鼓泡油膜萃取法处理氰化提金废水的新工艺

来源期刊:中国有色金属学报2020年第4期

论文作者:刘杰 吴晓红 黄焜 徐忠敏 郁丰善 刘会洲

文章页码:875 - 887

关键词:金;溶剂萃取;鼓泡;有机液膜;氰化提金废水

Key words:gold; solvent extraction; bubble; organic liquid membrane; auro-cyanide wastewater

摘 要:介绍一种鼓泡油膜萃取法处理氰化提金废水的新方法。结果表明:鼓泡油膜萃取法不仅可回收废水中高浓度的铜,还可经济回收极低浓度的金。废水中铜的脱除率达99%,金的萃取率达99%,氰根脱除率达91.9%。萃余液可返回选矿工艺重复利用,实现含氰废水的零排放。负载有机相经酸性硫脲反萃后可循环使用。采用锌粉置换法回收硫脲反萃余液中的金和铜。锌粉置换渣采用稀酸溶解法可实现金和铜的分离。金的总回收率达98.06%,铜的总回收率达94.74%。锌粉置换后液可制备硫化锌产品,锌回收率达96%。该工艺成本低,绿色环保,具有潜在的应用推广前景。

Abstract: A new process based on gas bubble supported organic liquid membrane extraction technology was suggested to treat the auro-cyanide wastewaters. The results show that, not only the high-concentration copper(Ⅰ) in the auro-cyanide wastewaters can be recovered satisfactorily, but the very low concentration gold(Ⅰ) can also be extracted efficiently by the suggested gas bubble supported organic liquid membrane extraction technology. The percent recovery of copper(Ⅰ), gold(Ⅰ) and cyanide can reach 99%, 99%, and 91.9%, respectively. The raffinates after bubbling extraction can be returned back to the mineral separation process for reusing and recycling in the factories, so that almost zero discharge of the cyanide wastewaters comes true. The Cu(Ⅰ) and Au(Ⅰ) in the loaded organic phase can be stripped by acidic thiourea, and then the regenerated organic phase can be returned back for reusing. Zinc powder is used to recover gold(?) and copper(?) in the thiourea solutions. Then, gold and copper can be separated by two-steps of dissolving the zinc powder replacement residues with dilute acid. The total percent recovery of gold(Ⅰ) and copper(Ⅰ) can reach 98.06% and 94.74%, respectively. The raffinates after the zinc powder replacement process can be used to produce zinc sulfide products. The total recovery of zinc reaches 96%. The suggested new process based on gas bubble supported organic liquid membrane extraction technology is economical and with a low processing cost. It is also environmental friendly, and might find potential industrial application in the future.

DOI: 10.11817/j.ysxb.1004.0609.2020-35735

刘 杰1, 2,吴晓红1,黄 焜1, 3,徐忠敏4,郁丰善5,刘会洲1

(1. 中国科学院 青岛生物能源与过程研究所,中国科学院生物基材料重点实验室,青岛 266100;

2. 青岛理工大学 环境与市政工程学院,青岛 266520;

3. 北京科技大学 冶金与生态工程学院,北京 100083;

4. 招金矿业股份有限公司 金翅岭金矿,招远 265400;

5. 江西省汉氏贵金属公司,上饶 334000)

摘 要:介绍一种鼓泡油膜萃取法处理氰化提金废水的新方法。结果表明:鼓泡油膜萃取法不仅可回收废水中高浓度的铜,还可经济回收极低浓度的金。废水中铜的脱除率达99%,金的萃取率达99%,氰根脱除率达91.9%。萃余液可返回选矿工艺重复利用,实现含氰废水的零排放。负载有机相经酸性硫脲反萃后可循环使用。采用锌粉置换法回收硫脲反萃余液中的金和铜。锌粉置换渣采用稀酸溶解法可实现金和铜的分离。金的总回收率达98.06%,铜的总回收率达94.74%。锌粉置换后液可制备硫化锌产品,锌回收率达96%。该工艺成本低,绿色环保,具有潜在的应用推广前景。

关键词:金;溶剂萃取;鼓泡;有机液膜;氰化提金废水

文章编号:1004-0609(2020)-04-0875-12 中图分类号:TF831 文献标志码:A

黄金冶炼过程产生大量氰化提金废水[1-2]。除含微量金外,还含有较高浓度的铜、锌、铁等有价金属离子[3]。以山东某厂选矿废水为例,金含量仅0.5~2 mg/L。但是,铜含量高达 2.4 g/L[4]。为了满足环保要求,大部分黄金冶炼企业都尽量将产生的提金氰化废水在厂区内循环使用,以实现污水零排放[5]。但是,氰化废水回用过程会造成铜、锌、铁等离子在回用水中大量累积,严重影响后续工艺指标,因此,往往不得不定期外排[6]。如果此类废水不加以处理直接外排,不仅会对环境造成严重污染,还会造成金、铜等有价资源大量流失[7-8]。从经济性和资源环保性综合考虑,研究开发一种既能从氰化提金废水中回收高浓度的铜,同时也能经济回收微量金的新工艺势在必行。

目前,国内外已报道的氰化提金废水处理工艺主要有破坏法和回收法两大类。其中,回收法又分为沉淀法[9-10]、离子交换法[11-12]、活性炭吸附法[13-14]、膜分离法[15-16]、溶剂萃取法[17-21]等。沉淀法可高效去除铜、铁等重金属离子。但是,废水中的微量金也随之进入沉淀渣,难以经济分离和回收。此外,沉淀过程消耗大量化学试剂,沉淀渣堆放很容易造成二次污染。膜法、离子交换法与活性炭吸附法等虽然可脱除提金废水中的重金属离子,但从含大量铜、锌、铁等金属离子的废水中分离、回收极低浓度金十分困难。已报道的工艺大多效率低、饱和容量小、吸附速率慢、成本高,无法满足高效、经济处理冶炼厂内大量滞留提金废水的需求。溶剂萃取法可以从含金氰化液中选择性地提取和分离回收金。但是,传统的溶剂萃取技术和设备无法用于从含大量铜、锌、铁等金属离子的废水中分离、回收极低浓度金。通常地,采用传统溶剂萃取装置处理极低浓度稀溶液须在较大的水油相比条件下操作,极小体积的有机萃取剂很难实现在极大体积的水相中均匀分散[22-24]。连续萃取过程不仅工艺经济性极差,而且有机萃取剂分散损失严重,极易夹带进入萃余水相对回用水造成二次油污染。

