文章编号:1004-0609(2007)07-1135-08

预制体制备方式对PCM法泡沫铝发泡行为的影响

王录才1, 2,曾松岩2,王 芳1,游晓红1

(1. 太原科技大学 材料科学与工程学院,太原 030024;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨150001)

摘 要:采用冷压法、热压法和挤压法3种方式制备了预制体试样,研究试样在不同加热炉温下的发泡行为。结果表明:采用冷压法时,几种加热温度下制备的预制体均不能发泡;采用热压法制备的预制体的发泡效果随加热速度而异,炉温为725 ℃时,没有发泡,试样裂开;炉温为750 ℃和800 ℃时,试样发泡成功;采用挤压法制备的预制体在不同炉温下均能发泡。当压力平衡温度(Tp)小于可发泡温度(Tf)时,预制体不能发泡;当Tp>Tf时,预制体可以发泡,且Δ(Tp-Tf)越大,发泡效果越好;预制体制备方式和加热速度对PCM法制备泡沫铝的发泡效果和行为有显著影响,其中采用挤压法制备的预制体性能最好。

关键词:泡沫铝;PCM法;前驱体;发泡行为

中图分类号:Tb 383 文献标识码:A

Effects of PCM methods on foaming behavior of

Al-TiH2 precursor

WANG Lu-cai1, 2, ZENG Song-yan2, WANG Fang1, YOU Xiao-hong1

(1. School of Materials Science and Engineering, Taiyuan University of Science and Technology, Taiyuan 030024, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The foaming behavior of Al-TiH2 precursor made by different compaction methods of cold pressing, hot pressing and extrusion at different furnace temperatures was studied. The results show that the precursor made by cold pressing cannot foam no matter what the furnace temperature is. The foaming behavior of precursor produced by hot pressing changes with heating rate, the precursor cannot foam and crack occurs at furnace temperature of 725 ℃, inversely, it can foam at furnace temperature of 750 ℃ and 800 ℃. The precursor made by extrusion can foam at any furnace temperature under the experimental condition. Based on theory analysis of experiment results, pressure balance temperature (Tp) and foaming temperature (Tf) were defined. Foaming mechanism and influence of precursor compaction methods and heating rate on foaming behavior were explored using the concepts of Tp and Tf. It is clarified that precursor processing methods and heating rate have remarkable effects on foaming behavior of PCM aluminum foams and the extrusion method is the best one for preparation of PCM aluminum foams.

Key words: aluminum foam; PCM method; precursor; foaming behavior

由于泡沫铝同时具有多项优良性能,成为近年来材料领域一个持续的研究热点。欧美日等发达国家在此方面花费大量的人力物力,已在制备工艺、材料结构、性能等方面积累了大量的基础知识,并已在欧洲开始商业化应用,且其新的应用领域还在不断被开发出来[1-2]。粉末压实熔化(Powder compact melting, PCM)法是近年来在国外研究比较集中的一种工艺,由于其具有工艺稳定,能实现近终形产品的一次成形,易于

和实体结构形成三明治复合结构等特点,虽然研究起步较熔体发泡法和渗流法晚,但发展较快并率先进入应用领域[2-6]。

PCM工艺也称粉末冶金法,在国外开展较早,以德国的Fraunhofer材料研究所和奥地利的Alulight公司为代表,进行连续深入研究并取得很大进展[4, 7]。在欧洲,PCM法泡沫铝已在轻质结构和吸收冲击零件上获得应用、并进入了小批量生产阶段[3-4, 7],同时基础研究也在不断深入[7-11]。而国内这方面的研究相对起步较晚,目前主要集中于制备工艺[12-16]、发泡机理及发泡过程控制、熔体增粘及TiH2处理方法等的研究,还未进入应用领域。

在PCM工艺中,预制体(即前驱体)的制备是重要一环,其制备方式有3种,即冷压法、热压法和挤出法。Banhart等[5]采用挤出法与轧制法制备了各种泡沫铝材[5],王芳、魏莉等[13-14]研究了冷压法泡沫铝制备工艺及并分析了发泡过程;高洪吾等[15]采用冷压法和浸入式预热进行了泡沫铝实验研究;朱勇刚等[16]分别用冷压和热压法研究泡沫铝孔结构及泡壁微观组织的演变等问题。但国内对挤出法的研究以及在同一条件下对3种方法进行对比的研究尚未见报道。因此,本文作者采用同种原材料,对3种不同工艺制备的前驱体的发泡行为进行研究和比较,以确定其工艺参数,并就前驱体制备方式对发泡行为影响的机理进行分析探讨,为后续研究和应用提供基础。

