文章编号:1004-0609(2014)07-1804-08

不同纳米氧化铝含量Ni-P-Al2O3化学镀层的高温磨损性能

郑晓华1,刘 辉1,章 荣1,杨芳儿1,陈 琍2,周 军2

(1. 浙江工业大学 材料科学与工程学院,杭州 310032;

2. 浙江工业大学 机械工程学院,杭州 310032)

摘 要:采用化学镀技术制备不同纳米氧化铝含量的Ni-P-Al2O3 复合镀层,并利用扫描电子显微镜(SEM)、X射线能谱仪(EDS)和X射线衍射仪(XRD)对镀层的表面形貌、化学成分及微观结构进行表征,考察镀层在600 ℃下的高温氧化性能,并采用高温摩擦磨损试验机对镀层在200 ℃和600 ℃下的摩擦磨损性能进行测试,分析其磨损机理。结果表明:纳米氧化铝的加入可有效提高镀层的高温耐磨性能和抗高温氧化性能。随着镀液中纳米Al2O3用量的增加,镀层的氧化质量增加,摩擦因数先减少后增加,镀层的磨损机理发生变化。镀液中纳米Al2O3用量为3 g/L时,镀层具有优异的抗高温氧化性能、较低的摩擦因数和较低的磨损率。复合镀层在较高温度磨损过程中呈现出较高的磨损率和较低的摩擦因数。

关键词:纳米Al2O3;镍磷合金;化学镀;摩擦;磨损;高温氧化

中图分类号:TQ153.2 文献标志码:A

High-temperature wear properties of electroless Ni-P-Al2O3 composite coatings with various contents of nano-Al2O3

ZHENG Xiao-hua1, LIU Hui1, ZHANG Rong1, YANG Fang-er1, CHEN Li2, ZHOU Jun2

(1. College of Materials Science and Engineering, Zhejiang University of Technology, Hangzhou 310032, China;

2. College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou 310032, China)

Abstract: Ni-P-Al2O3 composite coatings with various contents of nano-Al2O3 particles were prepared by using electroless plating technique. The morphology, microstructure and chemical composition of the coatings were characterized by scanning electron microscopy (SEM), energy disperse spectrum (EDS) and X-ray diffraction (XRD) techniques. The high-temperature oxidizing behavior of the coatings at 600 ℃ was investigated, the tribological properties of the coatings at 200 ℃ and 600 ℃ were evaluated by high-temperature wear instrument, and the wear mechanism was also discussed. The results show that the addition of nano-Al2O3 particles in electroless plating bath can effectively improve the high-temperature wear resistance and the high-temperature oxidation resistance of the composite coatings. With the increase of nano-Al2O3 concentration in bath, the oxidation mass increment and the friction coefficient of the coatings decrease at first, and then increase, and the wear mechanism of the coatings is altered. The composite coating prepared by a nano-Al2O3 concentration of 3 g/L in bath exhibits a good high-temperature oxidation resistance, low friction coefficient and low wear rate. Compared those of the coatings tested at lower temperature, a higher wear rate and a lower friction coefficient of the coatings are obtained under higher test temperature.

Key words: Nano-Al2O3; Ni-P alloy; electroless plating; friction; wear; high-temperature oxidation

化学镀Ni-P合金镀层由于具有厚度均匀、耐腐蚀性好、耐磨性较高、镀覆工艺简便等优点,在化工设备、电子、航空、汽车工业等方面得到了广泛应用[1]。然而,传统化学镀Ni-P合金已经完全不能满足日益苛刻的性能要求。近二十年来,人们陆续开展化学镀液中添加不溶性微粒如SiC、Al2O3、B4C、ZrO2、TiO2、PTFE、纳米碳管、钛酸钾晶须、金刚石等制备复合镀层的相关研究,期望获得具有较高硬度值、耐磨、耐蚀、自润滑性等不同物理、化学性质的功能性复合镀层[2-10]。随着粉体制备技术的进步,加入镀液中的微粒的尺寸已由微米量级逐渐过渡到亚微米或纳米量级[11]。

纳米Al2O3颗粒因为具有较高硬度、较好化学稳定性且廉价易得等一系列优点而被优先复合到镀层中。目前,国内外关于Ni-P-Al2O3复合镀层的研究已有许多报道,但工作大都集中在镀层制备工艺改进,表面形貌的表征以及单一的镀层硬度和耐磨性能的测试等方面[12-15]。虽然文献[16-17]报道了纳米颗粒的添加量对复合镀层的耐腐蚀性能和常温摩擦磨损性能的影响,但是纳米颗粒添加量对复合镀层的高温氧化性能及高温摩擦磨损性能的影响尚鲜有报道。高温氧化及高温摩擦磨损性能对服役在高速、重载滑动摩擦环境下的复合镀层的使用寿命起决定性作用。本文作者重点考察不同纳米Al2O3含量Ni-P-Al2O3复合镀层在高温氧化和高温摩擦磨损过程中的基本规律,为定量描述镀层在高温(或实际工况)条件下的摩擦学行为提供基础实验数据,也为优化Ni-P-Al2O3复合镀层的Al2O3含量、拓展复合镀层的使用领域提供理论基础和实验依据。

