DOI: 10.11817/j.issn.1672-7207.2015.05.027

缓倾斜中厚矿体崩落开采矿石流动规律仿真与放矿参数优化

胡建华,郭福钟,罗先伟,周科平,纪大波

(中南大学 资源与安全工程学院,湖南,长沙,410083)

摘要:采用正交数值仿真和盈利因子评价函数,建立了分段高度(H)、进路间距(L)、崩矿边孔角(α)、截止贫化率(g)四因素三水平的正交仿真模型,获得矿岩放矿流动行为规律。研究结果表明:4个因素对放矿最优效果的影响权重从大到小依次为进路间距L,截止贫化率g,崩矿边孔角α,分段高度H。得到(H-L-α-g)的最优组合,即H=12 m,L=8 m,α=30°,g=0.5,在此条件下,可以使放出矿石经济效益达到最大,盈利因子F=17.38。对于缓倾斜中厚矿体,适当降低采场结构参数,采用低贫化放矿管理方式,有利于提高矿石回收率,降低贫化率。

关键词:正交实验;PFC2D数值模拟;低贫损放矿;参数优化

中图分类号:TD862 文献标志码:A 文章编号:1672-7207(2015)05-1772-06

Simulation of ore flow behavior and optimization of discharge parameters for caving method in gently inclined medium thickness ore-body

HU Jianhua, GUO Fuzhong, LUO Xianwei, ZHOU Keping, JI Dabo

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstracts: Taking the sublevel height (H), approach spacing (L), caving side hole angle (α), and cut-off grade (g) as dependent factors, the orthogonal experiment, which contains four factors and three levels, was designed with the help of PFC2D numerical simulation and earnings factor function. The results show that the effect weights ranking of each factor is approach spacing (L), cut-off grade (g), caving side hole angle (α) and sublevel height (H). Optimal combination is H=12 m, L=8 m, α=30°, g=0.5, which leads to maximum economic benefit, and the benefit factor F=17.38. For gently inclined medium thickness ore-body, appropriate reduction of structural parameters and improved ore management are good for increasing ore recovery and reducing its dilution.

Key words: orthogonal experiment; PFC2D numerical simulation; low loss and dilution caving; parameter optimization

无底柱分段崩落法是地下金属矿山开采中广泛应用的一种采矿方法,主要采用崩落上覆岩层处理空区,在松散岩层的覆盖条件下进行回采工作,损失贫化大是该方法的主要问题之一。为了改进无底柱分段崩落法的开采效果,降低矿石损失贫化这一难题,国内外研究者进行了大量的研究工作。张志贵等[1]基于随机介质理论,用大量的实验证实了低贫化放矿理论和工艺的可行性;陶干强等[2]开展了崩落矿岩的散体流动参数试验,发现随机介质放矿理论的散体流动参数可较好地反映崩落矿岩的流动特性;余健等[3-4]通过对厚大急倾斜矿体的大结构参数下的无底柱分段崩落法进行研究认为:高分段、大间距结构参数能大大提高生产效率,降低贫化损失率;王培涛等[5-6]利用PFC2D对崩落法放矿规律进行数值仿真发现:端壁侧压力随边孔角增大而增大以及边孔角越小,极限平衡拱形成和崩解越频繁的规律;徐帅等[7]对梅山铁矿崩矿步距进行优化,获得该矿山在结构参数为18 m×20 m的最优崩矿步距为4.4 m;Brunton等[8]研究并总结了Ridgeway gold mine矿山中影响崩落法矿石回收效果的因素为放矿口位置、爆破参数、几何参数、放矿控制;Panczakiewicz[9]利用物理模型模拟厚大矿体无底柱分段崩落法放矿,实现了采场结构参数优化;吴爱祥等[10-11]使用数值分析方法模拟崩落放矿过程的矿石流动规律。对厚大规整、急倾斜矿体的崩落法开采,已越来越多地采用高分段、大间距[3]的结构参数,极大地提高了生产效率[12]。但对于赋存条件不优的矿体(例如缓倾斜中厚矿体),采用大结构参数崩落矿石,则会造成极大的边角损失以及废石混入。目前,人们对这类赋存条件下的崩落法参数优化研究较少,在生产实践中矿体的赋存条件往往达不到厚大规整、急倾斜的条件,传统的研究成果很难有效应用于这类矿体的开采。此外,在当前的结构参数优化中,主要考虑了分段高度、进路间距、边孔角或崩矿步距的单独影响作用,缺乏多因素的综合作用对放矿效果的影响规律研究,放矿管理方式对矿石回收效果的影响也有待研究。为此,本文作者以铜坑矿92#缓倾斜中厚矿体为对象,建立多因素多水平正交仿真模型,采用离散元数值模拟软件PFC2D对放矿过程进行模拟[13-14],对无底柱分段崩落法矿石流动行为、多因素综合作用的影响规律进行研究,并找到最佳的多因素组合,使放矿效果最优。

