文章编号:1004-0609(2015)-11-3202-07

锡阳极泥硫化焙烧分离锑

卢红波1, 2

(1. 云南锡业郴州矿冶有限公司 高新材料分公司,郴州 423000;

2. 云南锡业股份有限公司,个旧 661000)

摘 要:提出一种硫化焙烧处理锡阳极泥分离锑的新工艺,对硫化焙烧过程进行热力学分析,在热力学分析的基础上,系统考察焙烧温度、焙烧时间、黄铁矿配比及焦粉配比对锑挥发率和锡残留率的影响。结果表明:温度升高有利于Sb2O4和SnO2硫化反应的进行,且在同一温度下,Sb2O4比SnO2硫化的趋势更强。在黄铁矿配比为30%(质量分数)、焦粉配比为7%(质量分数)、焙烧温度为1323 K、焙烧时间为2 h的条件下,焙砂中的锑含量为2.96%、锡含量为31.98%、锑的挥发率为85.56%、锡的残留率为88.75%,锡阳极泥硫化焙烧分离锑效果较佳。

关键词:锡阳极泥;锑;硫化焙烧;饱和蒸汽压

中图分类号:TF814;TF818 文献标志码:A

Separation of antimony from tin anode slime by sulfidation roasting

LU Hong-bo1, 2

(1. Hi-tech and New Materials Branch of Yunnan Tin Chenzhou Mining and Metallurgy Co. Ltd., Chenzhou 423000, China;

2. Yunnan Tin Co. Ltd., Gejiu 661000, China)

Abstract: A new technology of sulfidation roasting process for tin anode slime to separate antimony was proposed. Thermodynamic analysis of sulfidation roasting process was conducted. Based on the thermodynamic analysis, the influences of calcination temperature, calcination time, pyrite ratio and coke ratio on the volatilization rate of antimony and the residual rate of tin were investigated. The results show that high temperature benefits for Sb2O4 and SnO2 sulfidation reaction,while Sb2O4 sulfidation trend is stronger than that of SnO2 at the same temperature. While the pyrite content is 30% (mass fraction), coke content is 7% (mass fraction), the calcination temperature is 1323 K, the roasting time is 2 h, the antimony content in calcine is 2.96%, tin content is 31.98%, the volatilization rate of antimony is 85.56%, the residual rate of tin is 88.75%, the effect of separating antimony from tin anode slime by sulfidation roasting is better.

Key words: tin anode slime; antimony; sulfidation roasting; saturated vapor pressure

随着锡矿资源的逐渐贫化,低品位多金属复杂矿物的增多,锡精矿成分益加复杂[1],使得锡冶炼难度加大。尤其锑对锡电解及阳极泥处理工艺均有不良影响,它使锡回收率大大降低[2]。对于锡电解精炼,粗锡中因锑过高变脆,直接影响阳极板的浇铸;而且,在电解时会形成一种坚固致密的“隔膜”,改变了电极与电解液之间的双电层结构,并遏制电化学反应进行,导致阳极钝化[3],故锡电解精炼对杂质含量有较严格的要求,其中Sb一般在0.55%左右,最高也不超过1%[4]。而锡阳极泥是粗锡在电解精炼过程中不溶于电解液而沉于槽底的部分,集中了粗锡中几乎所有的杂质,即有价金属,极具有回收价值[5-6];但锑的处理较为复杂和困难,锡阳极泥含锑高会影响其处理效果及银的回收,传统工艺流程不适合综合处理此类阳极泥[7]。因此,锑不能开路回收,含锑的锡返料返回熔炼,再次进入粗锡及阳极泥中,造成恶性循环,两者中锑含量愈来愈高,对冶炼工艺的危害很大。

