文章编号:1004-0609(2015)-01-0009-06

热工艺参数对TC17合金静态球化动力学的影响

孙 新1,曾卫东1,张志金2,贾志强1,徐建伟1

(1. 西北工业大学 凝固技术国家重点实验室,西安 710072;

2. 北京航空制造工程研究所,北京 100024)

摘 要:对TC17合金在820和860 ℃下进行等温锻造,随后在相同温度下进行热处理10 min~8 h,利用定量金相法研究变形量、热处理温度等工艺参数对片状α相静态球化的影响规律。结果表明:随着变形量的增加,在随后热处理过程中片状α相更容易发生晶界分离而形成球化组织,球化速率明显提高。温度影响扩散过程,对静态球化有促进作用,且在应变较低时影响更为明显。在球化率随热处理时间增大的同时,球化速率逐渐减小至常值,JMAK方程可以用来描述TC17合金静态球化的规律。

关键字:TC17合金;静态球化;等温锻造;热处理

中图分类号:TG146.2 文献标志码:A

Effect of thermal processing parameters on static globularization kinetics of TC17 alloy

SUN Xin1, ZENG Wei-dong1, ZHANG Zhi-jin2, JIA Zhi-qiang1, XU Jian-wei1

(1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. Beijing Institute of Aviation Manufacturing Engineering, Beijing 100024, China)

Abstract: The isothermal compression of TC17 alloy at 820 and 860 ℃, and subsequently annealing for 10 min-8 h were conducted, and the effects of deformation degree, annealing temperature and annealing time on static globularization of TC17 titanium alloy were investigated. The results show that the deformation degree greatly influences the boundary splitting, so that the static globularization kinetics of α phase increases with increasing deformation degrees. As a thermally activated process, the diffusivity of solutes is determined by annealing temperature. Thus, the static globularization can be accelerated by increasing the temperature, especially when the strain is low. Meanwhile, globularization ratio increases while static globularization kinetics decrease to a constant with increasing the annealing time. The JMAK equation can be used to describe the static globularization kinetics.

Key words: TC17 titanium alloy; static globularization; isothermal compression; heat treatment

片状组织球化是制造双性能整体叶盘的核心技术[1-2],其研究已在国内外广泛展开。目前,片状组织球化分为动态与静态球化两个方面,在动态球化方面国内外学者已经进行了广泛的研究[3-7],研究表明,获取钛合金完全动态球化的微观组织往往需要较高的应变。王凯旋等[4]研究Ti-17合金动态球化时,发现当应变达到1.34~5.36时片状组织才能完全动态球化,吴成宝等[7]在研究TA15合金热变形行为时也得出获得完全TA15合金球化组织需要应变为3.4~6.8。如此高的应变水平在钛合金热加工中很难实现。因此,后续的热处理使其发生静态球化是获得双性能整体叶盘必不可少的关键环节,是国内外学者关注的焦点之一。STEFANSSON等[8-9]分别对Ti-6Al-4V合金的静态球化动力学与机理问题展开了研究,他们认为变形引起的位错亚结构对静态球化影响很小,而热处理温度可以大大促进静态球化;CHEN等[10]研究了TC11合金的静态球化行为,认为静态球化过程包括β相的动态再结晶、α相的静态回复以及随后的球化与晶粒粗化。

TC17钛合金[1]具有高强度、高韧性和高淬透性,是制造双性能整体叶盘的备选材料之一,但对其静态球化规律还鲜见报道。此外,国内外目前研究片状组织球化普遍采用热模拟压缩试验,试样尺寸小,与实际情况有所差异。因此,本文作者拟采用8个d 75 mm×180 mm的TC17合金棒材,在820和860 ℃下进行等温镦饼试验,随后分别在锻造相同的温度下进行不同时间的热处理,以研究不同的变形程度、热处理温度以及时间等工艺参数对片状α相静态球化的影响规律。研究结果对制造双性能整体压气机叶盘具有重要意义。