1 实验方案设计

1.1 影响因素分析

放矿椭球体理论[15]认为,分段高度和进路间距及边孔角决定了椭球体的形态,影响出矿效果。同时,放矿截止贫化率也会对矿石流动行为产生影响。一般而言,影响崩落法放矿效果的主要因素有:

1) 矿岩的物理性质(块度、摩擦因数等)。对于特定矿山,块度分布和矿岩摩擦因数基本不可变,因此,实验中选用现场获取的参数。

2) 结构参数。包括分层高度H、进路间距L、崩矿步距d、边孔角α。

3) 截止贫化率g(截止层)。

1.2 实验设计

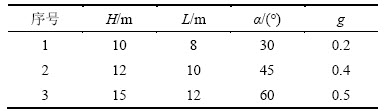

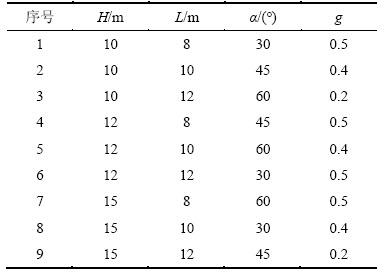

各因素及相对应水平设置见表1,组成四因素三水平正交设计表L(34),见表2。

表1 各因素及相应水平表

Table 1 Factors and their levels

表2 四因素三水平正交表

Table 2 Orthogonal table of four factors and levels

2 崩落矿石流动行为仿真模型构建

2.1 工程概况

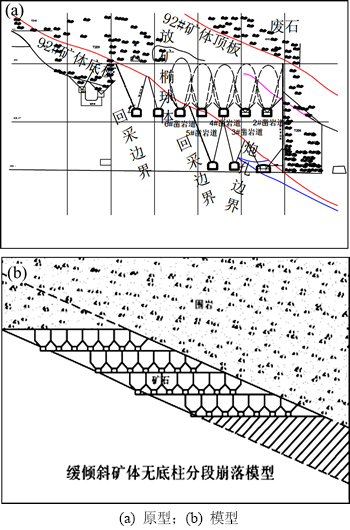

92号矿体是广西华锡集团的重要矿产资源,其矿体倾角为22°,平均厚度为20 m,走向长度200 m,为缓倾斜中厚矿体。目前采用了大分段大间距无底柱分段崩落法。在实际生产中,主要问题是崩落矿石块度大、矿石流动性差,以及出矿损失贫化率居高不下。以+455~+355水平中的某矿段为试验对象,建立仿真模型,探求矿岩流动特性和放矿参数优化。现场调查发现,覆盖岩层块度300~450 mm,崩落矿石块度为200~300 mm,服从均匀概率密度分布,矿石孔隙率取0.18,废石孔隙率取0.2,矿岩摩擦因数为0.2。使用铲运机出矿,进路断面长×宽为4 m×3 m。根据92号矿体提供的矿体赋存条件及现场物理参数,结合设计的正交实验方案,建立了9组仿真模型,如图1所示。

