文章编号:1004-0609(2012)08-2230-08

热轧淬火Cu-Cr系合金的性能和组织演变

夏承东1, 2,汪明朴1, 2,张 婉1, 2,贾延琳1, 2,吴一凤1, 2,董琦 1, 2,魏海根1, 2,徐根应1, 2

1, 2,魏海根1, 2,徐根应1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:利用在线热轧-淬火工艺和随后的形变热处理工艺制备Cu-Cr系列合金带材,并采用硬度、电导率测试与光学显微镜、透射电子显微镜观察的方法,研究合金在制备加工过程中的性能和组织演变。结果表明:在线热轧-淬火和后续的形变热处理工艺可成功地制备高硬度、高导电和抗软化性能优异的Cu-Cr系合金带材。具有有序FCC结构、与基体呈立方-立方位向关系的Cr相从过饱和固溶体中分解出来是时效过程中合金硬度和电导率提高的原因。Cu-Cr系合金的高硬度是细晶强化、应变强化和析出强化共同作用的结果,而高电导率是由于时效析出极大地降低了基体中溶质原子浓度。

关键词:Cu-Cr系合金;热轧-淬火;析出相;强化;抗软化性能

中图分类号:TG146.1 文献标志码:A

Properties and microstructure evolution of hot rolled-quenched Cu-Cr system alloys

XIA Cheng-dong1, 2, WANG Ming-pu1, 2, ZHANG Wan1, 2, JIA Yan-lin1, 2,

WU Yi-feng1, 2, DONG Qi-yi1, 2, WEI Hai-gen1, 2, XU Gen-ying1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The strips of Cu-Cr system alloys were manufactured by online hot rolling-quenching (HR-Q) and subsequent thermomechanical treatments process. The properties and microstructure evolution of alloys were investigated by measurements of microhardness and electrical conductivity, and observations of optical microscopy (OM) and analytical transmission electron microscopy (TEM). The results show that the HR-Q and thermomechanical treatments process can successfully manufacture the strips of Cu-Cr system alloys with high hardness, high conductivity and excellent softening resistance. The Cr precipitates with ordered FCC structure, which are decomposed from the thermomechanically treated alloys, are responsible for the improvement of properties during near peak aging. The high hardness of the alloys is ascribed to the interactions of grain boundary strengthening, strain hardening and precipitation hardening, and the high electrical conductivity results from the reduction of the solute atoms concentration in the matrix during aging treatment.

Key words: Cu-Cr system alloy; hot rolling-quenching; precipitate; hardening; softening resistance

铜基合金因其具有优良的电学性能和导热性能以及力学性能,且容易实现大规模生产,被广泛应用于集成电路引线框架、电极、电触头、高强度导线等既要求高导电性能也要求高强度的领域,也可用于与导电性无直接关系的热交换环境或作为耐磨材料使 用[1-3]。LIU等[4]指出,理想的大规模或超大规模集成电路用引线框架材料要求合金抗拉强度大于600 MPa,硬度大于180 HV,电导率大于80%IACS。

Cu-Cr系合金由于极易产生强烈的析出强化效果而被认为是最有潜力满足大规模或超大规模集成电 路引线框架要求的合金。为改善和提高该系列合金的强度和电导率,国内外对该系列合金进行大量的研 究[1, 4, 5-9],并取得了一定进展。如LIU等[1]研究了加工工艺和热处理对Cu-Cr-Zr合金时效行为的影响,合金在480 ℃时效1 h后得到了强度和电导率的良好结合(530 MPa, 78%IACS)。钟建伟等[5]报道了Cu-Cr-Zr合金经固溶处理和随后的形变热处理后,其抗拉强度和电导率分别可达到527 MPa和82%IACS。

然而,目前几乎所有针对Cu-Cr系合金研究工作均采用固溶与形变热处理相结合的处理工艺,而该工艺仅适用于实验室研究,与铜合金板带材工业化批量生产存在很大的差距。目前,在线淬火工艺已广泛应用于铝合金的生产,而对于析出强化型铜合金板带材的研究和生产鲜有报道[10-11]。将在线淬火工艺与热轧相结合,可通过一次加热完成均匀化和快速热轧-淬火处理,同时达到在线固溶的目的,从而避免了传统工艺中将热轧板材重新加热到高温进行固溶处理。因此可大大提高生产效率,降低成本[11]。本文作者尝试着将该在线热轧-淬火工艺应用于Cu-Cr系合金板带材的生产,并利用硬度、电导率测试以及金相显微镜、透射电子显微镜观察的方法研究在该工艺下制备的合金的性能和组织演变,并分析讨论该系列合金获得良好综合性能的原因,为该类合金制定合理的加工和热处理工艺提供试验依据。