1 实验

1.1 复合镀层的制备

实验采用Q235钢板为基底,其规格为20 mm×30 mm×2 mm,所用Al2O3粉末为市售商业α-Al2O3粉,平均粒径约为30 nm,纯度>99.9%。镀层试样的制备工艺流程如下:砂纸打磨→机械抛光至Ra 0.1 mm左右)→除油→水洗→除锈→水洗→活化→水洗→化学镀。化学镀槽液配方及工艺参数如表1所列。

在化学镀之前,先将一定量的Al2O3粉末放入含有适量表面活性剂的镀液中(体积为50 mL)超声波分散30 min,备用。当试样镀覆Ni-P合金5 min之后,再匀速添加纳米Al2O3悬浊液到槽液中进行复合镀,时间2 min。搅拌方式为机械搅拌,转速为400~450 r/min。按纳米Al2O3不同用量制备了5组试样,纳米Al2O3的加入量分别为0、1.5、3、4.5和6 g/L。每组制备8片合格试样,镀覆时长为2~3.5 h,获得的镀层厚度分别为13.3、13.2、12.7、12.3和12.1 μm。所得试样依次在去离子水和无水酒精中超声波清洗10 min,热风干燥后备用。采用常规的贴滤纸法测得镀层的孔隙率分别为1.15、0.75、0.45、0.5和0.6斑点数每平方厘米。

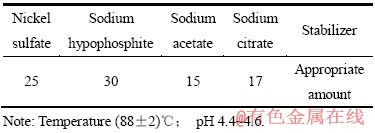

表1 镀液配方浓度

Table 1 Concentration of electroless plating (g·L-1)

1.2 性能测试和表征方法

镀层的高温氧化实验在箱式电阻炉中进行。从刚镀覆好的试样(镀态试样)中每组各取4片,在ESJ80-5型电子分析天平(精度0.01 mg)上称量并获得初始质量;然后将其等间距悬挂在预先准备好的挂架上(可以确保试样之间不发生覆盖或遮挡),随后将挂架平稳放入600 ℃的电阻炉中进行保温,当炉温再次升到600 ℃时开始计时,温度控制精度为±10 ℃。每隔1 h取出一片试样,自然冷却到室温后再进行称量,得到试样氧化后的质量。试样氧化后与氧化前的质量之差即为试样的质量增加。每片试样总共称量10次,然后取平均值。

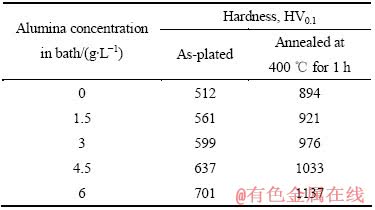

镀层的摩擦学特性测试在HT-500高温摩擦磨损试验机上进行。先将镀态试样置于真空热处理炉中进行真空退火(背底气压5 mPa),温度400 ℃,保温 1 h;然后将退火试样分别在200 ℃和600 ℃的温度条件下进行摩擦磨损测试。退火试样作为摩擦盘,对磨件为表面抛光的Si3N4陶瓷球(直径5 mm),法向载荷 为200 g,干滑移速度为0.176 m/s,测试时间为15 min,摩擦因数极限值fmax=2。采用Dektak 3型台阶仪对试样的表面粗糙度和磨损体积进行测定。磨损体积测定方法:先测出试样表面磨痕的横截面轮廓,然后通过计算每个试样的磨痕截面面积和磨损体积。在每个试样的摩擦圆上随机选取10~12个位置进行测量,试样的最终磨损体积为前几次测量计算的平均值。依据滑行距离、法向载荷和试样磨损体积,最终计算出镀层的磨损率。镀层在镀态和400 ℃经1 h真空退火后的硬度采用HVM-IT维氏硬度计测量,载荷0.98 N,保持时间15 s,取20次的平均值,其结果如表2所列。