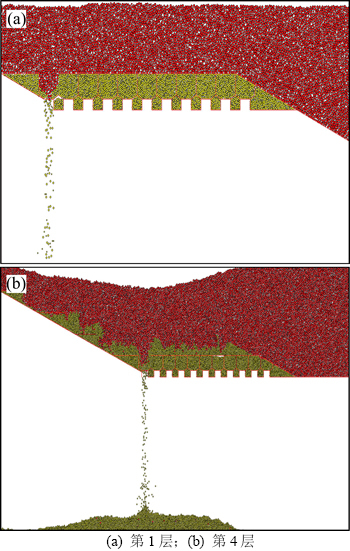

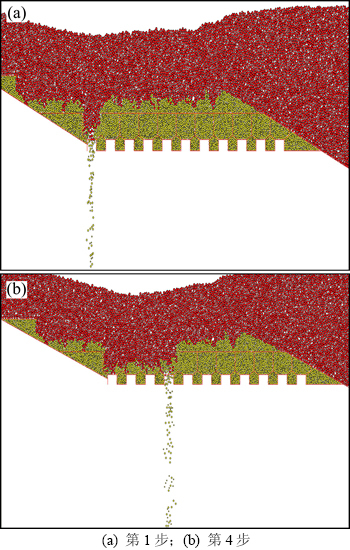

2.2 放矿PFC2D模型

实验共设置了4个矿体层,1个上覆岩层,前3层矿体按低贫化放矿管理。最后一层矿体按贫化率截止放矿,截止贫化率分别为0.2,0.4和0.5。在放矿过程中,对每个进路统计矿石损失与贫化率,每层矿体放矿结束后,记录该层总的损失贫化率。上层矿体放矿截止,调入下层矿体程序,转入下层矿体出矿,PFC模型如图2所示。

图1 原型及模型图

Fig. 1 Prototype and model

图2 PFC2D模型图(以4号模型为例)

Fig. 2 PFC2D model (Taking model 4 as example)

3 矿岩流动规律研究

3.1 矿岩流动形态

截取4号模型的第2层矿石第1步和第4步出矿模拟图,如图3所示。由图3可知:在有边界约束情况下,矿岩颗粒界面的变化不再完全按放矿椭球体理论所描述的模式进行。第1个放矿口由于受两边的未爆破体的夹制作用,废石的混入相对比较困难,按直线式的废石混入,形成两侧矿石残留损失;随着第2个放矿口的开始放矿,前一混入的废石从交界侧面挤入,形成垂直的侧向双重混入,在上部未放出体中形成包裹体,阻止了矿石的继续放出。这个现象的存在也决定了低贫化放矿的层数不能太多,否则被两侧废石包裹的矿石量将显著增加。在最后一层截止放矿时,为提高资源回收率,将以更高的贫化作为代价,不利于矿石的低贫化损失回收。

图3 4号模型第2层放矿过程模拟图

Fig. 3 Ore drawing process of second level in model 4

3.2 回收率和贫化率随放矿过程的变化规律

3.2.1 放矿回收率和贫化率统计结果

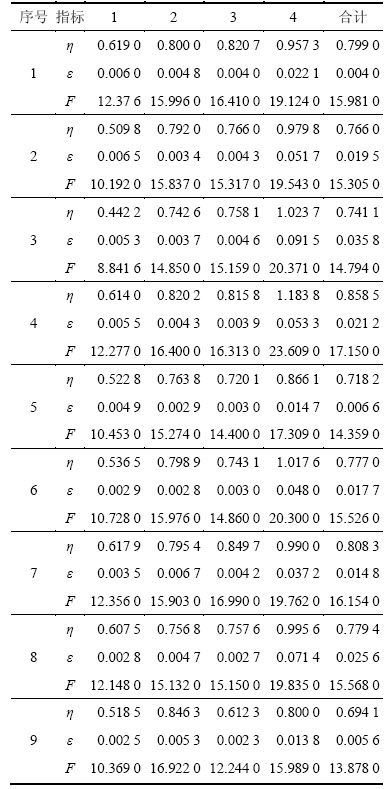

放矿截止后,对9组放矿模型进行损失贫化统计,统计结果如表3所示,其中,η和ε 分别表示矿石回收率和贫化率;F表示盈利因子,是关于η和ε的函数,将回收率、贫化率统一成一个综合的经济指标。

