文章编号:1004-0609(2012)07-2069-06

石煤提钒的浮选工艺及吸附机理

孙 伟,王 丽,曹学锋, 刘润清,徐龙华,韩海生

(中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:针对传统石煤提钒工艺中钒回收率低、环境污染严重等问题,在工艺矿物学研究的基础上,采用浮选的方法对含钒石煤矿进行条件实验和闭路实验,设计出提钒浮选流程,并利用分子动力学模拟研究捕收剂分子在矿物解理面的吸附过程。结果表明:石煤中主要含钒矿物为钒云母,主要的脉石矿物为石英;通过闭路浮选实验,得到了五氧化二钒品位为3.20%(质量分数)、回收率为74.50%的钒精矿;捕收剂分子容易在钒云母(001)面发生吸附,而在石英(001)面几乎不吸附,从而实现了石煤中钒云母和石英的浮选分离。

关键词:石煤;钒云母;浮选;分子动力学模拟

中图分类号:TD923 文献标志码:A

Flotation technology and adsorption mechanism of vanadium extraction from stone coal

SUN Wei, WANG li, CAO Xue-feng, LIU Rui-qing, XU Long-hua, HAN Hai-sheng

(School of Mineral Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: In order to avoid the problems of pollution and low recovery in the conventional process, the flotation was adopted in the treatment of stone coal containing vanadium before leaching on the basis of mineralogical analysis. The proper flotation route was proposed based on condition experiments and closed-circuit test. The method of molecular dynamics simulation was used to study the adsorption process of the collector on roscoelite and quartz, providing a fundamental understanding of the flotation mechanism. The results show that the primary vanadium mineral in stone coal is roscoelite, while the main gangue is quartz. Roscoelite concentrate is eventually obtained with V2O5 grade of 3.20% (mass fraction) and the recovery of 74.50% by a flotation closed-circuit process. The collector is easy to be adsorbed on the surface of roscoelite (001), while hardly on that of quartz (001), which leads to the flotation separation of roscoelite and quartz in stone coal.

Key words: stone coal; roscoelite; flotation; molecular dynamics simulation

钒是一种重要的战略性物质,广泛应用于钢铁工业、航天工业、化工业和国防尖端技术行业[1-2]。在我国,钒主要存在于石煤和钒钛磁铁矿中。其中石煤是作为钒单独矿床开采的低品位含钒碳质页岩,广泛分布于湖南、湖北、江西、浙江和陕西各省,占我国钒矿总储量的87%,是钒金属的重要来源[3-7],也是近年来选矿冶金行业的重点研究方向。

我国传统的石煤提钒工艺主要采用钠化焙烧-水浸-酸沉粗钒-碱溶-铵盐沉钒-热解脱氨制精钒的工艺流程[8],该生产流程稳定,成本较低,但钒回收率和转化率都很低,产业化程度不高,且焙烧过程中产生大量的氯气和氯化氢等有害气体,严重污染环境[9]。因此,根据我国钒金属富集现状,研究高回收率、低污染的提钒新工艺显得十分迫切。浮选法能够脱除矿石中绝大部分尾矿并能降低后续处理成本,在石煤提钒中展现出广阔的应用前景。姚金江等[10]对某地石煤钒矿进行了选冶联合提钒工艺,用浮选的方法将V2O5品位由0.16%提高到1.28%,钒精矿回收率达到74.62%,同时,在选矿过程中脱除了方解石等耗酸物质,大大减少了冶炼处理量,能够提高低品位钒矿的资源利用率,但是,钒精矿中含有大量碳,在冶金过程中会产生很多有害气体。向平等[11]对阿克苏石煤钒矿进行了浮选实验,该地钒矿中的主要有用矿物是钒云母,且钒粒级分布极不均匀,通过“湿式分级+浮选”联合流程处理,获得了较好的实验指标,对V2O5品位为0.7%的原矿进行处理,获得精矿品位为3.2%,钒回收率达74.5%,但是该方法中的实验流程过于复杂,且对石煤矿进行的筛分分级限制了其工业应用。

针对陕西低品位含钒石煤矿,本文作者在前人研究的基础上,通过浮选条件实验和闭路实验,确定石煤提钒合理的浮选工艺流程和药剂制度;同时,利用分子动力学模拟方法研究捕收剂分子与矿物表面的吸附作用,进一步探讨石煤提钒的浮选机理。

1 实验

1.1 原矿成分

实验用矿样取自陕西某石煤矿,主要化学组成列于表1。由多元素化学成分分析可知,该石煤矿中 SiO2的含量达到88.34%(质量分数),V2O5的品位为1.10%,具有工业开采价值。