1 实验

1.1 PCM法工艺原理

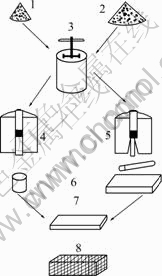

PCM法工艺原理[5]如图1所示。首先将铝粉和发泡剂粉末混合,然后将充分混合的粉末混合物通过压缩得到没有残余通孔的气密结构的预制品,压制工艺可以采取轴向冷压缩、热压缩、热挤出、粉末轧制等工艺。所得到的预制体可以直接利用也可以加工成所需要的形状,最后将预制体或加工品加热到等于或高于铝粉熔点的温度。在加热过程中,发泡剂受热分解,释放出大量气体,首先形成气孔然后气孔长大迫使压实的预制体膨胀,形成具有多孔结构的泡沫铝。

1.2 实验仪器与设备

实验仪器和设备主要如下。

KP200型四柱式液压机;RHL-P610型红外线加热炉;自制冷压、热压、和热挤出模具;Nikon4500型数码照相机;NR-2500型数据采集仪。

图1 PCM法工艺原理

Fig.1 Principle of powder compact foaming process: 1—Foaming agent; 2—Al powder; 3—Mixing; 4—Uniaxial compaction; 5—Extrusion; 6—Precursor; 7—Machining; 8—Al-foam

1.3 实验材料与方法

1) 实验材料

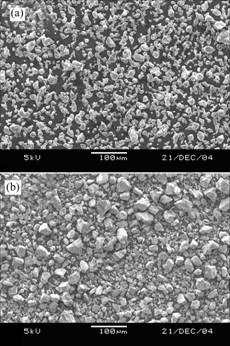

铝粉为工业用纯铝粉,纯度99%,平均粒度 44 μm,粒度与形状如图2(a)所示。发泡剂为TiH2粉,粒度小于45 μm,其粒度与形状如图2(b)所示。

图2 Al粉和TiH2粉的形貌

Fig.2 SEM micrographs of Al powder(a) and TiH2 powder(b)

2) 实验方法

首先将铝粉和TiH2发泡剂粉(TiH2加入量为0.5%,质量分数)在搅拌器内充分混合,然后分别用轴向冷压缩、热压缩、挤压法制备预制体试样。实验参数分别为:①冷压法的压力为300 MPa,温度为常温;②热压法的温度为400~450 ℃,压力为150~200 MPa;③挤压法的温度为450~500 ℃,压力为150~200 MPa。各种方法制备的试样均基本达到致密化程度(密度约为2.67 g/cm3)。接着将预制体试样用红外线加热炉进行加热发泡,用CCD数码相机记录其发泡过程。温度变化曲线用数据采集仪采集,用计算机记录显示。

3) 分析方法

首先宏观观察试样发泡情况,进行定性判断;然后采用相对投影面积定量分析发泡的程度,相对投影面积(Relative area, R)为试样在某一温度下的最大投影面积与试样未发泡前的截面积之比。

2 实验结果

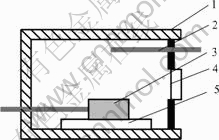

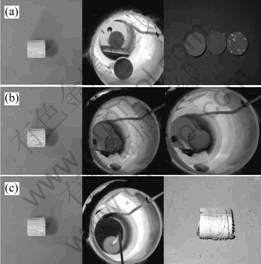

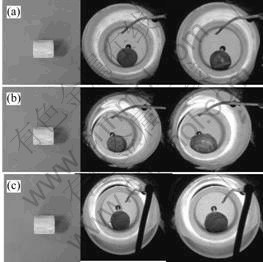

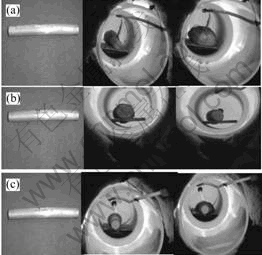

对3种工艺制备的预制体分别在725,750和800 ℃的炉温下进行加热发泡(炉温不同试样的加热速度不同),实验装置示意图如图3所示。冷压法试样发泡过程的照片如图4所示。热压法试样发泡过程的照片如图5所示。挤压法试样发泡过程的照片如图6所示。

