文章编号:1004-0609(2017)-02-0234-09

重固溶-不同温度T8再时效2195铝锂合金的力学性能与显微组织演化

马云龙1,李劲风2,刘观日1,刘丹阳2,叶志豪2,汪洁霞2,郑子樵2

(1. 北京宇航系统工程研究所,北京 100076;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:以5.2 mm厚度2195-T8铝锂合金为对象,进行重固溶、4.5%预变形后不同温度(145C~160 ℃)的T8再时效处理,研究其力学性能与晶内显微组织演化。结果表明:重固溶处理后的晶粒形态与原始2195-T8态晶粒形态一样,仍然保持为拉长的带状晶粒组织。重固溶并经4.5%预变形后,再采用适当的温度和时间进行T8时效处理,2195铝锂合金可以回复到原始T8态的显微组织和力学性能,即2195铝锂合金采用重固溶-T8再时效处理不会明显损害其力学性能。2195铝锂合金的晶内时效析出相包括T1相(Al2CuLi)、δ′相(Al3Li)、θ′相(Al2Cu)及θ″相(Al2Cu),其中优先析出相为T1相;较低温度及较短时间时效可形成较多δ′相和θ″相;随着时效时间延长,T1相生长,θ″相转化为θ′相并减少,δ′相消失;时效温度提高可促进该转变过程,加快铝锂合金的时效响应速度。

关键词:铝锂合金;重固溶;再时效;显微组织;力学性能

中图分类号:TG146.2 文献标志码:A

铝锂合金是航空航天最理想的结构材料,其发展大致可分为3个阶段,相应出现的铝锂合金产品也划分为三代[1-4]。20世纪90年代以来开发的第三代铝锂合金具有密度小、模量高、良好的强度-韧性平衡、优良的耐损伤性能、各向异性小、热稳定性好、耐腐蚀、加工成形性好等优点[4-6],其中尤以低各向异性铝锂合金和高强可焊铝锂合金最引人注目。由于综合性能提高,第三代铝锂合金在航空及航天工业上已经获得广泛应用。

第三代铝锂合金在航天工业中最成功、最具有里程碑意义的应用是2195铝锂合金(美国)及1460铝锂合金(前苏联)在航天飞机外挂燃料贮箱和运载火箭上的应用。美国于1997年采用2l95铝锂合金代替22l9铝合金,制造了直径8.4 m、长47 m的航天飞机超轻外挂燃料外贮箱(Super Lightweight Tank, SLWT),用于盛装低温燃料;在随后的20多年时间内,SLWT连续发射了43次直至航天飞机退役。按照NASA原计划,航天飞机退役后的航天工程“星座计划”中,战神(Ares)系列火箭(战神-Ⅰ、Ⅳ、Ⅴ)将成为执行美国空间探索的新型运输基础设施的重要单元。原设计战神-Ⅰ火箭上面级和芯级的液氢、液氧贮箱将全部采用2195铝锂合金制造[7-8]。

我国已经可以成熟进行2195铝锂合金的工业化生产,但一直没有进行应用。2195铝锂合金是一种时效强化型铝合金,主要通过固溶淬火处理、人工时效后析出的析出第二相进行强化。铝合金的时效析出与固溶是可逆过程,即铝合金中已经时效析出的第二相在高温时可以重新发生固溶,在随后的时效过程中又可再次析出。因此,对于时效强化型铝合金而言,如果由于时效处理制度不当而导致性能差异,应该可以采用这一可逆热处理(即重固溶、再时效)工艺进行性能的调整;或者由于加工过程的需要,已经时效硬化的铝合金需要先软化加工,之后再进行时效强化处理。

目前已有部分7XXX系铝合金重固溶再时效研究报道[9-12]。但这一重固溶再时效过程是否导致2195铝锂合金的性能损害,或2195铝锂合金能否进行重固 溶-再时效处理,目前尚无文献报道。基于此,本文作者进行了2195-T8铝锂合金重固溶后,采用4.5%的预拉伸变形,之后再于不同温度(145~160 ℃)进行T8再时效处理,研究了其显微组织及力学性能。

1 实验

研究材料为2195-T8铝锂合金板材成品(已进行T8热处理,即505~510 ℃固溶处理、约4.5%预变形之后再于150 ℃时效),其厚度为5.2 mm,合金成分经分析如表1所列。板材于508 ℃重新固溶处理50 min、冷水淬火后,再次经4.5%的预变形后,分别于145、152及160 ℃进行时效处理。时效前预变形为拉伸预变形,通过拉伸试验机,采用引伸计进行预变形量的控制。