1 实验

本实验制备了3种合金:Cu-Cr、Cu-Cr-Zr和Cu-Cr-Zr-Ni-Si。试验原料为电解铜、纯铬、纯镍、纯硅和13%(质量分数)的铜锆中间合金。在中频感应炉中真空熔炼,然后充氩气保护,浇铸成尺寸为180 mm×120 mm×30 mm坯锭。用ICP-AES测定铸锭成分列于表1中。

铸锭去除表面铸造缺陷后在保护气氛中均匀化退火,退火温度为920 ℃,时间为5 h。均匀化后快速热轧成5 mm的板材,并淬火冷却。铣去热轧板两面的表面缺陷后,分别进行60%和80%冷轧,然后截取试样分别进行等时和等温时效。等时时效时间为60 min,温度为350~650 ℃,其中550 ℃及以下温度在盐浴炉中进行,高于550 ℃则在箱式电阻炉中完成;等温时效在盐浴炉中进行,温度为450 ℃,时间为1~1 800 min。根据不同的冷轧变形量,将60%和80%冷轧分别标注成工艺A和B。

表1 Cu-Cr系合金铸锭的化学成分

Table 1 Chemical composition of cast Cu-Cr system alloy ingots

显微硬度在HV-5型显微硬度计上测量,载荷为24.5 N,加载时间为10 s。在QJ-19型双臂电桥上测定电阻,并根据国际退火铜标准,将电阻率转换为电导率。在LEICA EC3光学显微镜下进行显微组织观察。TEM试样在30%硝酸甲醇溶液中双喷减薄,电解温度约为-40 ℃,电压15~20 V,电流70~90 mA。在FEI Tecnai G220透射电子显微镜上进行组织和析出相观察,加速电压为200 kV。

2 结果与分析

2.1 等时时效

热轧淬火并冷轧后的试样在每隔50 ℃的时效温度下测定其硬度和电导率,以得到Cu-Cr系列合金的最佳时效温度。最佳时效温度可认为是时效60 min后,硬度和电导率能达到良好结合所对应的温度。图1所示为热轧淬火并冷轧后Cu-Cr系列合金等时时效60 min后的硬度和电导率曲线。

由图1可看出,所有合金随温度的升高具有强烈的时效硬化反应。硬度和电导率均随温度的升高而显著增加,而后开始降低。经80%冷轧后的Cu-Cr和 Cu-Cr-Zr合金的硬度峰值出现在400 ℃时效,而Cu-Cr-Zr-Ni-Si合金的硬度峰值则出现在450 ℃时效,其峰值分别为156、177和 179 HV。500 ℃以上时效导致过时效的发生,80%冷轧后的Cu-Cr合金在550 ℃时效后硬度迅速下降到89 HV,而Cu-Cr-Zr和Cu-Cr-Zr-Ni-Si合金在650 ℃时效60 min后才下降到81 HV。这表明Cu-Cr合金相比于其他两种合金更易于过时效。3种合金的电导率在450 ℃时效60 min后达到一个近似平台,然后随温度升高缓慢上升,并在550 ℃达到峰值,而在更高温度时效时,电导率稍有降低。这是由于时效温度越高,合金的过饱和固溶度越低,固溶在基体中的溶质原子也越多,电导率也越低。由于在450 ℃下时效,硬度接近峰值,且电导率达到一个较高且稳定的值。因此,450 ℃可认为是这3种合金的合适时效温度。

图1 Cu-Cr系合金60 min等时时效的硬度(a)和电导率(b)

Fig. 1 Hardness (a) and conductivity (b) of Cu-Cr system alloys isochronally aged for 60 min

不同变形量的合金显示出相似的时效硬化行为。同一成分合金经80%冷轧+450 ℃时效后的峰值硬度均高于60%冷轧+450 ℃时效后的峰值硬度,而时效后的电导率几乎相同。同一变形量下,合金的硬度和电导率随合金成分变化显著。80%冷轧+450 ℃时效60 min后,3种合金的硬度分别为147、174和179 HV,其相应的电导率分别为87.4%IACS、84.1%IACS和80.4%IACS。