由图4可以看出,无论加热速度的快慢如何,冷压法试样在实验温度范围内均不能发泡,试样也未熔化,但各试样均有铝粉颗粒熔化并渗出的现象;炉温为725 ℃时,试样裂断成3段;炉温为750 ℃和800 ℃时,试样没有裂断但均出现多处裂纹。由图5可以看出,热压法预制体试样发泡与否取决于试样的温度及升温的速度,炉温为725 ℃时,试样没有发泡,其中部先有微小的凸起,然后试样端部有裂开;炉温为 750 ℃和800 ℃时,试样均可发泡。由图6可以看出,

图3 实验发泡装置示意图

Fig.3 Schematic illustration of set-up for aluminum foaming: 1—RHL-P610 infrared lamp heating equipments; 2—Thermocouple; 3—Sample; 4—Observe hole; 5—Support

图4 冷压法试样发泡过程

Fig.4 Foaming behavior of cold pressing precursor at different furnace temperatures: (a) 725 ℃; (b) 750 ℃; (c) 800 ℃

图5 热压法制备试样的发泡过程

Fig.5 Foaming behavior of hot pressing precursor at different furnace temperatures: (a) 725 ℃; (b) 750 ℃; (c) 800 ℃

挤压法试样在各个炉温即不同升温速度下,均能发泡,但发泡的情况随炉温和试样的温度而变化。试样温度达到熔点后即开始发泡,发泡效果明显优于热压法。

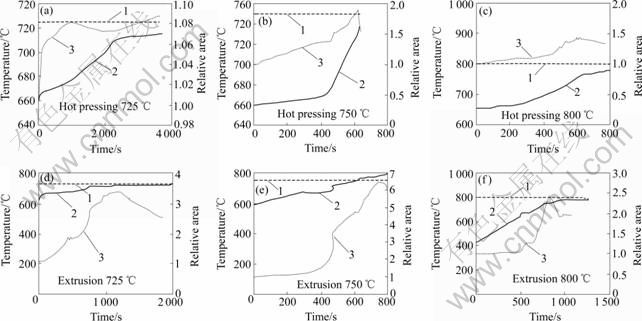

图7所示为不同炉温时热压法和挤压法发泡试样的升温曲线及相对投影面积的变化。图8所示为热压法发泡试样不同炉温下试样断面的照片,图9所示为挤压法发泡试样不同炉温下试样断面的照片。

图7(a), (b)和(c)显示热压法试样的R值均略大于1,且R呈先增加后减小的现象;图7(b)显示R最大值在1.5左右,R值先随温度升高而增大,在750 ℃

图6 挤压法试样发泡过程

Fig.6 Foaming behavior of extrusion precursor at different furnace temperatures: : (a) 725 ℃; (b) 750 ℃; (c) 800 ℃

左右达到最大值,然后减小;图7(d), (e)和(f)显示挤压法试样R最大值均大于2,且R值也随温度升高而增大;图7(d)显示R在700 ℃左右达到最大值,然后减小;图7(e)显示R炉温为750 ℃时试样发泡效果最好,R最大值达到了6.5。另外,由图7还可以看出,炉温越高试样的升温速度越快,炉温为725 ℃时试样升温速度明显很慢;同一炉温时,挤压法试样的升温速度大于热压法的,这可能是引起两者发泡行为不同的原因之一。图8和9表明发泡试样的断面孔结构及其均匀性和预制体制备方法、升温速度及试样温度关系很大,挤压法优于热压法和冷压法。

3 讨论与分析

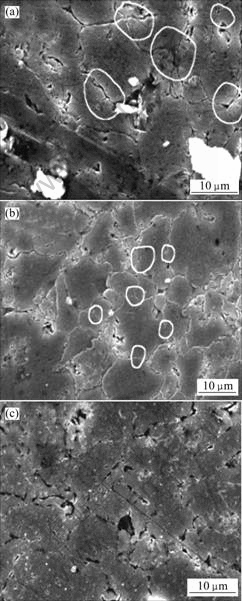

3.1 3种预制体的微观组织及压制机理分析

图10所示为3种方式所制得预制体的微观组织形貌。由图可以看出,挤压法制得的预制体中,粉末颗粒互相连接成一体,组织结构最致密;冷压法制得的预制体中,粉末颗粒均互相独立,边界存在大量缝隙;而热压法制得的预制体中,颗粒之间的缝隙明显减少,有部分颗粒紧密结合在一起,这是由其不同制备工艺决定的。