镀层在镀态及高温氧化后的微观结构采用Thermo ARL型X射线衍射仪(XRD)进行分析,衍射角扫描范围为20°~80°,Cu靶,Kα射线(λ=0.154056 nm),X射线管电流为40 mA,电压为40 kV,步长为0.033 (°)/s。采用Hitachi-S4700型场发射扫描电子显微镜(FESEM)观察镀层磨损前后的表面形貌,加速电压为15 kV。镀态镀层的化学成分采用电子显微镜自带的能谱装置(EDS)进行分析,采样时间为100 s。

表2 热处理前后镀层的硬度

Table 2 Hardness of coatings before and after heat treatment

2 结果与讨论

2.1 复合镀层的成分与形貌

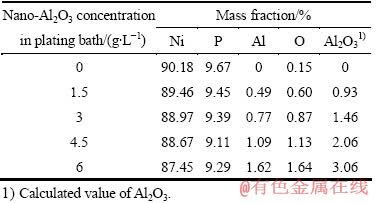

表3所列为镀态镀层的化学成分。主要包含Ni、P、Al和O元素。由于能谱法仅能获得元素的含量,表中Al2O3的含量是根据Al元素的含量和Al2O3的化学计量比计算得到的。因为试样表面存在少量的吸附O,所以实测的氧含量比化学计量比要高一些。由表3可知,随着镀液中纳米Al2O3用量的增加,镀层中纳米Al2O3的质量分数增加,且通过进一步的计算可知镀层中Ni元素和P元素的质量分数之比波动较小,说明纳米Al2O3的加入对Ni-P基体镀层的P含量影响较小。

表3 镀层的化学成分

Table 3 Composition of Ni-P-nano Al2O3 coating

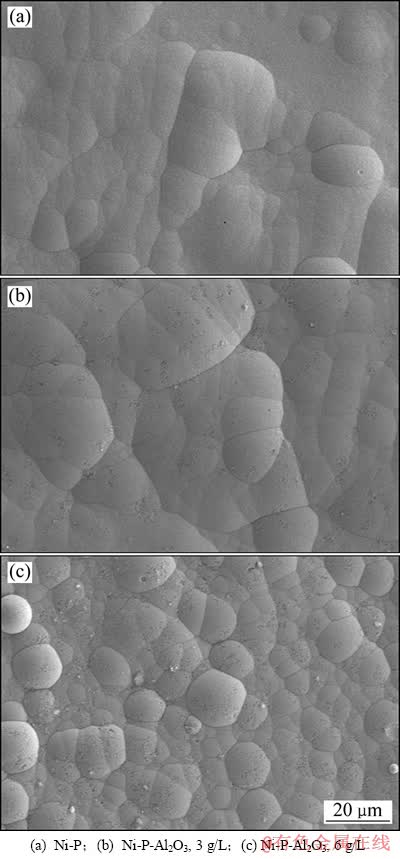

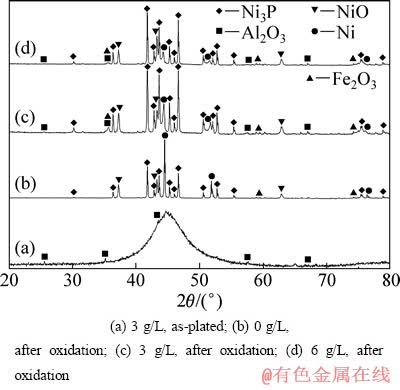

镀态镀层的表面形貌如图1所示。通过对比可知,图1(a)中Ni-P镀层所呈现的胞状结构形状各异且大小不一,而图1(b)中复合镀层的胞状结构形状逐渐趋于规则且尺寸相近。这是因为Al2O3颗粒弥散分布在镀层中改变了Ni胞状结构生长环境的结果,且镀层中Al2O3含量越高,这种现象越明显,如图1(c)所示。图1(c)中胞状结构表面出现的大量小黑点代表了表面层Al2O3团聚体所在的位置,且胞状结构之间的边界也较为清晰。镀层的表面粗糙度测量结果表明,随着镀液中Al2O3用量的增加,镀层的粗糙度从0.43 mm升高至0.67 mm。

图1 不同氧化铝用量的化学镀层在镀态时的表面形貌

Fig. 1 Surface morphologies of as-plated electroless coatings with various alumina concentrations in bath