我们前期工作曾提出一种气泡支撑有液膜萃取新方法[4, 25-28]。利用有机萃取剂的表面活性,将极小体积的有机萃取剂分散包覆在气泡表面,形成一层有机萃取剂油膜。利用气泡表面包覆的有机萃取剂薄膜萃取富集极大体积水相中的极低浓度目标金属离子。萃取过程水油相比可高达600以上,可实现极低浓度目标金属离子的高效、经济富集提取。因萃取过程引入气浮,萃余水相中的有机萃取剂夹带损失极低。新技术和配套新装置的提出,突破了传统萃取法无法经济分离提取极低浓度金属离子的局限。更重要的是,如果将该方法用于处理氰化提金废水,不仅可实现废水中极低浓度的金与高浓度铜、锌等有效分离,还可进一步萃取回收废水中的铜、锌等有价金属资源,充分发挥萃取法在处理多金属复杂溶液方面的竞争优势。

本文以山东某黄金冶炼厂提供的氰化提金废水为研究对象,详细考察了鼓泡油膜萃取新方法处理氰化提金废水,分离回收高浓度铜离子、并提取极低浓度金的可行性。在此基础上,提出了一种综合回收废水中各种有价金属资源的新工艺,以实现废水资源化高效利用的目的。

1 实验

1.1 试剂与材料

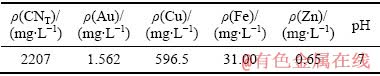

实验所用水相料液取自山东某黄金冶炼厂含金氰化废水,主要成份见表1。有机相为0.25 mol/L 的N263 (甲基三辛基氯化铵)煤油溶液。N263为工业级试剂,购自厦门先端科技有限公司。煤油(8008-20-6)购自中国石化总公司济南煤油厂。硫脲、盐酸和氢氧化钠均为分析纯,购自国药集团化学试剂有限公司。

表1 氰化提金废水的化学成分分析

Table 1 Analysis on chemical components in auro-cyanide wastewater

1.2 仪器与设备

萃取试验采用自制的柱式鼓泡油膜萃取装置[26]。水油两相输送采用恒流计量泵(BT1-100L-LCD,上海琪特分析仪器有限公司生产)。鼓气采用市售空压机(GA-81,上海硅莱实业有限公司生产),用玻璃转子流量计 (LZB-3WB,常州爱德克斯仪器仪表有限公司生产)控制气体流速。

1.3 实验方法

1.3.1 鼓泡油膜萃取

1) 萃取柱内水相不动、油相一次过柱开路萃取:首先,封住萃取柱下端出水口,从萃取柱上端进水口泵入废水料液,待料液充满整个萃取柱后停泵。水相料液在萃取柱内不流动,总体积为 650 mL。然后,从萃取柱底部进气口连续泵入空气气泡,泵气气速为150 mL/min。待气泡稳定生成后,从萃取柱下端进油口连续泵入含有有机萃取剂的油相,泵油速度为60 mL/min。有机萃取剂铺展包覆在气泡表面,形成“油泡”,连续穿过整个柱内水相,在萃取柱顶部气液相界面破裂、聚并,然后从萃取柱上端溢流口流出并收集。以萃取柱内开始产生稳定的油泡分散相时刻开始计时,从萃取柱下端出水口取不同时刻的柱内水相,检测金、铜的质量浓度。每个时刻取3个平行样,每个平行样10 mL。

2) 萃取柱内水相循环、油相循环过柱萃取:首先,封住萃取柱下端出水口,从萃取柱上端进水口泵入废水料液,待料液充满整个萃取柱后,打开萃取柱下端出水口,继续以10 mL/min的流量从萃取柱上端进水口泵入废水料液,收集从萃取柱下端出水口流出的水相,再次从萃取柱上端进水口泵入。水相料液在萃取柱内连续循环进、出。参与循环的水相料液总体积为1000 mL。然后,从萃取柱底部进气口连续泵入空气气泡,泵气气速为150 mL/min。待气泡稳定生成后,从萃取柱下端进油口连续泵入含有有机萃取剂的油相,泵油速度为60 mL/min。包覆了有机萃取剂的“油泡”上升穿过整个柱内水相,在萃取柱顶部气液相界面破裂、聚并,然后从萃取柱上端溢流口流出。收集流出的萃取剂油相,再次从萃取柱下端进油口泵入。萃取剂油相连续、循环进出萃取柱。以萃取柱内开始产生稳定的油泡分散相时刻开始计时,从萃取柱下端出水口取不同时刻流出的柱内水相,检测金、铜的质量浓度。每个时刻取3个平行样,每个平行样10 mL。

1.3.2 反萃

将一定量的硫脲溶于0.5mol/L的盐酸水溶液中,配制成含1.2 mol/L硫脲的盐酸水溶液作为反萃剂。然后取鼓泡油膜萃取收集得到的负载有机相,按相比A:O=1:1,在负载有机相中加入反萃剂,室温下通气搅拌15 min。静置澄清后,取下水相(即,反萃余液)分析检测金、铜的质量浓度。二次反萃重复上述步骤,取一次反萃后的有机相进行二次反萃。然后,收集所有反萃余液备用。

1.3.3 有机相再生循环使用

将经过二级反萃再生后的有机相重新泵入萃取装置,继续与新鲜的废水料液接触,鼓泡油膜萃取的具体操作同1.3.1节。分析检测萃余液中得金、铜质量浓度。

1.3.4 锌粉置换

收集一级与二级反萃余液,称取过量锌粉,加入反萃余液中进行搅拌置换,24 h后,将固液混合物用定量真空抽滤装置过滤,取滤液测定其中金、铜的质量浓度。锌粉置换母液与滤渣均收集待用。

1.3.5 锌粉置换渣酸溶除锌、分离金铜

1) 酸溶分离锌:取锌粉置换后的滤渣于烧杯中,加入50 mL 0.1 mol/L H2SO4溶液,搅拌溶解30 min,静置过滤,取滤液测定其中金、铜的质量浓度,滤液与滤渣分别收集备用。

2) 酸溶分离金、铜:取酸溶分离锌后的滤渣,置于100 mL 0.5 mol/LH2SO4溶液中,通空气加热,搅拌,30 min后过滤,取滤液测其中金、铜的质量浓度。

1.3.6 硫化锌的制备

将锌粉置换母液与酸溶分离锌后的滤液混合,加入50 mL 2 mol/L的氢氧化钠溶液,在80 ℃下加热反应3 h,过滤,将滤渣烘干得到硫化锌产品。

1.4 分析方法

萃余水相中的金、铜离子质量浓度采用美国安捷伦ICP-MS7500测定;pH值采用梅特勒台式酸度计S20测定。

1.5 数据处理

1.5.1 萃取率的计算

实验中金、铜萃取率(E)的计算公式如下:

(1)

(1)

式中:E为金/铜萃取率,%; 为料液中的初始金/铜离子质量浓度,mg/L;

为料液中的初始金/铜离子质量浓度,mg/L; 为萃取过程中某一时刻萃余液中的金/铜离子质量浓度,mg/L。

为萃取过程中某一时刻萃余液中的金/铜离子质量浓度,mg/L。

1.5.2 反萃率的计算

实验中金、铜反萃率(S)的计算公式如下:

(2)

(2)

