文章编号:1004-0609(2014)02-0552-09

浮选过程颗粒输运行为数值模拟

闫红杰1, 2,毛 成1,孙 伟2,耿志强2

(1. 中南大学 能源科学与工程学院,长沙 410083;

2. 中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:浮选过程中颗粒相的输运行为对浮选效率有着直接的影响,根据颗粒间的相互作用理论,建立了浮选过程中待浮矿粒在气泡与液相中的输运方程。以实验室CPT浮选柱为研究对象,采用欧拉双流体模型计算气-液两相基本流场并耦合浮选过程矿粒输运的方法,获得矿粒在气-液两相中稳定的浓度场分布,实现浮选过程中气-液-固三相流动数值模拟。结果表明:实验室CPT浮选柱中发泡区域周围存在较大漩涡,具有较低的矿粒浓度,柱中气泡与矿粒的平均碰撞速率为2.156×108 m-3·s-1,平均碰撞概率、捕获概率和脱附概率分别为0.017、0.904和0.097。

关键词:浮选柱;颗粒输运;数值模拟

中图分类号:TD923 文献标志码:A

Numerical simulation of particle transport behavior in flotation process

YAN Hong-jie1, MAO Cheng1, SUN Wei2, GENG Zhi-qiang2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: The transport behavior of the particle phase has a direct impact for flotation efficiency in the flotation process. Based on the theory of the interaction of particles, the transport equation for mineral particles to be floating in the bubbles and the liquid phase of the flotation process was conducted. The laboratory CPT flotation column was studied with Eulerian two-fluid model to calculate the gas-liquid two-phase flow, which was coupled with the method for mineral particles transport in flotation process to obtain concentration field distribution of the mineral particles in the gas-liquid two-phase. The gas-liquid-solid three-phase flow simulation in the flotation process was achieved with the methods above. The results show that large whirlpools are found around the flotation foam area in laboratory CPT column, and the flotation foam area has lower concentration of mineral particles, the average collision rate between bubbles and mineral particles in the column is 2.156×108 m-3·s-1, and the average probabilities of collision, adhesion and detachment are 0.017, 0.904 and 0.097, respectively.

Key words: flotation column; particle transport; numerical simulation

浮选是根据矿物颗粒表面物理化学性质的不同,从矿石中分离有用矿物的技术方法。浮选柱是细粒矿物浮选的有效设备,有着广阔的市场应用前景。对浮选柱内多相流动过程进行研究,可以更好地了解浮选柱选矿机制,优化选矿条件,提高选矿效率。但由于矿物浮选中气-液-固三相复杂的作用过程,以及多相流测量技术的困难与局限,使得研究困难且得到的数据有限。目前的研究主要在实验室设计的简单流况下进行,采用高速摄影仪来拍摄颗粒的行为,得到颗粒间相互作用过程的规律[1-3]。

随着计算流体力学和计算软件的发展,使得用数值模拟的方法来研究浮选设备中的流况成为可能。其中对浮选设备中单相流场的计算流体力学(CFD)研究较多,如KOH等[4]分别对Metso浮选槽与Outokumpu浮选槽的液相流场进行了三维稳态仿真,发现了不同的搅拌桨对流场影响显著。对于浮选设备气-液两相的模拟可以有效地了解气相的分布,LEE等[5]对VersaFlo浮选柱进行气-液两相模拟,采用CFD技术设计改进了气泡发生器,使得浮选柱中气相在水平截面分布更均匀,浮选效率更高。国内采用数值模型方法对浮选柱的研究包括流体返混的研究[6]、浮选柱自吸气射流微泡发生器的研究[7]以及射流浮选柱气-液两相流场研究[8-9],而对浮选过程中气-液-固三相流动的数值模拟,首先要求对矿粒与气泡发生的碰撞、粘附及脱附的微观过程进行定量描述,并在此基础上得到矿粒在浮选设备中的浓度场,完成气-液-固三相流动仿真。其中以KOH等[10-13]对机械搅拌式浮选槽三相流动建模与仿真的研究最为突出。

本文作者根据颗粒碰撞的相关理论,建立起描述浮选过程中矿粒输运的方程,并以实验室CPT浮选柱为对象进行了气-液-固三相流动模拟,得到了浮选柱中稳定工作条件下的气-液两相流场与气-液两相中矿粒浓度场,以期对后续修正浮选过程中气泡矿粒相互作用的模型参数提供基础,并为理解与优化浮选条件提供帮助。

1 浮选过程中多相流动建模

浮选过程中矿粒与气泡碰撞、粘附和脱附的微观过程,现有的多相流模型并不能直接描述,解决的办法是对实际浮选工艺进行一定简化,以现有的多相流模型为基础,采用描述微观过程的相关理论来建立矿物浮选过程的模型,完成对浮选过程中气-液-固三相流动的描述。