在国外,有研究者根据Mg3Sb2有较小的密度以及锡、铅、锑具有不同电化学行为的特点,分别做了加镁除锑和电解除锑的研究,但都不适合于Sb含量大于4%(质量分数)的高锑物料[8]。在国内,云南锡业公司很早就采用加铝除砷、锑的方法[9],但该法易产出高熔点化合物且带走相当数量的锡。李伟[10]采用两步真空碳热还原工艺处理锡阳极泥,将阳极泥中的化合物锑还原并分解为Sb2O3后迅速挥发而脱除,锑的脱除率较高,但是真空设备投资大、维护成本高、处理量小,而且不能连续作业。杨建广等[11]以电解锡阳极泥为原料,在充分回收其有价金属的基础上,以该阳极泥直接生产出的高纯氯氧锑和高纯氯锡酸铵为原料,采用配合-共沉淀方法合成出超细ATO粉,该工艺采用二次物料制备功能材料,具有创新性,但是流程较长,废水处理是个难题。此外,国内公开报道介绍锡阳极泥中锑处理工艺相关的方法主要有氧化焙烧-硝酸浸出法、硝酸低温焙烧-盐酸浸出法、氧化焙烧-硫酸氯化钠混合液浸出法和选-冶联合法。但这些工艺不同程度的存在流程长、污染环境、操作强度大、作业环境恶劣等缺点,在生产上难以应用[12]。

因此,为使锡冶炼、焊锡电解及阳极泥等处理工艺正常化;同时,进一步回收有价金属,锑的开路回收是当务之急。本文作者提出硫化焙烧处理锡阳极泥分离锑的新工艺,在热力学分析基础上,系统考察焙烧温度、焙烧时间、黄铁矿配比及焦粉配比对锑挥发率和锡残留率的影响,以期为下一步的半工业及工业化提供理论指导和数据支撑。

1 实验

1.1 试验原料

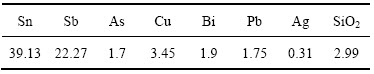

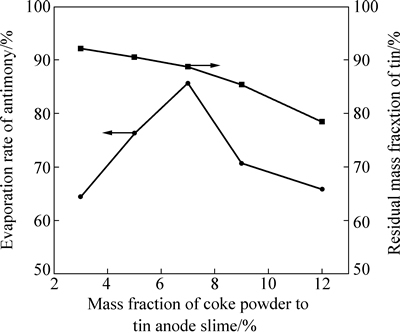

试验原料为云南某厂锡电解精炼过程中产出的锡

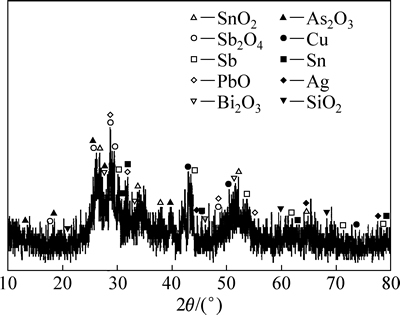

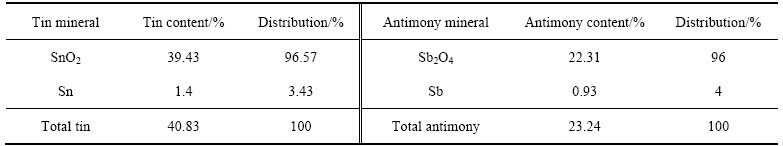

阳极泥,已堆存多年,呈灰黑色疏松的块状物,其化学元素分析结果如表1所列。由表1可知,锡阳极泥中元素Sn和Sb含量最高。该阳极泥的XRD分析如图1所示,其中锡和锑物相分析见表2。结合图1和表2可知,锡阳极泥中Sn、Sb、Pb和Bi等主要以氧化物形态存在,其次还有少量的Sn、Sb、Ag和Cu以金属形态存在。其中,锡阳极泥中的锡主要以SnO2存在,而锑主要以Sb2O4存在。由于锡阳极泥长年堆存,在空气与电解液(硅氟酸)的双重作用下,已发生了比较严重的风化,其中的锡、锑等主要金属并非金属态,而系呈氧化物[13-14]。XRD分析结果未见氟的物相,可能是由于锡阳极泥在长期的堆存过程中,硅氟酸分解为具有挥发性的氟化物,导致氟含量过低,无法检测到。