2.2 复合镀层的结构

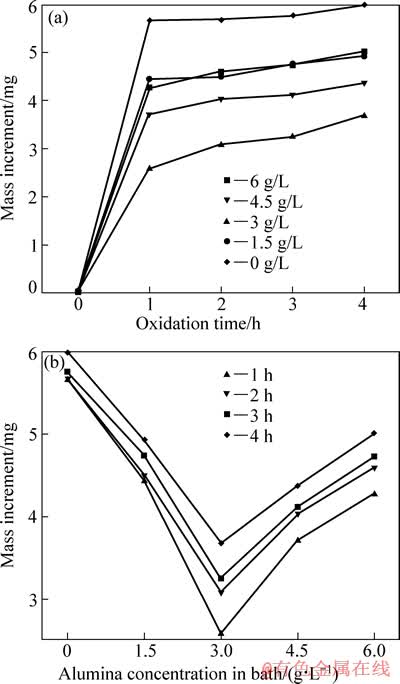

图2(a)所示为镀液中纳米Al2O3用量为3 g/L的镀层(Al2O3质量分数为1.46 %)在镀态时的XRD谱,在在2θ为45°左右出现一个极度宽化的散射峰,对应于镍磷合金的无定形或微晶结构,而结晶相的衍射峰对应于镀层中的Al2O3颗粒。众所周知,化学镀镍磷合金在磷含量为7%~8%时,常呈现出无定形结构,本研究中试样的磷含量约为9.4%,较好地验证了该结论。其他Al2O3用量下的复合镀层在镀态时的衍射图谱与此十分相似,镍磷合金基体均为无定形或微晶状态。

镀态镀层经过600 ℃氧化4 h后的XRD谱如图2(b)~(d)所示。在图2(b)中,镍磷合金镀层出现了Ni、Ni3P和NiO相。这说明镀层在600 ℃条件下发生了晶化反应,非晶合金分解为晶态的Ni和Ni3P相,而NiO相来自于镀层的氧化。事实上,镍磷非晶合金在 400 ℃左右就能发生较为完整的晶化[18-19]。当镀液中Al2O3用量分别为3和6 g/L时,从镀层的XRD谱(见图2(c)和(d))中均能观察到Al2O3、Ni、Ni3P、NiO相的衍射峰。Al2O3颗粒因为性质稳定,在氧化过程中未发生明显分解或结构转变。另外,所有镀层经过高温氧化后出现了一定量的Fe2O3相,原因是镀层厚度较薄并存在一定数量的孔隙,经过较长时间氧化后,氧化反应进入了样品基体。

图2 不同氧化铝用量的化学镀层的XRD谱

Fig. 2 XRD patterns of electroless coatings with various alumina concentrations in bath

2.3 复合镀层的高温氧化性能

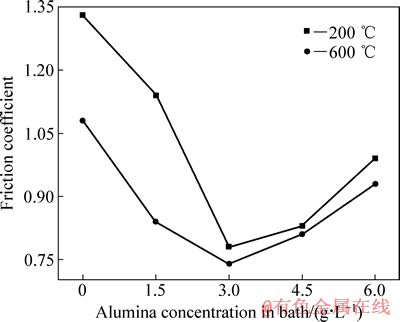

图3所示为镀层试样经过600 ℃高温氧化后的质量增加随氧化时间和Al2O3用量的变化情况。由图3(a)可知,在试样发生氧化的第一个小时内,各组试样的质量增加均最多,随后各组试样的质量增加缓慢增加。这是由于镀层中非晶态的Ni转化成晶态的Ni和Ni3P的同时,镀层表面包裹着一层较为致密的NiO,减缓镀层内部被进一步氧化的结果。事实上,图3(a)中试样的质量增加随氧化时间的变化近似遵循氧化过程的经典抛物线关系模型[20]。图3(b)中,在各种氧化时间下,随着镀液中纳米Al2O3用量的增加,试样的质量增加均呈现出先减小后变大的趋势,且复合镀层的质量增加始终比Ni-P镀层的要小。这说明纳米Al2O3的加入可以有效地提高镀层的抗高温氧化性能,且纳米Al2O3用量为3 g/L时,试样的抗高温氧化能力达到最强。这种现象可归结为纳米Al2O3自身优异的抗高温氧化性能以及对镀层的机械屏蔽作用。当镀层中不含纳米Al2O3或者含量很低时,暴露的Ni-P合金基体面积相对较大,致使镀层的氧化质量增加迅速增加而表现出较差的抗高温氧化性能。当镀层中的纳米Al2O3逐渐增多且均匀弥散分布于复合镀层中时,Al2O3的机械屏蔽作用,使得复合镀层中Ni-P合金基体暴露的面积减少,从而使得试样的质量增加减小。另外,纳米Al2O3颗粒可以作为氧化膜的形核质点,促进氧化膜的形核与长大,使复合镀层的表面形成一层致密且有良好稳定性的氧化膜,减轻了镀层内部的氧化作用,所以复合镀层的氧化质量增加较少,表现出较好的抗高温氧化性能[21]。此外,镀层孔隙率的降低也有利于减轻镀层的氧化。然而,当镀层中的纳米Al2O3含量进一步增多时,纳米粒子的分散不均匀、团聚现象增加,缺陷或孔隙率增多,镀层的致密程度下降,O原子的扩散速度加快,Al2O3的机械屏蔽作用被显著削弱,加之镀层的厚度有减少的趋势[22-23],最终使得氧化作用又增强,试样的质量增加而表现出镀层的抗高温氧化性能下降。