2.2 等温时效

热轧淬火并冷轧后Cu-Cr系合金在450 ℃等温时效的硬度和电导率曲线如图2所示。由图2可见,该系列合金在等温时效过程中也同样具有强烈的时效硬化反应。硬度随时效时间的延长先到达峰值后开始下 降,而电导率快速上升到达一个近似平台后缓慢上 升。Cu-Cr合金在时效初期硬度有小幅下降,这是由于时效初期析出强化效果不能补偿回复产生的硬度损失[12]。该合金经80%冷轧+450 ℃时效15 min后,达到峰值硬度(159 HV),更长时间时效导致了过时效的发生,时效960 min后,硬度下降到92 HV,而后保持稳定。

图2 Cu-Cr系合金450 ℃等温时效的硬度(a)和电导率(b)

Fig. 2 Hardness (a) and conductivity (b) of Cu-Cr system alloys isothermally aged at 450 ℃ for different times

对于同一合金,大冷变形量的合金硬度在时效过程中始终高于小冷变形量的合金硬度。在工艺A和工艺B条件下,Cu-Cr-Zr和Cu-Cr-Zr-Ni-Si合金峰值硬度均提高了约10 HV。这表明冷轧产生的加工硬化显著提高了合金强度。添加Ni和 Si 到 Cu-Cr-Zr合金中较大地提高了合金的硬度。经工艺A和工艺B处理并时效120 min后,Cu-Cr-Zr-Ni-Si合金的硬度值分别达到了169和180 HV,而相同状态下的Cu-Cr-Zr合金的硬度值分别为162和170 HV。80%冷轧的Cu-Cr-Zr和Cu-Cr-Zr-Ni-Si合金时效1 200 min后,其硬度相对于峰值的降幅分别为17和9 HV,对应下降率分别为9.7%和5%,而Cu-Cr合金时效仅960 min降幅就达67 HV,对应下降率为42.2%。这表明,Cu-Cr合金在时效中极为敏感而易于过时效,而两种Cu-Cr-Zr合金特别是Cu-Cr-Zr-Ni-Si合金,则具有极其优异的抗软化性能。该结果与等时时效结果完全一致。

图2(b)显示了3种合金在450 ℃等温时效电导率曲线。与硬度相似,所有合金均显示出强烈的时效硬化反应。由于在时效初期溶质原子从过饱和固溶体中析出,3种合金的电导率均迅速上升。时效30 min后,电导率到达一个平台后增长速率减缓。这是由于此时基体中溶质原子浓度接近该温度的平衡浓度。在所有合金中Cu-Cr合金的电导率最高,时效30 min后,其电导率达85.2%IACS,而此时Cu-Cr-Zr和Cu-Cr-Zr- Ni-Si合金分别只有81.7%IACS和78.2%IACS。对于不同变形量同一成分的合金,在时效过程中其电导率几乎相同,表明在本试验条件下,冷变形对合金时效过程的电导率几乎没有影响。由以上的结果可以得出,80%可认为是Cu-Cr系合金合适的变形量。

2.3 微观组织

2.3.1 金相组织

图3所示为Cu-Cr系合金在不同处理条件下的金相组织。由图3(a)可见,经过920 ℃均匀化5 h后,合金的显微组织已无明显枝晶,主要是由粗大的等轴晶组成,同时可观察到一些微米级的颗粒在晶内和晶界上出现。由Cu-Cr合金二元相图可知,Cr在Cu中的最大溶解度(质量分数)为0.65%(1 076 ℃),而在920 ℃的平衡溶解度约为0.3%。由于本试验合金成分中的Cr略高于其在920 ℃的平衡溶解度,因此在热轧前的均匀化退火不能完全溶解合金凝固过程中形成的微米级过剩Cr相。热轧淬火工艺通过大变形热轧破碎晶粒和高温下的动态再结晶,极大地细化了晶粒,如图3(b)所示。随后的冷轧变形进一步减小晶粒尺寸,同时增加了合金的长宽比。因此,热轧淬火-冷轧-时效工艺可获得晶粒细小的显微组织。

