文章编号:1004-0609(2011)07-1681-07

等离子体电解氧化弧光放电的瞬态测定及温度场模拟

刘晓静1, 2, 李 光1, 段红平1, 夏 原1

(1. 中国科学院 力学研究所,北京 100190;2. 中国科学院 研究生院,北京 100049)

摘 要:为描述等离子体电解氧化(PEO)过程中单个弧光放电通道内部及周围温度场分布,构建圆柱形放电通道模型。采用高速摄像机和概率统计方法,测定铝合金PEO膜层生长典型阶段弧光放电的弧斑密度及通道尺寸等特征参数;通过计算单个弧光的延迟寿命(140 μs)以及能量,获得模型参数。采用Ansys软件模拟单个弧光放电通道内部及周围温度场分布,计算得出弧光通道中心温度超过2×104 K,从传热学角度解释了PEO陶瓷层中γ-Al2O3和α-Al2O3的生成过程以及陶瓷层微结构的形成原因。

关键词:等离子体电解氧化;单弧光;瞬态放电;温度场模拟

中图分类号:TG178 文献标志码:A

Instantaneous measurement and temperature field simulation of arc discharge in plasma electrolytic oxidation process

LIU Xiao-jing1, 2, LI Guang1, DUAN Hong-ping1, XIA Yuan1

(1. Institute of Mechanics, Chinese Academy of Sciences, Beijing 100190, China;

2. Graduate University of Chinese Academy of Sciences, Beijing 100049, China)

Abstract: In order to describe the temperature field distribution around a single discharge channel exactly during plasma electrolytic oxidation (PEO) process, a cylinder-shaped discharge model was designed. In the typical stage of the PEO coating growth on aluminium alloy, by using the high-speed camera and statistical method, the characteristic parameters of discharges, such as the spatial density of arc spot and size of channel, were measured, the lifetime (140 μs) and energy of a single spark were also calculated. The parameters of the model were obtained. The Ansys software was adopted to simulate the temperature field around a single discharge channel. The center temperature of the discharge channel was over 2×104 K. The results can explain the formation of γ-Al2O3 and α-Al2O3 and microstructure in the ceramic coatings from the heat transfer theory.

Key words: plasma electrolytic oxidation; single spark; instantaneous discharge; temperature filed simulation

等离子体电解氧化(Plasma electrolytic oxidation,PEO)过程涉及电化学及较为复杂的物理化学反应,其典型特征是通过高电压、大电流使置于电解液中的电极表面产生瞬间等离子体微弧放电,击穿钝化层并烧结形成陶瓷层[1-10]。在此过程中,陶瓷层的生长不仅源于阴、阳离子的相互作用、陶瓷层的击穿、熔化,而且还与高温熔融产物在金属基体及电解液冷却作用下的凝固过程密切相关[11-12]。然而,由于PEO反应过程的复杂性及目前实验和检测手段的局限性,尚缺乏对PEO反应过程及氧化膜生长机制的准确描述。

文献[12-14]的研究结果表明,微区放电热效应是影响陶瓷层生长、熔化和凝固的重要因素之一,因此,对PEO放电微区热效应的研究将有助于理解陶瓷层的形成机理。已有研究表明,采用温度场数值计算的方法,可预测PEO单弧光放电的温度分布。但是,人们在模拟单个微放电通道温度场时采用了太多的假定条件,如KLAPKIV[13]根据已有研究结果,假设单个微放电通道中物质分布情况及存在形态并结合其存在条件,推测了PEO过程中单个微放电通道内部温度的大致分布;YEROKHIN等[11]忽略通道内部各点因为位置不同而造成的温度差异,设定PEO过程中单个微放电通道内部单位体积氧化膜温度的变化公式,并建立相应模型,研究了单个微放电通道内部各点的温度变化,初步计算了冷却过程的冷却速率;王立世等[14]基于微放电的圆柱形通道模型,借鉴点热源的传热公式,在模型尺寸假定的前提下,从二维角度计算通道内部及放电衰退过程中毗邻膜层的温度场,初步分析膜层中存在的物相种类及晶态类型;此外,李华平等[12]设定微弧熔区的初始温度,采用Ansys软件对其淬冷过程进行模拟,分析了淬冷过程对氧化铝微观结构的影响,阐述了单个弧光的淬冷过程对陶瓷层表面形貌的影响。