1.1 颗粒碰撞过程

微细矿粒与气泡的作用过程发生在微尺度上,其研究属于颗粒的相互作用范畴,在1979年SCHUBERT和BISCHOFBERGER[14]将ABRAHAMSON[15]提出的湍流中由于惯性效果起主要作用而导致的碰撞应用于浮选过程的气泡与矿粒的相互作用,建立了浮选过程的碰撞速率模型,如式(1)所示[14]。

(1)

(1)

式中:nl和ng分别为矿粒浓度和气泡浓度,单位为m-3;rc的单位为m-3·s-1。式(1)中,

(2)

(2)

式中:Up和Ub分别表示矿粒和气泡相对于流体的湍流脉动速度,是局部湍动能耗散率ε的函数,采用式(3)计算。

(3)

(3)

式中: 和

和 分别为流体运动黏度和密度。式(2)应用于惯性效应诱发碰撞的湍流,要求颗粒尺寸满足下式:

分别为流体运动黏度和密度。式(2)应用于惯性效应诱发碰撞的湍流,要求颗粒尺寸满足下式:

>

> (4)

(4)

式中:di和 分别为气泡或矿粒的直径和密度,对于气泡需考虑虚拟质量,此时取

分别为气泡或矿粒的直径和密度,对于气泡需考虑虚拟质量,此时取 ;Uf为时均湍流脉动速度。若不满足式(4)条件,则考虑是处于低湍流耗散区域涡内的气泡与矿粒的碰撞,采用SAFFMAN和TURNER[16]提出式(5)描述:

;Uf为时均湍流脉动速度。若不满足式(4)条件,则考虑是处于低湍流耗散区域涡内的气泡与矿粒的碰撞,采用SAFFMAN和TURNER[16]提出式(5)描述:

(5)

(5)

1.2 捕集概率的计算

在浮选过程气泡矿粒碰撞模型的基础上,可以得到气泡与矿粒在单位时间与单位容积内发生碰撞的次数。但对于复杂的浮选过程,由于不同矿粒与流体间的物理化学作用,要求对碰撞的有效性作出描述。研究者们在考虑这些微观效果的基础上,提出了一系列的概率计算式,并在其后的研究中将概率细化为碰撞概率、粘附概率以及脱附概率。这些概率综合考虑了矿粒的气泡与粒径大小、表面张力、接触角、感应时间和局部的流体动力学特性等的影响,使浮选过程微观过程得到更为精细的描述。

碰撞概率用于处理由于矿粒流线绕过气泡而实际未与气泡发生碰撞的情况,这种情况在矿粒比气泡较小时十分明显。碰撞概率采用YOON与LUTTRELL[17]提出的计算式:

(6)

(6)

式中:气泡雷诺数由 计算得到。

计算得到。

浮选过程中矿粒与气泡碰撞后是否会发生粘附,与矿粒在气泡表面的滑行时间以及矿粒与气泡间薄膜破裂并分开所需要的感应时间有关。如果滑行时间大于感应时间,发生粘附的可能性就比较大。文献[17]根据气泡矿粒大小以及气泡雷诺数和感应时间得到如下的粘附概率表达式:

(7)

(7)

式中:tind是感应时间。而感应时间是关于矿粒大小及接触角的函数,文献[12]采用下式进行计算:

(8)

(8)

式中: 为矿粒的湿润接触角。

为矿粒的湿润接触角。

碰撞粘附发生后,为进一步描述粒子是否会稳定地停留在气泡表面,提出稳固概率的模型,由BLOOM 和HEINDEL[18]提出的计算式为

(9)

(9)

式中:As为经验常数,取值0.5; 数可用下式计算得到

数可用下式计算得到

(10)

(10)

式中: 、

、 和g分别为流体表面张力和重力加速度。

和g分别为流体表面张力和重力加速度。

由式(6)、(7)和(9)得到捕集概率如式(11)所示:

(11)

(11)

1.3 矿粒输运过程建模

在基于上述碰撞模型和概率模型的基础上,对目标待浮矿粒在浮选柱中的浓度场进行描述。

建模过程忽略矿物颗粒在液相中的扩散作用。可以认为目标矿粒在浮选柱中存在两种状态,即:存在于液相或存在于气相气泡。对气相和液相分别建立矿粒的浓度方程,用以描述矿粒在气-液两相运动过程中的输运。对于矿粒由于捕集作用或脱附作用在气-液两相中的转移,可以在控制容积中添加输运方程的源项来完成描述,分别写出气-液两相中矿粒输运方程如下式所示:

(12)

(12)

(13)

(13)