式中: 为反萃余液中的金/铜离子质量浓度,mg/L;Va为反萃液的体积,L;

为反萃余液中的金/铜离子质量浓度,mg/L;Va为反萃液的体积,L; 为反萃前负载有机相中的金/铜质量浓度,mg/L;Vo为负载有机相的体积,L。

为反萃前负载有机相中的金/铜质量浓度,mg/L;Vo为负载有机相的体积,L。

2 结果与讨论

2.1 鼓泡油膜萃取回收金和铜

2.1.1 萃取柱内水相不动,无负载的新鲜有机相一次过柱开路萃取

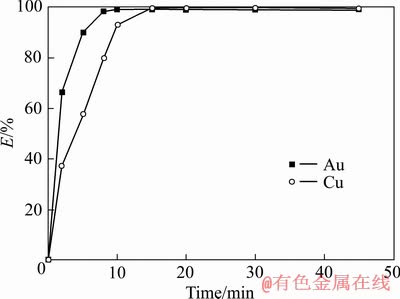

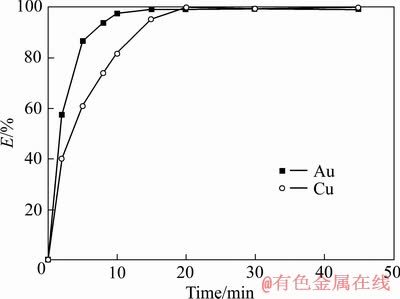

为了对比金、铜的萃取行为,图1所示为无负载的新鲜有机相一次过柱开路萃取回收金和铜的实验结果(水相料液在萃取柱内不流动)。

图1 无负载的新鲜有机相一次过柱开路萃取时萃余水相中的金、铜萃取率随时间的变化

Fig. 1 Change in percent extraction of gold and copper with reaction time during fresh and no loaded organic phase passing through extraction column only once

由图1可以看出,废水中的铜氰络离子可以被高效萃取。萃取反应15 min后,萃余液中的铜氰络离子浓度即降至1.132 mg/L,铜萃取率高达99.8%。同时,高浓度铜氰废水中的低浓度金氰络离子也可被快速萃取,且金氰络离子的萃取速率要快于铜氰络离子。萃取反应10 min后,萃余液中的金氰络离子浓度即可降至0.016 mg/L,金萃取率高达99%。因此,采用鼓泡油膜萃取技术处理含金、铜的氰化废水,不仅可以高效回收废水中高浓度的铜,还可以快速富集低浓度的金。

为了对比,进行了分液漏斗的摇瓶萃取实验。将10 mL含有有机萃取剂的油相与100 mL的废水料液置于分液漏斗中,振荡萃取30 min。静置分相后,取下层萃余水相测定其中金、铜的浓度。试验结果表明,金氰络离子的单级萃取率仅为61.9%,铜氰络离子的单级萃取率为85.9%。显然,鼓泡油膜萃取技术比传统萃取方式更加高效。究其原因,传统萃取技术是将有机萃取剂分散成小油滴,均匀分散在水相中。金、铜离子萃取速率取决于油滴的分散和聚并速率,不仅与单位体积水相中被分散的油滴相含率有关,而且与油滴表面更新、暴露在水相中的新鲜界面面积有关。决定传统萃取技术萃取效率的关键因素是单位时间内油水两相的总界面面积,界面面积又与振荡强度和频率有关[29-30]。参与反应的有机相总体积越小,越难实现有机小油滴在水相中的均匀分散,导致萃取速率和萃取效率均下降。鼓泡油膜萃取是一种全新的萃取模式,将极小体积的有机萃取剂分散包覆在气泡表面,形成一层超薄的有机萃取剂油膜,可实现水相料液与有机萃取剂的接触面积最大化[25]。由于鼓泡过程可实现油泡均匀分散在水相中,可充分利用油相中的有机萃取剂,不仅大大缩短了萃取反应时间,而且金、铜离子的萃取率也相应提高。此外,油泡从萃取柱底端上升到顶端的过程中,因与水相发生逆流剪切作用,油膜层表面更新速度加快,不断有新鲜有机界面暴露在水相中,强化了目标离子的传质过程,也进一步加快了金、铜离子的萃取速率。

由图1还可以看出,鼓泡油膜萃取过程中金氰络离子萃取速率要快于铜氰络离子的萃取速率。这是因为:一方面,金氰络离子的离子半径大于铜氰络离子的离子半径,其疏水性也大于铜氰络离子。水相中的金氰络离子更容易被吸附到油泡分散相的表面,被优先萃取。另一方面,铜以 的形式在水相中存在[31],而金与游离氰根结合形成的是AuCN-。AuCN-与N263萃取剂分子中R3CH3N+结合形成络合物的稳定性要高于

的形式在水相中存在[31],而金与游离氰根结合形成的是AuCN-。AuCN-与N263萃取剂分子中R3CH3N+结合形成络合物的稳定性要高于 与R3CH3N+结合形成的络合物。因此,AuCN-对油水相界面N263萃取剂分子的亲和力要明显高于

与R3CH3N+结合形成的络合物。因此,AuCN-对油水相界面N263萃取剂分子的亲和力要明显高于 [32-33]。

[32-33]。

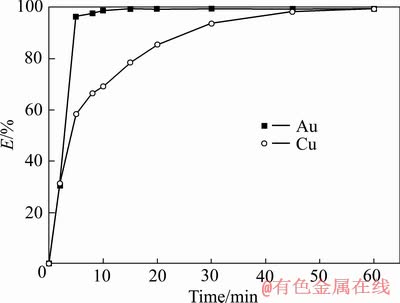

2.1.2 萃取柱内水相不动,已负载一定量铜的有机相一次过柱开路萃取

为了考察萃取负载了一定量铜氰络离子的有机相对金、铜离子萃取行为的影响,将2.1.1节反应后得到的已负载铜有机相与新鲜料液再次接触,进行一次过柱开路萃取实验(水相料液在萃取柱内不流动)。铜在萃取有机相中的预负载量为143.3 mg/L。图2所示为萃余液中金、铜萃取率随时间的变化。

由图2可以看出,即使有机相中负载了高浓度的铜氰络离子,也不影响金氰络离子的优先萃取行为。废水中低浓度的金氰络离子仍然可以被优先快速萃取,且金氰络离子的萃取速率仍略快于铜氰络离子。萃取20 min后,萃余液中铜氰络离子浓度可降至2.217 mg/L,铜的萃取率达到99.6%。萃余液中金氰络离子的浓度降至0.016 mg/L,金的萃取率达到99%。

图2 已负载一定量铜的有机相一次过柱开路萃取时萃余水相中的金、铜萃取率随时间的变化

Fig. 2 Change in percent extraction of gold and copper with reaction time during organic phase loaded with certain amount of Cu(Ⅱ) passing through extraction column only once