图3 600 ℃高温氧化后试样的质量增加与氧化时间和氧化铝用量的关系

Fig. 3 Relationships among mass increment of samples and oxidation time (a) and alumina concentration in bath (b) after high-temperature oxidation at 600 ℃

2.4 复合镀层的摩擦学性能

图4所示为镀层的摩擦因数和镀液中纳米Al2O3用量之间的关系。由图4可知,在两种测试温度下,镀层的摩擦因数均随纳米Al2O3用量的增加先下降后上升,且Ni-P-Al2O3复合镀层的摩擦因数始终比Ni-P合金镀层的低。这说明纳米Al2O3的加入能有效降低复合镀层的摩擦因数且纳米Al2O3的用量存在最佳值(3 g/L)。这种现象可归结为纳米Al2O3颗粒改变了摩擦副界面间的接触状态(或摩擦机理)。当镀层中纳米Al2O3 含量不高时,镀层比较光滑,摩擦副的实际接触面积较大,从而具有较高的摩擦因数;随着镀层中纳米Al2O3 含量的逐渐增加,由于弥散分布的高硬度Al2O3颗粒能有效降低摩擦副的实际接触面积,所以镀层的摩擦因数逐渐降低。当纳米Al2O3含量超过临界值之后,镀层表面的胞状结构更为明显且粗糙度增加(见图1(c)),其机械变形阻力的增加是摩擦因数升高的主要原因。也就是说,复合镀层的摩擦因数最优值与镀层中Al2O3质量分数的某个区间相对应,在此区间内,纳米Al2O3能有效降低镀层的摩擦因数,此结果与文献[15]一致。另外,从图4中还可以看到,镀层在600 ℃下的摩擦因数比200 ℃的低,这主要是因为镀层在600 ℃下具有更低的机械强度,剪切阻力更小。另一个可能原因是600 ℃时镀层表面的氧化程度比200 ℃时的严重,在镀层表面形成了一层致密且较厚的NiO氧化膜,而NiO膜具有良好的塑性和粘着性,能缓解陶瓷球和镀层的接触与焊合,起到高温润滑的作用[24]。值得注意的是,镀液中纳米Al2O3的用量低于3 g/L时,镀层在两种测试温度下的摩擦因数差异很大,而高于3 g/L之后则极为相近,这一现象良好地佐证了这一事实:高纳米Al2O3含量的镀层的摩擦磨损机理与低纳米Al2O3含量的镀层存在显著差异。

图4 氧化铝用量对镀层摩擦因数的影响

Fig. 4 Effects of alumina concentration in bath on friction coefficient of coatings