1 实验

本实验中材料是由宝钢股份有限公司特殊钢分公司提供的d 75 mm的TC17钛合金棒材。其化学成分为(质量分数,%)5.12 Al、2.03 Sn、2.10 Zr、4.04 Mo、3.94 Cr、0.10 Fe、0.012 C、0.007 N、0.007 H、0.12 O、余量为Ti,采用金相法测定其相变温度为893 ℃。

将d 75 mm的棒材截成8个d 75 mm×180 mm的圆柱,在2000T压力机上进行等温锻造。等温锻造分为两步,首先在相变点以上30 ℃的β单相区变形50%,以获得网篮交错分布的片状组织,然后在两相区变形,促使片状组织球化。锻造温度为820和860 ℃,变形量分别为20%、40%、60%和80%。等温锻造后进行静态球化热处理试验,热处理温度与锻造温度相同,热处理时间分别为10 min、30 min、1 h、2 h、4 h和8 h,处理后水冷以保持其高温组织。由于镦粗过程中摩擦和金属不均匀流动的影响,镦粗后圆饼的各部分应变不同,为了保证每个圆饼上取出的试样初始应变相同,热处理试样均在圆饼截面1/2R处沿弦向切取,试样尺寸为10 mm×15 mm×20 mm,采用DEFORM-3D软件计算出不同变形量下所取试样位置的等效应变分别为0.28、0.55、1.05和1.30。采用JSM×6390扫描电镜观察热处理后的高倍组织纵截面,显微组织参数定量分析采用Image-pro plus 5.0图像分析软件。为了保证测量的准确性,每个试样选取6张照片进行显微组织参数的计算并取其平均值。根据王杨等[11]的研究结果,本实验中将片状α的长宽比(Feret ratio)≤2.5定义为球化组织。

2 结果与分析

2.1 TC17钛合金静态球化微观组织演变规律

图1 820 ℃下等效应变为0.55不同热处理时间的显微组织

Fig. 1 Microstructures developed after deformation to nominal strain of 0.55 and annealing at 820 ℃ for forging state (a), 30 min (b), 2 h (c), 8 h (d), then water quenched

由于本试验包含了多种热工艺参数的组合,为简化起见,只选取其中一组典型的组织进行分析。图1所示为820 ℃、变形量40%等温锻造后在820 ℃热处理不同时间的微观组织。从图1可以看出,热加工及后续的热处理对显微组织球化过程的影响十分显著。

由图1(a)可知,试样经历β区等温锻造后,原始网篮交错分布的片状组织仍然含有大量的长条α相,只有一小部分α相被球化,说明此时的动态球化率较低。同时α-β界面基本保持平滑,但部分α相发生了弯折或扭转(见图1(a)箭头所指)。这种弯折或扭转在后续热处理过程中可以大大促使片层组织的断裂,从而形成球化组织。热处理30 min的微观组织(见图1(b))中较大长宽比的α相相对减少,球化率已提高至18.3%,同时,热开槽的出现(见图1(b)箭头所指)可以进一步促进组织球化,所谓热开槽就是指在β相向α相锲入这种条件下由于保持界面能平衡而在α相上形成的沟槽,也正是由于这个原因,热开槽在扩散作用下容易发生界面迁移[1]并促使α片层组织断裂。热处理2 h后(见图1(c)),受扩散因素的影响,α相体积分数下降且厚度增大,平均长宽比变小,热开槽数量进一步增加,球化率大大提高。当热处理时间达到8 h(见图1(d)),长宽比进一步减小,α相组织变得更少,组织均匀化程度大大提高。随着α相进一步粗化,片层组织最终完全球化。

进一步分析SEM像发现:对于其他应变水平下的微观组织变化也有类似的结论,只不过不同应变下获得上述相似的微观组织热处理时间不同,应变较高的热处理时间更短,同理,应变较低的热处理时间更长。经860 ℃热处理的组织变化规律与820 ℃的类似,但球化过程快得多。