放电微区热效应的研究进展深化了对PEO反应过程中单个弧光放电通道温度场的认识,也为深入分析PEO过程中陶瓷层的生长机制提供了重要的理论依据,因此,减少必要的假设条件,开展基于微弧放电特征实验测定的温度场模拟十分必要。为此,本文作者针对PEO过程中氧化膜生长的典型阶段(稳定微弧放电阶段),利用实验和概率统计的方法得到弧光放电特征参数,并基于实验结果构建圆柱形放电通道模型;采用Ansys软件进行有限元模拟,获得单个弧光放电通道内部及周围三维温度场分布,从传热学角度解释PEO陶瓷层中γ-Al2O3和α-Al2O3的生成过程以及陶瓷层微结构的形成原因,推测了PEO陶瓷层的生长机制。

1 实验

试样选用含1.6%Si(质量分数)铸铝合金,圆饼形试样直径为38 mm,厚度为5 mm,通过聚四氟乙烯夹具密封,使之单面(直径为30 mm)接触电解液;PEO处理过程采用交变脉冲恒流模式,电流密度为0.8 mA/mm2,峰值电压为420 V,处理时间根据条件进行设定。电解液采用碱性硅酸盐体系,电解液温度控制在(25±2) ℃。采用FEIsirion 400NC 型扫描电镜观察PEO陶瓷层的表面形貌;采用涡流测厚仪测定PEO陶瓷层的厚度。对PEO过程中某一时刻,采用高速摄像机(10 000 帧,像素768×768,曝光时间1/40 000 s)获得铝合金表面弧光放电形态。

2 模型的构建与相关实验

在实验条件下,PEO过程在6~30 min,呈现稳定的弧光放电特征,即氧化膜生长的典型阶段。本文作者针对氧化膜生长的典型阶段(PEO处理时间为10 min,陶瓷层厚度约为10 μm),构建单个弧光放电通道内部及周围温度场模拟模型,并对弧光特征参数进行实验测定以获取模型参数。

2.1 模型的构建

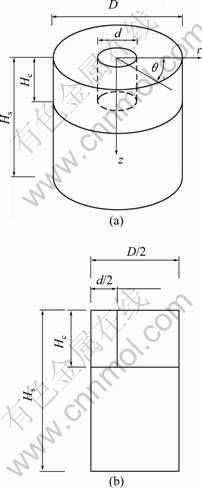

基于PEO陶瓷层中放电微孔的三维结构特征,不考虑文献[15]中膜层表面的微孔部分,构建圆柱形放电通道模型,如图1(a)所示,对单个弧光放电通道内部及周围温度场进行数值模拟,考虑到基体温度在PEO进行过程中的升幅较小,取初始温度为333 K[12]。边界条件如下:电解液对膜层的冷却作用为对流散热,对流系数为15 kW/(m2·K)[12],电解液温度为298 K,同时鉴于在放电通道区域有体热源的作用,引入荷载因素。

考虑到该模型为轴对称,如图1(b)所示,可以将三维温度场分布简化为二维温度分布,进而解释模型整体的温度分布情况。

相应的传热方程如下。

在圆柱坐标系下,瞬态热传导方程为

(1)

(1)

考虑到轴对称空间热传导问题,则温度不随θ变化,瞬态热传导方程可以简化为

(2)

(2)

侧面及底面的绝热边界条件为

侧面: (3)

(3)

底面: (4)

(4)

电解液的冷却作用可以用表面对流散热条件来 表示:

(5)