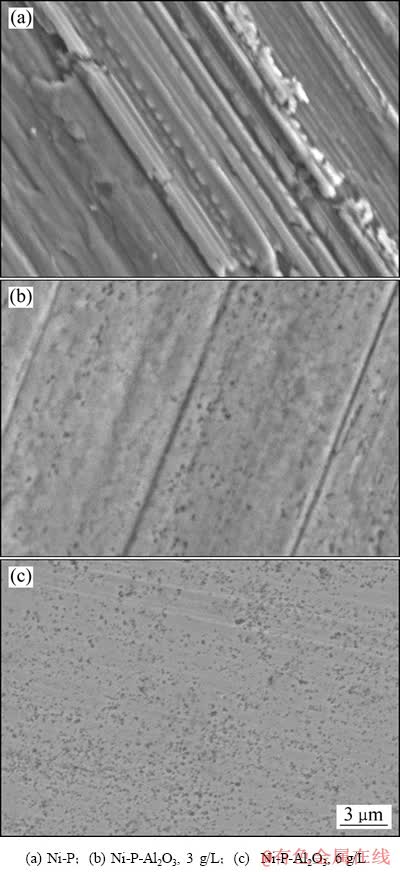

图5 镀层经600 ℃高温磨损后的表面形貌

Fig. 5 Surface morphologies of wear scar of coatings after wear testing at 600 ℃

图5所示为镀层经过600 ℃磨损之后的表面形貌。通过对比可知,图5(a)中Ni-P合金试样表面较为粗糙,划痕较深且纹路清晰,其磨损主要以陶瓷球的犁削作用为主,试样的塑性变形、犁沟和粘着效应都比较明显;图5(b)中试样表面相对光滑,磨痕上分布着少量深划痕和许多小黑点(对应于纳米Al2O3颗粒团聚体脱落后留下的孔洞);而图5(c)中试样表面更加光滑并均匀地分布着大量小黑点(纳米Al2O3颗粒团聚体的孔洞),几乎观察不到深划痕。由此可以看出,随着镀层中纳米Al2O3含量的增加,镀层的犁沟效应明显减弱,而磨粒的抛光效应逐渐增强。这主要是由于加入的Al2O3颗粒作为硬质相,能显著降低摩擦副的实际接触面积,从而有效抑制了陶瓷球表面微凸体对镀层表面的犁沟作用,且纳米Al2O3 弥散分布在镀层中,使得发生粘着效应的有效接触面积减少。此外,磨损过程中脱落的Al2O3颗粒还对镀层起到机械抛光的作用。因此,Ni-P-纳米Al2O3复合镀层的磨损以磨粒磨损和少量的粘着磨损为主[23, 25]。镀层在200℃下的磨损情况与600 ℃的类似,只是各镀层之间的差异比600 ℃时的小,且磨损程度也比600 ℃时的轻。

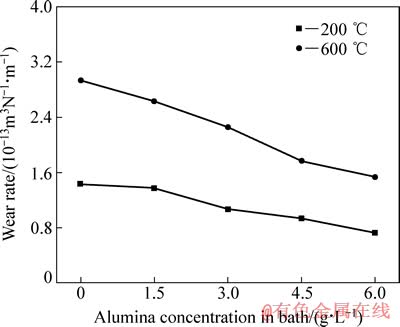

图6所示为镀层的磨损率和镀液中纳米Al2O3用量的关系。由图6可知,无论是在200 ℃还是600 ℃,镀层的磨损率均随着镀液中纳米Al2O3用量的增加而减小,这说明镀层中纳米Al2O3含量的增加可以有效提高镀层的耐磨性能。一般认为,在摩擦过程中具有较高硬度的Al2O3颗粒具有很好的耐磨性,并且作为硬质相在镀层表面上能对摩擦表面载荷起到一个支撑作用,从而缓解合金基体的磨损,进而大幅度改善镀层的耐磨性能。另外,弥散分布在镀层中的Al2O3颗粒在脱落时可以使摩擦形式由滑动摩擦变为滑动与滚动复合摩擦,从而降低了摩擦因数,有效减小了磨损过程中的剪切应力。再者,由于Al2O3颗粒具有良好的抗高温特性,能对位错的滑移和晶粒的长大起到一定的阻碍作用,从而强化镀层,硬度上升(见表2),使镀层的耐高温摩擦性能提升。因此,镀层中Al2O3颗粒复合量越多,Ni-P-Al2O3复合镀层的耐磨性能就越好[14, 17, 26]。图6中,镀层在200 ℃下的磨损率比600 ℃下的小很多,这是因为在600 ℃下,复合镀层中Ni3P及Ni相聚集长大、晶粒粗化,镀层的硬度、弹性模量和剪切强度等性能指标降低,在相同的磨损机理和试验条件下,镀层的软化程度增加,塑性变形量增大,导致镀层的剪切变得容易,摩擦因数下降,磨损量增加[27]。此外,随着镀液中纳米Al2O3用量的增加,600 ℃时,镀层磨损率的下降速度(斜率)比200 ℃时的大,这说明600 ℃时纳米Al2O3颗粒对镀层的增强效应更为明显。

图6 镀层磨损率与氧化铝用量的关系

Fig. 6 Relationship between wear rate of coating and alumina concentration in bath

3 结论

1) 镀层在600 ℃氧化过程中经历非晶态的Ni逐渐转变成晶态的Ni、Ni3P和NiO相,而Al2O3颗粒保持原有晶态结构。

2) 随着镀液中纳米Al2O3用量的增加,镀层中Al2O3的含量随之增加,镀层的氧化质量增加和摩擦因数均呈现出先降低后升高的趋势,镀层的磨损率则单调下降,镀层的磨损机制由磨粒磨损和粘着磨损并重逐渐转变为磨粒磨损为主。

3) 镀层在600 ℃时的摩擦因数和耐磨性均比200 ℃时的要低,但纳米Al2O3对镀层高温耐磨性的增强作用在600 ℃时更有效。当镀液中纳米Al2O3用量为3 g/L时,镀层的抗高温氧化性能最好,摩擦因数也最低(约为0.75),磨损率为1.1×10-13~2.3×10-13 m3/(N·m),综合高温性能优良。

REFERENCES

[1] 李 宁. 化学镀实用技术[M]. 北京: 化学工业出版社, 2012: 2-5.