式中:nl为液相中矿粒数浓度;ng为气相中矿粒数浓度; 为液相的体积分数;

为液相的体积分数; 为气相的体积分数;

为气相的体积分数; 和

和 分别为浮选过程中由于捕集和脱附产生的矿粒转移源项。

分别为浮选过程中由于捕集和脱附产生的矿粒转移源项。

由式(1)可知,对于控制容积中由于捕集过程导致矿粒从液相向气相的转移源项 为

为

(14)

(14)

式中: 为控制容积中液相中的矿粒数浓度,

为控制容积中液相中的矿粒数浓度, 为有效气泡浓度,则

为有效气泡浓度,则 为气泡与矿粒在单位时间与体积下的碰撞次数。

为气泡与矿粒在单位时间与体积下的碰撞次数。

对于一定尺寸的气泡,装载矿粒的能力有限。假设每个气泡最多装载的矿粒数为 ,在计算时假设一些气泡装载满矿粒,而其他的为干净的气泡。在此基础上提出有效气泡浓度概念,即气泡浓度减去已经满负荷气泡的浓度,如式(15)所示:

,在计算时假设一些气泡装载满矿粒,而其他的为干净的气泡。在此基础上提出有效气泡浓度概念,即气泡浓度减去已经满负荷气泡的浓度,如式(15)所示:

(15)

(15)

式中:nb由控制容积中气体体积分数除以单个气泡体积得到。基于有效气泡浓度的计算,考虑了浮选过程中气泡输运矿粒载荷的限制,完善了浮选模型。

对于控制容积中由于脱附过程导致矿粒从气相向液相的转移源项 如下:

如下:

(16)

(16)

式中:pd为脱附概率,且 ;

; 为控制容积中已经装载满矿粒的气泡浓度;其中脱附频率

为控制容积中已经装载满矿粒的气泡浓度;其中脱附频率 基于气泡粒子组合体与其周围流体的相对速度估算,由文献[18]提出的计算式如下:

基于气泡粒子组合体与其周围流体的相对速度估算,由文献[18]提出的计算式如下:

(17)

(17)

式中:C1为经验常数,取值0.1。

1.4 浮选过程多相流模型

描述气-液两相流场的连续性方程与运动方程分别如式(18)和(19)所示:

(18)

(18)

(19)

(19)

式中: 为q相的应力—应变张量;

为q相的应力—应变张量; 为相间作用力,采用Ishii-Zuber[19]曳力模型;

为相间作用力,采用Ishii-Zuber[19]曳力模型; 为升力,取升力系数为0.5的升力模型;

为升力,取升力系数为0.5的升力模型; 为外部体积力,对于颗粒相与气-液两相的相互作用,不考虑液相中悬浮颗粒与液相的相互作用,但是考虑矿物颗粒的自身重力作用于所黏附的气泡,而导致平衡部分气泡上升浮力的影响。因此,在矿粒相与气泡相的作互作用中,对浮选柱中气相的运动方程加入动量源项如式(20)所示:

为外部体积力,对于颗粒相与气-液两相的相互作用,不考虑液相中悬浮颗粒与液相的相互作用,但是考虑矿物颗粒的自身重力作用于所黏附的气泡,而导致平衡部分气泡上升浮力的影响。因此,在矿粒相与气泡相的作互作用中,对浮选柱中气相的运动方程加入动量源项如式(20)所示:

(20)

(20)

式中:Vp为单个矿粒的体积, 为矿粒相的密度。

为矿粒相的密度。

采用FLUENT软件中的欧拉多相流模型对浮选过程进行气-液两相模拟,并在求解过程中加入描述矿粒的输运方程的两个标量方程,如式(21)所示:

(21)

(21)

(22)

(22)