表1 石煤矿的主要化学成分

Table 1 Main chemical composition of stone coal ore (mass fraction, %)

1.2 矿物组成及钒的赋存状态

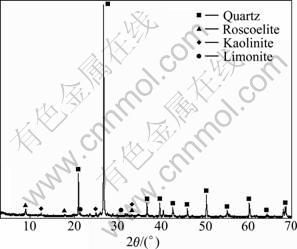

图1所示为石煤矿的XRD谱,表2所列为原矿的物相分析结果。分析可知,该地石煤矿的主要成分是石英、云母、高岭石和褐铁矿;主要含钒矿物是钒云母、氧化铁及粘土矿物,其中,云母类矿物中的钒占62.28%,氧化铁及粘土类矿物中的钒占37.11%。

2 结果与分析

2.1 粗选实验

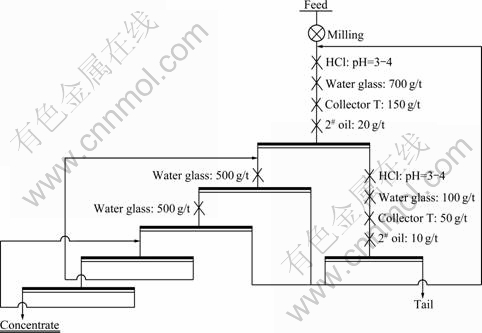

粗选条件实验按图2所示流程进行,通过对磨矿细度、pH值调整剂盐酸用量、抑制剂水玻璃用量和捕收剂T(胺类阳离子捕收剂)用量进行粗选单因素实验,最终确定当磨矿细度小于0.074 mm占 85%,矿浆pH值为3~4,水玻璃用量为700 g/t,捕收剂T用量为150 g/t时,可以达到最好的粗选实验指标,粗精矿V2O5品位可达2.01%,回收率达到88%以上。

图1 石煤矿的XRD谱

Fig. 1 XRD pattern of stone coal ore

表2 钒原矿的物相分析结果

Table 2 Phase analysis of results vanadium raw pre

图2 浮选条件实验流程

Fig. 2 Flowsheet of flotation condition test

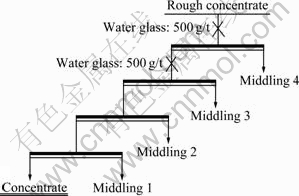

2.2 精选实验

在粗选条件实验的基础上对粗精矿进行精选实验,精选实验流程如图3所示。采用4次精选,精选一和精选二添加水玻璃 500 g/t,浮选指标见表3。通过此精选实验结果可以确定中矿的返回地点。

图3 精选实验流程

Fig. 3 Flowsheet of concentrating circuit flotation

表3 精选实验结果

Table 3 Test results of concentrating circuit

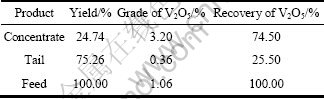

2.3 闭路浮选实验

根据以上针对含钒石煤矿进行的粗选和精选条件实验,设计出合理的浮选流程,通过图4所示闭路实验,可以获得理想的浮选指标。表4所列为含钒石煤矿闭路浮选指标,可得V2O5品位达到3.20%的钒云母精矿,尾矿中V2O5的品位可降到0.36%以下,可使冶金提钒中每吨钒所需原料由200 t降至60 t左右[11],大大降低了提钒的生产成本。

3 捕收剂与矿物作用的分子动力学模拟

分子动力学模拟已成为研究固液界面性质的一种强有力工具,能在分子水平上提供实验上难以观察和检测到的吸附结构和动力学过程[12-16]。选矿药剂与矿物表面作用的研究将随着分子模拟技术的快速发展而不断深入。在选矿新药剂的筛选和开发过程中,分子动力学方法已经成为一种快捷的工具,新的原子层面的分析技术也将为研究矿物晶体表面-药剂-水溶液体系的界面物理化学变化提供微观图像[13]。为了研究该含钒石煤矿的浮选机理,本文作者选择含钒石煤矿中有用矿物钒云母的极完全解离面(001)面和主要脉石矿物石英的一个Si—O面(001)面为研究对象,对捕收剂T与钒云母和石英的作用分别进行分子动力学模拟。使用MS(Materials Studio)5.0版-Discover模块- Compass力场进行分子动力学模拟和计算,药剂分子结构优化计算采用MS的DMol3模块。所有计算工作在Intel(R)Xeon(R),E5420@ 2.50 GHz、内存为16 GB的计算机上完成。