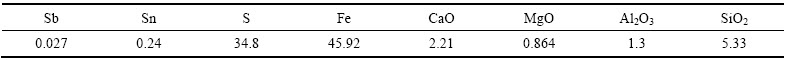

本试验需要添加剂为黄铁矿和焦粉,其化学分析结果如表3和4所列。

表1 锡阳极泥化学成分

Table 1 Chemical composition of tin anode slime (mass fraction, %)

图1 锡阳极泥的XRD谱

Fig. 1 XRD patterns of tin anode slime

表2 锡阳极泥中锡和锑物相分析

Table 2 Mineral composition of tin and antimony in tin anode slime

表3 黄铁矿的化学成分

Table 3 Chemical composition of pyrite (mass fraction, %)

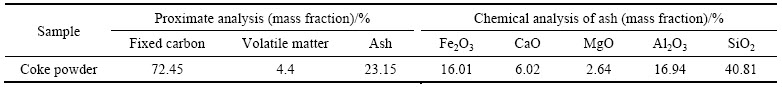

表4 焦粉工业及化学分析结果

Table 4 Proximate analysis and chemical analysis of coke powder

1.2 试验装置及分析仪器

试验采用炉膛尺寸为d 220×2000 mm回转窑,采用硅碳棒为加热元件,额定功率为20 kW,通过调节电流来实现炉膛升温速率的控制。收尘设备为布袋除尘器,布袋收尘器前段设有一个沉降室,布袋收尘器后设有一台抽风机;尾气用石灰水进行吸收处理。

分析检测设备为日本理学TTRIII型X射线衍射仪和AA320N原子吸收分光光度仪。

1.3 试验方法

对硫化焙烧分离锑的工艺进行试验研究,考察焙烧温度、焙烧时间、黄铁矿配比和焦粉配比对锑挥发率及锡残留率的影响,优化工艺参数,达到锡阳极泥中锡锑分离的目的。试验步骤为:1) 按一定的质量配比称取锡阳极泥、黄铁矿和焦粉,将三者混匀后加入少量的粘结剂进行制粒,并烘干备用;2) 开启回转窑,程序升温至设定值后,加入步骤1)中制备好的混合料,开始计时反应;3) 反应结束后,将焙砂自然冷却,然后取样分析。

锑挥发率及锡残留率的计算公式如式(1)和(2)所示:

(1)

(1)

(2)

(2)

式中:ESb为锑挥发率;RSn为锡残留率;cSb为焙砂中元素锑含量;cSn为焙砂中元素锡含量;MSb为混合料中元素锑含量;MSn为混合料中元素锡含量;η为焙砂产率。

1.4 试验原理

焙烧过程中,主要发生反应如式(3)~(7)所示:

2FeS2=2FeS+S2(g) (3)

S2(g)+2O2(g)=2SO2(g) (4)

4FeS+7O2(g)=2Fe2O3+4SO2(g) (5)

SnO2+1/2S2(g)+C=SnS+CO2(g) (6)

Sb2O4+3/2S2(g)+2C=Sb2S3+2CO2(g) (7)

SnO2+SO2(g)+2C=SnS+2CO2(g) (8)

Sb2O4+3SO2(g)+5C=Sb2S3+5CO2(g) (9)

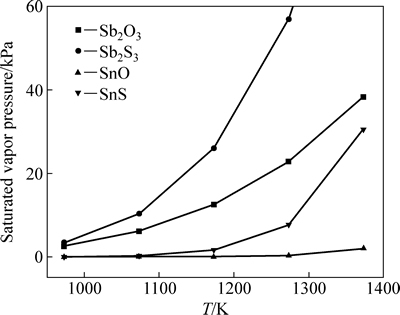

锡、锑硫化物和氧化物不同温度下的饱和蒸汽压如图2所示。由图2可知,随着温度的升高,Sb2S3、SnS、Sb2O3和SnO的饱和蒸汽压逐渐增大,Sb2S3的增长趋势最为迅猛。在该温度范围内同一温度下,Sb2S3的饱和蒸汽压比SnS的大很多,Sb2O3的饱和蒸汽压也比SnO的大;在1273 K之后,SnS的饱和蒸汽压随着温度的升高增长趋势加快。基于以上原理,结合锡、锑硫化物不同温度下的饱和蒸汽压可知,同一温度下,Sb2S3比SnS的饱和蒸汽压大很多,故锡阳极泥可以经硫化焙烧使锑以三硫化二锑的形式挥发[15-16],达到锑开路的目的。