2 浮选过程数值模拟及实验验证

2.1 研究对象及相关简化

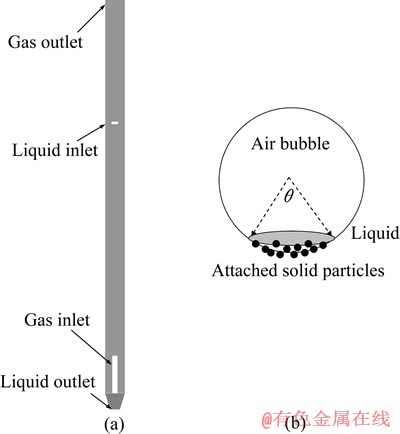

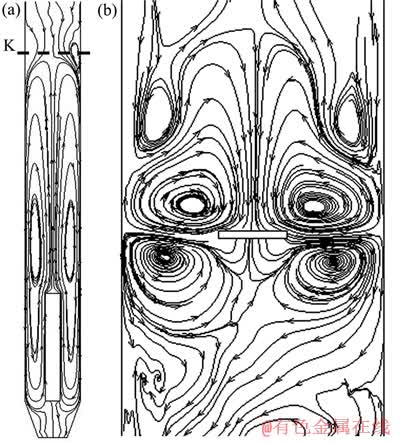

本文作者以文献[20]中的实验室CPT浮选柱为对象展开研究,如图1(a)所示。实验室CPT浮选柱主体直径7.62 cm,去除泡沫层后矿浆区高170 cm,在底部高约20 cm的区域采用多孔陶瓷产生微泡。浆矿从距离柱体顶部1/3柱高处(z=1.2 m)垂直向下给入,且假设矿浆中只包含目标待浮矿物颗粒。物理模型采用分块画分网格进行离散。数值计算进行过程中浮选柱下部产生的气泡在上升过程中与矿浆作用,捕获矿粒成为矿化气泡,并上浮至脱气边界层后被吸收,同时气泡上的矿粒被去除,即完成气泡的收集得到了精矿,经过浮选后的液相从底部排出,计算区域不包含泡沫层。

图1 实验室CPT浮选柱示意图和气泡满载矿粒示意图

Fig. 1 Schematic diagram of Lab-CPT flotation column(a) and schematic diagram of particles fully loaded bubble(b)

2.2 边界条件及求解策略

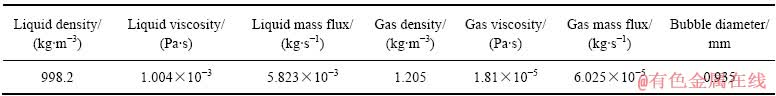

气-液两相流体物性及边界条件如表1所列。为简化建模,目前的研究假设浮选柱中气泡尺寸单一且不发生破碎与聚并。

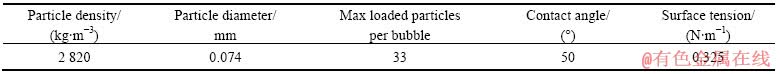

对于所求解矿粒浓度的标量方程组,程序中计算所采用的相关参数如表2所列,正浮选目标矿粒磨矿细度(<74 μm)占90%,为简化计算条件,采用统一矿粒直径为7.4×10-5 m计算。给矿口处液相入口矿粒浓度为5.307×109 m-3,发泡处气相入口矿粒浓度为0,即入口气相均为未矿化气泡。

表1 气-液两相物性参数

Table 1 Property parameters of gas phase and liquid phase

表2 计算矿粒相输运引用的参数

Table 2 Parameters used for computing transfer of fine particle

正浮选目标矿物为胶磷矿,其中假设气泡装载满矿粒时覆盖的气泡表面与球心形成锥角为60°的球面, 如图1(b)所示,此时气泡约装载33个矿粒。粘附概率的计算与感应时间相关,经浮选药剂处理后,计算感应时间采用的胶磷矿目标矿物的湿润接触角约为50°,计算稳固概率时所引用的液相表面张力为0.032 5 N/m。

计算过程中,先采用欧拉模型进行基本的气-液两相流场计算至收敛,然后新增描述矿粒输运的标量方程,以及矿粒相对气相的作用力,初始化液相中矿粒浓度场为5.307×109 m-3开始计算,保证每个时间步残差都达到10-3的精度,监视浮选柱中气-液两相中的矿粒平均浓度直至计算稳定,得到矿粒在气相与液相中的稳定的浓度场。

2.3 计算模型验证

CPT浮选柱的流场实验数据较少,但浮选柱属于一种工业鼓泡塔设备,具有典型的气-液两相流场,因此可以采用鼓泡塔仿真计算及实验的相关文献进行对比,以验证数值计算模型的准确性,确定能准确描述CPT浮选柱流场的计算模型。

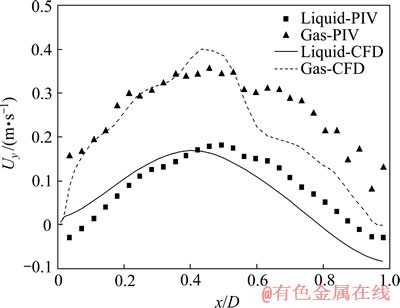

验证计算过程采用FLUENT软件对DEEN[21]所做的鼓泡塔模型实验进行仿真,并与其PIV检测数据进行对比。三维网格建模中,对实验过程中的气泡入口采用6×6个控制单元(0.03 m×0.03 m)进行简化,对壁面网格适当加密,完成142 560个网格。保证实验所采用的表观气速,确定气相入口速度为0.12 m/s,气泡尺寸为4 mm,模型高度为0.55 m,初始液位为0.45 m,采用压力出口边界条件,用修正的k-ε模型模拟液相湍流,考虑气相对液相的湍流作用。采用考虑了表面张力的Ishii-Zuber曳力模型替换FLUENT软件默认的Schiller-Naumann[22]模型以及升力系数为0.5的升力模型作用于液面以下区域,计算中对对流项采用三阶QUICK格式进行离散,计算至80 s后达到周期性稳定,然后每隔10 s取气-液两相轴向速度数据,求所得10组数据的平均值,所得结果与PIV实验数据如图2所示。