图3所示为无负载的新鲜有机相、以及有一定铜负载量的有机相萃取氰化废水中的金、铜离子时,萃余液中金、铜浓度随时间的变化。由图3可以看出,当采用负载铜的有机相萃取废水中金、铜氰络离子时,其萃取速率低于新鲜无负载有机相的。这主要是由于有机相中负载金属离子后,黏度变大,不利于有机相在气泡表面铺展与更新。因此,当采用有一定铜负载量的有机相进行萃取时,金、铜氰络离子的萃取速率变慢。

2.1.3 萃取柱内水相不动,已负载一定量铜的有机相在萃取柱内循环过柱萃取

采用N263进行鼓泡油膜萃取时,除金、铜氰络离子被萃取外,废水中的锌、铁等其他杂质离子也会被萃入有机相。有机相中锌、铁等杂质离子的积累将导致金、铜氰络离子的萃取率下降。为了实现有机相的连续循环使用,我们将萃取后的有机相用0.1 mol/L的稀盐酸洗涤,以除去负载在有机相中的锌、铁等杂质离子。然后,将酸洗后的铜负载有机相在萃取柱内循环过柱,与新鲜料液接触萃取。图4给出了当萃取柱内水相不动,已负载一定量铜的有机相循环过柱萃取时,萃余液中金、铜的萃取率随时间的变化。

由图4可以看出,萃取30 min时,萃余液中铜氰络离子浓度降至1.140 mg/L,铜的萃取回收率达到99.81%。金氰络离子的萃取速率略高于铜氰络离子。萃取20 min时,萃余液中的金氰络离子浓度即降至0.044 mg/L,金萃取率达到97.16%。由此可知,负载有机相酸洗除杂后,可高效萃取废水中的金、铜氰络离子。

图3 有机相负载铜离子对萃余液中金、铜萃取速率的影响

Fig. 3 Effect from organic phase loaded with certain amount of Cu(Ⅱ) on extraction rate of gold and copper

图4 已负载一定量铜的有机相在萃取柱内循环过柱萃取时萃余水相中的金、铜萃取率随时间的变化

Fig. 4 Change in percent extraction of gold and copper with reaction time when Cu-loaded organic phase after acid-scraping was used (Aqueous feed solution did not flow in extraction column. Organic phase passed through the extraction column circularly and were not discharged out of tower)

与2.1.2节不同,本节实验的有机相在萃取柱内反复循环流动,有机相的铜负载量随循环次数的增加而逐渐增大。因此,金萃取率稍有下降。但由于采用水相不流动的萃取方式,有机相负载量远小于其饱和容量,负载有机相仍然可以高效萃取金、铜氰络离子。此外,有机相经过酸洗除杂后,金和铜的可萃取容量也相应增大。但是随着有机相使用次数的增加,有机相的铜负载量不断增大,导致气泡表面有机液膜的黏度不断增加,不利于油泡表面的油膜层进行界面更新,金、铜氰络离子的萃取速率相应变慢,萃余液中残留的金、铜氰络离子浓度稍有增加。

2.1.4 水相料液循环过萃取柱的同时,已负载一定量铜的有机相在萃取柱内循环过柱萃取

为了考察有机相铜负载量增加对金、铜萃取效率的影响,将有一定铜预负载量的有机相循环过柱,且一定体积的废水料液也循环过柱。图5所示为萃余液中金、铜萃取率随时间的变化。

由图5可以看出,萃取60 min时,萃余液中铜氰络离子浓度可降至4.577 mg/L,铜萃取回收达到99.23%。同时,萃取15min时,萃余液中的金氰络离子浓度为0.016 mg/L,金萃取率达到99%。显然,金、铜氰络离子的萃取率均能达到99%以上,且萃取达到平衡前,金氰络离子的萃取速率明显高于铜氰络离子的。

图5 水相循环、有机相循环对金、铜萃取率的影响

Fig. 5 Change in percent extraction of gold and copper with reaction time when organic phase loaded with certain amount of Cu(Ⅱ) used (Aqueous feed solution and organic phase passed through extraction column circularly and were not discharged out of tower)

与2.1.3节数据相比,实验前有机相中铜氰络离子的负载量为429.7 mg/L。负载有机相连续萃取时,有机相中铜氰络离子的负载量连续增大,金氰络离子的萃取速率高于水相不动时的萃取率。但是,铜氰络离子的萃取速率却明显低于水相不动时的萃取率。究其原因,主要是当水相连续流动时,油泡上升过程中与水相发生逆流剪切作用,使得油水界面快速更新,水相不断接触新鲜的有机萃取剂,强化了离子的传质过程,从而促使金离子迅速富集到有机液膜层。因此,水相流动时,水相中低浓度的金氰络离子的萃取速率要快于水相不动时的萃取率。水相流动时,铜的萃取速率低于水相不动时的萃取率,是因为负载有机相的薄层油膜中铜氰络离子浓度增加,参与反应的自由N263分子数目减少,导致水相中高浓度铜氰络离子的萃取速率变慢。

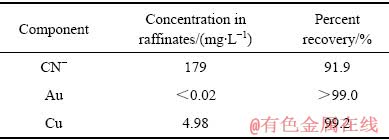

氰化提金废水经鼓泡油膜萃取后,萃余液中残留的金、铜及游离氰根浓度见表2。

表2 氰化提金废水经鼓泡油膜萃取后萃余液中残留的金、铜及游离氰根浓度

Table 2 Concentrations of gold, copper and free CN- in raffinates after gas bubble supported organic liquid membrane extraction

由表2可以看出,氰化提金废水经过鼓泡油膜萃取后,废水中的金、铜氰络离子几乎完全萃取,萃取率均达到99%以上。铜氰络离子浓度降至4.98 mg/L,金氰络离子浓度降至0.02 mg/L以下。废水中的游离氰根浓度降低至179 mg/L,氰根回收率达到91.9%,可以返回使用浸取金,无需外排,解决了氰化提金废水循环使用时铜、锌、铁等杂质离子浓度累积的难题,实现了废水的资源化利用。

由实验结果还可知, N263萃取剂优先与金、铜氰络离子发生反应。待与金、铜氰络离子反应完全后,才会与游离氰根反应。因此,N263萃取金、铜氰络离子的萃取率大于游离氰根离子的。

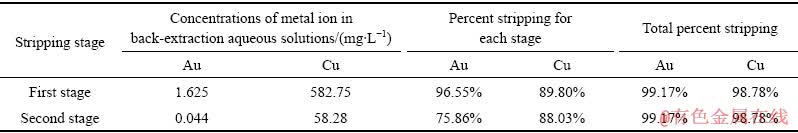

2.2 负载有机相反萃回收金和铜

经鼓泡油膜萃取后的负载有机相可以用酸性硫脲进行反萃[34-35]。表3所列为负载有机相经两级反萃后,反萃余液中金、铜离子的浓度及相应的反萃率计算值。负载有机相反萃前,有机相中金含量为1.683 mg/L、铜含量为648.95 mg/L。