表1 2195铝锂合金化学成分

Table 1 Chemical composition of 2195 Al-Li alloy (mass fraction, %)

重固溶-T8再时效2195铝锂合金的室温拉伸性能采用MTS 810材料试验机进行测试,拉伸速度为2 mm/min。拉伸测试样品平行段宽度12.5 mm,平行段长度为 50 mm。

分别进行原始T8态及重固溶-T8再时效处理后板材的金相组织观察。样品经打磨、抛光及阳极覆膜处理后,再采用Leica DMILM 金相显微镜进行观察。

原始T8态及重固溶-T8再时效处理后显微组织观察采用透射电镜(TEM)进行观察。TEM试样首先机械减薄至0.08 mm左右,而后采用双喷电解减薄仪制取。电解溶液为25%硝酸+75%甲醇(体积分数)混合溶液,采用液氮冷却至-20 ℃以下,工作电压为15~20 V,电流控制在80~95 mA。而后在Tecnai G220型TEM上进行观察,加速电压为200 kV。

2 实验结果

2.1 时效力学性能

图1所示为2195铝锂合金重固溶后不同温度再T8时效(4.5%预变形)的时效拉伸性能曲线。为评价其重固溶再时效行为,图1中同时绘出了原始2195-T8铝锂合金板材实测性能及ASM标准的最低性能。由图1可知,不同温度进行T8时效时,合金的时效响应速度明显不同;145 ℃时,时效响应速度最慢,约时效40 h左右,强度达到原始2195-T8铝锂合金实测性能;160 ℃时,时效响应速度最快,约时效20 h时,其测试强度即可达到原始2195-T8铝锂合金实测性能。152 ℃时,时效22 h时后其强度达到原始2195-T8铝锂合金实测性能。

另外,比较2195铝锂合金ASM标准,可以发现重固溶-T8再时效后2195铝锂合金的强度、伸长率均满足ASM标准的性能最低值。上述结果说明2195铝锂合金重固溶-T8再时效后的力学性能完全可以回复到原始T8态力学性能,即重固溶-T8再时效处理没有明显损害2195铝锂合金力学性能。

图1 2195铝锂合金重固溶-不同温度T8再时效(4.5%预变形)的时效拉伸性能曲线

Fig. 1 Tensile properties of 2195 Al-Li alloy as function of T8 re-aging time at different temperatures

2.2 显微组织

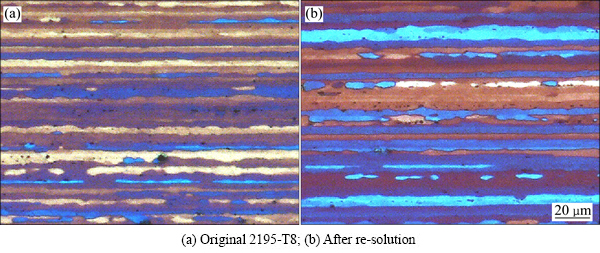

图2所示分别为原始2195-T8铝锂合金及重固溶处理后纵截面的金相照片,二者纵截面均表现为明显拉长的带状晶粒组织,且重固溶处理后晶粒长大程度很小。由于2195铝锂合金时效温度(152 ℃)远低于其固溶温度(505~510 ℃),时效处理时不会对晶粒组织(包括晶粒尺寸、形态、织构等)产生影响。因此,上述金相观察表明重固溶处理基本没有改变原始2195-T8铝锂合金晶粒组织。

