分别两边取对数可得:

(5)

(5)

(6)

(6)

(7)

(7)

由式(5)和(6)可知,当温度一定时,ln 与σ、ln

与σ、ln 与ln σ之间均成正比关系。β和n分别为σ—ln

与ln σ之间均成正比关系。β和n分别为σ—ln 和lnσ—ln

和lnσ—ln 和曲线的斜率。采用一元线性回归处理,可分别绘制σ—ln

和曲线的斜率。采用一元线性回归处理,可分别绘制σ—ln 和lnσ—ln

和lnσ—ln 曲线,如图2所示。

曲线,如图2所示。

图2 流变应力与应变速率的关系曲线

Fig.2 Relationships between flow stress and strain rate: (a) Curves of σ—ln ; (b) Curves of lnσ—ln

; (b) Curves of lnσ—ln

由式(7)可知,当温度恒定时,

(8)

(8)

当应变速率恒定时,

(9)

(9)

联立式(8)和(9),可得

(10)

(10)

采用线性回归方法绘制材料压缩变形时各变形条件下的ln[sinh(ασ)]—ln 关系曲线和ln[sinh(ασ)]—1/T关系曲线,如图3所示。根据式(10)可求出Ag-SnO2(10%)复合材料高温变形的变形激活能为Q=590 kJ/mol,其值明显高于采用反应合成法制备的Ag-SnO2(8%)复合材料的变形激活能218.65 kJ/mol[13]。变形激活能的大小反映材料变形的难易程度。分析认为,Ag-SnO2复合材料塑性变形行为受SnO2颗粒的尺寸、分布、形状等因素影响[10],SnO2颗粒含量越大,颗粒分布越弥散,变形过程中对位错运动产生的钉扎作用越大,弥散强化效果越明显,因此材料的变形抗力显著提高,材料塑性变形越困难。

关系曲线和ln[sinh(ασ)]—1/T关系曲线,如图3所示。根据式(10)可求出Ag-SnO2(10%)复合材料高温变形的变形激活能为Q=590 kJ/mol,其值明显高于采用反应合成法制备的Ag-SnO2(8%)复合材料的变形激活能218.65 kJ/mol[13]。变形激活能的大小反映材料变形的难易程度。分析认为,Ag-SnO2复合材料塑性变形行为受SnO2颗粒的尺寸、分布、形状等因素影响[10],SnO2颗粒含量越大,颗粒分布越弥散,变形过程中对位错运动产生的钉扎作用越大,弥散强化效果越明显,因此材料的变形抗力显著提高,材料塑性变形越困难。

图3 ln[sinh(ασ)]—ln 关系曲线和ln[sinh(ασ)]—1/T关系 曲线

关系曲线和ln[sinh(ασ)]—1/T关系 曲线

Fig.3 Relation curves of ln[sinh(ασ)]—ln (a) and ln[sinh(ασ)]—1/T (b)

(a) and ln[sinh(ασ)]—1/T (b)

将计算的变形激活能Q值代入式(4)可求得各变形条件下的Z值。对式(4)两边取自然对数得

(11)

(11)

根据式(11)绘制ln Z与ln[sinh(ασ)]关系曲线,如图4所示,根据其斜率和截距可求得更为精确的材料常数n和A值如下:n=21.36,A=2.102×1026。利用n和β值可求得α=0.012。将求得的Q、n、A和α等材料参数代入式(3),可得Ag-SnO2(10%)复合材料热压缩变形时的流变应力本构方程为

式中:Z参数表达式为 。

。

图4 流变应力与Z参数的关系

Fig.4 Relationship between Zener-Hollomon parameter and flow stress

2.3 实验值与预测值比较分析

为了验证上述实验得到的Ag-SnO2(10%)复合材料热变形本构模型的准确性,图5给出了不同变形条件下峰值应力计算值与实验数据的对比分析。结果表明,峰值应力计算值与实验结果非常接近,其最大相对误差为6.9%。这说明所建立的Ag-SnO2(10%)复合材料热变形本构方程具有较高的准确度,可为Ag-SnO2(10%)复合材料热加工工艺的制定提供理论依据。