LI Ning. Practical technology of electroless plating[M]. Beijing: Chemical Industry Press, 2012: 2-5.

[2] ZHANG Shu-sheng, HAN Ke-jiang, CHENG Lin. The effect of SiC particles added in electroless Ni-P plating solution on the properties of composite coatings[J]. Surface and Coatings Technology, 2008, 202(12): 2807-2812.

[3] 郑晓华, 宋仁国, 姚建华. 镍-磷-纳米氧化铝化学镀层的激光热处理及其摩擦磨损性能[J]. 中国激光, 2008, 35(4): 610-614.

ZHENG Xiao-hua, SONG Ren-guo, YAO Jian-hua. Laser heat treatment and wear resistance of electroless plating Ni-P-nano Al2O3 composite coatings[J]. Chinese Journal of Lasers, 2008, 35(4): 610-614.

[4] EBRAHIMIAN-HOSSEINABADI M, AZARI-DORCHEH K, VAGHEFI S M M. Wear behavior of electroless Ni-P-B4C composite coatings[J]. Wear, 2006, 260(1/2): 123-127.

[5] 宋影伟, 单大勇, 陈荣石, 韩恩厚. AZ91D镁合金化学复合镀Ni-P-ZrO2的工艺与性能[J]. 中国有色金属学报, 2006, 16(4): 625-630.

SONG Ying-wei, SHAN Da-yong, CHEN Rong-shi, HAN En-hou. Process and properties of electroless Ni-P-ZrO2 composite coating on AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 625-630.

[6] MOMENZADEH M, SANJABI S. The effect of TiO2 nanoparticle codeposition on microstructure and corrosion resistance of electroless Ni-P coating[J]. Materials and Corrosion, 2012, 63(7): 614-619.

[7] GER M D, HWANG B J. Effect of surfactants on codeposition of PTFE particles with electroless Ni-P coating[J]. Materials Chemistry and Physics, 2002, 76(1): 38-45.

[8] MENG Zhen-qiang, LI Xi-bin, XIONG Yong-jun, ZHAN Jing. Preparation and tribological performances of Ni-P-multi-walled carbon nanotubes composite coatings[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2719-2725.

[9] 金亚旭, 华 林. 镍-磷-钛酸钾晶须化学复合镀层的制备及性能[J]. 中国有色金属学报, 2007, 17(8): 1280-1285.

JIN Ya-xu, HUA Lin. Preparation and properties of electroless composite plating of nickel-phosphorus-potassium titanate whisker[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1280-1285.

[10] 刘蕴锋, 朱永伟, 刘婷婷, 张尚文, 彭 雁. Ni-P-纳米金刚石黑粉化学复合镀层的摩擦磨损性能[J]. 摩擦学学报, 2013, 33(3): 267-274.

LIU Yun-feng, ZHU Yong-wei, LIU Ting-ting, ZHANG Shang-wen, PENG Yan. Friction and wear properties of Ni-P electroless composite coatings with core-shell nanodiamond[J]. Tribology, 2013, 33(3): 267-274.

[11] 许乔瑜, 何伟娇. 化学镀镍-磷基纳米复合镀层的研究进展[J]. 电镀与涂饰, 2010, 29(10): 23-26.

XU Qiao-yu, HE Wei-jiao. Research progress of Ni-P based nanoparticle composite coatings by electroless plating[J]. Electroplating and Finishing, 2010, 29(10): 23-26.

[12] de HAZAN Y, WERNER D, Z'GRAGGEN M, GROTEKLAES M, GRAULE T. Homogeneous Ni-P/Al2O3 nanocomposite coatings from stable dispersions in electroless nickel baths[J]. Journal of Colloid and Interface Science, 2008, 328(1): 103-109.

[13] BALARAJU J N, KALAVATI, RAJAM K S. Influence of particle size on the microstructure, hardness and corrosion resistance of electroless Ni-P-Al2O3 composite coatings[J]. Surface and Coatings Technology, 2006, 200(12/13): 3933-3941.

[14] 姚素薇, 穆高林, 张卫国. 化学镀Ni-P/纳米Al2O3复合镀层结构及性能研究[J]. 材料保护, 2007, 40(10): 26-28.

YAO Su-wei, MU Gao-lin, ZHANG Wei-guo. Properties of electroless Ni-P/nano-Al2O3 composite coatings[J]. Journal of Materials Protection, 2007, 40(10): 26-28.

[15] 王 芳, 俞宏英, 孙冬柏, 王旭东, 孟惠民, 杨德钧. Ni-P-纳米Al2O3复合镀层耐磨性能研究[J]. 电镀与涂饰, 2007, 26(3): 1-4.