对比数据可知,仿真所得气-液两相速度与PIV实验结果基本一致,气相速度峰值略比实验值大,气-液两相速度峰值均往同一侧偏移,这归因于计算所得气泡流随时间的摆动行为。此外,HANSEN[23]采用FLUENT软件对DEEN[21]的实验进行了仿真,并认为采用曳力模型和升力模型而不采用虚拟质量力模型和BIT模型可以更为真实地描述鼓泡塔气-液运动,其结果与笔者计算试验一致。因此,在目前的计算中采用修正的标准k-ε湍流模型描述液相湍流、Ishii-Zuber曳力模型和升力系数为0.5的升力是可行的,可以用来完成对浮选柱中气-液两相流场的描述。

图2 高度0.25 m、径深0.075 m处气-液两相轴向时均速度分布图

Fig. 2 Profiles of time averaged simulated and measured axial liquid and gas velocities at height of 0.25 m and depth of 0.075 m

3 计算结果分析

采用上述得出的合理的多相流模型实现了气-液-固三相流动的建模计算,得到实验室CPT浮选柱浮选过程中连续稳定的矿粒浓度场,对数值计算结果进行分析,可以深入地了解目标矿物粒子在浮选柱中的输运状态。

3.1 CPT浮选柱基本流场分析

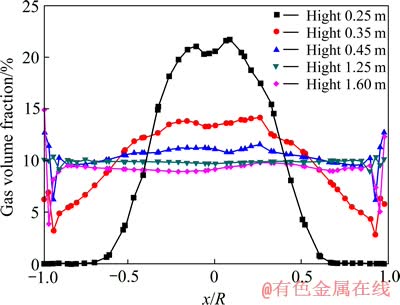

浮选柱中气泡的分布直接影响浮选效率,微气泡在浮选柱中上升时主要受浮力、曳力及升力的作用,其中升力的作用使得气泡在上浮过程中向径向方向弥散分布,统计不同高度处气相沿径向的体积分数分布,如图3所示。

图3 不同高度处气相沿径向的体积分数分布

Fig. 3 Volume fraction distribution of gas phase along radial direction at different heights

由图3可以看到,气泡从0.25 m上升到0.45 m过程中,气相沿径向分布逐渐平缓,气泡得到充分弥散。由高度1.25和1.60 m处的数据可知,而当气泡上升至接近给矿口时,气相因绕过给矿口而远离浮选柱中心存在近壁流动,导致浮选柱中心区域气相含量降低。

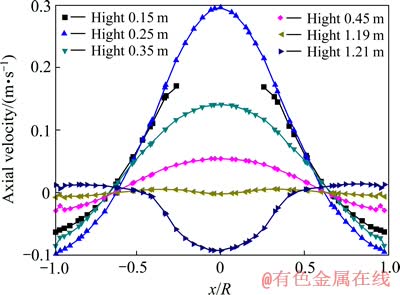

浮选柱中多孔介质产生的气泡上浮,而进入的矿浆下沉由底部排出,两相逆流使得流动较复杂。在不同高度处液相沿径向的轴向速度分布如图4所示,可以较为全面地描述矿浆在浮选柱中的流动情况。

由图4结合图5(a)可知,在高度为0.25~0.45 m之间,液相被上浮的气相带动,在柱轴线中心区域呈现较高流速,而两侧存在竖直往下方向速度,其中一部分向出矿口排出,大部分在气相的牵引作用下回流,因而在多孔介质发泡区域外侧形成旋流。在给矿口附近形成4个漩涡,如图5(b)所示,这是由于矿浆进入柱体后遇到向上流动的气相,在气相绕过给矿口过程中带动矿浆向壁面运动,至壁面附近后转向下运动,在给矿口下端两侧形成漩涡,并且在接近给矿口的高度为1.19 m处速度很小。而高度1.21 m处存在较大的竖直向下的速度,其原因是在给矿口上部的液相流向给矿口,接近给矿口后迅速流向两侧,然后被壁面附近上升的气相带动向上流动而完成循环。