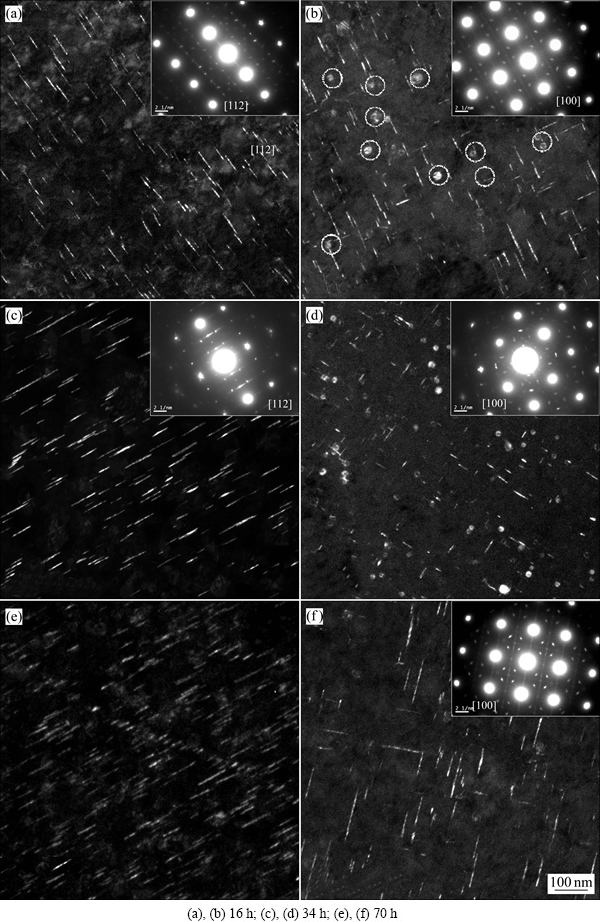

Al-Cu-Li系合金中时效析出的强化相比较多,可能的析出强化相包括T1相(Al2CuLi)、θ′相(Al2Cu)、δ′相(Al3Li)。为方便通过衍射斑点确认第二相,图3直接给出文献中铝锂合金<100>及<112>入射方向的衍射斑图谱中第二相的对应斑点[13-14]。值得注意的是合金中θ′相形成过程中可能会先形成亚稳过渡相θ″相(或GPII区),再转化成亚稳相θ′相。在衍射花样中θ″相表现为连续茫线(见图3(c)),与θ′相显示的不连续斑点不同(见图3(d))。

图2 2195铝锂合金纵截面金相照片

Fig. 2 Metallographic images of 2195 Al-Li alloy

图3 铝锂合金衍射斑点示意图

Fig. 3 Diffraction patterns of Al-Cu-Li alloy

图4所示为145 ℃进行T8再时效不同时间的衍射斑点及相应TEM暗场像。时效16 h时,<112>入射方向的存在非常明显的T1相斑点,相应的暗场相中也发现较多的T1相(见图4(a))。而<100>入射方向的衍射斑点中则可以发现比较明显的θ″相(Al2Cu)连续茫线和θ′相斑点,相应的暗场相中也发现较多垂直分布的θ″相和θ′相(见图4(b))。同时,<100>入射方向的衍射斑点中也可发现微弱的δ′相斑点,暗场像中则观察到δ′相(见图4(b)中白色虚线圆圈球状相)。当时效时间延长至34 h,在该温度(145 ℃)仍然处于欠时效阶段(见图1),其T1相尺寸略有增加(见图4(c)),同样存在比较多垂直分布的θ″相和θ′相(尺寸较小),但θ″相明显含量降低;而且仍然可以发现δ′相,但其尺寸缩小(见图4(d))。当时效时间进一步延长至70 h(对应于峰时效),T1相数量增加(见图4(e)),另一个明显不同的是δ′相基本消失(见图4(f));另外,θ″相的连续茫线转变为不连续分布的斑点,表明此时形成θ′相(而不是θ″相),相应暗场像也可观察到比较粗大而且垂直分布的θ′相(见图4(f))。

图4 145 ℃时效不同时间的衍射斑及TEM暗场像

Fig. 4 Dark field TEM images of 2195 Al-Li alloy after re-solution followed by T8 re-aging at 145 ℃ for different time ((a), (c), (e) T1 precipitate, b=<112>; (b), (d), (f) θ″ (or θ′) precipitate, b=<100>)