图2 饱和蒸汽压与温度的关系

Fig. 2 Relationships between saturated vapor pressure and temperature

2 结果与讨论

2.1 硫化焙烧热力学分析

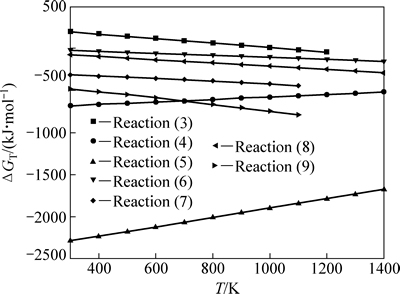

查阅热力学数据手册[17]及参考相关资料[18]对锡阳极泥硫化焙烧过程进行热力学分析。图3所示为式(3)~(9)的标准吉布斯自由能与温度的关系。由图3可知,从热力学角度考虑,在计算的温度范围内,式(3)的标准自由能在1039 K时由正值变为负值,热力学趋势逐渐变强,表明仅当温度升高至1039 K后,式(3)才自发进行;式(4)~(9)的标准自由能为负值,说明式(4)~(9)可以自发进行;随着温度的升高,式(4)~(9)的热力学趋势由大到小依次为:式(9)、式(7)、式(8)、式(6),而式(4)~(5)的热力学趋势减弱,表明式(4)~(5)为放热反应。综上可知,温度升高有助于Sb2O4和SnO2硫化反应的进行,且Sb2O4的硫化趋势比SnO2的更强。

图3 标准吉布斯自由能(ΔGT)与温度(T)的关系

Fig. 3 Relationships between ΔGT and T

2.2 焙烧温度的影响

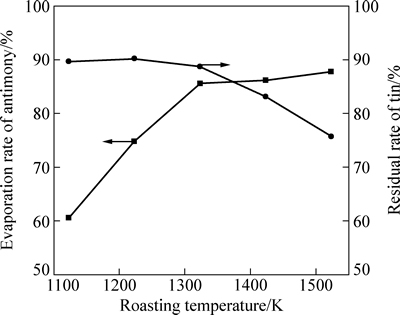

根据热力学分析结果,高温条件下更有利于锑硫化反应的进行。在锡阳极泥为500 g、黄铁矿配比为30%(质量分数)、焦粉配比为7%(质量分数)、焙烧时间为2 h的条件下,考察焙烧温度(1123~1523 K)对锑挥发率和锡残留率的影响,其结果如图4所示。

由图4可见,随着温度的升高,锑的挥发率逐渐增大,1323 K后增大趋势减小;锡的残留率随着温度的升高而降低,当温度大于1323 K时,降低趋势增大。温度的升高均有利于锡、锑硫化反应的进行,同时,高温有利于锡、锑硫化物的挥发。所以,在一定范围内,随着温度升高,锑的挥发率呈上升趋势,锡的残留率虽然下降,但是波动不大;当温度超过该范围时,虽然锑的挥发率继续上升,但是阳极泥中的锡硫化成SnS大量挥发[19-21],导致锡的残留率下降趋势增大,而且当温度过高时,会出现结窑现象。综合考虑,焙烧温度以1323 K为宜。

图4 焙烧温度对锑挥发率和锡残留率的影响

Fig. 4 Effect of roasting temperature on evaporation rate of antimony and residual rate of tin