(5)

式中:T为温度;t为时间;C为比热容; 为

为

材料的导温系数;θ、z和r为柱坐标;k为材料的导热参数;Q为体热源密度;ρ为材料的密度; Tf为电解液温度;h为对流散热系数;Hs为基体和陶瓷层的总体厚度。

图1 单弧光放电通道模型(Hc为陶瓷层厚度;d为单个弧光放电通道直径)

Fig.1 Model of single discharge channel(Hc is thickness of ceramic coating and d is diameter of single discharge channel): (a) Cubic diagram; (b) Simplified section diagram

陶瓷层为氧化铝,基体材料近似为纯铝,考虑到PEO放电区为金属-电介质-气体-电解液四相体系,放电区尺寸小、边界条件复杂、温度梯度大、体系的某些热力学参数很难准确测定,本研究中采用常温值。模拟中使用的Al和Al2O3的物性参数如表1所列。

弧光放电温度场模拟所需参数由两部分组成:物性参数和模型参数。表1给出了物性参数,而模型参数的获取需要对单个弧光的放电特征参数进行实验 测定。

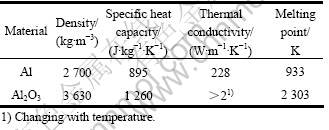

表1 Al和Al2O3的物性参数[11-12, 16-17]

Table 1 Physical parameters of Al and Al2O3[11-12, 16-17]

2.2 单个弧光放电特征参数的测定

2.2.1 弧光延迟时间及弧斑数量分析

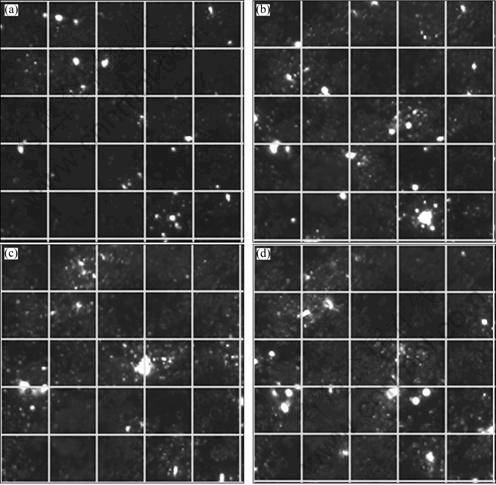

高速摄像机得到的一组图像,能够直观显示弧光从出现到消失的整个过程,本研究选取试样表面放电的固定区域考察弧光放电寿命。如图2所示,图像拍摄的相隔时间为?100 μs,可以认为如果某个位置的弧光在N张图片中一直出现,那么这个弧光的延迟寿命为(N×100) μs,通过概率统计计算可以得到弧光的延迟寿命约为140 μs,即瞬态放电分析的时间为140 μs。

由图2可知,在一个脉冲期间,所有产生弧光图片的弧光数目基本相同,在弧光产生阶段,假设弧光是成批出现的,每批弧光个数相同,并且相隔时间为一个弧光的延迟寿命,根据实验得到在一个脉冲期间弧光的存在时间为2 000 μs,依据高速摄像机分析结果,单个弧光的延迟寿命为140 μs,计算得到在一个脉冲期间有14批弧光产生。

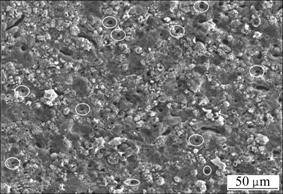

图3所示白圆圈(直径为30 mm)统计了一批弧光典型照片中的弧斑数量,得到弧光数目约为250个(弧光分布密度为3.5×105个/m2),即每批产生250个弧光,因此,在一个脉冲期间总共产生约3 500个弧光。

2.2.2 单弧光能量分析

采用PEO工艺设备中装配的信号采集系统,可以得到每一时刻施加在电极两端的电压和电流特征波形。图4所示为在PEO典型阶段处理时间为10 min时单个脉冲的瞬时电压—时间曲线和电流—时间曲线。

