42CrMo钢形变奥氏体的静态再结晶

蔺永诚1, 2,陈明松1, 2,钟 掘1, 2

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 中南大学 现代复杂装备设计与极端制造教育部重点实验室,湖南 长沙,410083)

摘 要:利用双道次热压缩的方法,在Gleeble-1500热模拟实验机上研究42CrMo钢在高温变形道次间隔时间内的静态软化行为。讨论变形温度、应变速率、变形程度与初始奥氏体晶粒尺寸对其静态再结晶行为的影响。根据实验结果,建立42CrMo钢静态再结晶动力学模型,相应的静态再结晶激活能约为187.68 kJ/mol。结果表明:变形程度对42CrMo钢的静态再结晶影响最大,变形温度和应变速率次之,初始奥氏体晶粒尺寸对其影响较小;在变形温度较低(850 ℃)时,随着道次间隔时间的增加,静态再结晶分数逐渐趋于稳定(约为0.4),这是因为在变形温度较低时,道次间不能发生完全的静态再结晶。在变形程度较小、道次间隔时间较短时,几乎不发生静态再结晶。将静态再结晶动力学模型的预测结果与实验结果进行比较,二者较吻合。

关键词:42CrMo钢;静态再结晶;静态软化;双道次热压缩试验

中图分类号:TG142.33 文献标识码:A 文章编号:1672-7207(2009)02-0411-06

Static recrystallization behaviors of deformed 42CrMo steel

LIN Yong-cheng1, 2, CHEN Ming-song1, 2, ZHONG Jue1, 2

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Modern Complex Equipment Design and Extreme Manufacturing, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The static recrystallization behaviors in 42CrMo steel were investigated by two-pass hot compression tests on Gleeble-1500 thermo-simulation machine. The effects of deformation temperature, strain rate, deformation degree, and initial austenite grain size on the static recrystallization behaviors were studied. Based on experimental results, the kinetic equations for the static recrystallization behaviors of 42CrMo steel were proposed with the activation energy of 187.68 kJ/mol. The Results indicate that the effect of deformation degree on the static softening is significant, while that of the initial austenitic grain size is slight. With the increase of the inter-pass time, the static recrystallization fraction falls into a stable value (about 0.4) when the deformation temperature is 850 ℃. This indicates that the incomplete static recrystallization occurs when the deformation temperature is relatively low. A good agreement between the experimental and predicted results show that the proposed kinetic equations can give an accurate estimation of the static softening behaviors for hot deformed 42CrMo steel.

Key words: 42CrMo steel; static recrystallization; softening fraction; two-pass hot deformation experiments

在热变形过程中,当所施加的应变量达到动态再结晶临界应变εc时开始发生动态再结晶,发生动态再结晶的部分组织在随后的间隙时间里将发生亚动态回复、亚动态再结晶,没有发生动态再结晶部分组织在间隙时间里会发生静态回复、静态再结晶,将直接影响加工后工件的内部质量。因此,研究材料热成形间隙时间里的再结晶规律,是对材料热加工组织性能进行模拟,优化生产工艺的重要基础工作。自20世纪60年代以来,国内外学者对钢和铝合金在变形过程中的动态回复及动态再结晶、静态回复及再结晶与亚动态再结晶规律进行了大量的研究。近年来,人们针对新钢种和铝合金的静态再结晶规律和亚动态再结晶规律的研究仍很多。研究表明,静态再结晶和亚动态再结晶的规律有很大不同,前者受变形量影响较大,后者基本不受变形量的影响[1-5]。因此,应分别研究静态及亚动态再结晶的动力学规律。

42CrMo钢是一种中碳合金结构钢,广泛应用于强度要求高,断面尺寸较大的构件。目前,国内外对其进行的研究主要集中在42CrMo钢的热处理工艺、抗疲劳、耐腐蚀性能、流变行为和动态回复及再结晶行为等方面,还未见对其热成形过程中静态再结晶与亚动态再结晶的研究报道[6-10]。在自由锻造与热轧加工过程中,需要通过控制工艺参数来控制产品的最终微观组织。因而,研究42CrMo钢在热变形后保温时间里的静态再结晶及亚动态再结晶规律对制定其热成形工艺是十分必要的。在此,本文作者主要通过双道次的热模拟实验,研究42CrMo钢在道次间隔时间里的静态软化规律。