由图5可以看出,从给矿口出来的液相矿浆被上升气流冲刷,大部分矿浆被带到壁面区域沿壁面竖直向下流动,也有一部分随气相沿壁面往上流,进入精选区。由于流动的不稳定性,可能在给矿口两侧形成不对称的流动,使得给矿口以上区域的液相与给矿口下部液相发生交换。

3.2 浮选柱矿粒浓度分布

图4 不同高度处液相沿径向的轴向速度分布

Fig. 4 Axial velocity of liquid phase along radial direction at different heights

图5 气相入口与液相入口附近流线图

Fig. 5 Streamline contours of liquid phase around gas inlet(a) and liquid inlet(b)

气-液两相的流动以及涉及浮选动力学的捕集与脱附速率决定了矿粒在气-液两相中的浓度分布,而矿浆浓度的分布直接反映浮选条件的优劣,因此研究矿粒在气相与液相中的分布对于改善流场具有显著意义。

数值模拟初始化浮选柱中液相矿粒浓度为5.307×109 m-3,随着浮选时间的推移,气-液两相中矿粒的平均体积浓度逐渐降低,最后达到稳定,且液相中单位时间内给矿量近似等于净捕获量与排出量之和。沿浮选柱高度每隔2 cm取0.5 cm厚度区域,对每一个厚度区域采用式(23)运算,得到气相或液相中的矿粒浓度。

(23)

(23)

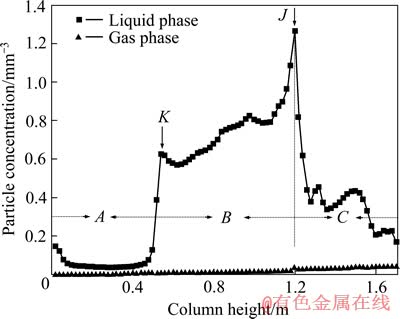

式中:Vcell为控制容积体积,分子表示q相(气相或液相)中局部矿粒总数,分母为局部体积。由此得到的关于柱高变化的矿粒浓度数据如图6所示,由其中气相中矿粒浓度可知,经多孔陶瓷进入的干净气泡在上浮过程中逐渐被矿化,气相中矿粒浓度逐渐增高。

图6 沿浮选柱高度上气相与液相中矿粒体积浓度

Fig. 6 Distribution of particle concentration in liquid phase and gas phase along column height direction

由图6可见,达到稳态后液相中矿粒浓度可以分A、B和C 3个区间进行描述。B区域液相中矿粒随J点处给浆口进入柱体后下降过程中被气泡逐渐捕获,沿下降方向浓度逐渐降低。图中K点对应图5(a)中大旋涡的顶端,在该处上部下降的液相与下部被气相带动上升的液相相遇;K点以下的液相在参与漩涡的循环中矿粒被气泡捕获,液相中矿粒浓度保持低水平,与K点上部下降的较高浓度矿粒浓度形成巨大浓度差。在K处竖直方向的速度趋于0,液相均沿径向迅速分流,然后沿壁面向下流动;含较高浓度的矿浆在向下流动过程中,绝大部分会卷吸到柱中心参与反复循环,在循环过程中被气泡捕获;同时,也存在少量矿粒浓度较高的液相沿壁面下沉到底部出矿口,因而造成0~0.05 m处的液相含较高浓度的矿粒,统计得到由出矿口排出的矿粒占给矿量的3.97%。被上升气流带入C区的液相中含高浓度的矿粒,继续被气相捕获,矿粒浓度迅速降低。而浮选柱C处的液相矿粒浓度高是由初始液相矿粒浓度场与浮选速率达到动态平衡的结果,该区域液相中的矿粒一方面被气相捕获带走,另一方面由未被捕获完全的含高浓度矿粒的液相沿壁面上升而得到补充。该区域由于气相中矿粒浓度较高,因而也为脱附较多的区域。

3.3 浮选过程中颗粒间碰撞、黏附与脱附

浮选的微观过程表现为微气泡与液相中悬浮的矿物粒子碰撞并发生捕获或脱附的过程。根据细微颗粒相互作用的相关理论,可以对浮选柱中气泡与矿粒碰撞速率进行计算,从而更加深入地了解浮选柱中气泡与矿粒的相互碰撞作用强度。