锡阳极泥中锑的硫化属气-固反应,其反应步骤为:1) 反应物S2由气相扩散边界层扩散至混合料颗粒表面;2) 反应物S2通过混合料颗粒孔隙和裂缝扩散至化学反应界面,同时固态含锑物相向外扩散;3) S2在气-固相反应界面上发生物理吸附和化学吸附;4) 被吸附S2与锑物相(主要为Sb2O4)发生反应,生成气态产物Sb2S3和SO2;5) 气体产物Sb2S3和SO2在气-固反应界面上脱附;6) Sb2S3和SO2通过多孔产物层扩散至固体反应物表面;7) 气体产物Sb2S3和SO2通过气相扩散边界层扩散至气相本体。由图4可见,在1123~1323 K范围内,锑的挥发率随温度升高而增大,且近似为线性关系,说明锡阳极泥硫化焙烧挥发锑的过程为扩散控制。因此,在提高锡残留率和降低结窑率的前提下,要提高焙烧过程中锑的硫化挥发速率,应尽量提高其焙烧温度。

2.3 焙烧时间的影响

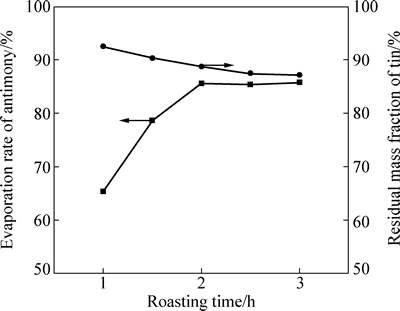

热力学研究是对反应进行的可能性及趋势进行分析,而反应速率及最终反应效果则取决于动力学因素。因此,在锡阳极泥为500 g、黄铁矿配比为30%、焦粉配比为7%、焙烧温度为1323 K的条件下,考察焙烧时间(1~3 h)对锑挥发率和锡残留率的影响,其结果如图5所示。

由图5可知,随着焙烧时间的增加,锑的挥发率呈上升趋势,焙烧2 h之后趋于平稳;而锡的残留率之前下降趋势较大,焙烧2 h之后也趋于平稳,总体来说锡的残留率变化不是很大。反应初期,反应物的量多,反应速率较快,随着反应的进行,黄铁矿和焦粉逐渐消耗,故在反应后期,反应速率降低,锑的挥发率和锡的残留率趋于稳定。焙烧3 h与焙烧2 h相比,锑的挥发率变化不是很大,但锡的残留率随焙烧时间的增加而降低,所以选择合适的焙烧时间,对焙砂中锡和锑的含量有重要影响,结果表明,焙烧时间以2 h为宜。

图5 焙烧时间对锑挥发率和锡残留率的影响

Fig. 5 Effect of roasting time on evaporation rate of antimony and residual mass fraction of tin

2.4 黄铁矿配比的影响

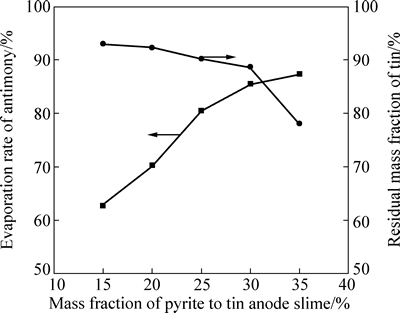

在硫化焙烧过程中,黄铁矿充当硫化剂,其用量直接影响反应的效果。因此,在锡阳极泥为500 g,焦粉配比为7%,焙烧温度为1323 K,焙烧时间为2 h的条件下,考察黄铁矿配比(15%~35%)对锑挥发率和锡残留率的影响,其结果如图6所示。

图6 黄铁矿配比对锑挥发率和锡残留率的影响

Fig. 6 Effect of mass fraction of pyrite to tin anode slime on evaporation rate of antimony and residual mass fraction of tin

由图6可以看出,随着黄铁矿配比的增加,锑挥发率逐渐升高;而锡的残留率呈下降趋势,当黄铁矿配比在15%~30%范围内时,下降趋势较为平缓;当黄铁矿配比大于30%时,下降趋势较为迅猛。由Sn-S-O系和Sb-S-O系的优势区相图[22]可知,当系统中的氧势和硫势控制得当时,均有利于锡和锑的硫化,而在相同条件下,锑比锡更容易硫化。故当黄铁矿配比较低时,锡硫化能力较弱,所以锡的残留率波动不大;当黄铁矿配比增加时,硫化气氛增强,反应过程中硫势增加,相应的氧势也在减小,锑硫化强度越来越大,所以锑挥发率也越来越大,锡也逐渐被硫化成硫化物而挥发,所以导致锡残留率降低幅度变大。由此可见,黄铁矿的配比为30%时,锡残留率为88.75%,保持在较佳水平。