1 实 验

试样所用的材料为工业用的42CrMo钢,其化学成分如表1所示。

表1 42CrMo钢的主要化学成分

Table 1 Main chemical composition of 42CrMo steel w/%

按模拟实验要求将材料加工成直径×长度为 10 mm×15 mm的Rastegaev型试样。圆柱体试样两端车有0.2 mm深的凹槽以减小试样与实验机压头的摩擦,使热压缩变形过程试样变形均匀。双道次压缩实验在Gleeble-1500热模拟机上进行,压缩过程中圆柱体两端的凹槽内填充润滑剂(75%石墨+20%机油+5%硝酸三甲苯酯),以减少摩擦对应力状态的影响。 双道次压缩实验分为4部分:

a. 考虑变形温度的影响。各次压缩的应变速率均为0.1 s-1,变形温度分别为850,950和1 050 ℃,第1道次的变形量为15%,道次间隔时间分别为1,5,10,30和100 s。

b. 考虑应变速率的影响。各次压缩的变形温度均为1 050 ℃,应变速率分别为0.01,0.1,0.5和1 s-1,第1道次的变形量也为15%,道次间隔时间分别为5,10和100 s。

c. 考虑变形量的影响。各次压缩的变形温度均为1 050 ℃,应变速率均为0.1 s-1,第1道次的变形量分别为5%,10%与15%,道次间隔时间分别为1,5,10,30和100 s。

d. 考虑初始晶粒尺寸的影响。先加热试样至不同的温度1 050,1 150和1 200 ℃,保温一段时间,以得到不同的初始奥氏体晶粒尺寸54,104和155 μm,然后,降至变形温度950 ℃,压缩时应变速率为0.1 s-1,第1道次的变形量为15%,道次间隔时间分别为1,5,10,30和100 s。

热变形的工艺如下:试样先以10 ℃/s 的速度加热到1 200 ℃(第4部分除外),保温5 min,然后,以10 ℃/s的冷速冷却到变形温度,保温1 min后,进行第1次压缩,间隔一定时间后进行第2次压缩,第2次压缩的变形条件与第1次的相同。纪录实验的载荷行程数据,计算得到各种变形条件下的真应力—真应变曲线。由前期研究可知[11-12],本实验范围内的应变都小于动态再结晶临界应变。因此,热变形后的材料在道次间只发生静态回复和静态再结晶。

2 结果与讨论

2.1 静态再结晶软化率与体积分数的测定

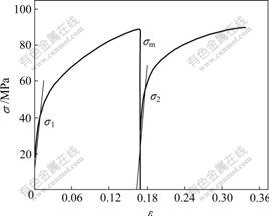

图1所示为形变奥氏体双道次软化的典型示意图。目前,采用间断的双道次变形测定静态再结晶软化率与体积分数的方法主要有补偿法(屈服应力所对应的塑性应变分别为0.2%或2%)、后插法、5%总应变法和平均应力法[1-5, 13]。本研究采用补偿法(0.2%)确定软化率,与其他方法比较,补偿法处理 数据的人为误差较小,补偿法的软化率Fs由下式测定[14]:

用0.2%的补偿法测得的软化率包括静态回复和静态再结晶造成的软化。一般认为,静态再结晶约在软化率为0.2时开始[15],因而,静态再结晶的体积分数

用0.2%的补偿法测得的软化率包括静态回复和静态再结晶造成的软化。一般认为,静态再结晶约在软化率为0.2时开始[15],因而,静态再结晶的体积分数 可由下式确定:

可由下式确定:

道次间隔时间为10 s,初时晶粒尺寸为54 μm

图1 双道次热压缩的真应力—真应变曲线

Fig.1 True stress—true strain curves of two-pass hot compression

2.2 工艺参数对42CrMo钢静态再结晶的影响

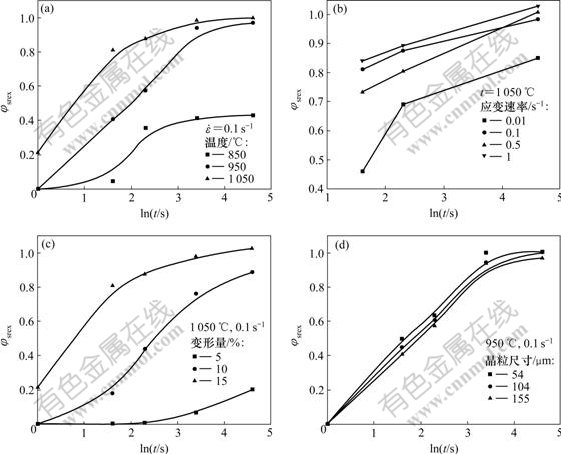

静态再结晶的过程包括形核和长大。随着道次间隔时间的增加,形核的数目不断增加,再结晶晶粒长大,因而,静态再结晶的体积分数也逐渐增加。在不同的变形条件下,静态再结晶的速度也不同。下面分别讨论变形温度、应变速率、变形量与初始奥氏体晶粒尺寸对42CrMo钢静态再结晶速度的影响规律。工艺参数对42CrMo钢静态再结晶体积分数的影响如图2所示。

(a) 变形温度;(b) 应变速率;(c) 变形量;(d) 初始奥氏体晶粒尺寸

图2 工艺参数对42CrMo钢静态再结晶体积分数的影响

Fig.2 Effects of processing parameters on static recrystallization volume fractions

2.2.1 变形温度对42CrMo钢静态再结晶的影响规律

变形温度对42CrMo钢静态再结晶的影响如图2(a)所示。可见,变形温度升高,42CrMo钢静态再结晶的速率明显增快。如在应变速率为0.1 s-1,道次间隔时间为5 s,第1道次的变形量为15%时,静态再结晶体积分数在变形温度为850,950和1 050 ℃时分别为4.6%,40.9%和80.8%。这是由于在其他条件一定时,变形温度越高,形变储存能越大,因而,静态再结晶的速率越快。由图2(a)还可知,当温度较低时 (850 ℃),42CrMo钢静态再结晶体积分数随道次间隔时间的增加先快速增加,然后,趋于一稳定值(约为40%)。这可能是由于在温度较低的情况下,再结晶过程会出现析出现象,因而对再结晶的继续进行产生阻碍作用,从而导致不完全的静态再结晶[16]。

2.2.2 应变速率对42CrMo钢静态再结晶的影响规律

应变速率对42CrMo钢静态再结晶的影响如图2(b)所示。可见,应变速率增大,静态再结晶速率也增大。如在变形温度为1 050 ℃,道次间隙时间为5 s,第1道次变形量为15%的情况下,应变速率为0.01 s-1时静态再结晶体积分数仅为45%,而在应变速率为1 s-1时静态再结晶体积分数达到83.7%。这是由于在其他条件相同的情况下,应变速率越高,一方面,位错密度增殖的速率越快,另一方面,动态回复的程度越低,位错的消失速率越慢,因而热压缩后材料内部的位错密度越大,静态再结晶的驱动力也越大,从而静态再结晶速率也越快。

2.2.3 变形量对42CrMo钢静态再结晶的影响

变形量对42CrMo钢静态再结晶的影响如图2(c)所示。随着变形量的增加,静态再结晶速率增加。如在变形温度为1 050 ℃,应变速率为0.1 s-1,道次间隙时间为5 s时,变形量为5%时几乎没有发生静态再结晶;而当变形量为15%时,静态再结晶体积分数高达80.8%。这说明变形量对静态再结晶的影响很大。这是由于在应变未达到动态再结晶之前, 加工硬化在变形过程中起主导作用,因而,随着变形量的增加,材料的位错密度迅速增加,静态再结晶的驱动力增大。

