文章编号:1004-0609(2009)04-0677-05

Cu对Mg-Zn-Ca合金非晶形成能力与力学性能的影响

邱克强1,王 猛1,张洪兵1,柏笑君1,任英磊1,张 涛2

(1. 沈阳工业大学 材料科学与工程学院,沈阳 110178;

2. 北京航空航天大学 材料科学与工程学院,北京 100083)

摘 要:采用铜模铸造制备直径为3 mm的Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)系列合金。分别采用扫描电镜(SEM)、X射线衍射仪(XRD)、力学性能试验装置研究合金的显微组织、相组成和铸态样品的压缩性能,并对断口形貌进行分析。结果表明:Mg69Zn25Ca5Cu1可以形成直径为3 mm的非晶合金,其强度和塑性应变分别为690 MPa和1.7%。与Mg-Zn-Ca合金相比,其非晶形成能力和塑性应变均有提高。同时这也是目前在直径大于2 mm的Mg基非晶合金中所发现的最大塑性应变量。

关键词:Mg-Zn-Ca合金;Cu;非晶形成能力;力学性能

中图分类号:TB 139 文献标识码:A 文章编号:

Effect of Cu on glass forming ability and mechanical properties of Mg-Zn-Ca alloys

QIU Ke-qiang1, WANG Meng1, ZHANG Hong-bing1, BAI Xiao-jun1, REN Ying-lei1, ZHANG Tao2

(1. School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110178, China;

2. School of Materials Science and Engineering, Beijing University of Aeronautics and Astronautics, Beijing 100083, China)

Abstract: Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5) as-cast alloys with 3 mm in diameter were produced by using copper mold casting method. The microstructures, phase constitutes and mechanical properties of as-cast samples were investigated by scanning electron microscopy (SEM), X-ray diffractometry (XRD) and compression tester. The fracture surfaces were also analyzed by SEM. The results show that the critical sample size for glass formation, the fracture strength and the plastic strain of Mg69Zn25Ca5Cu1 alloy are 3 mm in diameter, 690 MPa and 1.7%, respectively. Both of the glass forming ability and the plastic deformation are improved obviously compared with Mg-Zn-Ca alloys. Up to now the plastic strain is the largest one in the samples with diameter larger than 2 mm for Mg-based bulk metallic glasses.

Key words: Mg-Zn-Ca alloy; Cu; glass forming ability; mechanical properties

高比强度轻质材料通常被认为是航空航天、节能降耗等领域优先选用的重要材料。Mg基非晶合金的高比强度在工程上有重要的应用前景。因此,自1991年发现具有代表性的Mg65Cu25Y10[1]块体非晶合金(BMG)以来,人们投入大量的精力研究与开发块体Mg基非晶合金。目前已经在 Mg-Cu-RE (RE=Y, Gd, Nd, Tb, Dy)[2-4]、Mg-Ni-RE[5]和Mg-Zn-Ca[6-7]等合金体系发现Mg基 BMGs,同时一些提高非晶形成能力或热稳定性的合金化元素,如Ag[8]、Zn[9]、Ni[10]等被先后采用。这些元素在Mg-Cu-RE合金体系中发挥了重要的作用,由此制备出直径尺寸达到16~25 mm[8]的BMGs。然而这些非晶合金在室温下的力学性能很差,主要表现为:当样品尺寸大于2 mm时,这些非晶合金表现为脆性断裂,没有任何塑性,甚至在弹性变形范围内,由于缺陷引起的裂纹敏感性,造成材料的强度几乎没有再现性。因此这种材料在工程上的应用是不可能的。如果Mg基非晶合金的强度具有可靠性或具有一定的韧性,有可能将其应用于商业上。因此,很多研究者致力于改善Mg基非晶合金的韧性或提高材料强度的可靠性。本文作者在系统研究了Mg-Zn-Ca[7]非晶的基础上,设计Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)合金,通过改变元素Cu的含量以寻找更高强度和塑性的非晶合金。