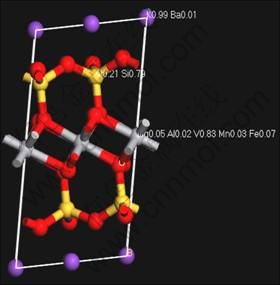

图5所示为钒云母原始晶体结构示意图。晶格参数为a=0.529 nm、b=0.913 nm、c=1.021 nm、α=90°,β=100.98°,γ=90°。从图5可以看出,钒云母的晶体结构与钾云母的类似,为三层结构的铝硅酸盐矿物,即两个硅氧四面体夹一层钒(铝)氧八面体层的“三明治”结构。其中一些Al3+类质同象替换硅氧四面体中的Si4+,因此,夹心面带一个单位层间阳离子补偿的电荷。钒云母晶体中由于中和负电性的阳离子充填于夹层中,键力较弱,因此解离沿着此层即(001)面进行。

图4 石煤矿闭路浮选流程

Fig. 4 Flowsheet of closed circuit flotation of stone coal ore

表4 石煤矿闭路浮选指标

Table 4 Test results of closed circuit flotation of stone coal ore

图5 钒云母晶体结构示意图

Fig. 5 Schematic diagram of roscoelite crystal

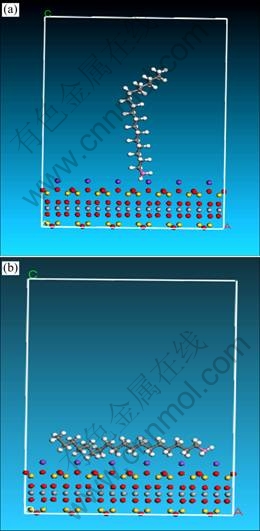

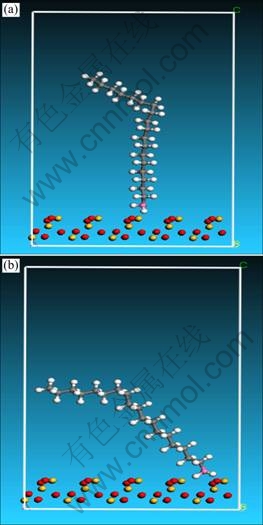

本研究中晶体结构的优化和动力学模拟都是基于钒云母的极完全解离面(001)面和石英的(001)面,将捕收剂分子T置于矿物表面建立初始模型。捕收剂T在钒云母和石英表面作用的初始状态分别如图6(a)和7(a)所示;经几何、能量优化和动力学模拟后,捕收剂T分别与钒云母和石英表面吸附的最低能量构效图分别如图6(b)和7(b)所示。

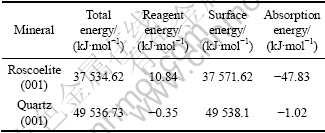

为了进一步描述捕收剂分子在矿物表面的相互作用,定量计算了捕收剂T在钒云母和石英表面的吸附能(Ead),吸附能反应捕收剂T与矿物表面的结合强度,其数值越小,分子的吸附越强,越稳定。用DISCOVER模块分别对终态吸附体系的总能量、捕收剂T分子的能量和钒云母和石英的能量进行计算,则吸附能的计算按式(1)[17]进行。

图6 捕收剂T在钒云母(001)面的吸附模型

Fig. 6 Adsorption model of collector T on roscoelite (001): (a) Initial adsorption model; (b) Final adsorption model

Eaads=Etot-(Ereag+Esurf) (1)

其中:Etot、Ereag和Esurf分别是优化后吸附络合模型,吸附剂模型和被吸附表面模型的能量。相互作用能(Eads)的大小表示吸附体系的稳定性,Eads值越负,表明吸附体系越稳定、吸附越容易发生;Eads为0或正值时吸附难以发生。捕收剂分子T与钒云母(001)面和石英(001)面的吸附能计算结果见表5。

计算结果显示,捕收剂T在钒云母(001)面的吸附能比在石英(001)面的吸附能低很多。所以,捕收剂T更容易在钒云母表面吸附,其吸附能Eads=-47.83 kJ/mol。相比之下,在石英(001)面的吸附能为Eads= -1.02 kJ/mol,表明捕收剂T在石英(001)面的吸附作用很弱。上述模拟过程没有考虑钒云母表面阳离子在水中的溶解,由于实际浮选过程中钒云母表面的阳离子会在水溶液中溶解并与H+进行交换,使表面带负电[18],捕收剂T分子是阳离子捕收剂,在水溶液中带正电,钒云母表面和捕收剂T会发生很强的静电作用,所以,实际过程中钒云母与药剂的作用比模拟计算的还要强很多。