2.2.4 初始奥氏体晶粒尺寸对42CrMo钢静态再结晶的影响规律

初始奥氏体晶粒尺寸对42CrMo钢静态再结晶的影响如图2(d)所示。减小初始晶粒尺寸,静态再结晶速率有所增加,但速率增加的幅度较小。如在变形温度为950 ℃,应变速率为0.1 s-1,道次间隙时间为 10 s时,初始奥氏体晶粒尺寸为54,104和155 μm时对应的再结晶体积分数分别为62.9%,60%和57%。因此,对于42CrMo钢,初始的奥氏体晶粒大小对其静态再结晶的影响不是主要因数。

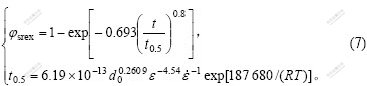

2.3 42CrMo钢静态再结晶动力学方程

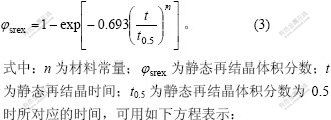

静态再结晶动力学方程一般用Avrami方程表 示[17]:

2.3.1 系数n的确定

将式(3)化简为

。 (5)

。 (5)

由于t0.5和n对某一具体的变形参数和材料是定值,因此,经回归得到n的平均值为0.8(见图3)。

图3 ln{ln[1/(1-φsrex)]}与ln t的关系

Fig.3 Relationships between ln{ln[1/(1-φsrex)]} and ln t

2.3.2 t0.5公式中各系数的确定

将式(4)化简为

。 (6)

。 (6)

根据实验数据对各个系数进行线性回归,得到h=0.260 9,n=-4.54,m=-1.00,a=6.19×10-13,Q=187.68 kJ/mol。

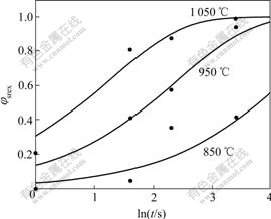

2.4 模型验证

42CrMo钢静态再结晶的动力学公式如下:

图4所示是应变速率为0.1 s-1时,静态再结晶体积分数实验值与预测值的比较。显然,预测结果与实验结果较吻合。故本研究推导出的42CrMo钢静态再结晶动力学模型具有较高的可信度,可为42CrMo钢热成形工艺的制定提供理论依据。

曲线表示预测值,圆点表示实验值

图4 静态再结晶体积分数的实验值与预测值比较

Fig.4 Comparisons between experimental results and predicted results of static recrystallization volume fractions

3 结 论

a. 随道次间隔时间的不断延长,42CrMo钢的静态再结晶体积分数逐渐增加。

b. 变形程度对42CrMo钢的静态再结晶行为影响最大。随着变形量的增加,静态再结晶的驱动力增大。当变形量较小、道次间隔时间较短时,几乎没有发生静态再结晶;其次是变形温度和应变速率。变形温度升高,42CrMo钢静态再结晶的速率明显增大,但是,当变形温度较低时,将发生不完全的静态再结晶;随着应变速率增大,静态再结晶的驱动力也越大,从而静态再结晶速率也越大。此外,初始的奥氏体晶粒尺寸对其影响较小。

c. 基于实验结果,推导出该合金钢的静态再结晶的动力学方程为:

;

;

。

。

且动力学方程的计算结果和实验结果较吻合,故该方程可为42CrMo钢热成形加工工艺的制定提供理论 依据。

参考文献:

[1] 沈丙振, 方能炜, 沈厚发, 等. 低碳钢奥氏体再结晶模型的建立[J]. 材料科学与工艺, 2005,13(5): 516-520.

SHEN Bing-zhen, FANG Neng-wei, SHEN Hou-fa, et al. Construction of the receystallization model of low carbon steel during deformation [J]. Materials Science & Technology, 2005,13(5): 516-520.

[2] Kim S, Lee Y, Jang B L. Modeling of recrystallization and austenite grain size for AISI 316 stainless steel and its application to hot bar rolling[J]. Mater Sci Eng A, 2003, 357(1/2): 235-239.

[3] Kazeminezhad M. On the modeling of the static recrystallization considering the initial grain size effects[J]. Mater Sci Eng A, 2008, 486(1/2): 202-207.

[4] 李立新, 洪 杰, 邓 宁, 等. 含硼微合金钢静态及亚动态再结晶动力学模型研究[J]. 武汉科技大学学报: 自然科学版, 2004, 27(4): 334-336.