2.3.2 TEM组织和结构

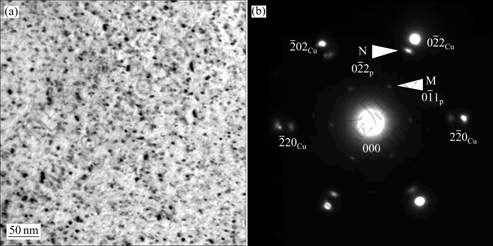

图4所示为Cu-Cr-Zr-Ni-Si热轧淬火态的TEM组织和相应的选区电子衍射谱。由图4(a)可见,热轧淬火后,合金晶粒细小,并沿轧制方向略微拉长。同时在晶界上形成了细小的再结晶晶粒,这表明热轧过程中发生了动态再结晶。相应的选区电子衍射显示了Cu基体的衍射斑点被轻微拉长,拉长的斑点相对于透射斑约有2°的角度差,如图4(b)所示。这表明热轧淬火态合金的晶粒是由具有很小角度晶界的亚晶结构组成的。在图4(b)中还发现了除基体衍射外的额外衍射斑点,这表明热轧过程中发生了部分沉淀析出。

图3 Cu-Cr系合金在不同状态下的金相组织

Fig. 3 Optical microstructures of Cu-Cr system alloys under different conditions: (a) As homogenized (920 ℃, 5 h); (b) As hot rolled; (c) As 80% cold rolled

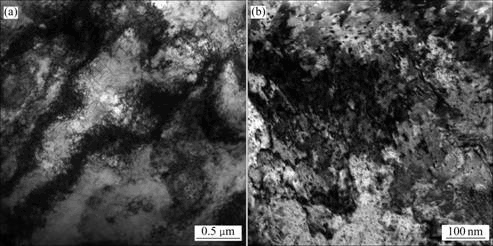

图5所示为80%冷轧态Cu-Cr-Zr-Ni-Si合金和随后其在450 ℃时效60 min的TEM像。由图5可看出,80%冷轧在Cu-Cr-Zr-Ni-Si合金中产生了高密度的位错。这些位错分布不均匀,并相互缠结形成了胞状结构。经80%冷轧+450 ℃时效60 min引起了亚晶内部强烈的位错重排或湮灭,因此位错密度有所降低,同时析出了大量细小弥散的粒子,如图5(b)所示。这表明冷轧态合金的一些变形特征在时效过程中保留了下来,同时发生了大规模的沉淀析出。冷轧变形产生的高密度位错为纳米粒子的析出提供了形核位置,同时析出的第二相又钉扎位错运动,导致了强烈的强化效应。

图4 热轧淬火态Cu-Cr-Zr-Ni-Si合金的TEM明场像及其选区电子衍射谱

Fig. 4 TEM BF image (a) and corresponding SAED pattern (b) of hot rolled-quenched Cu-Cr-Zr-Ni-Si alloy, zone axis close to [011]Cu

图5 不同处理状态下Cu-Cr-Zr-Ni-Si合金的TEM像

Fig. 5 TEM images of Cu-Cr-Zr-Ni-Si alloy under different conditions: (a) As 80% cold rolled; (b) As 80% cold rolled+(450 ℃, 60 min)

图6所示为Cu-Cr-Zr-Ni-Si合金在450 ℃时效 60 min的TEM明场像和[111]Cu晶带轴下的选区电子衍射谱。由图6(a)可见,大量细小的第二相粒子(小于10 nm)弥散分布于基体中。由图6(b)可见,在 [111]Cu带轴下,除了基体衍射斑以外,出现了非常明显的额外衍射,如图中箭头N所示;同时,在额外衍射斑和透射斑中间发现超衍射斑点,如图中箭头M所示。对电子衍射花样标定分析表明,这些析出相具有有序的FCC结构,其晶胞比铜基体大,与基体存在立方-立方的取向关系。