WANG Fang, YU Hong-ying, SUN Dong-bo, WANG Xu-dong, MENG Hui-ming, YANG De-jun. Study on the wear resistance performance of Ni-P-nano-Al2O3 composite coatings[J]. Electroplating and Finishing, 2007, 26(3): 1-4.

[16] 于赫薇, 李谋成. 纳米颗粒添加量对Ni-P-Al2O3化学复合镀层的耐腐蚀性影响[J]. 腐蚀与防护, 2013, 34(3): 223-227.

YU He-wei, LI Mou-cheng. Influence of addition of nano-particles on corrosion resistance of Ni-P-Al2O3 composite coatings[J]. Corrosion and Protection, 2013, 34(3): 223-227.

[17] SHARMA A, SINGH A K. Electroless Ni-P and Ni-P-Al2O3 nanocomposite coatings and their corrosion and wear resistance[J]. Journal of Materials Engineering and Performance, 2013, 22(1): 176-183.

[18] 吴玉程, 邓宗钢. 非晶态镍磷合金的组织结构与性能[J]. 中国有色金属学报, 1998, 8(3): 415-419.

WU Yu-cheng, DENG Zong-gang. Microstructure and properties of amorphous Ni-P alloys[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(3): 415-419.

[19] 高加强, 刘 磊, 沈 彬, 朱建华, 胡文彬, 丁文江. 纳米氧化铝粒子对化学镀镍-磷合金晶化行为的影响[J]. 中国有色金属学报, 2004, 14(1): 64-68.

GAO Jia-qiang, LIU Lei, SHEN Bin, ZHU Jian-hua, HU Wen-bin, DING Wen-jiang. Crystallization behavior of Al2O3 nano-composite coatings prepared by electroless plating[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 64-68.

[20] 李铁藩. 金属高温氧化和热腐蚀[M]. 北京: 化学工业出版社, 2003: 139-152.

LI Tie-fan. Metals high-temperature oxidation and hot corrosion[M]. Beijing: Chemical Industry Press, 2003: 139-152.

[21] 袁庆龙, 凌文丹, 李 平. Ni/ZrO2纳米复合刷镀层的抗高温氧化性[J]. 功能材料, 2012, 43(21): 2930-2933.

YUAN Qing-long, LING Wen-dan, LI Ping. High temperature oxidation resistance of nickel-base nano-ZrO2 composite coating prepared with electro-brush plating[J]. Journal of Functional Materials, 2012, 43(21): 2930-2933.

[22] 宫玉梅. 化学复合镀 Ni-P/Al2O3制备工艺及耐蚀性能的研究[D]. 哈尔滨: 哈尔滨工业大学, 2009: 40-41.

GONG Yu-mei. Preparation and corrosion properties of electroless composite Ni-P-Al2O3 alloy[D]. Harbin: Harbin Institute of Technology, 2009: 40-41.

[23] ALIREZAEI S, MONIRVAGHEFI S M, SALEHI M, SAATCHI A. Wear behavior of Ni-P and Ni-P-Al2O3 electroless coatings[J]. Wear, 2007, 262(7/8): 978-985.

[24] JIANG Xu, LIU Wen-jin, DONG Shi-yun, XU Bin-shi. High temperature tribology behaviors of brush plated Ni-W-Co/SiC composite coating[J]. Surface and Coatings Technology, 2005, 194(1): 10-15.

[25] ZHOU Guang-hong, DING Hong-yan, ZHOU Fei, ZHANG Yue. Structure and mechanical properties of Ni-P-nanoAl2O3 composite coatings synthesized by electroless plating[J]. Journal of Iron and Steel Research International, 2008, 15(1): 65-69.

[26] 吴玉程, 王文芳, 叶 敏, 宋光明. 氧化铝增强化学镀镍基合金涂层的性能[J]. 中国有色金属学报, 2000, 10(S1): s64-s68.

WU Yu-cheng, WANG Wen-fang, YE Min, SONG Guang-min. Effect of alumina reinforcement on properties of electroless deposited nickel-matrix coating[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): s64-s68.

[27] LEON O A, STAIA M H, HINTERMANN H E. High temperature wear of an electroless Ni-P-BN(h) composite coating[J]. Surface and Coatings Technology, 2003, 163: 578-584.

(编辑 李艳红)

基金项目:浙江省自然科学基金资助项目(Y4110645)

收稿日期:2013-12-16;修订日期:2014-03-26

通信作者:郑晓华,副教授,博士;电话:0571-88320479;E-mail:zhengxh@zjut.edu.cn