表3 放矿回收率、贫化率统计

Table 3 Recovery and dilution statistics of ore drawing

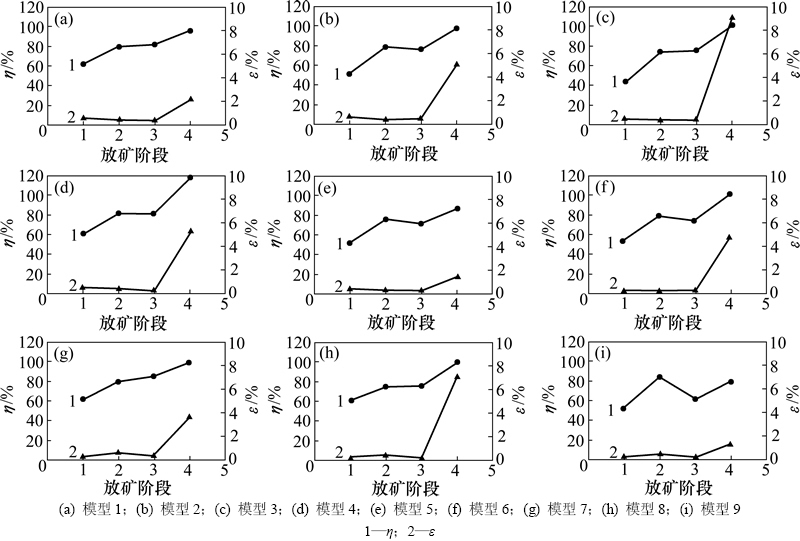

3.2.2 回收率和贫化率随放矿过程的变化规律

各模型回收率和贫化率随放矿过程的走势情况如图4所示。从图4可以发现:由于采用低贫化放矿方式管理,第1层在出矿口混入废石时立即停止出矿,低贫化回收率较低;随着放矿继续,第2层和第3层矿石在上层残留矿石的覆盖下放矿,可以较多地放出矿石,甚至回收上部残留的矿石;第2层和第3层矿石回收率变化比较平稳,最后一层截止放矿可以多回收上部残留矿体,同时,对整体的贫化率影响不大。第4层采用了截止贫化率放矿,回收率得到了极大提升。由于前3层矿体都采用了低贫化放矿,前3层的贫化率很低(1%左右),到第4层采用截止贫化率出矿,贫化率有所提升,但最大值仍控制在10%以内。

4 优化分析

4.1 优化指标选择

为实现正交实验数据分析,将损失率和贫化率合成一个综合指标即回贫差[3](η-ε)。回贫差越大,表明放矿效果越好。但回贫差不能很好地区分参数优劣,缺乏经济效益评价,如:1) η1=0.9,ε1=0.2;2) η2=0.8,ε2=0.1,虽然这2组数据的回贫差相等,但放矿效果差异性明显。因此,在分析回收率、贫化率的经济意义基础上,提出了盈利因子F的概念,作为统一回收率、贫化率的指标。盈利因子是一个关于(η-ε)的二元函数,与盈利函数f成正比,回收率对经济效益的作用是正向的,而贫化率则相反。以往的研究大多孤立地看待这2个参数,定性地认为回收率越高,贫化率越低,则经济效果越好。在多组回收率、贫化率指标中,很难根据这个定性结论进行评价。盈利因子综合反映了矿石回收率、贫化率与总的经济效益之间的关系函数,将回收率和贫化率整合成一个指标,实现了定量评价各组回收率、贫化率指标的手段,为方案优劣评价提供了有力的理论依据。其推导如下:设废石品位为0,总矿量为A0,放出矿量为A1,放出废石量为A2,每吨纯矿石盈利为M1,每吨废石增加成本为M2,则:

(1)

(1)

(2)

(2)

(3)

(3)

令 ,N为常量,由矿山参数获得,本文根据矿山资料,取N=20。化简式(3)得:

,N为常量,由矿山参数获得,本文根据矿山资料,取N=20。化简式(3)得:

(4)

(4)

(5)

(5)