3 讨论

合金的硬度和电导率强烈地依赖于材料的显微组织,而显微组织又决定于合金的加工和热处理工艺。因此,加工及热处理工艺对合金的性能影响巨大。

添加微量合金元素的Cu-Cr系列合金是一类典型的具有高强高导的析出强化型合金。这类合金在时效过程中具有强烈的析出强化效果。析出强化效果则依赖于过饱和固溶体分解形成第二相的体积分数和粒径大小。因此,对于析出强化型铜合金,高的过饱和溶解度是实现高强高导的首要条件[13]。传统的固溶处理方法可以将合金在高温下的固溶度有效地保留到室温。但这种工艺需要将热轧或热挤压后的材料重新加热到固溶温度,保温后淬火。在线热轧-淬火工艺可在完成均匀化处理和热轧的同时,通过高温快速热轧和快速冷却将合金在高温下的固溶度保留到室温,从而实现在线固溶的目的。在本研究中,热轧淬火Cu-Cr系列合金在时效过程中具有强烈的时效硬化反应,表明大部分溶质原子如Cr、Zr、Ni和Si在热轧淬火后固溶到合金中,经快速淬火形成了过饱和固溶体,并在随后的时效过程中沉淀析出,从而获得高强高导的铜合金。因此,在线热轧-淬火工艺的效果达到了传统的固溶处理的效果,且这种工艺可方便地应用于目前铜合金板带材的生产线。同时,在线热轧-淬火工艺可获得的细小变形晶粒和具有小角度晶界的亚晶组织(如图3和4所示),为合金后续的冷加工和热处理提供了良好的组织准备。

图6 Cu-Cr-Zr-Ni-Si合金的析出相形貌和选区电子衍射谱

Fig. 6 TEM image(a) and SAED pattern(b) of precipitated phase of Cu-Cr-Zr-Ni-Si alloy after near peak aging at 450 ℃ (Zone axis close to [111]Cu; p presents precipitated phase)

冷变形产生的高密度位错不仅可作为淬火空位槽并阻碍GP区的形成[14],同时还可作为析出形核的优先位置和溶质原子扩散的快速通道[15]。因此,冷变形常常用在析出强化合金的加工工艺中[5-8, 16]。本研究结果显示,冷轧进一步破碎了晶粒(见图3(c)),并产生了高密度的位错(见图5(a)),大大地强化了该系列合金。同时,由位错引起的电子散射使合金的电导率下降了1%~3%IACS。这与HUTCHINSON[17]的预测完全一致。变形量越大,合金的硬度越高,但对于不同变形量的同一种合金,其电导率在时效到达平台后基本相同。

由于冷轧变形形成的变形组织在时效过程中得以部分保留,同时过饱和固溶体的分解产生大量弥散分布的细小粒子,净化了铜基体,因此Cu-Cr系合金硬度和电导率均得到很大程度的提高。由于在合金接近峰时效时得到有序FCC结构的析出相,因此合金硬度和电导率的提高可归因于该析出相的沉淀析出。KNIGHTS和WILKES[18]在Cu-Cr合金中观察到棒状的颗粒,并认为该析出相具有亚稳的面心立方(FCC)结构,然而,文中并未给出FCC的Cr相的直接证据。根据本试验所得到的合金选区电子衍射花样(图6(b))和公式Rd=Lλ,同时利用铜基体的衍射斑点来校正Lλ的值,可计算得出该系列合金析出相的点阵常数为0.421 9 nm。该析出相的点阵参数与文献[19]报道的面心立方的纳米团簇Cr点阵常数(0.413 nm)非常接近。因此,在本试验条件下,从过饱和固溶体分解出来的析出相可认为是具有FCC结构的Cr相,该Cr相与基体具有立方-立方的位向关系。

添加微量的合金元素可大大改善Cu-Cr合金的性能。TANG等[20]认为峰时效是有序的CrCu2(Zr,Mg)相析出的结果。BATAWI等[21]认为Zr的添加促进了析出相更均匀地析出。WATANABE等[9]指出Zr的添加减小了Cr相粒子的间距,并在位错上优先形成了盘状的Cu5Zr粒子,导致了强度的升高。值得注意的是,添加Zr、Ni和Si不仅大大提高了合金的硬度,而且极大地改善了合金抗软化性能,如图1和2所示。这是由于添加的微量合金元素Zr、Ni和Si等在时效过程中偏聚在Cr析出相周围[22],松弛了Cr相与基体非共格界面所产生的应变, 从而阻碍了Cr颗粒的粗化,故而大大地提高了合金的抗软化性能。添加合金元素的作用机制尚需要进一步的探讨。