根据等离子体电解氧化放电原理,仅正向电压对放电火花提供能量来源。因此,在分析能量问题时,本文作者只考虑正向电压(U)及电流(I)所带来的所有

能量(W),利用积分原理 ,可以得到一个

,可以得到一个

脉冲期间的总能量消耗为5.76 J。

在PEO处理过程中,每一次弧光放电是陶瓷层生长的直接驱动力,根据电流利用率的计算公式[18],设PEO生长膜层密度为3 630 kg/m3[16],通过对电流利用率的计算,得到实际用于弧光放电的能量约占总能量的43%。由上节研究得出,在一个脉冲期间共产生 3 500个弧光,因此单个弧光的能量为7.08×10-4 J。假设能量在通道均匀分布,则体热源密度为1.79×1016 W/m3,即体热源作用荷载为1.79×1016 W/m3。

图2 PEO典型阶段弧光放电图像(处理时间10 min, 连续拍摄过程时间间隔为?100 ms)

Fig.2 Pictures of sparks in typical stage of PEO (treated for 10 min): (a), (b), (c), (d) Continuous capture process with interval of 1?00 μs

图3 PEO典型阶段弧光分布图(处理时间为10 min)

Fig.3 Distribution diagram of sparks in typical stage of PEO (treated for 10 min)

2.2.3 微弧瞬态放电时微弧尺寸及热影响区分析

假设微弧放电之间相互绝热,根据表面弧光数,得到单个弧光的影响区域半径为950 ?μm,弧光对铝基体的影响区半径取1 000? μm,即D = 1 900 μm;HS = 1 010 μm。

图5所示为样品在PEO曲型阶段的SEM像。由图5可以看出,放电通道大小很不规则,这是由于其相互覆盖造成的,选择一些比较规则的孔洞(白圆圈内),统计得到其直径范围为3~6 μm,取单个弧光放电通道直径为6 μm,即d = 6 μm,实际的放电通道直径一般在1 ~ 10 μm[3],与统计数据相符。

图4 单个脉冲的瞬时电压—时间曲线和瞬时电流—时间曲线(处理时间为10 min)

Fig.4 Instantaneous voltage and current waveforms of single pulse (treated for 10 min): (a) Voltage—time curve; (b) Current—time curve

图5 PEO典型阶段膜层的表面形貌(处理时间为10 min)

Fig.5 Surface morphology of coating in typical stage of PEO (treated for 10 min)

3 结果分析与讨论

3.1 弧光放电特征参数

PEO过程伴随着试样表面产生一系列弧光放电现象。在膜层生长的典型阶段,弧光不断闪烁并移动,其寿命非常短暂,本文作者根据放电击穿介质的实验现象,构建圆柱形放电通道模型;用实验方法获得弧光寿命以及单个弧光的能量,对每个弧光产生的放电通道及周围温度场的分布进行瞬态计算分析。

因此,针对PEO过程膜层生长的典型阶段前期,本文作者采用高速摄像机进行试样表面弧光放电的捕捉拍摄,根据统计方法得到弧光寿命约为140 μs,可见,弧光的寿命在微秒级,这与BAOVAN等[19]测算的“单个火花”寿命为0.17 ms比较接近,由于其短暂性,采用瞬态计算分析方法是有效的。同时,根据实验观察得到在一个脉冲期间弧光的存在时间为2 000 μs,将此与处理时间为10 min时单脉冲的瞬时电流—时间曲线进行比较(如图4(b)所示),存在弧光的时间范围为2.1~4.1 ms,在此阶段,根据图4(a),电压的变化范围为445~565 V,而在脉冲的其他时间范围,电压快速降低,由于电压的集中性,产生批次弧光时每批的弧光数目接近。