采用轴向冷压成形时,当对压模中粉末初步施加压力后,粉末颗粒间发生相对移动,粉末颗粒将填充孔隙,使粉末体的体积减小,粉末颗粒迅速达到最紧密的堆积。当粉末体进一步受到外力作用时,粉末颗粒之间由于位移和变形,外表面不规则的凹凸不平的形状,可以互相楔住和勾连,粉末颗粒之间的结合加强,粉末体的强度增大[17]。这种压制方式只是将粉末

图7 不同炉温时热压法和挤压法试样升温曲线及相对投影面积

Fig.7 Temperature evolution curve and foam expansion evolution curve of samples at different furnace temperatures by hot pressing and extrusion: 1—Furnace temperature curve; 2—Temperature evolution curve of samples; 3—Foam expansion evolution curve (R)

图8 热压法发泡试样在不同炉温下的断面照片

Fig.8 Cross-sectional photos of Al foam prepared by hot pressing at different furnace temperatures: (a) 725 ℃; (b) 750 ℃; (c) 800 ℃

图9 挤压法发泡试样在不同炉温下的断面照片

Fig.9 Cross-sectional photos of Al foam prepared by extrusion at different furnace temperatures: (a) 725 ℃; (b) 750 ℃; (c) 800 ℃

颗粒机械的压实在了一起,而且粉末只是颗粒本身发生变形,没有大量的相互位移变形,互相之间的结合不够紧密。粉末表面的氧化膜、粉末表面吸附的水分和其他杂质将会继续在界面存在,颗粒之间也还有很多间隙。因此,整个试样组织不太致密,强度也较低。

采用轴向热压成形时,粉末的变形和位移方式和冷压成形相同,但在高温高压下保持一段时间后,产生以下效应:1) 使得压力传递更加充分,进而有利于预制品中各部分的密度均匀;2) 使粉末中的空气有足够时间通过模壁和模冲之间的缝隙逸出;3) 给粉末之间的机械啮合和变形以较充分的时间,有利于应变驰豫的进行;4) 可以使原子的运动加剧,颗粒界面处的原子通过扩散,使界面互相结合,形成冶金结合的粘结面。在压力一定时,温度越高,越有利于粒子间原子的扩散,而粒子间原子的扩散加速粒子间的联结。从而使得铝粉颗粒之间形成密闭腔,将发泡剂粉末颗粒紧密地包围起来。这些作用使预制体的组织更为致密。比较图10中(a)和(b)可以看出,热压法较冷压法在较大范围内使得颗粒之间更容易紧密结合。图10(a)中有较多的缝隙,如图中圆圈部位所示,而图10(b) 中许多部位都达到颗粒间的紧密结合。

图10 3种压制方式所制得预制体的微观组织形貌

Fig.10 Morphologies of precursors processed by cold pressure(a), hot pressure(b) and extrusion(c)

当采用挤压法压制预制体时,除了受到挤压杆的正压力以外,还受到模壁的侧压力;同时,还有物料与模壁、摸冲(挤压杆)之间因相对移动而产生的摩擦力。在挤压过程中,靠近挤压杆的混合料受力最大,随着远离挤压杆距离的增大而逐渐减小。在挤压筒的径向方向上,愈靠近模壁,物料受到的摩擦力愈大,愈接近中心,物料受到的摩擦力愈小。粉末颗粒除了具有上述两种方式的变形和位移的一些共性外,还会发生大变形量的塑性变形,通过变形使得铝粉颗粒之间结合更为紧密。挤压也是在高温高压下进行,所以它也具有热压法所具有的特点。这些特点使得预制体的组织更为致密和均匀,强度也更高,如图10(c)所示。

3.2 发泡机理分析

如前所述,预制体发泡的过程是TiH2分解形成气泡然后气泡长大并迫使压实的预制体膨胀的过程,所以发泡能否成功取决于TiH2分解和预制体的特性这两个方面。TiH2的分解反应式为 TiH2→Ti+H2↑,TiH2在空气中加热到400 ℃以上后,便开始分解产生气体,600 ℃以上后其分解速度加快,到1 200 ℃分解完 毕[18],TiH2的分解量与温度和时间都有关系。