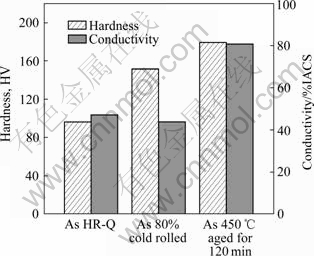

图7所示为Cu-Cr-Zr-Ni-Si合金在不同加工和处理状态下的硬度和电导率。由图7可见,热轧淬火(HR-Q)后经80%冷轧变形,合金硬度提高了56.7%,可达152 HV,而电导率仅下降3.4%IACS。该阶段是由于大变形细化了晶粒,同时产生强烈的应变强化效果,因此大幅度提高了合金硬度而微弱地降低了电导率。80%冷轧后再经450 ℃时效120 min,合金的硬度和电导率均得到进一步提高,分别达到180 HV和81.1%IACS。此时,合金性能的改善归因于溶质原子从过饱和固溶体中析出,净化了基体中的溶质原子,同时产生了强烈的析出强化效果。因此,按照均匀化→热轧淬火→80%冷轧→450 ℃时效120 min的工艺路线进行加工和热处理,Cu-Cr-Zr-Ni-Si合金可获得高硬度与高电导率的良好结合。

图7 Cu-Cr-Zr-Ni-Si加工和热处理过程中的硬度和电导率

Fig. 7 Hardness and conductivity of Cu-Cr-Zr-Ni-Si alloy under various conditions

4 结论

1) 在线热轧-淬火工艺和随后的形变热处理工艺成功应用于制备Cu-Cr系列合金板带材。热轧-淬火工艺简化了生产工序,降低了生产成本,可以有效地取代传统析出强化合金的固溶处理。

2) 在线热轧-淬火工艺结合后续形变热处理工 艺制备的合金带材具有良好的力学性能、电学性能和优异的抗软化性能。添加合金元素Zr、Ni和 Si较大地改善了合金的性能。经80%冷轧和450 ℃时效120 min后,Cu-Cr-Zr-Ni-Si合金的硬度和电导率分别可达180 HV和81.1% IACS。

3) 具有有序FCC结构、与基体具有立方-立方的位向关系的Cr相从过饱和固溶体中分解出来,这是时效过程中Cu-Cr系合金硬度和电导率提高的原因。

4) 热轧淬火Cu-Cr系合金的高硬度是细晶强化、应变强化和析出强化共同作用的结果,而高电导率是由于时效析出极大地降低了基体中溶质原子浓度。

REFERENCES

[1] LIU Q, ZHANG X, GE Y, WANG J, CUI J Z. Effect of processing and heat treatment on behavior of Cu-Cr-Zr alloys to railway contact wire[J]. Metall Mater Trans A, 2006, 37(11): 3233-3238.

[2] SU J H, DONG Q M, LIU P, LI H J, KANG B X. Research on aging precipitation in a Cu-Cr-Zr-Mg alloy[J]. Mater Sci Eng A, 2005, 392(1/2): 422-426.

[3] LI Z, PAN Z Y, ZHAO Y Y, XIAO Z. Microstructure and properties of high conductivity, super high strength Cu-8.0Ni-1.8Si-0.6Sn-0.15Mg alloy[J]. J Mater Res, 2009, 24(6): 2123-2128.

[4] LIU P, KANG B X, CAO X G, HUANG J L, GU H C. Strengthening mechanisms in a rapidly solidified and aged Cu-Cr alloy[J]. J Mater Sci, 2000, 35(7): 1691-1694.

[5] 钟建伟, 周海涛, 赵仲恺, 李庆波, 周 啸. 形变热处理对Cu-Cr-Zr合金时效组织和性能的影响[J]. 中国有色金属学报, 2008, 18(6): 1032-1038.

ZHONG Jian-wei, ZHOU Hai-tao, ZHAO Zhong-kai, LI Qing-bo, ZHOU Xiao. Effects of thermo-mechanical heat treatment processing on microstructure and properties of Cu-Cr-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1032-1038.

[6] 慕思国, 曹兴民, 汤玉琼, 向朝建, 杨春秀, 郭富安, 唐谟堂. 时效态Cu-Cr-Zr-Mg-RE合金的组织和性能[J]. 中国有色金属学报, 2007, 17(7): 1112-1118.

MU Si-guo, CAO Xing-min, TANG Yu-qiong, XIANG Chao-jian, YANG Chun-xiu, GUO Fu-an, TANG Mo-tang. Microstructure and properties of aging Cu-Cr-Zr-Mg-RE alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1112-1118.