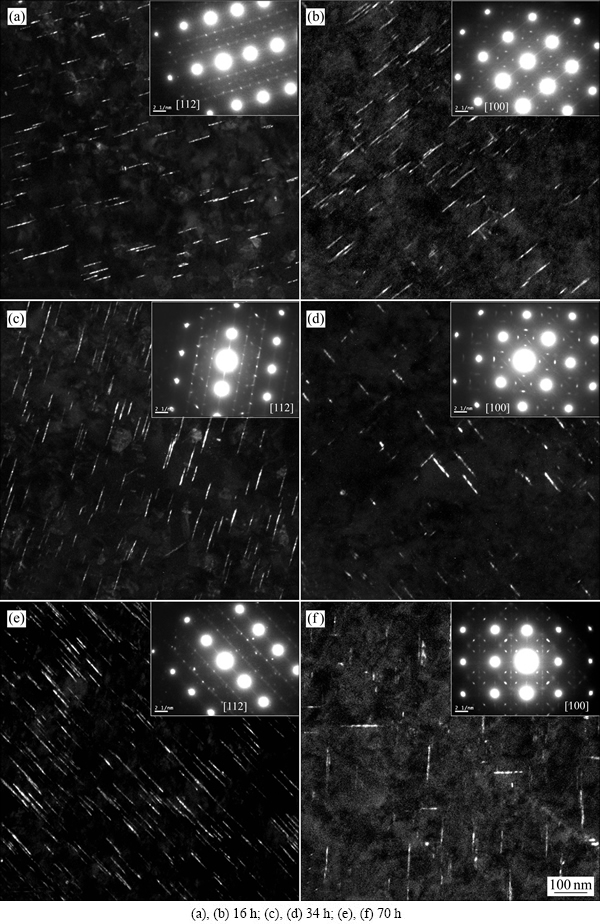

图5所示为152 ℃进行T8再时效不同时间时的衍射斑点图及相应TEM暗场像。时效16 h时,析出较多的T1相(见图5(a)),同时<100>入射方向衍射斑表明有θ″相和θ′相形成,暗场像则观察到较多互相垂直θ″相和θ′相,同时没有出现δ′相(见图5(b))。当时效时间延长至34 h时,T1相尺寸及分数增加(见图5(c));而根据<100>入射方向衍射斑点分析,{100}面析出相以θ′相为主,θ″相基本消失(见图5(d))。当时效时间进一步延长至70 h,T1相尺寸及分数进一步增加(见图5(e));θ″相完全消失,θ′相尺寸有所长大但数量减少(衍射花样表现为不连续斑点)(见图5(f))。

图5 152 ℃时效不同时间的衍射斑及TEM暗场像

Fig. 5 Dark field TEM images of 2195 Al-Li alloy after re-solution followed by T8 re-aging at 152℃ for different time ((a), (c), (e) T1 precipitate, b=<112>; (b), (d), (f) θ′(or θ″) precipitate, b=<100>)

图6所示为160 ℃进行T8再时效不同时间时的衍射斑及相应TEM暗场像。15 h时效时,析出较多的T1相(见图6(a)),同时形成较多的θ″相和θ′相,且没有观察到δ′相存在(见图6(b));当时效时间延长至34 h,主要析出相为T1相及θ′相,θ″相消失(见图6(c),(d))。时效时间进一步延长至60 h,T1相粗化(见图6(e));而θ′相部分粗化,部分尺寸减小,但总的分数减少(见图6(f))。

图6 160 ℃时效不同时间的衍射斑及TEM暗场像

Fig. 6 Dark field TEM images of 2195 Al-Li alloy after re-solution followed by T8 re-aging at 160 ℃ for different time ((a), (c), (e) T1 precipitate, b=<112>; (b), (d), (f) θ′ (or θ″) precipitate, b=<100>)

图7所示为原始2195-T8铝锂合金衍射斑及TEM暗场像,合金主要第二相为T1相(见图7(a))及θ′相(衍射花样表明应该为θ′相)。根据T1相密度、θ′相衍射斑点及其分布与尺寸综合分析,可以发现原始2195-T8铝锂合金中时效析出相与152 ℃进行T8(4.5%预变形)再时效34 h(见图6(c), (d))的合金一致。即2195-T8铝锂合金重固溶处理后,采用合理的预变形、时效温度和时效时间组合进行T8再时效后,可以回复到原始T8态的显微组织,进而获得与原始T8态一致的力学性能。

图7 原始2195-T8铝锂合金衍射斑及TEM暗场像

Fig. 7 Dark field TEM images of original 2195-T8 Al-Li alloy

3 分析与讨论

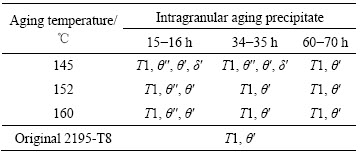

综上所述,2195-T8铝锂合金经重固溶-T8再时效处理后,可能的晶内时效析出相包括T1相、θ′相、θ″相及δ′相,不同温度及时间时效后析出组成归纳如表2所列。较低温度(145 ℃)或较短时间时效时,在优先析出T1相的同时,一个重要的特征是有θ″相、θ′相及δ′相析出;提高温度或延长时效时间,T1相生长的同时消耗δ′相,δ′相消失,θ″相演变为θ′相并逐渐减少。而且,在相同温度时效至峰时效阶段后,合金析出相以T1相和θ′相为主;随时效时间进一步延长,T1相生长,部分θ′相粗化,但θ′相总分数降低。