4.2 优化结果与仿真验证

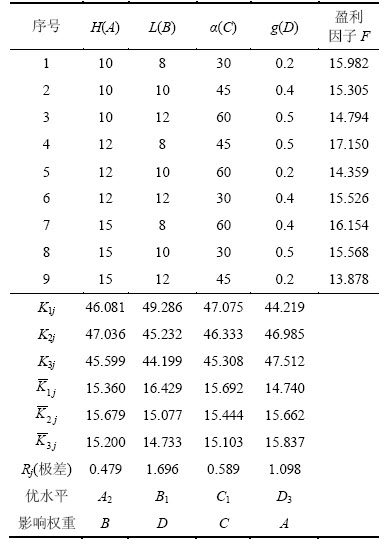

将统计表3中的盈利因子作为衡量放矿效果的指标,与H-L-α-g及其各自水平共同组成正交表,如表4所示,对正交表进行极差分析,

(i=1, 2, 3;j=1, 2, 3, 4) (6)

(i=1, 2, 3;j=1, 2, 3, 4) (6)

(i=1, 2, 3;j=1, 2, 3, 4) (7)

(i=1, 2, 3;j=1, 2, 3, 4) (7)

(8)

(8)

式中:i为水平数;j为因素序数;Kij为第i列中盈利因子之和; 为第i列中盈利因子均值;Rj为第j个因素第1个水平下的盈利因子之和。

为第i列中盈利因子均值;Rj为第j个因素第1个水平下的盈利因子之和。

图4 回收率和贫化率走势图

Fig. 4 Trend of recovery and dilution

经过正交实验极差分析可知:4个因素中,对放出矿石最优效果影响从大到小的顺序为进路间距L、截止贫化率g、崩矿边孔角α、分段高度H。

在已给出的因素和水平中,可得最优组合A2B1C1D3,即:H=12 m,L=8 m,α=30°,g=0.5可以使放出矿石经济效益达到最大,其盈利因子达到了F=17.15(完全回收矿石的情况下,F=20),据此预计最优组合的盈利因子将不低于17.15。为验证预测结果,实验建立了最优组合的放矿模型,通过数值模拟,得出最终回收率η=0.87,ε=0.024 5,盈利因子F=17.38。

优化分析结果表明:缓倾斜中厚矿体崩落法不宜使用大结构参数。在铜坑矿92号矿体+455~+355水平崩落法生产中,建议在现有的结构参数基础上,适当降低结构参数,推荐的参数组合为:H=12 m,L=8 m,α=30°,g=0.5,采用低贫化放矿管理方式,使放出矿石经济效益最大化。

表4 正交实验结果处理

Table 4 Processing results of orthogonal experiment

5 结论

1) PFC2D能有效地应用于矿石流动规律研究,为崩落法放矿规律研究提供了一种方法。在采场结构参数和截止贫化率优化条件下,建立了铜坑矿崩落放矿模型,其影响放矿效果从大到小依次为进路间距、放矿截止贫化率、崩矿边孔角、分段高度。

2) 最优组合H=12 m,L=8 m,α=30°,g=0.5,放矿回收率η1=0.87,贫化率ε1=0.024 5,盈利因子F=17.38。

3) 对于铜坑矿缓倾斜薄矿体崩落开采,采用低贫化放矿方式,适当降低结构参数,有利于提高矿石回收率,降低贫化率。

参考文献:

[1] 张志贵, 刘兴国. 无底柱分段崩落法低贫化放矿: 低贫化放矿理论及其在矿山的实践[M]. 沈阳: 东北大学出版社, 2007: 81-108.

ZHANG Zhigui, LIU Xingguo. Sublevel caving method without dilution ore: No dilution of ore theory and its practice in the mines[M]. Shenyang: Northeastern University Press, 2007: 81-108.

[2] 陶干强, 杨仕教, 任风玉. 随机介质放矿理论散体流动参数试验[J]. 岩石力学与工程学报, 2009, 28(S2): 3465-3469.

TAO Ganqiang, YANG Shijiao, REN Fengyu. Test on granules flow parameters of ore drawing with stochastic medium theory[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(S2): 3465-3469.

[3] 余健. 高分段大间距无底柱分段崩落法贫化损失预测与结构参数优化研究[D]. 长沙: 中南大学资源与安全工程学院, 2007: 58-68.

YU Jian. Dilution and loss prediction and optimization of structural parameters applied to high segmented and large pitched no-pillar sublevel caving method[D]. Changsha: Central South University. School of Resources and Safety Engineering, 2007: 58-68.