由表3可以看出,负载有机相经过两级反萃后,金的总反萃率达到99.17%,铜的总反萃率达到98.78%,由此说明,负载有机相经过硫脲反萃后,有机相中的金、铜可几乎完全被反萃下来。酸性硫脲在反萃过程中会产生HCN气体,可通过氢氧化钠溶液吸收后,实现氰根的资源回收和返回工艺使用。

2.3 有机相再生循环使用性能

图6所示为有机相反萃再生后重新上柱萃取时萃余液中金、铜的萃取率随时间的变化情况。水相循环过柱,有机相也循环过柱。

由图6可以看出,在水相循环、有机相循环的萃取过程中,萃取60 min时,萃余液中铜氰络离子浓度降至23.25 mg/L。但是,萃取45 min时,萃余液中的金氰络离子浓度仅为0.099 mg/L。金萃取率达到93.68%,铜回收率为96.10%。显然,反萃再生后的有机相仍可满意地萃取回收金、铜氰络离子,有机相再生后可以循环使用。

与2.1.2节数据相比,反萃后再生的有机相上柱前有机相中铜氰络离子的浓度为7.923 mg/L。反萃再生后的有机相萃取金、铜氰络离子的萃取速率要低于新鲜有机相的萃取速率。分析其原因,可能是由于有机相反萃未完全所致。与2.1.2节类似,油泡分散相表面油膜层有一定量的铜负载量时,金、铜氰络离子的萃取速率下降。因此,反萃效果对于鼓泡油膜萃取有一定的影响。在实际生产过程中,应尽量反萃完全后再重新返回使用。实验也考察了将负载有机相经三级反萃后再返回使用的情况,金、铜氰络离子的萃取率可增加至99%以上,证实了上述观点。

表3 反萃余液中金属离子浓度与反萃率

Table 3 Percent stripping of gold and copper and their concentrations in back extraction raffinates

图6 有机相反萃再生后对金、铜萃取率的影响

Fig. 6 Change in percent extraction of gold and copper with reaction time after regenerated organic phase used (Both aqueous feed solution and organic phase passed through extraction column circularly and were not discharged out of tower)

2.4 锌粉置换回收反萃余液中的金和铜

负载有机相经酸性硫脲反萃后,反萃余液中的金、铜可以用锌粉置换回收[36-37]。取两级反萃余液的混合溶液,其中金含量为0.835 mg/L、铜含量为320.515 mg/L。表4所列为经锌粉置换、过滤后滤液中的金、铜离子浓度及其相应的置换率计算值。

表4 锌粉置换后滤液中离子浓度与置换率

Table 4 Percent recovery of Au and Cu by zinc powder replacement and their concentrations in filtrate after zinc powder replacement

由表4可以看出,金的置换率达到99.9%以上,锌粉置换几乎可以完全回收硫脲反萃余液中的金。铜的置换率达到96.1%。金的置换率略高于铜的。

2.5 锌粉置换渣酸溶除锌、分离金和铜

硫脲反萃余液锌粉置换渣中除含有金、铜外,还有一定量的锌。锌粉置换渣中金含量为4.503 mg, 占锌粉置换渣的质量分数为0.016%;铜含量为1.663 g,占锌粉置换渣的质量分数为59.17%;锌含量为1.143 g,占锌粉置换渣的质量分数为40.67%。

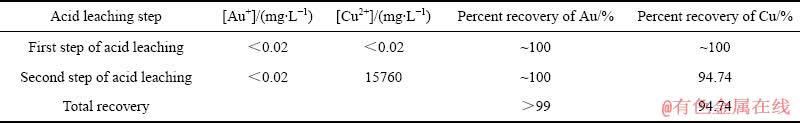

为提取锌粉置换渣中的金、铜,采用两步酸溶法:首先,将置换渣用0.1mol/L的稀硫酸溶解,除锌。然后,将除锌后的滤渣加入0.5 mol/L的硫酸溶液中,通空气加热浸出[38],分离金、铜。结果见表5。

实验结果表明,经一步酸溶后,滤液中的金离子浓度<0.02 mg/L,铜离子浓度<0.02 mg/L,金、铜均不溶于稀硫酸,锌则优先转入溶液,达到了分离锌的目的。将分离锌后的滤渣进行二步酸溶,滤液中金离子浓度<0.02 mg/L,金不溶于稀硫酸,而铜则优先转入溶液,达到了金、铜分离的目的。滤渣为金富集物,金含量大于90%,可送后续精炼回收金。整个工艺金的总回收率高达98.06%以上;铜的总回收率达到94.74%。通过鼓泡油膜萃取法处理氰化废水,最终可回收金1.532 g/m3氰化废水,产生副产品硫酸铜41.50 kg/m3氰化废水。

2.6 硫化锌的制备

为了回收锌,在锌粉置换后的置换母液中加入2 mol/L氢氧化钠溶液,加热到80 ℃,搅拌反应3 h左右,过滤,得到的硫化锌滤渣[39]。

实验结果表明,如果锌粉的加入量按0.755 kg/m3,则产生硫化锌产品1.079 kg/m3,锌回收率达到96%。因此,锌粉置换后的置换母液可通过加碱加热生成硫化锌产品的方式进行回收,实现资源综合回收目的。

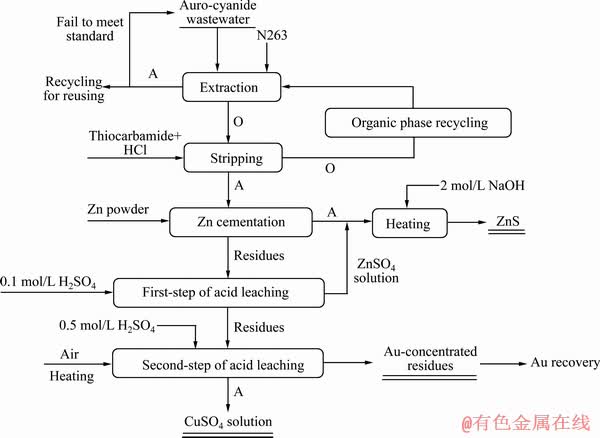

2.7 鼓泡油膜萃取法处理氰化废水的新工艺流程

综上所述,图7所示为处理含金氰化废水的新工艺流程。

含金氰化废水首先采用鼓泡油膜萃取的方式回收高浓度铜并富集极低浓度金,萃余液可返回选矿工艺重复使用。萃取饱和有机相采用酸性硫脲反萃。反萃液采用锌粉置换回收金和铜。锌粉置换渣首先用稀硫酸溶解优先分离锌,然后再用稀硫酸浸出分离金、铜。滤渣烘干后可得到品位大于90%的金富集物,滤液为硫酸铜溶液。锌粉置换后的置换母液经过加碱、加热处理,得到硫化锌产品。

表5 酸溶后滤液中离子浓度与回收率

Table 5 Percent recovery of Au and Cu and their concentrations in acid-leaching solutions of zinc powder replacement