对于Cu含量为2%~5%(质量分数) 的Al-Cu-Li系合金,时效析出顺序的过程大致如下[15]:α过饱和固溶体→GP区+δ′相→T1相+δ′相+(θ′相)→T1相。有文献认为θ″相也是GP区,并定义为GPII区[13]。表2所列的时效析出相组成可以反应这一规律。低温(145 ℃)时效时,由于原子扩散速度更小,析出速率更低,因此16 h及34 h时效时可以观察到δ′相。较高温度(152 ℃、160 ℃)时效时,原子扩散速度增加,析出速率加快,δ′相在更短的时效时间内即已析出,并转化为T1相而消失,因此152~160℃,16 h时效时较难观察到δ′相。

表2 重固溶- T8再时效(4.5%预变形)2195铝锂合金晶内时效析出相组成

Table 2 Intragranular aging precipitates of 2195- Al-Li alloy after re-solution and T8 re-aging with 4.5% pre-deformation

另外,根据TEM观察,2195铝锂合金进行T8态时效处理时,T1相为优先析出相,其时效析出速度明显快于δ′相和θ′相的,这与合金成分及时效前预变形有关。2195铝锂合金同时添加微合金元素Mg和Ag,Mg-Ag之间的具有很强的相互作用,淬火后及时效初期,可形成大量Ag-Mg原子团簇,促使Li和Cu原子不断向Ag-Mg原子团簇扩散,从而促进T1相析出[16-17]。时效前进行预变形,在基体中引入位错,对盘状T1相和θ′相的形核析出均具有促进作用。但在Al-Cu-Li系合金中,存在T1相和θ′相竞争析出关系,位错对T1相形核具有更大的促进作用[18-19],相应地对θ′相形核的促进作用减弱。上述两个因素导致T8态时效处理时2195铝锂合金中T1相优先析出。

根据上述显微组织分析,在T1相生长的同时,δ′相逐渐减少直至完全消失,而θ′相虽然存在且有部分θ′相粗化,但其总分数降低。由于T1相组成元素包括Al、Cu、Li元素,其生长过程必须有Cu、Li元素不断提供。当合金中Cu、Li元素以第二相θ′相及δ′相形式析出后,T1相继续生长则消耗θ′相及δ′相的Cu、Li元素[20],从而导致δ′相消失,θ′相总分数降低。

可时效强化铝合金的力学性能主要由两部分决定,一方面是其晶粒组织形态,另一方面是时效强化相的类型与分布。由于原始固溶处理时形变储能释放,重固溶处理时不会发生新的再结晶晶粒形核过程;而且2195铝锂合金中微合金元素Zr形成弥散Al3Zr粒子,具有钉扎晶界、阻碍晶界迁移的作用[21],因而在50 min重固溶时间内晶粒难以长大,导致重固溶处理后仍然保持为原始2195-T8铝锂合金的拉长带状晶粒组织。这种晶粒组织形态特征不变是重固溶-T8再时效后2195铝锂合金力学性能不降低的基础。另外,在晶粒形态特征不变的基础上,经适当预变形及时效温度和时效时间组合的T8再时效,可以控制合金中时效析出相的类型、分布与尺寸(如152 ℃,34 h)与原始T8态一致,从而回复到原始2195-T8铝锂合金的力学性能。

4 结论

1) 重固溶处理后的晶粒形态与原始2195-T8态晶粒形态一样,仍然保持为拉长的带状晶粒组织。

2) 2195铝锂合金时效阶段中的晶内时效析出相包括T1相、δ′相、θ′相和θ″相,其中T1相为优先析出相。较短时间时效,可形成较多δ′相和θ″相;时效时间延长,θ″相转化为θ′相,T1相生长并消耗δ′相和θ′相。

3) 提高时效温度,可促进上述转变过程,加快铝锂合金的时效响应速度。

4) 重固溶处理后,经4.5%预变形,再采用适当时效温度和时效时间组合的T8再时效,可回复到原始T8态的显微组织,进而获得与原始T8态基本一致的力学性能,即2195-T8铝锂合金可以采用重固溶-T8再时效工艺进行处理。

REFERENCES

[1] STARKER E A Jr. Aerospace materials for future technologies[J]. Journal of the Japan Institute of Light Metals, 2001, 51: 77-85.