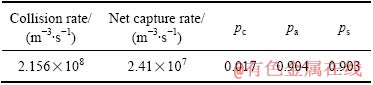

统计浮选柱中气泡与矿粒间相互作用的体积平均参数如表3所列,其中净捕获速率为捕获速率减脱附速率。

表3 颗粒间相互作用参数

Fig. 3 Interaction parameters between bubble and particle

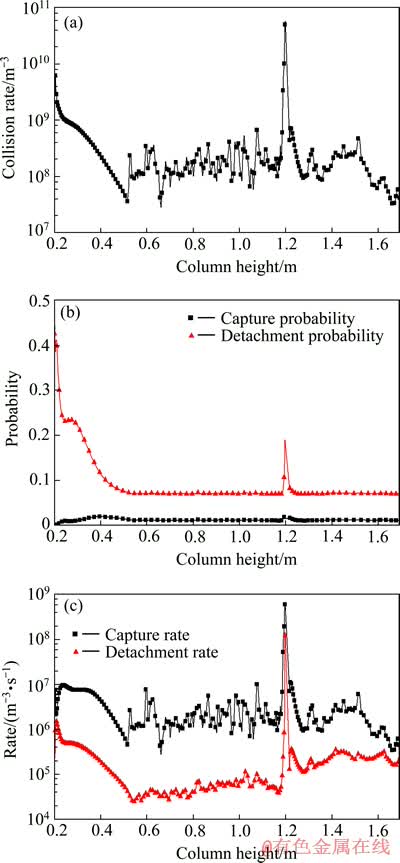

统计发泡区域以上沿浮选柱中心轴线的碰撞速率如图7(a)所示,捕获概率和与脱附概率如图7(b)所示,捕获速率和脱附速率如图7(c)所示。

由图7(a)可知,在0.2 m处(发泡区域的顶端),由于气-液两相速度较大,颗粒间存在较大的碰撞速率,其后随轴线处的速度衰减,碰撞速率迅速减小。另外,在1.2 m(给矿口)处由于液相存在最大的矿粒浓度而呈现高碰撞速率。

浮选过程中捕获概率和脱附概率反映气泡与矿粒间相互作用条件的优劣,综合衡量气泡、矿粒尺寸、液相表面张力、局部流态、矿粒气泡接触感应时间和湿润接触角等对浮选过程中气泡与矿粒相互作用的影响。由图7(b)可以看到,在0.2~0.5 m区间存在较高的气相速度和湍动能耗散,脱附概率高而捕获概率低,另外,在给矿口存在较大的湍动能耗散,也导致脱附概率较高。

捕获速率和脱附速率的计算可以直接反映浮选柱中的浮选效率。如图7(c)所示,在0.2~0.55 m区间存在较大的捕获速率和脱附速率,但是净捕获速率却不高;而0.55~1.2 m区间具有较高的捕获速率和较低的脱附速率,因此净捕获速率高,是浮选柱中的气泡捕获矿粒效率最高的区域;在给矿口1.2 m以后,由于气相中存在较高浓度矿粒,脱附速率增高,净捕获速率下降。

图7 气泡矿粒碰撞速率、捕获概率和脱附概率以及捕获速率和脱附速率

Fig. 7 Collision rate between bubble and particle(a), probabilities of capture and detachment(b) and rates of capture and detachment(c)

4 结论

1) 提出有效气泡浓度的概率,建立浮选柱中矿粒在气-液两相中的输运方程,并进行了数值模拟,发现实验室CPT浮选柱中在高度为0.54~1.24 m区间矿浆浓度高,发泡造成的漩涡区(0.5 m以下)矿浆浓度低。

2) 气泡捕获矿粒区域主要在给矿口以下,并且处在0.5~1.2 m之间的非漩涡区具有较大的捕获速率。

3) 通过浮选过程颗粒间相互作用的基本理论,得到实验室CPT浮选柱中平均碰撞速率为2.156×108次/(m3·s),以及对应浮选工况下的平均碰撞概率为0.017,捕获概率为0.904,脱附概率为0.097。

4) 本研究成果可用于对浮选过程矿粒输运的定量描述,对了解浮选过程中颗粒输运和优化浮选工况具有重要意义。

REFERENCES

[1] HUANG Z, LEGENDRE D, GUIRAUD P. A new experimental method for determining particle capture efficiency in flotation[J]. Chemical Engineering Science, 2011, 66(5): 982-997.

[2] VERRELLI D I, KOH P T L, NGUYEN A V. Particle-bubble interaction and attachment in flotation[J]. Chemical Engineering Science, 2011, 66(23): 5910-5921.

[3]  M. Collision processes involving a single rising bubble and a larger stationary spherical particle[J]. International Journal of Mineral Processing, 2010, 94(1): 58-66.

M. Collision processes involving a single rising bubble and a larger stationary spherical particle[J]. International Journal of Mineral Processing, 2010, 94(1): 58-66.

[4] KOH P T L, SCHWARZ M P, ZHU Y, BOURKE P, PEAKER R, FRANZIDIS J P. Development of CFD models of mineral flotation cells[C]// The Third International Conference on CFD in the Minerals and Process Industries. Melbourne, Australia: CSIRO, 2003: 171-175.