1 实验

本试验采用纯度为99.9%Mg、Zn、Ca 和Cu为原料,按设计成分进行配比,在高纯氩气保护条件下,利用感应炉熔化方法,制备Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)母合金。采用感应加热的方法,使用喷铸技术将合金浇入铜模中,制成直径为3 mm的试样。采用万能材料试验机在室温、应变速率为1×10-4/s条件下,对直径为3 mm、高为6 mm的合金试样进行压缩实验。为了能较准确地反应合金的力学性能,每一种成分的合金至少做5次压缩实验。采用S-3400N型扫描电镜对试样进行组织分析和断口形貌观察,采用X射线衍射(XRD)分析样品的相组成,利用阿基米德方法分析合金的密度。

2 结果与分析

2.1 样品微观组织的SEM分析

图1所示为Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)系列合金的SEM像。从图1(a)中可以看出,Mg69Zn25Ca5Cu1铸态合金组织为典型的非晶合金特征组织。对比图1(a)可以看出,合金Mg68Zn25Ca5Cu2组织发生了明显的变化,开始出现组织特征,有些特征组织从基体中剥落,形成小坑(见图1(b))。而在图1(c)中,特征组织和组织剥落所造成的小坑数量减少,同时出现了一种细小的花瓣状组织。当Cu含量增加到5%时,显微组织(见图1(d))发生了明显的改变,小凹坑已经完全消失,而在非晶基体相上均匀分布着大量的晶体颗粒,这些晶体颗粒在试样的表面密集存在,甚至开始转变成片状分布,其颗粒尺寸一般为1~2 ?m。

图1 Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)合金的SEM像

Fig.1 SEM images of Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5) as-cast alloys: (a) Mg69Zn25Ca5Cu1; (b) Mg68Zn25Ca5Cu2; (c) Mg66.5Zn25Ca5Cu3.5; (d) Mg65Zn25Ca5Cu5

2.2 XRD谱分析

图2所示为直径为3 mm的Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)合金的XRD谱。从图2中可以看出,在2θ=30?~45?处,Mg69Zn25Ca5Cu1的XRD谱呈现典型的非晶态漫反射馒头峰,无明显的晶态相衍射峰,这说明其组织是由非晶相组成。结合SEM观察结果,进一步确定直径为3 mm的Mg69Zn25Ca5Cu1合金是完全非晶态结构。当Cu含量(摩尔分数)增至2%时,它的漫反射峰上存在少许晶态衍射峰,说明在非晶基体上有晶态相析出,经分析为Mg和CaCu相,但衍射峰强度不高,说明晶态相含量不多,其组织为非晶和少量晶态相的混合组织;在Cu含量为3.5%时,衍射峰强度有所下降。这说明,随着Cu含量的升高,组织中非晶成分增加;但当Cu含量达到5%时,晶态峰又重新出现,但与Cu含量为2%时晶态峰所出现位置并不相同,说明所形成的是两种完全不同的晶态相,经分析此时产生的晶态相为Cu0.64Zn0.36和CuMgZn相。这与组织照片上所观察到的现象是相符合的。

图2 Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)合金XRD谱

Fig.2 XRD patterns for Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5) as-cast alloys with 3 mm in diameter

2.3 力学性能和断口分析

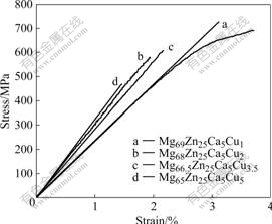

图3所示为Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)合金准静态压缩曲线。从图3中可以看出,直径3 mm的Mg69Zn25Ca5Cu1合金具有较大的塑性,其塑性变形量ep可以达到1.7%,这是目前在直径为2 mm以上的Mg基块体非晶合金中所发现的最大塑性应变。Mg66.5Zn25Ca5Cu3.5的塑性变形量为0.16%,其他两种合金都几乎没有任何塑性应变。合金Mg69Zn25Ca5Cu1的断裂强度σf也是最高的,达到了690 MPa,其次是Mg66.5Zn25Ca5Cu3.5合金,其断裂强度为610 MPa。而Mg68Zn25Ca5Cu2 和Mg65Zn25Ca5Cu5的断裂强度则分别只有581和481 MPa。