2.4 显微组织分析

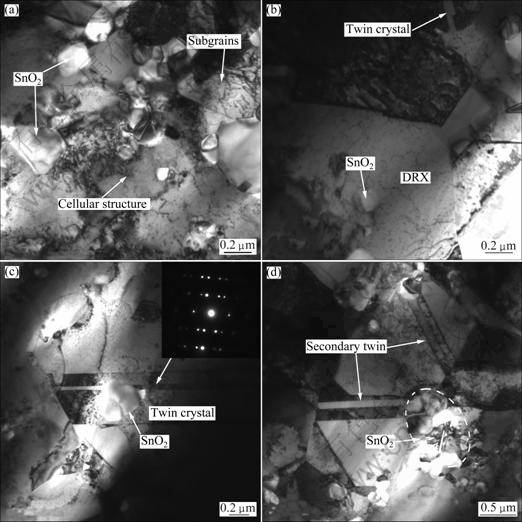

图6所示为Ag-SnO2(10%)复合材料在850 ℃、不同应变速率条件下的TEM像。从图6可以看出,Ag-SnO2复合材料在热压缩变形过程中发生了明显的动态再结晶。SnO2颗粒具有高硬度和高切变模量,在Ag-SnO2复合材料变形过程以Ag基体的塑性变形为主,SnO2颗粒则起到强化基体和阻碍变形的作用。由于SnO2颗粒对位错运动的钉扎作用,在颗粒周围区域形成了大量的位错缠结和胞状组织(见图6(a))。 对比分析图6(a)和(b)可知,增强相SnO2颗粒对Ag-SnO2复合材料的动态再结晶行为有显著影响。材料动态再结晶的驱动力是变形过程中的储能,而亚晶的形核、长大是通过晶界迁移来实现的。SnO2颗粒的存在一方面导致位错增殖和塞积,提高材料变形储能,促进亚晶形核;另一方面则阻碍亚晶界的迁移运动,抑制亚晶长大。因此,在SnO2颗粒富集区域可以观察到大量亚晶组织(见图6(a)),而在SnO2颗粒稀少的区域,亚晶长大受到的阻碍作用较小,再结晶晶粒尺寸较大,晶界平直(见图6(b))。

图5 不同变形条件下峰值应力实验结果与预测值比较 分析

Fig.5 Comparison of theoretic and experimental results of peak stress under different conditions: (a)  =0.01 s-1; (b)

=0.01 s-1; (b)  =0.1 s-1; (c)

=0.1 s-1; (c)  =1 s-1

=1 s-1

图6 Ag-SnO2(10%)材料在850 ℃热压缩后的TEM像

Fig.6 TEM images of Ag-SnO2(10%) composites after compressed at 850 ℃: (a), (b)  =0.01 s-1; (c)

=0.01 s-1; (c)  =0.1 s-1; (d)