LI Li-xin, HONG Jie, DENG Ning, et al. Static and meta-dynamic recrystallization kinetic models for boron microalloyed steel[J]. Journal of Wuhan University of Science and Technology: Natural Science Edition, 2004, 27(4): 334-336.

[5] Zhang Z H, Liu Y N, Liang X K, et al. The effect of Nb on recrystallization behavior of a Nb micro-alloyed steel[J]. Mater Sci Eng A, 2008, 474(1/2): 254-260.

[6] Celik A,Karadeniz S. Improvement of the fatigue strength of AISI 4140 steel by an ion nitriding process[J]. Surf Coat Technol, 1995, 72(3): 169-173.

[7] 赵莉萍, 刘宗昌, 杨 慧, 等. 42CrMo 钢的贝氏体组织相变[J]. 特殊钢, 2004, 25(4): 21-23.

ZHAO Li-ping, LIU Zhong-chang, YANG Hui, et al. Transformation of bainitic structure of steel 42CrMo[J]. Special Steel, 2004, 25(4): 21-23.

[8] 王毛球, 董 瀚, 惠卫军, 等. 热处理对42CrMo钢的耐延迟断裂性能的影响[J]. 金属学报, 2002, 38(7): 715-719.

WAND Mao-qiu, DONG Hun, HUI Wei-jun, et al. Effect of heat treatment on delayed fracture resistance of structural steel 42CrMo[J]. Acta Metalluragica Sinica, 2002, 38(7): 715-719.

[9] 赵绪国. 42CrMo曲轴坏的工艺改正[J]. 机械工程与自动化, 2006, 137(4): 167-169.

ZHAO Xu-guo. Improvement of heat treatment process of 42CrMo steel crankshaft[J]. Mechanical Eng Autom, 2006, 137(4): 167-169.

[10] Sarioglu F. The effect of tempering on susceptibility to stress corrosion cracking of AISI 4140 steel in 33odium hydroxide at 80 ℃[J]. Mater Sci Eng A, 2001, 315(1/2): 98-102.

[11] 蔺永诚, 陈明松, 钟 掘. 42CrMo钢的热压缩流变应力行为[J]. 中南大学学报: 自然科学版, 2008, 39(3): 549-553.

LIN Yong-cheng, CHEN Ming-song, ZHONG Jue. Flow stress behaviors of 42CrMo steel during hot compression[J]. Journal of Central South University: Science and Technology, 2008, 39(3): 549-553.

[12] Lin Y C, Chen M S, Zhong J. Prediction of 42CrMo steel flow stress at high temperature and strain rate[J]. Mechan Res Commun, 2008, 35(3): 142-150.

[13] Laasraoui A, Jonas J J. Prediction of temperature distribution flow stress and microstructure during the multi-pass hot rolling of steel plate an strip[J]. ISIJ International, 1991, 31(1): 95-105.

[14] Rao K P, Prasad Y K D V, Hawboly E B. Study of fractional softening in multi-stage hot deformation[J]. J Mater Process Tech, 1998, 77(1/3): 166-174.

[15] SUN W P, Hawbolt E B. Comparison between static and metadynamic recrystallization an application to the hot rolling of steels[J]. ISIJ International, 1997, 37(10): 1000-1009.

[16] Humphreys F J, Hatherly M. Recrystallization and related annealing phenomena[M]. Oxford: Elsevier Science Ltd, 199.

[17] Cho S H, Kang K B, Jonas J J, et al. Effect of manganese on recrystallisation kinetics of niobium microalloyed steel[J]. Mater Sci Technol, 2002, 18(3): 389-395.

收稿日期:2008-03-01;修回日期:2008-05-29

基金项目:国家重点基础研究发展规划项目(2006CB705401);中国博士后科学基金资助项目(20070410302);中南大学博士后科学基金资助项目(2007年)

通信作者:蔺永诚(1976-),男,湖南浏阳人,副教授,博士,从事材料的高温流变特性及锻造成形工艺数字化仿真研究;电话:0731-8877915;E-mail: yclin@mail.csu.edu.cn