图3 Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)铸态合金的应力—应变曲线

Fig.3 Stress-strain curves of Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5) as-cast alloys with 3 mm in diameter

表1所列为Mg69Zn25Ca5Cu1和几种Mg-Zn-Ca合金的力学性能及比强度σf/ρ的对比,文献[7, 11]中试样直径D均为2 mm。由表1可看出,随着Cu元素的加入,合金的非晶形成能力得到提高(Mg70Zn25Ca5合金的临界非晶形成尺寸为直径2 mm[7]),同时断裂强度及韧性都得到明显的改善。Mg69Zn25Ca5Cu1非晶合金具有较高的比强度。但随着Cu含量的进一步增多,在非晶基体上开始有少量的晶态相出现,从而降低了非晶合金的强度和塑性。

表1 Mg69Zn25Ca5Cu1和几种Mg-Zn-Ca合金的力学性能

Table 1 Mechanical properties of Mg69Zn25Ca5Cu1 and several Mg-Zn-Ca alloys

图4 Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)合金的断口形貌

Fig.4 Fracture morphologies of Mg70-xZn25Ca5Cux as-cast alloys: (a) x=1; (b) x=2; (c) x=3.5; (d) x=5

图4所示为Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5)合金的断口形貌。从图4中可以看出,当合金中Cu含量为1%时,合金的断口有明显的脉络纹出现,在外力的作用下沿脉纹方向断裂,显示出韧性断裂特征(见图4(a));当Cu含量增加到2%时,合金断口显示出脆性断裂特征(见图4(b));当合金中Cu含量达到3.5%时,在断口上可以清晰地看到具有类似于脉络纹的条纹存在,与脆性断口的条状纹有明显的差别,因此该成分的合金具有一定的塑性。同时可以看到,在断口表面上出现了大量的颗粒相,这与前面SEM对组织的观察结果是一致的;当Cu含量为5%时,合金显示出非晶与晶态相的混合断口,表现为脆性断裂特征。

合金元素Ni和Cu的影响,在Mg-TM-RE(TM为过渡族金属,RE为Y或镧系稀土元素)非晶合金中已经报道[8, 10, 12],但关于过渡族金属在Mg-Zn-Ca合金体系的研究还没有见到报道。由本研究可以看到,过渡族金属在Mg-Zn-Ca合金体系的作用非常明显,但仅限于微合金化的作用。作者在Mg-Zn-Ca-Cu合金体系中曾进行过大量研究,发现在Cu含量和Ca含量大于5%时,即使有一定的非晶形成能力,性能也非常差。因此可以说明过渡族金属仅限于微合金化的作用。由于Mg元素的碱土金属性质以及密排六方体结构的原因[8],其非晶合金在很多体系中表现出脆性,甚至不能获得可靠的力学性能数据,因此提高合金的韧性显得非常重要。在以往的Mg基非晶合金中,塑性变形只能在直径小于2 mm的样品中发现,并且在已发表的文献中,所发现的最大应变量也只有1.28%[7],本实验在直径为3 mm的Mg69Zn25Ca5Cu1非晶合金中发现了其塑性应变为1.7%,这可以说是Mg基非晶合金塑性变形研究中的一个重要进展。本研究也说明,通过寻找合适的微合金化元素,可以达到改善非晶合金韧性的目的。

3 结论

1) 研究了Mg70-xZn25Ca5Cux(x=1, 2, 3.5, 5) 合金的非晶形成能力与力学性能。

2) 当x=1时,合金的非晶形成能力可以达到直径3 mm,压缩强度和塑性应变量分别为690 MPa 和1.7%。此塑性应变量是目前所发现的大尺寸Mg基非晶合金中的最大塑性应变量。

REFERENCES

[1] INOUE A, NAKAMURA T, NISHIYAMA N, MASUMOTO T, Mg-Cu-Y bulk amorphous alloys with high tensile strength produced by a high-pressure die casting method[J]. Materials Transactions JIM, 1992, 33(10): 937-945.