=0.1 s-1; (d)  =1 s-1

=1 s-1

同时,在Ag-SnO2(10%)复合材料变形后的样品中发现大量孪晶组织,而且随着应变速率增加,孪晶数量增多。当应变速率为0.01 s-1时,样品中只观察到数量很少而且尺寸较小的孪晶(见图6(b))。当应变速率为0.1 s-1时,样品中孪晶尺寸较大,孪晶宽度约为0.5 μm,数量也明显增多,图6(c)所示为孪晶形貌及对应的电子衍射花样。当应变速率为1 s-1时,孪晶不仅数量增多,孪晶尺寸较大(孪晶宽度约为1 μm),并且在一次孪晶内部形成了二次孪晶(见图6(d))。孪生是以均匀切变的方式进行变形,且孪晶形核所需的应力远比孪晶长大的大,只有当滑移受到阻碍时,才在应力集中处萌发孪晶。孪晶往往以极快的速度产生,变形突然增加使得应力迅速降低,从而真应力—真应变曲线呈锯齿状特征(见图1(c))。在Ag-SnO2(10%)复合材料的热压缩变形过程中,先发生滑移变形。由于SnO2颗粒对位错运动强烈的钉扎作用,在颗粒周围产生大量的位错塞积,位错塞积导致局部应力集中。当切应力达到孪生所需的临界剪切应力值时便发生孪晶形核。滑移和孪生均使晶体产生切变,但滑移时,位错相对移动集中在少数原子层上,而孪生是产生均匀切变,通过位错相继扫过每一层原子面而形成的。因此,位错滑动过程中遇到SnO2颗粒时,如果是滑移变形,位错将被SnO2颗粒钉扎,往往需要很大应力才能切割或绕过SnO2颗粒;若是孪生变形,当某一原子面上的位错被SnO2颗粒钉扎时,其他原子面的位错仍能继续滑动,因此孪晶能顺利长大。图6(c) 所示为孪晶跨过SnO2颗粒长大的组织形貌。孪晶的形成改变了晶格取向,促使新的滑移体系开动,但孪晶界可以作为障碍物阻碍位错的运动,位错在SnO2颗粒及孪晶界堆积产生新的应力集中,从而促进新的再结晶晶粒和孪晶形核,并可能形成二次孪晶。图6(d)所示为在一次孪晶内部形成的二次孪晶形貌。因此,动态再结晶与孪晶的共同作用是Ag-SnO2(10%)复合材料热压缩变形过程的主要变形机制。

3 结论

1) Ag-SnO2(10%)复合材料的真应力—真应变曲线呈稳态流变特征,即在恒定变形温度下,流变应力随应变速率的升高而增大;在恒定应变速率下,流变应力随变形温度的升高而减小。

2) Ag-SnO2(10%)复合材料热压缩变形过程的流变应力可以用Zener-Hollomon参数的双曲函数形式进行描述,计算获得的热变形激活能Q=589.05 kJ/mol,建立了流变应力本构方程。

3) 计算获得的流变应力本构模型的计算结果与实验值吻合较好,最大相对误差仅为6.9%。故此本构方程可为热成形加工工艺的制定提供理论依据。

4) 动态再结晶和孪晶共同作用是Ag-SnO2 复合材料热压缩变形的主要变形机制,随应变速率增加,孪晶数量增多,并伴随二次孪晶的形成。

REFERENCES

[1] 谢永忠, 陈京生. 欧盟二指令对我国电触头材料发展及出口影响分析[J]. 电工材料, 2004(2): 38-41.

XIE Yong-zhong, CHEN Jing-sheng. The influence analysis of our country’s contact materials development and export for two injunction of European Union[J]. Electrical Engineering Materials, 2004(2): 38-41.

[2] CHI L, STREICHER E, FITZGERALD D, COOK J. High current erosion of Ag/SnO2 contacts and evaluation of indium effects in oxide properties[C]//Proceedings of the 52nd IEEE Holm Conference on Electrical Contacts. Piscataway: IEEE, 2006: 143-150.

[3] CHO H, HWANG D Y, JO H H. A study on the development of environment-friendly Ag-SnO2 electric contact materials through a powder metallurgy [J]. Materials Science Forum, 2007, 539/543: 2761-2766.

[4] SHIBATA A. Silver-metal oxide contact materials by internal oxidation process[C]//Proceedings of the 7th International Conference on Electrical Contacts. Pairs: IEEE, 1974: 214-220.

[5] BEHRENS V, HONIG T, KRAUS A, MICHAL R, SAEGER K, SCHMIDBERGER R, STANEFF T. An advanced silver/tin oxide contact material[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology. Part A, 1994, 17(1): 24-31.

[6] OMMER M, KLOTZ U E, GONZA'LEZ D, BERGER F, WIELAGE B. Arc behaviour and material deterioration of silver based composites used for electrical contacts[C]//Proceedings of the Annual Holm Conference on Electrical Contacts. Charleston: IEEE, 2010: 494-504.