[2] WARNER. Recently-developed aluminium solutions for aerospace applications[J]. Materials Science Forum, 2006, 519/521: 1271-1278.

[3] FRIDLYANDER I J. Aluminum alloys in aircraft in the periods of 1970-2000 and 2001-2015[J]. Metal Science and Heat Treatment, 2001, 43(1/2): 6-10.

[4] 郑子樵, 李劲风, 陈志国, 李红英, 李世晨, 谭澄宇. 铝锂合金的合金化与微观组织演化研究[J]. 中国有色金属学报, 2011, 21(10): 2337-2349.

ZHENG Zi-qiao, LI Jin-feng, CHEN Zhi-guo, LI Hong-ying, LI Shi-chen, TAN Cheng-yu. Alloying and microstructural evolution of Al-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2337-2349.

[5] RIOJIA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical & Materials Transactions A, 2012, 43(9): 3325-3337.

[6] MORAN J P, BOVARD F S, CHRZAN J D, VANDENBURGH P. Corrosion performance of new generation Aluminum Lithium alloys for aerospace applications[C]// Proc 13th International Conference on Aluminum Alloys (ICAA13). USA: TMS, 2012: 425-430

[7] 李劲风, 郑子樵, 陈永来, 张绪虎. 铝锂合金及其在航天工业上的应用[J]. 宇航材料工艺, 2012, 42(1): 13-19.

LI Jin-feng, ZHENG Zi-qiao, CHEN Yong-lai, ZHANG Xu-hu. Al-Li alloys and their application in aerospace industry[J]. Aerospace Materials and Technology, 2012, 42(1): 13-19.

[8] PRASAD N E, GOKHALE A A, WANHILL R J H. Aluminum-lithium alloys: Processing, properties and applications[M]. London: Butterworth-Heinemann, 2014: 525-528.

[9] 尚 勇, 李建康, 张立武. 重固溶再时效处理对7175铝合金组织和性能的影响[J]. 热加工工艺, 2005(5): 35-38.

SHANG Yong, LI Jian-kang, ZHANG Li-wu. Effect of re-solution re-aging on microstructure and properties of 7175 aluminum alloy[J]. Hot Working Technology, 2005(5): 35-38.

[10] 李 海, 郑子樵, 王芝秀. 过时效-重固溶-再时效处理对7055铝合金组织与性能的影响[J]. 材料热处理学报, 2004, 25(3): 57-61.

LI Hai, ZHENG Zi-qiao, WANG Zhi-xiu. Effect of over-ageing and re-solution and re-ageing treatment on microstructures and properties of 7055 Al alloy[J]. Transactions of Materials and Heat Treatment, 2004, 25(3): 57-61.

[11] 尚 勇, 张立武. 重固溶再双级时效处理对7175铝合金力学性能和微观组织的影响[J]. 固体火箭技术, 2006, 29(3): 225-228.

SHANG Yong, ZHANG Li-wu. Effects of resolution and reaging treatment on mechanical properties and microstructure of 7175 aluminum alloy[J]. Journal of Solid Rocket Technology, 2006, 29(3): 225-228.

[12] 尚 勇, 张立武, 李建康. 重固溶再多级时效处理对7175铝合金组织和性能的影响[J]. 热加工工艺, 2005(7): 41-43.

SHANG Yong, ZHANG Li-wu, LI Jian-kang. Effects of re-solution and re-aging on microstructural and mechanical properties 7175 aluminum[J]. Hot Working Technology, 2005(7): 41-43.

[13] WANG S C, STARINK M J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys[J]. International Materials Reviews, 2005, 50(4): 193-215.

[14] WANG Z M, SHENOY R N. Microstructural characterization of aluminum-lithium alloys 1460 and 2195[R]. National Aeronautics and Space Administration, NASA/CR-1998- 206914.

[15] 陈秋妮, 郑子樵, 魏修宇, 李世晨, 王 哲. C47A 铝锂合金组织和性能的研究[J]. 稀有金属, 2008, 32(2): 129-134.