[5] LEE C M, FRANKIEWCZ T. Application of CFD for improved vertical column induced gas flotation (IGE) system development[C]// AIChE Spring National Meeting. Houston: NATCO Group, Inc., 2004.

[6] 杨彩云, 曾爱武, 刘 振. 运用 CFD 模拟浮选柱内的流体流动[J]. 煤化工, 2006(1): 46-49.

YANG Cai-yun, ZENG Ai-wu, LIU Zhen. Study on the hydrodynamics of flotation columns with CFD[J]. Coal Chemical Industry, 2006(1): 46-49.

[7] 郭 晟, 李浙昆. 气泡发生器内三相流动数值模拟[J]. 机电工程技术, 2007(3): 49-51.

GUO Sheng, LI Zhe-kun. Numerical simulation of three-phase flow in the generator of air bubble[J]. Mechanical & Electrical Engineering Technology, 2007(3): 49-51.

[8] 曾 鸣, 徐志强, 皇甫京华, 刘炯天, 张荣曾. 射流浮选柱的单相湍流数值模拟[J]. 辽宁工程技术大学学报: 自然科学版, 2008, 4: 520-522.

ZENG Ming, XU Zhi-qiang, HUANGFU Jing-hua, LIU Jiong-tian, ZHANG Rong-zeng. Single-phase turbulent numerical simulation of jet flotation column[J]. Journal of Liaoning Technical University: Natural Science, 2008, 4: 520-522.

[9] 曾 鸣, 徐志强, 皇甫京华, 刘炯天, 张荣曾. 射流浮选柱的两相流数值模拟[J]. 煤炭学报, 2008, 33(7): 794-798.

ZENG Ming, XU Zhi-qiang, HUANGFU Jing-hua, LIU Jiong-tian, ZHANG Rong-zeng. Two phase flow numerical simulation of jet flotation column[J]. Journal of China Coal Society, 2008, 33(7): 794-798.

[10] KOH P T L, MANICKAM M, SCHWARZ M P. CFD simulation of bubble-particle collisions in mineral flotation cells[J]. Minerals Engineering, 2000, 13: 1455-1463.

[11] KOH P T L, MANICKM M, SCHWARZ M P. CFD modeling of bubble-particle collision rates and efficiencies in a flotation cell[J]. Minerals Engineering, 2003, 16: 1055-1059.

[12] KOH P T L, MANICKM M, SCHWARZ M P. CFD modeling of bubble-particle attachments in a flotation cell[J]. Minerals Engineering, 2005, 19: 619-626.

[13] KOH P T L, MANICKM M, SCHWARZ M P. Modeling attachment rates of multi-sized bubbles with particles in a flotation cell[J]. Minerals Engineering, 2008, 21: 989-993.

[14] SCHUBERT H, BISCHOFBERGER C. On the optimization of hydrodynamics in flotation processes[C]// Proceedings of the 13th International Mineral Processing Congress. Warsaw, 1979, 2: 1261-1285.

[15] ABRAHAMSON J. Collision rates of small particles in a vigorously turbulent fluid[J]. Chemical Engineering Science, 1975, 30(11): 1371-1379.

[16] SAFFMAN P G, TURNER J S. On the collision of drops in turbulent clouds[J]. J Fluid Mech, 1956, 1(16): 16-30.

[17] YOON R H, LUTTRELL G H. The effect of bubble size on fine particle flotation[J]. Mineral Processing and Extractive Metallurgy Review, 1989, 5(1/4): 101-122.

[18] BLOOM F, HEINDEL T J. Modeling flotation separation in a semi-batch process[J]. Chemical Engineering Science, 2003, 58(2): 353-365.

[19] ISHII M, ZUBER N. Drag coefficient and relative velocity in bubbly, droplet or particulate flows[J]. AIChE Journal, 1979, 25(5): 843-855.

[20] 卿 黎. 胶磷矿柱浮选试验及理论研究[D]. 昆明: 昆明理工大学, 2010.

QING Li. Study on theory and experiment of column flotation for collophane ores[D]. Kunming: Kunming University of Science and Technology, 2010.

[21] DEEN N. An experimental and computational study of fluid dynamics in gas-liquid chemical reactors[D]. Aalborg University, 2001.

[22] SCHILLER L, NAUMANN Z. A drag coefficient correlation[J]. Z Ver Deutsch Ing, 1935, 77: 318-325.

[23] HANSEN R. Computational and experimental study of bubble size in bubble columns[D]. Aalborg University, 2009.

(编辑 何学锋)

基金项目:中南大学博士后科学基金资助项目(111033)

收稿日期:2013-05-14;修订日期:2013-10-08

通信作者:闫红杰,教授,博士;电话:13873102530;E-mail: s-rfy@csu.edu.cn