2.2 变形量对α相静态球化的影响

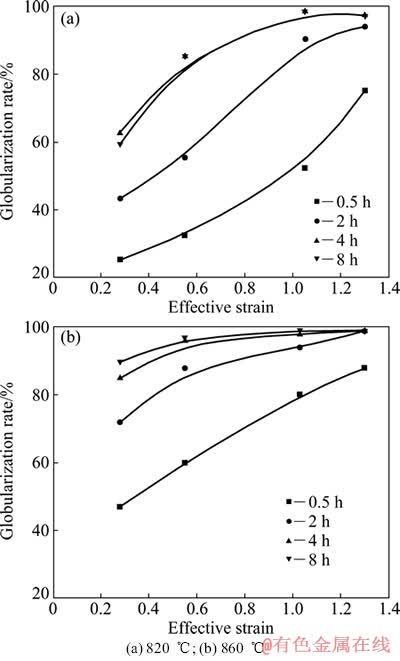

图2所示为不同温度及热处理时间下应变对球化率的影响。由图2可知,变形量对TC17合金后续静态球化至关重要。变形量越大,则球化速率越大。例如,820 ℃下等效应变为0.28的试样热处理2 h的球化率为43.3%,而同样热处理时间、局部应变为1.30的试样球化率却高达97.8%。另一方面,从图2中的曲线可以观察到,随着应变增加,位于图中下方的曲线球化分数的增加更大,也就是说热处理时间越短,静态球化率随应变的增加越明显,说明在热处理初期变形量对静态球化的影响更大。这种现象在860 ℃下尤其明显,当应变从0.28增加到1.30时,热处理0.5 h的试样球化率增加约40%,而热处理8 h的试样球化率增加不到10%。

等温锻造后,由于变形存储了大量的能量,很大程度上影响了热处理前期的α相晶界分离过程,因为驱使静态球化的亚结构的形成需要由变形提供能量,事实上已有研究表明晶界分离在很大程度上依赖于晶粒内部界面的错位取向[12-13]。虽然位错亚结构或者小角度晶界可以在较低应变水平下形成,但是大角度晶界所占比例却是跟随应变增加而增加,其中在晶界分离过程中起主要作用的是拥有更高能量的大角度晶界。另一方面,大角度晶界处往往位错密度较高,聚集较高的畸变能,这些能量会在高温的作用下快速释放,使片状α发生分离。而在低应变水平下,变形本身的不均匀性会使得某些α相晶粒应变极低,故这些晶粒没有获得用来驱动静态球化的能量,这大大减缓了静态球化过程。

图2 不同热处理条件下有效应变对球化率的影响

Fig. 2 Effect of effective strain on globularization rate under different heat-treatment conditions

2.3 热处理温度对TC17合金静态球化的影响

不同温度及应变下球化率随时间的变化由图3可知,热处理温度也是影响TC17合金静态球化的一个重要参数,且对球化起促进作用。不同热处理温度下球化率的变化规律基本一致,即球化率逐渐增加,球化速率逐渐下降至趋于常值的过程。然而,温度较高时明显地球化速率更高,如等效应变为0.55的试样在两种温度热处理1 h后球化率相差近40%,等效应变0.28的试样860 ℃热处理8 h后可以完全球化,而在820 ℃热处理同样时间的试样球化率仅为63%。STEFANSSON等[9]在研究Ti-6Al-4V时发现,热处理温度从900 ℃到提高到955 ℃的过程中,其球化速率提高了10倍左右。静态球化的两种经典机制(晶界分离与组织粗化)均主要受扩散影响,而扩散作为一个热激活过程通常能被温度控制,同时,静态球化本身也与静态再结晶和溶质析出过程相似,而这种过程均主要受温度影响[14]。