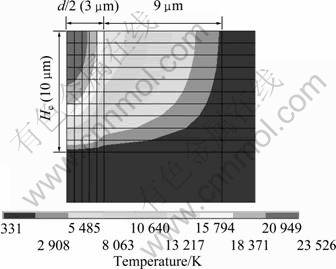

通过Ansys分析,图6所示为简化分析截面(见图1(b))放电通道附近的局部温度场分布。温度高于2 908 K 的区域主要集中在放电通道附近,通道中心温度超过2×104 K,而在其影响的大部分区域温度都低于2 908 K,因为2 908 K相对2×104 K非常低,因此,大部分区域的温度变化不大,单个弧光的放电能量对此区域的影响可以忽略,根据微弧放电之间的相互绝热性,估算了单个弧光的影响区大小,验证了弧光尺寸的合理性。另外,考虑到相机的通光量及曝光时间等参数的限制,统计得到的弧斑数量稍微偏小,但其占总消耗能量的绝大部分,可见,最终得到的温度值稍微偏高,但差别不大。

图6 PEO典型阶段单个弧光放电通道中心及周围温度场的分布云图

Fig.6 Temperature field distribution around single discharge channel in typical stage during PEO process

3.2 模拟结果与分析

根据所测定的弧光特征参数,采用Ansys模拟得到单个弧光放电通道内部及周围温度场的分布云图,如图6所示。可以看出,放电通道内部的温度最高超过2×104 K,明显高于Al2O3的熔点及γ-Al2O3和α-Al2O3的形成温度,具备Al2O3向γ-Al2O3和α-Al2O3转变的驱动力。说明PEO陶瓷层形成是由一系列熔化和凝固瞬态过程构成,每一个脉冲瞬态过程均存在Al及Al2O3等多相物质的瞬态熔化与瞬态凝固行为。

由图6还可以看出,放电通道中心温度高于两侧温度,均高于Al2O3的熔点,已形成熔池。温度梯度引起熔池表面张力梯度,由于表面张力温度系数通常为负值[12],温度与表面张力成反比,因为越靠近放电通道中心位置的温度明显高于偏离放电通道中心位置的温度,所以,前者熔池表面形成的张力小于后者熔池表面形成的张力,促使熔融的Al2O3向放电通道两侧流动,从而使放电通道中心形成孔洞,这也就解释了陶瓷层表面多孔的现象。同时,考虑到固体可见光辐射一般在1 000 ℃以上[12],弧光的面积大于放电通道的面积。

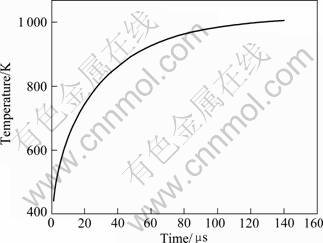

图7所示为放电通道中心底部与基体交接点温度随时间的变化曲线。可见,在单个弧光放电结束时,基体温度已高于其熔点,这表明铝会发生重熔现象。鉴于此,对陶瓷层的生长机制进行推测:在高电压、大电流的作用下,膜层被击穿,存在电子导电的同时,也存在离子导电,使熔化的铝形成铝离子并向膜层表面迁移;铝离子与电解液中OH-和大量水分子在放电通道附近反应形成高温状态下的氧化铝,可能的反应

图7 PEO典型阶段单个弧光放电过程通道中心底部与基体交接点温度随时间变化曲线

Fig.7 Temperature—time curves of connection node between bottle middle of discharge channel and substrate in single discharge in typical stage of PEO

方程式如下:

2Al+9H2O→Al2O3+6H3O++6e (6)

Al+3OH-→Al(OH)3+3e (7)

2Al(OH)3→Al2O3+3H2O (8)

本文作者未考虑放电结束后由于电解液冷却而产生的各点温度变化,实际上,每个放电过程后,通道内各点都会产生极高的冷却速度,将引发高温状态下的氧化铝发生复杂的相变行为[20-21],最终获得晶态或非晶态陶瓷涂层。