2.5 焦粉配比的影响

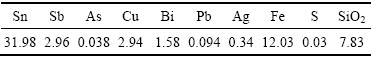

根据热力学分析结果可知,焦粉作为还原剂有利于锑硫化反应的进行,其用量也同样直接影响硫化反应的效果。因此,在锡阳极泥为500 g、黄铁矿配比为30%、焙烧温度为1323 K、焙烧时间为2 h的条件下,考察焦粉配比(3%~12%)对锑挥发率和锡残留率的影响,其结果如图7所示。

图7 焦粉配比对锑挥发率和锡残留率的影响

Fig. 7 Effect of mass fraction of coke powder to tin anode slime on evaporation rate of antimony and residual mass fraction of tin

由图7可知,随着焦粉的增加,锑挥发率先上升后下降,当焦粉配比为7%时,锑挥发率达到最大值85.56%;而锡残留率随焦粉配比的增加而下降,当焦粉配比小于7%时,锡残留率变化不大,当焦粉配比大于7%时,锡残留率下降趋势变大。在焙烧过程中,焦粉有两个作用:一是降低锑硫化反应的活化能,促进反应的进行;二是降低氧势,提供还原气氛,还原气氛有利于硫化反应的进行[23]。随着焦粉配比的增加,锑的挥发率波动较大,主要是因为当还原气氛增强时,碳不到促进锑硫化反应的进行,而是变为还原反应,将锑的氧化物还原成金属。此外,随着焦粉的增加,还原气氛增强锡和锑的氧化物被还原成金属,而锡和锑的熔点都比较低,故导致结窑现象的发生。因此,还原气氛能促进硫化反应,当焦粉配比为7%时,锡锑分离效果较佳。

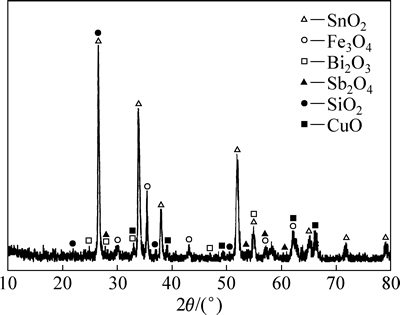

综上所述,硫化焙烧处理锡阳极泥分离锑最佳工艺条件为:黄铁矿配比为30%,焦粉配比为7%,焙烧温度为1323 K,焙烧时间为2 h。对最佳工艺条件硫化焙烧后的焙砂进行成分和XRD分析,化学分析结果如表5所列,XRD分析结果如图8所示。

表5 焙砂化学成分

Table 5 Chemical composition of calcine (mass fraction, %)

图8 焙砂的XRD谱

Fig. 8 XRD patterns of calcine

结合表5和图8可知,焙砂中主要以SnO2、Fe3O4、SiO2为主,经过硫化挥发后,Sb含量降至2.96%,锡含量为31.98%,锑与锡得到了有效分离;As和Pb的含量也大幅度下降,其在焙烧过程中挥发进入烟气中;由于配入了黄铁矿和焦粉,故焙砂中的Fe和Si含量增加,其他元素含量变化不大。

3 结论

1) 从热力学角度考虑,温度升高有助于Sb2O4和SnO2硫化反应的进行,且Sb2O4比SnO2硫化的趋势更强。

2) 在黄铁矿配比为30%、焦粉配比为7%、焙烧温度为1323 K、焙烧时间为2 h的条件下,焙砂中的锑含量为2.96%、锡含量为31.98%、锑的挥发率为85.56%、锡的残留率为88.75%,锡锑分离效果较好。

3) 本工艺为从锡阳极泥中分离锑开辟了一条新途径,与传统湿法处理锡阳极泥分离锑工艺相比流程短、污染小、成本低,应用前景广阔。

REFERENCES

[1] 王 忠. 大厂浮选锡中矿回转窑硫化挥发的研究[J]. 矿冶, 1996, 5(2): 71, 78-81.