从图3还可以看出,低应变下温度对TC17合金静态球化过程的影响更为明显。尽管应变比温度对形成错位晶界更具影响,但能量的释放却更受温度的控制。当应变较低时,动态球化过程中积累的能量还不足以使得α相扭转或者弯曲至断裂,这时后续的热处理便必须继续提供更高能量才能促其继续断裂并发生球化。而恰恰在热处理的前期,高温可以促进热激活过程,且温度越高提供的能量也越充足,也就是说在热变形后下已发生扭转或者弯曲的α相在820℃热处理下还不能断裂,而在860℃热处理下便可以发生断裂,并最终变成球化组织。

2.4 TC17合金静态球化动力学方程

合金的球化分数随着时间变化的规律具有指导实际生产的意义。通过以上分析,TC17合金片状组织静态球化过程大致可分为两个过程:片状组织分离和组织粗化。这与传统静态再结晶的形核与长大过程非常类似,这也是为什么静态球化可以被看作一种特殊的静态再结晶的原因。因此,可以借鉴静态再结晶的动力学模型来建立静态球化的动力学方程。对于静态再结晶,Johnson-Mehl-Avrami-Kolmogorov(JMAK)模型已经被广泛应用描述再结晶分数随热处理时间的变化规律[14-15]。并且该模型也被FAN等[16]成功用于TA15钛合金的静态球化动力学。对于本文作者研究的TC17钛合金,也可以通过JMAK模型来建立静态球化动力学方程:

(1)

(1)

式(1)即简化的JMAK方程。式中:X为静态球化分数,t为热处理时间,k为与晶粒分离和粗化有关的系数,n是Avrami指数。使用JMAK方程拟合实验值,拟合曲线如图4所示。可以看出,JMAK方程能够较好地描述TC17合金的球化规律,方程相关性平均达到90%以上,特别是820℃下等效应变为0.55的试样其相关性为98.48%,这说明JMAK方程可以用来描述TC17合金片状组织静态球化的规律。但同时必须指出的是,静态球化过程是一个非常复杂的组织演变过程,通过一个简单的公式是无法准确地描述这一复杂过程的,仅仅能够给出一个相对可靠地现象性描述。

图3 不同温度及应变时球化率与时间的关系

Fig. 3 Relationship between annealing time and globularization rate at different temperatures and strains

图4 球化率随时间变化的JMAK拟合曲线

Fig. 4 Predicted curves of globalarized fraction by JMAK equation

3 结论

1) 变形量影响着晶界分离从而影响静态球化。随着变形量提高,热处理前期的球化速率大大增加。由于变形量太大加工过程难以实现,根据分析确定变形量在40%~60%区间时,更有利于TC17静态球化。

2) 热温度影响扩散过程,从而可以促进TC17合金静态球化过程,特别是在应变较低时更为明显。考虑到热处理温度过高球化组织粗化明显,这不利于提高其力学性能,故确定热处理温度不应超过860 ℃。

3) JMAK方程可以描述TC17合金静态球化的过程,且球化率随热处理时间增大而增大的同时,球化速率却逐渐减小,并根据数据结果可以确定820 ℃下热处理4 h或者860 ℃下热处理2 h便可获得良好的球化组织。

REFERENCES

[1] 周 军. Ti-17钛合金片状组织球化规律研究[D]. 西安: 西北工业大学, 2005: 5-6.

ZHOU Jun. Globularized evolution on Ti-17 titanium alloy with initial lamellar microstructure[D]. Xi’an: Northwestern Polytechnical University, 2005: 5-6.

[2] 郭鸿镇, 姚泽坤, 虢迎光, 刘广义, 李园春. 等温精密锻造技术的研究进展[J]. 中国有色金属学报, 2010, 20(S1): s570-s576.

GUO Hong-zhen, YAO Ze-kun, GUO Ying-guang, LIU Guang-yi, LI Yuan-chun. Research progress of isothermal precision forging technology[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s570-s576.