4 结论

1) 针对PEO过程生长典型阶段,通过实验确定了弧光寿命约为140 μs、微弧尺寸约为6 μm;一个脉冲期间总的能量消耗为5.76 J。以单个弧光放电的有效转换能量计算,单个弧光的放电能量为7.08×10-4 J。

2) 针对PEO过程生长典型阶段,基于圆柱形放电通道模型和实验获得的模型参数,对单个弧光放电通道内部及周围区域温度场进行模拟,计算得出弧光放电通道中心温度超过2×104 K。

3) 放电通道内部及周围的高温作用使放电通道中心与基体交接点处铝发生重熔,结合通道附近复杂的化学反应以及相变行为,推测出PEO陶瓷层的生长机制。

REFERENCES

[1] XUE W B, ZHU Q Z, JIN Q, HUA M. Characterization of ceramic coatings fabricated on zirconium alloy by plasma electrolytic oxidation in silicate electrolyte[J]. Materials Chemistry and Physics, 2010, 120: 656-660.

[2] MATYKINA E, ARRABAL R, SKELDON P, THOMPSON G E. Investigation of the growth processes of coatings formed by AC plasma electrolytic oxidation of aluminium[J]. Electrochimica Acta, 2009, 54: 6767-6778.

[3] YEROKHIN A L, NIE X, LEYLAND A, MATTHEWS A. DOWEY S J. Plasma electrolysis for surface engineering[J]. Surface and Coatings Technology, 1999, 122: 73-93.

[4] MATYKINA E, ARRABAL R, SCURR D J, BARON A, SKELDON P, THOMPSON G E. Investigation of the mechanism of plasma electrolytic oxidation of aluminium using 18O tracer[J]. Electrochimica Acta, 2009, 54: 6767-6778.

[5] 姜兆华, 辛世刚, 王福平, 吴晓宏, 清水纪夫. 铝合金在水玻璃-KOH-NaAlO2体系中的微等离子体氧化[J]. 中国有色金属学报, 2000, 10(4): 519-524.

JIANG Zhao-hua, XIN Shi-gang, WANG Fu-ping, WU Xiao-hong, QINGSHUI Ji-fu. Micro-plasma oxidation of aluminum alloy in sodium silicate-KOH-NaAlO2[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(4): 519-524.

[6] 吴振东, 姜兆华, 姚忠平, 孙学通, 张雪林. 纯铝及其合金的微等离子体氧化成膜特征[J]. 中国有色金属学报, 2005, 15(6): 946-951.

WU Zhen-dong, JIANG Zhao-hua, YAO Zhong-ping, SUN Xue-tong, ZHANG Xue-lin. Coating-forming characteristics of pure aluminum and aluminum alloy during micro-plasma oxidation[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 946-951.

[7] DUAN H P, DU K Q, YAN C W, WANG F H. Electrochemical corrosion behavior of composite coatings of sealed MAO film on magnesium alloy AZ91D[J]. Electrochimica Acta, 2006, 51: 2898-2908.

[8] HUSSEIN R O, NIE X, NORTHWOOD D O, YEROKHIN A, MATTHEWS A. Spectroscopic study of electrolytic plasma and discharging behaviour during the plasma electrolytic oxidation(PEO) process[J]. J Phys D: Appl Phys, 2010, 43: 1-13.

[9] WU Z Q, XIA Y, LI G, XU F T. Structure and mechanical properties of ceramic coatings fabricated by plasma electrolytic oxidation on aluminized steel[J]. Applied Surface Science, 2007, 253: 8398-8403.

[10] GUAN Y J, XIA Y. Interface fracture property of PEO ceramic coatings on aluminum alloy[J]. Surface and Coatings Technology, 2008, 202(17): 4204-4209.

[11] YEROKHIN A L, SNIZHKO L O, GUREVINA N L, LEYLAND A, PILKINGTON A, MATTHEWS A. Discharge characterization in plasma electrolytic oxidation of aluminium[J]. Appl Phys, 2003, 36: 2110-2120.