WANG Zhong. Study on sulphidizing volatilization of tin middlings from Dachang flotation process with rotary kiln[J]. Mining and Metallurgy, 1996, 5(2): 71, 78-81.

[2] 刘志光. 从焊锡阳极泥的浸银渣(锡精矿)中提取锑及金银[J]. 云南冶金, 1988(6): 48-51, 56.

LIU Zhi-guang. Extracting antimony and gold and silver from residue (tin concentrate) of silver leaching from tin anode mud[J]. Yunnan Metallurgy, 1988(6): 48-51, 56.

[3] 莫正荣. 高锑粗锡电解精炼生产实践[J]. 云南冶金, 1993(2): 15-18.

MO Zheng-rong. Production practice of electrolytic refining crude tin with high antimony[J]. Yunnan Metallurgy, 1993(2): 15-18.

[4] 贺子凯, 阳书文. 锑在焊锡电解中引起的钝化研究[J]. 有色金属, 2001, 53(2): 55-58.

HE Zi-kai, YANG Shu-wen. The study of anode passivation caused by SbSn in electrolysis of solder containing antimony[J]. Nonferrous Metals, 2001, 53(2): 55-58.

[5] 孔 霞, 李沪萍, 罗康碧, 胡 创. 锡废料综合利用的研究进展[J]. 化工科技, 2011, 19(2): 59-63.

KONG Xia, LI Hu-ping, LUO Kang-bi, HU Chuang. Research advance on comprehensive utilization of the tin scraps[J]. Science & Technology In Chemical Industry, 2011, 19(2): 59-63.

[6] 杨建广. 锡阳极泥制取纯(NH4)2SnCl6、Sb4O5Cl2及纳米ATO的新工艺和理论研究[D]. 长沙: 中南大学, 2005.

YANG Jian-guang. A new technology and theory research on preparation of pure (NH4)2SnCl6, Sb4O5Cl2 and ATO nanoparticles from tin anode slime[D]. Changsha: Central South University, 2005.

[7] 杜 杰, 陈全福. 某厂电解锡阳极泥锡、锑分离试验研究[J]. 南方国土资源, 2004(11): 101-102.

DU Jie, CHEN Quan-fu. Experimental study on separation antimony from tin anode slime in a factory[J]. Land and Resources of Southern China, 2004(11): 101-102.

[8] 姚昌仁. 焊锡阳极泥浸铋渣处理新工艺的研究[J]. 有色冶炼, 1994(5): 31-34.

YAO Chang-ren. A new process study on treating residue of bismuth leaching from tin anode slime[J]. Nonferrous Metals, 1994(5): 31-34.

[9] 彭容秋. 锡冶金[M]. 长沙: 中南大学出版社, 2005: 164-171.

PENG Rong-qiu. Tin metallurgy[M]. Changsha: Central South University Press, 2005: 164-171.

[10] 李 伟. 锡阳极泥及锡烟尘处理新工艺的研究[D]. 长沙: 中南大学, 2013.

LI Wei. A novel treatment process for tin anode slime and tin dust[D]. Changsha: Central South University, 2013.

[11] 杨建广, 唐谟堂, 杨声海, 唐朝波. 配合-共沉淀法制备锑掺杂二氧化锡(ATO)粉[J]. 中国有色金属学报, 2005, 15(6): 966-974.

YANG Jian-guang, TANG Mo-tang, YANG Sheng-hai, TANG Chao-bo. Transparent conductive oxide ato powders prepared by complex-co-precipitation method[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 966-974.

[12] 刘志光, 黄孝祥, 刘云珍. 从焊锡阳极泥中提取锡、银、铅、铋、铜[J]. 云南冶金, 1987(6): 32-37.