[3] MA Xiong, ZENG Wei-dong, TIAN Fei, ZHOU Yi-gang. The kinetics of dynamic globularization during hot working of a two phase titanium alloy with starting lamellar microstructure[J]. Materials Science and Engineering A, 2012, 548(30): 6-11.

[4] WANG Kai-xuan, ZENG Wei-dong, ZHAO Yong-qing, LAI Yun-jin. Dynamic globularization kinetics during hot working of Ti-17 alloy with initial lamellar microstructure[J]. Materials Science and Engineering A, 2010, 527(10/11): 2559-2566.

[5] SEMIATIN S L, SEETHARAMAN V, WEISS I. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure[J]. Materials Science and Engineering A, 1999, 263(2): 257-271.

[6] PARK Chan-hee, KO Yang-gun, PARKC Jin-woo, LEE Chong-soo. Enhanced superplasticity utilizing dynamic globularization of Ti-6Al-4V alloy[J]. Materials Science and Engineering A, 2008, 496(1/2): 150-158.

[7] 吴成宝, 杨 合, 孙志超, 樊晓光. 片层组织TA15钛合金的热变形行为及组织球化[J]. 中国有色金属学报, 2010, 20(S1): s94-s98.

WU Cheng-bao, YANG He, SUN Zhi-chao, FAN Xiao-guang. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s94-s98.

[8] STEFANSSON N, SEMIATIN S L, EYLON D. The kinetics of static globularization of Ti-6Al-4V[J]. Metallurgical and Materials Transactions A, 2002, 33(11): 3527-3534.

[9] STEFANSSON N, SEMIATIN S L. Mechanisms of globularization of Ti-6Al-4V during static heat treatment[J]. Metallurgical and Materials Transactions A, 2003, 34(3): 691-698.

[10] CHEN Hui-qin, CAO Chun-xiao. Static globularization of TC11 alloy during hot working process[J]. Rare Metal Materials and Engineering, 2011, 40(6): 0946-0950.

[11] 王 洋, 曾卫东, 马 雄, 周建华, 王晓英, 王 腾. BT25钛合金在两相区变形过程中的显微组织定量分析[J]. 中国有色金属学报. 2013, 23(7): 1861-1865.

WANG Yang, ZENG Wei-dong, MA Xiong, ZHOU Jian-hua, WANG Xiao-ying, WANG Teng. Quantitative metallographic analysis of microstructure of BT25 titanium alloy deformed in two-phase field[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1861-1865.

[12] SALISHCHEV G A, ZEREBTSOV S V, MIRONOV S Y, SEMIATIN S L. Formation of grain boundary misorientation spectrum in alpha-beta titanium alloys with lamellar structure under warm and hot working[J]. Materials Science Forum, 2004, 467/470: 501-506.

[13] BIELER T R, SEMIATIN S L. The origins of heterogeneous deformation during primary hot working of Ti-6Al-4V[J]. International Journal of Plasticity, 2002, 18(9): 1165-1189.

[14] SEMIATIN S L, SUKONNIC I M, SEETHARAMAN V. An analysis of static recrystallization during continuous rapid heat treatment[J]. Metallurgy and Materials Transactions A, 1996, 27(7): 2051-2053.

[15] CHUN Y B, SEMIATIN S L, HWANG S K. Monte Carlo modeling of microstructure evolution during the static recrystallization of cold-rolled, commercial-purity titanium[J]. Acta Materialia, 2006, 54(14): 3673-3689.

[16] FAN Xiao-guang, YANG He, GAO Peng-fei. Mechanism and kinetics of static globularization in TA15 titanium alloy with transformed structure[J]. Journal of Alloys and Compounds, 2012, 533(25): 1-8.

(编辑 龙怀中)

基金项目:新世纪优秀人才计划资助项目(NCET-07-0696);教育部博士点基金资助项目(20136102110034)

收稿日期:2014-05-28;修订日期:2014-09-11

通信作者:曾卫东,教授,博士;电话:029-88494298;E-mail:zengwd@nwpu.edu.cn