图7 氰化提金废水处理工艺流程

Fig. 7 Technological process for treatment of auro-cyanide wastewater

该工艺已完成8~10 m3/d的中试验证,连续稳定运行6个月以上。鼓泡油膜萃取氰化废水新工艺可实现氰化废水中各种有价金属资源综合回收利用,回收率高,工艺成本低,可获得可观的经济效益。按日处理300 m3的氰化提金废水计算,工艺运行费用大约为0.22元/ m3,工艺收益为543.8元/ m3,企业可获得利润543.58元/ m3。新工艺在黄金废水厂推广是可行的,不仅可高效回收废水中的铜,同时还可回收极低浓度的金。萃取回收金属后的萃余液可满足回用要求,可实现含氰废水的闭路循环和近零排放。

3 结论

1) 鼓泡油膜萃取不仅可高效回收氰化废水中的高浓度铜,还可同时回收极低浓度的金。金的回收率达到99%以上,铜的回收率达到99.8%。萃取后的萃余液可在氰化厂内循环利用,氰根脱除率达到91.9%,无需外排,解决了氰化提金废水循环使用过程中,铜、锌、铁等杂质离子浓度累积的难题。

2) 萃取饱和后的有机相经过酸性硫脲反萃,金的总反萃率高达99.17%,铜的总反萃率为98.78%。反萃后有机相可以循环使用。

3) 采用鼓泡油膜萃取法处理氰化废水,锌粉置换回收反萃余液中的金和铜,然后锌粉置换渣两步酸溶先除锌、再分离金和铜。酸滤渣为金富集物,金含量大于90%,可送后续精炼回收金。整个工艺最终可回收金1.532 g/m3氰化废水,金总收率达到98.06%。产生副产品硫酸铜41.50 kg/m3氰化废水,铜的总回收率达到94.74%。锌粉置换母液可用于制备硫化锌产品,锌回收率达到96%。

4) 新工艺流程简单,操作方便,回收率高,成本低,能处理大体量的氰化提金废水且可以实现连续化生产。萃取后的废液可以进行工艺回用。整个工艺实现含氰废水的闭路循环和近零排放,既降低了能耗,又解决了环境污染的难题,具有潜在的应用推广前景。

REFERENCES

[1] 周 军, 王丽君, 张 华, 宋永辉, 党晓娥, 张秋利. 含铁氰化提金废水综合回收研究[J]. 稀有金属, 2015, 39(10): 922-927.

ZHOU Jun, WANG Li-jun, ZHANG Hua, SONG Yong-hui, DANG Xiao-e, ZHANG Qiu-li. Recycling of cyanide leaching gold wastewater containing iron[J]. Chinese Journal of Rare Metals, 2015, 39(10): 922-927.

[2] 陈芳芳, 张亦飞, 薛 光. 黄金冶炼污染治理与废物资源化利用[J]. 黄金科学技术, 2011, 19(2): 67-73.

CHEN Fang-fang, ZHANG Yi-fei, XUE Guang. Disposal to pollution and resource utilization to waste for gold smelting[J]. Gold Science and Technology, 2011, 19(2): 67-73.

[3] 石绍渊, 王军强, 王永春, 王国栋, 张曼曼, 孙 峙. 复杂黄金废水深度净化与脱盐回用技术研究与实践[J]. 黄金科学技术, 2018, 26(4): 535-543.

SHI Shao-yuan, WANG Jun-qiang, WANG Yong-chun, WANG Guo-dong, ZHANG Man-man, SUN Zhi. Research and practice of deep purification and desalination reuse technology for complex gold wastewater[J]. Gold Science and Technology, 2018, 26(4): 535-543.

[4] 刘 杰, 黄 焜, 吴怀之, 刘会洲. 大相比鼓泡油膜萃取氰化废水中的低浓度金[J]. 中国有色金属学报, 2018, 28(1): 199-204.

LIU Jie, HUANG Kun, WU Huai-zhi, LIU Hui-zhou. Recovery of gold(Ⅰ) with extremely low concentrations in cyanide wastewater by bubbling organic membrane extraction at large aqueous-to-oil phase ratios[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 199-204.

[5] 陈 鹏. 黄金冶炼废水零排放处理技术的工业应用[J]. 中国有色冶金, 2016, 45(4): 56-61.

CHEN Peng. Commercialization of zero waste water discharge technology in gold smelting[J]. China Nonferrous Metallurgy, 2016, 45(4): 56-61.

[6] 卢建丰. 黄金冶炼废水铜的萃取回收[J]. 有色冶金设计与研究, 2012, 33(4): 11-13.

LU Jian-feng. Copper extraction and recovery from wastewater of gold smelting[J]. Nonferrous Metals Engineering & Research, 2012, 33(4): 11-13.

[7] 孙彦文, 林明国, 孙留根, 梁东东, 徐晓辉. 含氰废水综合处理技术试验研究[J]. 矿冶, 2016, 25(5): 67-71.

SUN Yan-wen, LIN Ming-guo, SUN Liu-gen, LIANG Dong-dong, XU Xiao-hui. Experiment research on comprehensive treatment technology of cyanide-containing wastewater[J]. Mining & Metallurgy, 2016, 25(5): 67-71.

[8] 邢相栋, 兰新哲, 宋永辉, 张 静. 氰化法提金工艺中“三废”处理技术[J]. 黄金, 2008, 29(12): 55-61.

XING Xiang-dong, LAN Xin-zhe, SONG Yong-hui, ZHANG Jing. Disposal advances on “three wastes” treatment in the gold cynidation extraction process[J]. Gold, 2008, 29(12): 55-61.

[9] SCHWARTZ M O, PLOETHNER D. Removal of heavy metals from mine water by carbonate precipitation in the Grootfontein-Omatako canal, Namibia[J]. Environmental Geology, 2000, 39(10): 1117-1126.

[10] CHEN Quan-yuan, LUO Zhou, HILLS C, XUE Gang, TYRER M. Precipitation of heavy metals from wastewater using simulated flue gas: Sequent additions of fly ash, lime and carbon dioxide[J]. Water Research, 2009, 43(10): 2605-2614.

[11] 党晓娥, 兰新哲, 张秋利, 董 缘. 离子交换树脂和交换纤维处理含氰废水[J]. 有色金属(冶炼部分), 2012, 2: 37-41.

DANG Xiao-e, LAN Xin-zhe, ZHANG Qiu-li, DONG Yuan. Cyanide bearing waster water treatment with ion exchange resin and ion exchange fiber[J]. Nonferrous Metals (Extractive Metallurgy), 2012, 2: 37-41.

[12] 兰新哲, 宋永辉, 张秋利, 梁帅表. 201×7树脂吸附回收提金尾液中的氰化物及金属铜[J]. 黄金, 2006, 27(2): 45-48.