[7] CARNT N. Evaluation of relay contact materials[J]. Electrical Review, 2006, 239(10): 10-12.

[8] WITTER G, CHEN Z. A comparison of silver tin indium oxide contact materials using a new model switch that simulates operation of an automotive relay[C]//Proceedings of the 50th IEEE Holm Conference on Electrical Contacts and the 22nd International Conference on Electrical Contacts. Piscataway: IEEE, 2004: 382-387.

[9] BRAUMANN P, KOFFLER A. The influence of manufacturing process, metal oxide content, and additives on the switching behaviour of Ag-SnO2 in relays[C]//Proceedings of the 50th IEEE Holm Conference on Electrical Contacts and the 22nd International Conference on Electrical Contacts. Piscataway, NJ, USA: IEEE, 2004: 90-97.

[10] HERINGHAUS F, BRAUMANN P, RUHLICKE D, SUSNIK E, WOLMER R. On the improvement of dispersion in Ag-SnO2-based contact materials[C]//Proceedings of the 20th International Conference on Electrical Contact. Stockholm: IEEE, 2000: 199-204.

[11] 张志伟, 陈敬超, 潘 勇, 周晓龙, 刘方方, 张昆华, 管伟明. 大塑性变形改善反应合成制备Ag/SnO2材料性能研究[J]. 稀有金属材料与工程, 2008, 37(2): 338-341.

ZHANG Zhi-wei, CHEN Jing-chao, PAN Yong, ZHOU Xiao-long, LIU Fang-fang, ZHANG Kun-hua, GUAN Wei-ming. The performances of Ag/SnO2 materials by reactive synthesis via severe plastic deformation[J]. Rare Metal Materials and Engineering, 2008, 37(2): 338-341.

[12] 张国庆, 邓德国, 祁更新, 郭俊梅, 管伟明, 尹志民. Ag-SnO2复合材料变形断裂分析[J]. 贵金属, 1999, 20(4): 1-6.

ZHANG Guo-qing, DENG De-guo, QI Geng-xin, GUO Jun-mei, GUAN Wei-ming YIN Zhi-min. Analyses of Ag-SnO2 material fracture from deformation[J]. Precious Metals, 1999, 20(4): 1-6.

[13] 刘满门, 陈敬超, 张志伟, 周晓龙, 郭荣鑫, 张昆华, 耿永红. 反应合成Ag-SnO2复合材料本构关系研究[J]. 稀有金属材料与工程, 2008, 137(7): 1206-1208.

LIU Man-men, CHEN Jing-chao, ZHANG Zhi-wei, ZHOU Xiao-long, GUO Rong-xin, ZHANG Kun-hua, GENG Yong-hong. Constitutive equation of Ag/SnO2 composite prepared by reactive synthesis[J]. Rare Metal Materials and Engineering, 2008, 137(7): 1206-1208.

[14] 关德林. 晶体的高温塑性变形[M]. 大连: 大连理工大学出版社, 1989.

GUAN De-lin. High-temperature plastic deformation of the crystal[M]. Dalian: Dalian University of Technology Press, 1989.

[15] SHI H, MCLAREN A J, SELLARS C M, SHAHANI R, BOLINGBROKE R. Constitutive equations for high temperature flow stress of aluminum alloys[J]. Materials Science and Technology, 1997, 13(3): 210-216.

[16] SELLARS C M, TEGART W J M. On the mechanism of hot deformation[J]. Acta Metallurgica, 1996, 14(9): 1136-1138.

[17] ZENER C, HOLLOMON H. Effect of strain-rate upon the plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

(编辑 何学锋)

基金项目:“十一五”国家科技支撑计划资助项目(2006BAE03B03);广东省教育部产学研结合项目(2006D90404015)

收稿日期:2010-09-20;修订日期:2011-03-01

通信作者:易丹青,教授,博士;电话:0731-88830263;E-mail: yioffice@mail.csu.edu.cn