图7 捕收剂分子T在石英(001)面的吸附初始和最终模型

Fig. 7 Adsorption model of collector T on quartz (001): (a) Initial adsorption model; (b) Final adsorption model

表5 捕收剂T与钒云母和石英的互相作用能

Table 5 Interaction energies calculated for collector T with roscoelite and quartz

通过分子动力学模拟计算和矿物表面电荷溶解理论可以推出,捕收剂T在钒云母表面的作用力远大于在石英表面的作用力,在浮选过程中主要吸附在钒云母表面。由图6(b)可以看出,捕收剂T铺展在钒云母表面,疏水的碳链暴露在表面,使其易于粘附于气泡表面而成为泡沫产品;石英则由于与捕收剂T的作用很弱,不与气泡发生粘附,而是留在矿浆中成为尾矿产品。这就是捕收剂T能实现钒云母与石英浮选分离的机理,与实际浮选实验结果一致。

4 结论

1) 含钒石煤矿中含钒矿物主要为钒云母,脉石矿物主要为石英,浮选的主要目的是选择有效药剂将钒云母与石英分离;新型阳离子捕收剂T能够有效地分离云母和石英。

2) 采用闭路浮选实验可使精矿中V2O5的品位达到3%以上,尾矿中V2O5品位降到0.36%以下,用浮选的方法富集钒,进行钒矿湿法冶金前的预处理,可以大大节约钒浸出的成本,提高钒的资源利用效率。

3) 由捕收剂T在钒云母(001)面与石英(001)面吸附的分子动力学模拟可知,捕收剂T容易在钒云母(001)面发生吸附,而在石英(001)面几乎不吸附。

REFERENCES

[1] 潘 勇, 于吉顺, 吴红丹. 石煤提钒的工业评价[J]. 矿业快报, 2007, 23(4): 10-13.

PAN Yong, YU Ji-shun, WU Hong-dan. Process evaluation of vanadium extraction from stone coal [J]. Express Information of Mining Industry, 2007, 23(4): 10-13.

[2] 刘万里, 王学文, 王明玉, 胡 建, 张力萍. 石煤提钒低温硫酸化焙烧矿物分解工艺[J]. 中国有色金属学报, 2009, 19(5): 943-948.

LIU Wan-li, WANG Xue-wen, WANG Ming-yu, HU Jian, ZHANG Li-ping. Mineral decomposition process of vanadium recovery from stone coal by low temperature sulphating roasting [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 943-948.

[3] 屈启龙, 谢建宏, 王冠甫. 高碳钒矿综合回收石墨试验研究[J]. 矿业快报, 2007, 23(4): 35-37.

QU Qi-long, XIE Jian-hong, WANG Guan-fu. Study of comprehensive recovery of graphite from high carbon vanadium ore [J]. Express Information of Mining Industry, 2007, 23(4): 35-37.

[4] 吴惠玲, 魏 昶, 樊 刚, 李旻廷, 邓志敢, 葛怀文. 高碳石煤中钒的赋存状态与优先选煤[J]. 昆明理工大学学报: 理工版, 2008, 33(6): 17-21.

WU Hui-ling, WEI Chang, FAN Gang, LI Min-ting, DENG Zhi-gan, GE Huai-wen. Occurrence of vanadium in high carbon stone-coal and priority of preparation process [J]. Journal of Kunming University of Science and Technology: Science and Technology, 2008, 33(6): 17-21.

[5] 李昌林, 周向阳, 王 辉, 张太康, 李 劼, 欧 星, 江小舵. 强化氧化对石煤钙化焙烧提钒的影响[J]. 中南大学学报: 自然科学版, 2011, 42(1): 7-10.

LI Chang-lin, ZHOU Xiang-yang, WANG Hui, ZHANG Tai-kang, LI Jie, OU Xing, JIANG Xiao-duo. Effect of oxidation on vanadium extraction from stone coal with calcified roasting [J]. Journal of Central South University: Science and Technology, 2011, 42(1): 7-10.

[6] 刘建忠, 张保生, 周俊虎, 冯展馆, 岑可法. 石煤燃烧特性及其类属研究[J]. 中国电机工程学报, 2007, 27: 17-22.