LAN Xin-zhe, SONG Yong-hui, ZHANG Qiu-li, LIANG Shuai-biao. Recovery of cyanide and copper by 201×7 resin from leaching gold tail solution[J]. Gold, 2006, 27(2): 45-48.

[13] 吴向阳, 于振福, 韩路波, 贾文涛. 活性炭吸附选矿废水中金等有价金属[J]. 黄金科学技术, 2013, 21(2): 51-54.

WU Xiang-yang, YU Zhen-fu, HAN Lu-bo, JIA Wen-tao. Recovery of valuable metals by active carbon adsorption from mineral processing wastewater[J]. Gold Science and Technology, 2013, 21(2) : 51-54.

[14] 伍喜庆, 黄志华. 改性活性炭吸附金的性能[J]. 中国有色金属学报, 2005, 15(1): 129-132.

WU Xi-qing, HUANG Zhi-hua. Adsorption of gold on modified activated carbon[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 129-132.

[15] 侯新刚, 尹皓亮. 乳状液膜法回收酸性含铜废水中的铜[J]. 兰州理工大学学报, 2013, 39(4): 12-15.

HOU Xin-gang, YIN Hao-liang. Copper recycle from acidic water containing copper with emulsion liquid membrane[J]. Journal of Lanzhou University of Technology, 2013, 39(4): 12-15.

[16] 李 雅, 刘晨明, 石绍渊, 李玉平. 膜吸收法处理黄金冶炼含氰废水的试验研究[J]. 黄金, 2017, 38(3): 71-75.

LI Ya, LIU Chen-ming, SHI Shao-yuan, LI Yu-ping. Experimental study of cyanide wastewater treatment in gold smelting with membrane absorption[J]. Gold, 2017, 38(3): 71-75.

[17] 闫文飞, 马 刚, 周维金, 高宏成, 施 鼐, 吴瑾光, 徐光宪, 陈 景. 氰化金浸取液萃取机理研究[J]. 无机化学学报, 2000, 16(2): 261-266.

YAN Wen-fei, MA Gang, ZHOU Wei-jin, GAO Hong-cheng, SHI Nai, WU Jin-guang, XU Guang-xian, CHEN Jing. Mechanism of gold solvent extraction from alkaline aurocyanide solution[J]. Chinese Journal of Inorganic Chemistry, 2000, 16(2): 261-266.

[18] 潘学军, 陈 景. 碱性氰化液中加表面活性剂用TBP 萃取金的研究[J]. 稀有金属, 2000, 24(2): 90-95.

PAN Xue-jun, CHEN Jing. Study on gold(Ⅰ) solvent extraction from alkaline cyanide solution by TBP with addition of surfactant[J]. Chinese Journal of Rare Metals, 2000, 24(2): 90-95.

[19] 黄 昆, 陈 景, 吴瑾光, 高宏成, 崔 宁, 余建民. CTMAB萃取 体系中几种改性剂的对比[J]. 中国有色金属学报, 2001, 11(2): 307-311.

体系中几种改性剂的对比[J]. 中国有色金属学报, 2001, 11(2): 307-311.

HUANG Kun, CHEN Jing, WU Jin-guang, GAO Hong-cheng, CUI Ning, YU Jian-min. Effects of modifiers on  solvent extraction by CTMAB[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 307-311.

solvent extraction by CTMAB[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 307-311.

[20] 杨项军, 陈 景, 吴瑾光, 李楷中, 周维金. CTAB-TBP 体系载金有机相中金(Ⅰ)的转化还原反萃取[J].中国有色金属学报, 2003, 16(6): 1565-1569.

YANG Xiang-jun, CHEN Jing, WU Jin-guang, LI Kai-zhong, ZHOU Wei-jin, WEI Qun-yan, JIANG Jian-zhun, LI Qi-wei. Au(Ⅰ) stripping from gold loaded CTAB-TBP organic phase by transformation and reduction[J]. The Chinese Journal of Nonferrous Metals, 2003, 16(6): 1565-1569.

[21] SADEGHI N, ALAMDARI E K.Selective extraction of gold(Ⅲ) from hydrochloric acid-chlorine gas leach solutions of copper anode slime by tri-butyl phosphate (TBP)[J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 3258-3265.

[22] 杨项军, 陈 景, 吴瑾光, 张 欣, 黄 昆, 赵家春, 李奇伟, 陈奕然. 水相添加表面活性剂 CTAB对TBP萃取低浓度金的影响[J]. 中国有色金属学报, 2002, 12(6): 1309-1313.

YANG Xiang-jun, CHEN Jing, WU Jing-guang, ZHANG Xin, HUANG Kun, ZHAO Jia-chun, LI Qi-wei, CHEN Yi-ran. Effects of addition of CTAB in aqueous phase on extraction with TBP from low gold concentration cyanide solutions[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1309-1313.

[23] 周 扬, 李雪玲, 顾烁玥, 杨项军. 用 N503/TBP 从碱性氰化液中萃取低浓度金[J]. 中国有色金属学报, 2009, 19(7): 1345-1349.

ZHOU Yang, LI Xue-ling, GU Shuo-yue, YANG Xiang-jun. Solvent extraction of trace Au(Ⅰ) from alkaline cyanide solution by N503/TBP system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1345-1349.

[24] 舒万艮, 古映莹, 王开毅, 罗春艳. 溶剂萃取法从低含量金浸出液中提取金的研究[J]. 黄金, 1995, 16(1): 35-37.

SHU Wan-gen, GU Ying-ying, WANG Kai-yi, LUO Chun-yan. Extraction of gold from the liquor containing low concentration of gold by solvent extraction[J]. Gold, 1995, 16(1): 35-37.

[25] HUANG Kun, LIU Jie, WU Huai-zhi, LIU Hui-zhou. A new bubbling extraction tower: Toward liquid–liquid solvent extraction at large aqueous-to-oil phase ratios[J]. AIChE Journal, 2015, 61(11): 3889-3897.

[26] LIU Jie, HUANG Kun, WU Huai-zhi, LIU Hui-zhou. A feasible strategy for calculating the required mass transfer height of a new bubbling organic liquid membrane extraction tower directly based upon the experimental kinetic data[J]. Industrial & Engineering Chemistry Research, 2016, 55(16): 4426-4434.

[27] LIU Jie, HUANG Kun, WU Xiao-hong, LIU Hui-zhou. Enrichment of low concentration rare earths from leach solutions of ion-adsorption ores by bubbling organic liquid membrane extraction using N1923[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(9): 8070-8078.

[28] LIU Jie, HUANG Kun, WU Xiao-hong, LIU Wen-qian, SONG Wei-yuan, LIU Hui-zhou. Extraction of rare earths using bubbling organic liquid membrane with unsaponified P507[J]. Hydrometallurgy, 2018, 175: 340-347.