[4] 张国联, 宋守志, 邱景平. 无底柱分段崩落法大结构参数实验研究[J]. 中国矿业, 2003(6): 57-59.

ZHANG Guolian, SONG Shouzhi, QIU Jingping. Large structure parameter experimental research on no-pillar sublevel caving[J]. China Mining, 2003(6): 57-59.

[5] 王培涛, 杨天鸿, 柳小波. 无底柱分段崩落法放矿规律的PFC2D模拟仿真[J]. 金属矿山, 2010(8): 123-127.

WANG Peitao, YANG Tianhong, LIU Xiaobo. PFC2D numerical simulation of ore drawing rule with pillarless sublevel caving[J]. Metal Mine, 2010(8): 123-127.

[6] 王培涛, 杨天鸿, 柳小波. 边孔角对无底柱分段崩落法放矿影响的颗粒流数值模拟研究[J]. 金属矿山, 2010(3): 12-16.

WANG Peitao, YANG Tianhong, LIU Xiaobo. Particle flow numerical simulation investigation on influence of lateral opening angle on ore drawing with sublevel pillarless caving[J]. Metal Mine, 2010(3): 12-16.

[7] 徐帅, 安龙. 无底柱分段崩落法多端壁倾角下崩矿步距优化[J]. 东北大学学报(自然科学版), 2012, 33(1): 121-123.

XU Shuai, AN Long. Optimization of caving space for different angles of end-walls during pillarless sublevel caving[J]. Journal of Northeastern University (Natural Science), 2012, 33(1): 121-123.

[8] Brunton I D, Fraser S J, Hodgkinson J H, et al. Parameters influencing full scale sublevel caving material recovery at the Ridgeway gold mine[J]. International Journal of Rock Mechanics and Mining Science, 2010, 47(4): 647-656.

[9] Panczakiewicz T. Optimization of the sublevel caving mining method investigated by physical models[D]. Melbourne: University of Melbourne, 1977: 184.

[10] 吴爱祥, 武力聪. 无底柱分段崩落法结构参数研究[J]. 中南大学学报(自然科学版), 2012,4 3(5): 1846-1850.

WU Aixiang, WU Licong. Study on structural parameters of sublevel caving[J]. Journal of Central South University (Science and Technology), 2012, 43(5): 1846-1850.

[11] Alford C G. Computer simulation models for the gravity flow of ore in sublevel caving[D]. Melbourne: University of Melbourne, 1978: 383.

[12] Bull G, Page C H. Sublevel caving-today’s dependable low cost ore factory[R]. Victoria: Australian Institute of Mining and Metallurgy, 2000: 537-556.

[13] 孙其诚, 王光谦. 颗粒物质力学导论[M]. 北京: 科学出版社, 2009: 74-97.

SUN Qicheng, WANG Guangqian. Introduction of particulate matter mechanics[M]. Beijing: Science Press, 2009: 74-97.

[14] 吕同富, 康兆敏. 数值计算方法[M]. 北京: 清华大学出版社, 2012: 1-3.

L Tongfu, KANG Zhaomin. Numerical methods[M]. Beijing: Tsinghua University Press, 2012: 1-3.

Tongfu, KANG Zhaomin. Numerical methods[M]. Beijing: Tsinghua University Press, 2012: 1-3.

[15] 张志贵. 无底柱分段崩落法结构参数对矿石回收指标的影响研究[J]. 中国矿业, 2003(11): 31-34.

ZHANG Zhigui. Research on the influence of structural parameters of sublevel caving on ore drawing results[J]. China Mining, 2003(11): 31-34.

(编辑 赵俊)

收稿日期:2014-05-25;修回日期:2014-07-30

基金项目(Foundation item):“十二五”国家科技支撑计划项目(2012BAB14B01);中南大学研究生自主创新基金资助项目(2014zzts263) (Project(2012BAB14B01) supported by the National Science and Technology Pillar Program during the 12th ‘Five-year’ Plan Period; Project(2014zzts263) supported by the Graduate Innovation Fund of Central South University)

通信作者:胡建华,博士,副教授,从事高效安全采矿技术与岩土工程稳定性研究;E-mail: hujh21@126.com