LIU Jian-zhong, ZHANG Bao-sheng, ZHOU Jun-hu, FENG Zhan-guan, CEN Ke-fa. Combustion characteristics and classify attribute of stone coal [J]. Proceedings of the CSEE, 2007, 27: 17-22.

[7] 漆明鉴. 从石煤中提钒现状及前景[J]. 湿法冶金, 1999(4): 1-10.

QI Ming-jian. Current situation and prospect about extracting vanadium from stone coal [J]. Hydrometallurgy of China, 1999(4): 1-10.

[8] 何东升, 冯其明, 张国范, 欧乐明, 卢毅屏. 含钒石煤的氧化焙烧机理[J]. 中国有色金属学报, 2009, 19(1): 195-200.

HE Dong-sheng, FENG Qi-ming, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. Mechanism of oxidizing roasting process of vanadium containing stone coal [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 195-200.

[9] 钱 强. 石煤钒矿提取五氧化二钒的技术现状[J]. 中国资源综合利用, 2008, 26(3): 13-14.

QIAN Qiang. Current status on extraction technology of vanadium pentoxide from stone coal vanadium ore [J]. China Resources Comprehensive Utilization, 2008, 26(3): 13-14.

[10] 姚金江, 吴海国, 李 婕. 高钙低品位石煤提取五氧化二钒新工艺[J]. 湖南有色金属, 2009, 25(6): 21-23.

YAO Jin-jiang, WU Hai-guo, LI Jie. A new technology of extracting vanadium from high calcium low-grade stone-coal [J]. Hunan Nonferrous Metals, 2009, 25(6): 21-23.

[11] 向 平, 冯其明, 钮因健, 潘安新. 选矿富集阿克苏石煤钒矿中的钒[J]. 材料研究与应用, 2010, 4(1): 65-69.

XIANG Ping, FENG Qi-ming, NIU Yin-jian, PAN An-xin. Enrichment of vanadium from stone coal in Aksu vanadium mine by ore dressing method [J]. Materials Research and Application, 2010, 4(1): 65-69.

[12] 罗思岗, 王福良. 分子力学在研究浮选药剂与矿物表面作用中的应用[J]. 矿冶, 2009, 18(1): 1-4.

LUO Si-gang, WANG Fu-liang. Application of molecular mechanics in studying on flotation reagents interacting with minerals [J]. Mining and Metallurgy, 2009, 18(1): 1-4.

[13] Reimer U, Wahab M, Schiller P, Mogel H J. Monte- Carlo study of surfactant adsorption on heterogeneous solid surfaces [J]. Langmuir, 2005, 21(4): 1640-1646.

[14] Tarek M, Bandyopadhyay S, Klein M L. Molecular dynamics studies of aqueous surfactants systems [J]. Journal of Molecular Liquids, 1998, 78: 1-6.

[15] Leermakers F A M, Koopal L K, Goloub T P, VERMEER A W P, KIJLSTRA V. Confinement-induced symmetry breaking of interfacial surfactant layers [J]. Journal of Physical Chemistry B, 2006, 110(17): 8756-8763.

[16] 宋其圣, 郭新利. 十二烷基苯磺酸钠在SiO2表面聚集的分子动力学模拟[J]. 物理化学学报, 2009, 25(6): 1053-1058.

SONG Qi-sheng, GUO Xin-li. Molecular dynamics simulation of sodium dodecyl benzene sulfonate aggregation on silica surface [J]. Acta Physico-Chimica Sinica, 2009, 25(6): 1053- 1058.

[17] 张 军, 于维钊, 燕友果, 于立军, 任振甲. 咪唑啉缓蚀剂在Fe(001)表面吸附行为的分子动力学模拟[J]. 物理化学学报, 2010, 26(5): 1385-1390.

ZHANG Jun, YU Wei-zhao, YAN You-guo, YU Li-jun, REN Zhen-jia. Molecular dynamics simulation of the adsorption behavior of imidazoline corrosion inhibitors on a Fe(001) surface [J]. Acta Physico-Chimica Sinica, 2010, 26(5): 1385-1390.

[18] 孙传尧, 印万忠. 硅酸盐矿物浮选原理[M]. 北京: 科学出版社, 2001: 22-23.

SUN Chuan-yao, YIN Wan-zhong. The flotation principle of silicate mineral [M]. Beijing: Science Press, 2001: 22-23.

(编辑 陈卫萍)

基金项目:国家“十二五”科技支撑计划资助项目(2012BAB07B05)

收稿日期:2011-06-20;修订日期:2011-11-15

通信作者:刘润清,讲师,博士;电话:0731-88830482; E-mail: liurunqing@126.com