[29] XIAO Chuan-xu, HUANG Kun, LIU Hui-zhou. A novel constant interfacial area cell for determining the extraction kinetics of Er(Ⅲ) from chloride medium[J]. Chinese Journal of Chemical Engineering, 2018, 26(6): 1435-1441.

[30] 高自立, 孙思修, 沈静兰. 强搅拌体系萃取动力学研究的新进展[J]. 化学通报, 1991, 4: 1-5.

GAO Zi-li, SUN Si-xiu, SHEN Jing-lan. New progress in extraction kinetics of strong agitation systems[J]. Chemistry Bulletin, 1991, 4: 1-5.

[31] 傅建顺, 杨惠明, 周展云. 从氰化液中萃取铜的机理研 究[J]. 黄金, 1991, 12(4): 37-41.

FU Jian-shun, YANG Hui-ming, ZHOU Zhan-yun. Study on the mechanism of extracting copper from cyanide solution by quaternary ammonium salt[J]. Gold, 1991, 12(4): 37-41.

[32] 雷思明, 宋永辉, 屈学化, 兰新哲. 硫酸锌沉淀法处理高铜氰化废水的动力学研究[J]. 黄金, 2015, 36(3): 67-70.

LEI Si-ming, SONG Yong-hui, QU Xue-hua, LAN Xin-zhe. Kinetics of treatment process toward cyanide wastewater with high copper concentration by zinc sulfate precipitation[J]. Gold, 2015, 36(3): 67-70.

[33] D·巴西勒尔, 曹松腾, 李长根. 用离子交换法回收含铜金矿石污水中的氰化物[J]. 国外金属矿选矿, 2005, 42(3): 39-43.

BRAZIL D, CAO Song-teng, LI Chang-gen. Recovery of cyanide from copper-bearing gold ore wastewater by ion exchange[J]. Metallic Ore Dressing Abroad, 2005, 42(3): 39-43.

[34] 傅建顺, 周展云, 杨惠明. 用硫脲从季铵盐萃取液中反萃金、银、铜的探索[J]. 化学工业与工程, 1990, 7(3): 17-20.

FU Jian-shun, ZHOU Zhan-yun, YANG Hui-ming. Study on the gold, silver and copper stripping from quaternary ammonium salt extract by acidified thiourea[J]. Chemical Industry and Engineering, 1990, 7(3): 17-20.

[35] 唐红萍, 杨明德, 何培炯, 胡天斗, 张 静, 谢亚宁. EXAFS研究硫酸硫脲反萃季铵氰化金的机理[J]. 光谱学与光谱分析, 2004, 24(6): 752-755.

TANG Hong-ping, YANG Ming-de, HE Pei-jiong, HU Tian-dou, ZHANG Jing, XIE Ya-ning. EXAFS study on the stripping mechanism in N263 alkaline cyanide gold solution sulfuric thiourea system[J]. Spectroscopy and Spectral Analysis, 2004, 24(6): 752-755.

[36] 马方通, 高利坤, 董 方, 陈 龙. 硫脲浸金及置换法从硫脲溶液中回收金研究现状[J]. 湿法冶金, 2017, 36(4): 257-262.

MA Fang-tong, GAO Li-kun, DONG Fang, CHEN Long. Situations of leaching and replacement of gold in acidic thiourea solution[J]. Hydrometallurgy of China, 2017, 36(4): 257-262.

[37] 朱 萍, 古国榜. 从酸性硫脲浸金溶液中回收金的方法[J]. 黄金, 2001, 22(11): 28-32.

ZHU Ping, GU Guo-bang. Recovery of gold from acidic thiourea leaching solution of gold[J]. Gold, 2001, 22(11): 28-32.

[38] 张宗涛, 陈建华. 铜镍废渣生产工业硫酸铜工艺研究[J]. 无机盐工业, 2002, 34(3): 34-35.

ZHANG Zong-tao, CHEN Jian-hua. The technology study on the production of industrial copper sulfate from copper-nickel slag[J]. Inorganic Chemicals Industry, 2002, 34(3): 34-35.

[39] 邱行中. 硫脲法制备硫化锌及其应用[J]. 化学世界, 1985, 4: 124-126.

QIU Xing-zhong. Preparation of zinc sulfide by thiourea method and its application[J]. Chemical World, 1985, 4: 124-126.

LIU Jie1, 2, WU Xiao-hong1, HUANG Kun1, 3, XU Zhong-min4, YU Feng-shan5, LIU Hui-zhou1

(1. CAS Key Laboratory of Bio-based Materials, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, Qingdao 266100, China;

2. School of Environmental and Municipal Engineering, Qingdao University of Technology, Qingdao 266520, China;

3. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China;

4. Jinchiling Gold Mining, Zhaojin Mining in Dustry Co., Ltd., Zhaoyuan 265400, China;

5. Jiangxi Province Han’s Precious Metals Co., Ltd., Shangrao 334000, China)

Abstract: A new process based on gas bubble supported organic liquid membrane extraction technology was suggested to treat the auro-cyanide wastewaters. The results show that, not only the high-concentration copper(Ⅰ) in the auro-cyanide wastewaters can be recovered satisfactorily, but the very low concentration gold(Ⅰ) can also be extracted efficiently by the suggested gas bubble supported organic liquid membrane extraction technology. The percent recovery of copper(Ⅰ), gold(Ⅰ) and cyanide can reach 99%, 99%, and 91.9%, respectively. The raffinates after bubbling extraction can be returned back to the mineral separation process for reusing and recycling in the factories, so that almost zero discharge of the cyanide wastewaters comes true. The Cu(Ⅰ) and Au(Ⅰ) in the loaded organic phase can be stripped by acidic thiourea, and then the regenerated organic phase can be returned back for reusing. Zinc powder is used to recover gold(Ⅰ) and copper(Ⅰ) in the thiourea solutions. Then, gold and copper can be separated by two-steps of dissolving the zinc powder replacement residues with dilute acid. The total percent recovery of gold(Ⅰ) and copper(Ⅰ) can reach 98.06% and 94.74%, respectively. The raffinates after the zinc powder replacement process can be used to produce zinc sulfide products. The total recovery of zinc reaches 96%. The suggested new process based on gas bubble supported organic liquid membrane extraction technology is economical and with a low processing cost. It is also environmental friendly, and might find potential industrial application in the future.

Key words: gold; solvent extraction; bubble; organic liquid membrane; auro-cyanide wastewater

Foundation item: Projects(51574213, 21606248) supported by the National Natural Science Foundation of China; Project(2018GSF117028) supported by the Key Program of Research and Development of Shandong Province, China

Received date: 2019-04-03; Accepted date: 2019-11-06

Corresponding author: HUANG Kun; Tel: +86-10-62332926; E-mail: huangkun@qibebt.ac.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51574213,21606248);山东省重点研发计划资助项目(2018GSF117028)

收稿日期:2019-04-03;修订日期:2019-11-06

通信作者:黄 焜,教授,博士;电话:010-62332926;E-mail:huangkun@qibebt.ac.cn