[7] 贾淑果, 刘 平, 宋克兴, 陈讲彪, 陈小红, 田保红, 任凤章. Cu-Cr-Zr 原位复合材料的组织与性能[J]. 中国有色金属学报, 2010, 20(7): 1134-1138.

JIA Shu-guo, LIU Ping, SONG Ke-xing, CHEN Jiang-biao, CHEN Xiao-hong, TIAN Bao-hong, REN Feng-zhang. Microstructures and properties of Cu-Cr-Zr in-situ composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1134-1138.

[8] GAO N, TIAINEN T, HUTTUNEN-SAARIVIRTA E, JI Y. Influence of thermomechanical processing on the microstructure and properties of a Cu-Cr-P alloy[J]. J Mater Eng Perform, 2002, 11(4): 376-383.

[9] WATANABE C, MONZEN R, TAZAKI K. Mechanical properties of Cu-Cr system alloys with and without Zr and Ag[J]. J Mater Sci, 2008, 43(3): 813-819.

[10] 张立新. 在线淬火在铜带热轧中的应用分析[J]. 有色金属加工, 2009, 38(4): 13-15.

ZHANG Li-xin. Application analysis for on-line quenching in copper strip hot rolling[J]. Nonferrous Metals Processing, 2009, 38(4): 13-15.

[11] XIA C D, WANG M P, XU G Y, ZHANG W, JIA Y L, YU H C. Microstructure and properties of Cu-Cr alloys prepared by a shortened process and a conventional process[J]. Adv Mater Res, 2011, 199/200: 1890-1895.

[12] CHEMINGUI M, KHITOUNI M, JOZWIAK K, MESMACQUE G, KOLSI A. Characterization of the mechanical properties changes in an Al-Zn-Mg alloy after a two-step ageing treatment at 70 ℃ and 135 ℃[J]. Mater Des, 2010, 31(6): 3134-3139.

[13] LEI R S, WANG M P, LI Z, WEI H G, YANG W C, JIA Y L, GONG S. Structure evolution and solid solubility extension of copper-niobium powders during mechanical alloying[J]. Mater Sci Eng A, 2011, 528(13/14): 4475-4481.

[14] BONFIELD W, EDWARDS B C. Precipitation hardening in Cu 1.81wt% Be 0.28wt%Co[J]. J Mater Sci, 1974, 9(3): 415-422.

[15] HOYT J J. On the coarsening of precipitates located on grain boundaries and dislocations[J]. Acta Metall Mater, 1991, 39(9): 2091-2099.

[16] GAO N, HUTTUNEN-SAARIVIRTA E, TIAINEN T, HEMMILA M. Influence of prior deformation on the age hardening of a phosphorus containing Cu-0.61wt.%Cr alloy[J]. Mater Sci Eng A, 2003, 342(1/2): 270-278.

[17] HUTCHINSON B. The effect of alloying additions on the recrystallization behavior of copper—A literature review[R]. Swedish Institute of Metals, 1985, No. IM-2003.

[18] KNIGHTS R W, WILKES P. Precipitation of chromium in copper and copper-nickel base alloys[J]. Metall Trans, 1973, 4(10): 2389-2393.

[19] HUH S H, KIM H K, PARK J W, LEE G H. Critical cluster size of metallic Cr and Mo nanoclusters[J]. Phys Rev B, 2000, 62(4): 2937-2943.

[20] TANG N Y, TAPLIN D M, DUNLOP G L. Precipitation and aging in high conductivity Cu-Cr alloys with additions of zirconium and magnesium[J]. Mater Sci Technol, 1985, 1(4): 270-275.

[21] BATAWI E, MORRIS D, MORRIS M A. Effect of small alloying additions on behavior of rapidly solidified Cu-Cr alloys[J]. Mater Sci Technol, 1990, 6(9): 892-899.

[22] HATAKEYAMA M, TOYAMA T, YANG J, NAGAI Y, HASEGAWA M, OHKUBO T, ELDRUP M, SINGH B N. 3D-AP and positron annihilation study of precipitation behavior in Cu-Cr-Zr alloy[J]. J Nucl Mater, 2009, 386/388(4): 852-855.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51174234);安徽省科技攻关计划项目(08010201026)

收稿日期:2011-07-19;修订日期:2011-11-13

通信作者:汪明朴,教授;电话:0731-88830264;E-mail: wangmp@csu.edu.cn