[12] 李华平, 柴广跃, 彭文达, 阳 英, 高 敏, 郭宝平, 牛憨笨. 微弧熔区的淬冷过程及其对氧化铝膜微观结构的影响[J]. 无机材料学报, 2008, 23(1): 114-120.

LI Hua-ping, CHAI Guang-yue, PENG Wen-da, YANG Ying, GAO Min, GUO Bao-ping, NIU Han-ben. Simulation of quenching process during microarc oxidation(MAO) and its effect on the microstructure of Al2O3 coating[J]. Journal of Inorganic Materials, 2008, 23(1): 114-120.

[13] KLAPKIV M D. Simulation of synthesis of oxide-ceramic coatings in discharge channels of a metal-electrolyte system[J]. Materials Science, 1999, 33: 279-283.

[14] 王立世, 潘春旭, 蔡启舟, 魏伯康. 等离子体电解氧化过程中单个稳态微放电的热效应研究[J]. 物理学报, 2007, 56(9): 5341-5344.

WANG Li-shi, PAN Chun-xu, CAI Qi-zhou, WEI Bo-kang. Study of the heat effect of single steady-state microdischarge during plasma electrolytic oxidation[J]. Acta Physica Sinica, 2007, 56(9): 5341-5344.

[15] XUE W B. Features of film growth during plasma anodizing of Al 2024/SiC metal matrix composite[J]. Applied Surface Science, 2006, 252: 6195-6200.

[16] CURRAN J A, CLYNE T W. Porosity in plasma electrolytic oxide coatings[J]. Acta Materialia, 2006, 54: 1985-1993.

[17] ROHSENOW W M. 传热学手册(上册)[M]. 李荫亭, 译. 北京: 科学出版社, 1985: 125-128.

ROHSENOW W M. Handbook of heat transfer (Volume I)[M]. LI Yin-ting, transl. Beijing: Science Press, 1985: 125-128.

[18] 薛文斌, 邓志威, 来永春, 陈如意, 张通和. 铝微弧氧化电流效率的测定[J]. 电镀与精饰, 1998, 20(3): 1-5.

XUE Wen-bin, DENG Zhi-wei, LAI Yong-chun, CHEN Ru-yi, ZHANG Tong-he. Determination of current efficiency in microarc oxidation on aluminum[J]. Plating and Finishing, 1998, 20(3): 1-5.

[19] BAOVAN T, BROWN S D, WIRTZ G P. Mechanism of anodic spark deposition[J]. Ceramic Bulletin, 1977, 56(6): 563-566.

[20] 贺永胜, 赵志龙, 刘一洋, 刘 林. 铝合金微弧氧化热力学机理及影响因素的分析[J]. 电镀与环保, 2005, 25(6): 38-40.

HE Yong-sheng, ZHAO Zhi-long, LIU Yi-yang, LIU Lin. Thermodynamic mechanism and affecting factors analysis of aluminum alloy microarc oxidation[J]. Electroplating and Pollution Control, 2005, 25(6): 38-40.

[21] 薛文彬, 邓志威, 来永春, 陈如意. 铝合金微弧氧化陶瓷膜的相分布及其形成[J]. 无机材料学报, 1997, 11(2): 169-176.

XUE Wen-bin, DENG Zhi-wei, LAI Yong-chun, CHEN Ru-yi. Phase distribution and formation mechanism of ceramic coatings formed by microarc oxidation(MAO) on alloy[J]. Journal of Inorganic Materials, 1997, 11(2): 169-176.

(编辑 陈卫萍)

基金项目:国家自然科学基金面上项目(10772179);国家自然科学基金重点项目(10832011);中国博士后科学基金资助项目(20090460536)

收稿日期:2010-07-22;修订日期:2010-09-19

通信作者:夏 原,研究员,博士;电话:010-82543858;E-mail:xia@imech.ac.cn