CHEN Qiu-ni, ZHENG Zi-qiao, WEI Xiu-yu, LI Shi-chen, WANG Zhe. Microstructures and properties of C47A Al-Li alloy[J]. Chinese Journal of Rare Metals, 2008, 32(2):129-134.

[16] 罗先甫, 郑子樵, 钟继发, 张海锋, 钟 警, 李世晨, 李劲风. Mg、Ag、Zn多元微合金化对新型Al Cu Li合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

LUO Xian fu, ZHENG Zi qiao, ZHONG Ji fa, ZHANG Hai feng, ZHONG Jing, LI Shi chen, LI Jin feng. Effects of Mg, Ag and Zn multi-alloying on aging behavior of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1883-1842.

[17] 王瑞琴, 郑子樵, 陈圆圆, 李世晨, 魏修宇. Ag, Mg合金化对Al-Cu-Li合金时效特性和显微组织的影响[J]. 稀有金属材料与工程, 2009, 38(4): 622-626.

WANG Rui-qin, ZHENG Zi-qiao, CHEN Yuan-yuan, LI Shi-chen, WEI Xiu-yu. Effects of Ag, Mg micro-alloying on aging characteristics and microstructure of Al-Cu-Li alloy[J]. Rare Metal Materials and Engineering, 2009, 38(4): 622-626.

[18] 魏修宇, 郑子樵, 潘峥嵘, 陈圆圆, 李世晨, 陈秋妮. 预变形对2197铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

WEI Xiu-yu, ZHENG Zi-qiao, PAN Zheng-rong, CHEN Yuan-yuan, LI Shi-chen, CHEN Qiu-ni. The role of plastic deformation on microstructure and mechanical properties of 2197 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1996-1999.

[19] GABLE B M, ZHU A W, CSONTOS A A, STARKER E A Jr. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al-Li-Cu-X alloy[J]. Journal of Light Metals, 2004(1): 1-14.

[20] HUANG B P, ZHENG Z Q. Precipitation kinetics of an Al-4.01Cu-1.11Li-0.39Mg-0.19Zr-0.11Ti alloy[J]. Scripta Materialia, 1998, 38(4): 611-616.

[21] TSIVOULAS D, PRANGNELL P B. The effect of Mn and Zr dispersoid-forming additions on recrystallization resistance in Al-Cu-Li AA2198 sheet[J]. Acta Materialia, 2014, 77: 1-16.

Microstructural evolution and mechanical properties of 2195 Al-Li alloy during T8 re-aging at various temperatures following re-solution

MA Yun-long1, LI Jin-feng2, LIU Guan-ri1, LIU Dan-yang2, YE Zhi-hao2, WANG Jie-xia2, ZHENG Zi-qiao2

(1. Beijing Institute of Aerospace Systems Engineering, Beijing 100076, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Based on 2195-T8 Al-Li alloy with 5.2 mm thickness, the mechanical properties and intragranular microstructural evolution during T8 (4.5% pre-deformation) re-aging at 145-160 ℃ after re-solution were investigated. The results show that the grain after re-solution still maintains as elongated pancake-like appearance, which is the same as that of original 2195-T8. The micro-structures and mechanical properties can recover to those of the original 2195-T8 Al-Li alloy through using appropriate T8 re-aging temperature and time. Re-solution and T8 re-aging treatment do not obviously damage 2195 Al-Li alloy mechanical property. The intragranular precipitates include T1(Al2CuLi), δ′(Al3Li), θ′(Al2Cu) and θ″(Al2Cu), among which the preferential precipitates are T1 phases. Re-aging at lower temperature or for shorter time, much more δ′ and θ″ precipitates are formed. With time extension, T1 precipitates grow, but θ″ precipitates are transformed to θ′ precipitates, and δ′ precipitates disappear. As re-aging temperature is elevated, the transformation process is accelerated, and the aging response is promoted.

Key words: Al-Li alloy; re-solution; re-aging; microstructure; mechanical property

Foundation item: Project(2013AA032401) supported by the National High Research Development Program of China

Received date: 2016-03-28; Accepted date: 2016-08-31

Corresponding author: MA Yun-long; Tel: +86-10-68382013; E-mail: i56567@sina.com

(编辑 王 超)

基金项目:国家高技术研究发展计划资助项目(2013AA032401)

收稿日期:2016-03-28;修订日期:2016-08-31

通信作者:马云龙,高级工程师;电话:010-68382013;E-mail: i56567@sina.com