LIU Zhi-guang, HUANG Xiao-xiang, LIU Yun-zhen. Extracting tin, silver, lead, bismuth and copper from tin anode mud[J]. Yunnan Metallurgy, 1987(6): 32-37.

[13] 郭才虞, 龙琼芬. 从焊锡阳极泥中回收贵金属的处理工艺[J]. 云南冶金, 1982(6): 21-24.

GUO Cai-yu, LONG Qiong-fen. The technology of recovery precious metals from tin anode mud[J]. Yunnan Metallurgy, 1982(6): 21-24.

[14] 张增伦. 焊锡阳极泥湿法处理[J]. 稀有金属与硬质合金, 1993(6): 299-302.

ZHANG Zeng-lun. Hydrometallurgical treatment of tin anode slime[J]. Rare Metals and Cemented Carbides, 1993(6): 299-302.

[15] YANG Yong, HUA Yi-xin. Vaporization kinetics of Sb2S3 in argon fluid[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(1): 221-225.

[16] HUA Yi-xin, YANG Yong, ZHU Fu-liang. Volatilization kinetics of Sb2S3 in steam atmosphere[J]. J Mater Sci Technol, 2003, 19(6): 619-622.

[17] 叶大伦, 胡建华. 实用无机物热力学数据手册[M]. 北京: 冶金工业出版社, 2002: 175-948.

YE Da-lun, HU Jian-hua. Handbook of thermodynamic data for applied inorganic material[M]. Beijing: Mechanical Industry Press, 2002: 175-948.

[18] 李洪桂. 冶金原理[M]. 北京: 科学出版社, 2005: 128-218.

LI Hong-gui. Metallurgical principle[M]. Beijing: Science Press, 2005: 128-218.

[19] 邱在军, 李 磊, 王 华, 魏永刚, 廖 彬. 含锡铁精矿硫化焙烧脱锡的反应特征[J]. 过程工程学报, 2012, 12(6): 957-961.

QIU Zai-jun, LI Lei, WANG Hua, WEI Yong-gang, LIAO Bin. Reaction characteristics of removal of tin from tin-bearing iron concentrate by sulfidation roasting[J]. The Chinese Journal of Process Engineering, 2012, 12(6): 957-961.

[20] 秦 晋, 李 磊, 廖 彬, 邱在军, 桑秀丽. 高硫煤硫化磁化复合焙烧锡铁矿脱锡的热力学分析[J]. 材料导报, 2014, 28(24): 391-394.

QIN Jin, LI Lei, LIAO Bin, QIU Zai-jun, SANG Xiu-li. Thermodynamic study on the tin recovery from tin-bearing iron ore using sulfidation-magnetizing complex roasting process with high-sulfur coal[J]. Materials Review, 2014, 28(24): 391-394.

[21] 李 磊, 邱在军, 王 华, 魏永刚, 廖 彬, 桑秀丽. 锡铁精矿硫化焙烧脱锡[J]. 中国有色金属学报, 2014, 24(2): 519-527.

LI Lei, QIU Zai-jun, WANG Hua, WEI Yong-gang, LIAO Bin, SANG Xiu-li. Removing tin from tin-bearing iron concentrates with sulfidation roasting[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 519-527.

[22] 卢红波, 尹久发, 张启旺, 张 敏. 锡阳极泥硫化焙烧分离锑的热力学研究[J]. 稀有金属, 2013, 37(5): 845-850.

LU Hong-bo, YIN Jiu-fa, ZHANG Qi-wang, ZHANG Min. Thermodynamics of separation stibium from tin anode slime by sulfidation roasting[J]. Chinese Journal of Rare Metals, 2013, 37(5): 845-850.

[23] 黄位森. 锡[M]. 北京: 冶金工业出版社, 2000: 7-19, 269-343.

HUANG Wei-sen. Tin[M]. Beijing: Metallurgical Industry Press, 2000: 7-19, 269-343.

(编辑 王 超)

基金项目:云南锡业集团有限责任公司一类科研项目

收稿日期:2015-03-10;修订日期:2015-08-01

通信作者:卢红波,工程师;电话:0735-2485378;E-mail:hblu0506@163.com