[2] MA H, ZHENG Q, XU J, LI Y, MA E. Doubling the critical size for bulk metallic glass formation in the Mg-Cu-Y ternary system [J]. Journal of Materials Research, 2005, 20(9): 2252-2255.

[3] MEN H, KIM D H. Fabrication of ternary Mg-Cu-Gd bulk metallic glass with high glass-forming ability under air atmosphere[J]. Journal of Materials Research, 2003, 18(7): 1502-1504.

[4] XI X K, WANG R J, ZHAO D Q, PAN M X, WANG W H. Glass-forming Mg-Cu-RE (RE=Gd, Pr, Nd, Tb, Y, and Dy) alloys with strong oxygen resistance in manufacturability[J]. Journal Non-Crystalline Solids, 2004, 344: 105-109.

[5] LI Y, NG S C, ONG C K. New amorphous alloys with high strength and good ductility in the Mg-Ni-Nd system [J]. Journal of Materials Processing Technology, 1995, 48: 489-493.

[6] GU X, SHIFLET G J, GUO F Q, POON S J. Mg-Ca-Zn bulk metallic glasses with high strength and significant ductility[J]. Journal of Materials Research, 2005, 20 (8): 1935-1938.

[7] LI Q F, WENG H R, SUO Z Y, REN Y L, YUAN X G, QIU K Q. Microstructure and mechanical properties of bulk Mg–Zn–Ca amorphous alloys and amorphous matrix composites[J]. Mater Sci Eng A, 2008, 487: 301-308.

[8] MA H, SHI L L, XU J, LI Y, MA E. Discovering inch-diameter metallic glasses in three-dimensional composition space[J]. Applied Physics Letters, 2005, 87: 181915.

[9] MEN H, HU Z Q, XU J. Bulk metallic glass formation in the Mg-Cu-Zn-Y system[J]. Scripta Materialia, 2002, 46(10): 699-703.

[10] REN Y L, ZUO J H, QIU K Q, ZHANG H F, HU Z Q. Eutectic structure and bulk glass formation in Mg-based alloys[J]. Intermetallics, 2004, 12: 1205-1209.

[11] 翁慧茹, 任英磊, 刘云秋, 邱克强. 超高强度铸造镁合金的研究[J]. 特种铸造及有色合金, 2008, 28(1): 71-73.

WENG Hui-ru, REN Ying-lei, LIU Yun-qiu, QIU Ke-qiang. Super-high strength as-cast magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2006, 28(1): 71-73.

[12] 张青绒, 李金山, 王一川, 寇宏超, 胡 锐, 周 廉, 傅恒志. Ni对Mg-Cu-Tb非晶合金形成及力学性能的影响[J]. 中国有色金属学报, 2007, 17(2): 303-307.

ZHANG Qing-rong, LI Jin-shan, WANG Yi-chuan, KOU Hong-chao, HU Rui, ZHOU Lian, FU Heng-zhi. Effect of substitution of Ni for Cu on glass-forming ability and mechanical properties of Mg-Cu-Tb metallic glass alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 303-307.

基金项目:国家重点基础研究发展计划资助项目(2007CB613900);沈阳市科技局基础研究资助项目(1071112-2-00)

收稿日期:2008-09-28;修订日期:2008-12-20

通讯作者:邱克强,教授,博士;电话:024-25496020;E-mail: kqqiu@yahoo.com.cn

(编辑 何学锋)