TiH2在预制体中的分解发泡过程可分为两个环节:1) 气泡的形成;2) 气泡的演变。

1) 气泡的形成机理

用粉体发泡法制备泡沫铝,发泡剂颗粒被密封在压制得到的预制体中。当预制体温度升到一定值,TiH2的分解压大于周围环境的压力时,才可能分解形成气泡,而这种阻力主要来自于周围的母体材料。

从Hill的球体扩张理论可知,非加工弹塑性材料中的球体从零状态扩张成球体所需压力p与其弹性系数E,泊松比υ,屈服强度Y的关系为[19]:

对于一般金属,E/Y≈300~400,υ≈0.25~0.35。因此,可推出:p/Y≈4。

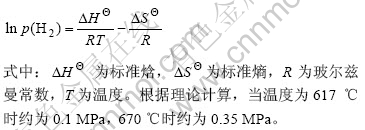

实验所用的发泡剂为TiH2,其平衡分解压可表示为[20]

显然,预制体处于固态时,TiH2不可能分解形成气泡并长大。所以发泡温度应在金属的熔点之上。

2) 气泡的长大过程

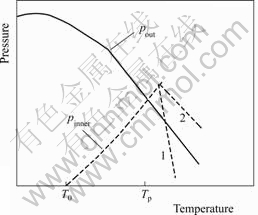

如上所述,只有当TiH2的分解压大于周围母体材料的强度时,才能分解形成气体。但能否形成气泡并长大则还要取决于试样本身的特性,以及预制体的加热工艺。为方便说明,引入以下两个概念。

① 可发泡温度(Tf) 当预制体温度大于熔点后,铝粉颗粒不断被熔化、周围的氧化膜也变软,试样的强度不断降低,可变形能力不断增强。对应于某一温度、预制体就具有连续变形能力或称为具有可发泡性,不同的预制体所对应的温度不同,将此温度定义为试样的可发泡温度,记为Tf,这时试样所具有的状态称为可发泡状态。显然Tf应在粉末材质的熔点(熔点温度用T0表示)以上,即Tf>T0。

② 压力平衡温度(Tp) 当预制体温度达到熔点以上后,随温度升高TiH2迅速分解,气体压力增加。某一温度时,气体压力和周围环境压力相等,二者达到平衡,把达到这一平衡时的温度称为压力平衡温度,记为Tp。显然只有在平衡温度以上,气体压力才会大于周围环境压力,试样才可能发泡。预制体的强度越高,平衡温度Tp也越大。由上述分析可知,Tp>T0。

预制体在加热升温过程中,外部压力(pout)包括周围母体材料的强度或粘度、液体静压力、气体的压力以及表面张力所引起的附加压力[10]。其中,试样强度随试样温度的增加迅速减小,气泡的附加压力随气泡的长大迅速减小。pout和TiH2分解产生的气体压力pinner随温度变化的示意图可如图11所示。

图11 气泡长大过程中内外压力随试样温度T及Tp, Tf的 变化

Fig.11 Schematic illustration of temperature dependence of pout and pinner: 1—Tp<Tf ; 2—Tp>Tf

当试样温度T<Tp时,气体压力小于周围环境压力,试样不会发泡或裂开;当试样温度T>Tp时,气体压力大于周围环境压力,这时可能出现两种情况:如果Tp<Tf (见图11曲线1),预制体还未达到可发泡的状态,则预制体会发生开裂(如图1及图2(a)所示的情况);如果Tp>Tf (见图11曲线2),预制体已达到了可发泡的状态,则预制体可以实现发泡。当气体能形成并长大时,其长大过程始终由pout和pinner的相对值决定,这两种力始终处于动态平衡之中。气泡在长大过程中,会发生合并、上升和逸出现象。发泡时间越长,试样温度越高,这种现象越严重。发泡时间过长或温度过高,试样会因气体的逸出而发生塌陷,发泡结束。控制好试样的发泡温度和时间,并及时冷却可获得好的发泡效果。

3.3 预制体制备方式和试样加热速度对发泡过程的影响

基于上述发泡机理的分析,可以进一步说明几种不同预制体制备方式所制试样的发泡行为。

1) 冷压法

如前述实验所示,冷压法在试验的几种加热温度下都未能发泡。这是因为,由于粉末颗粒表面氧化膜的存在,预制体内粉末颗粒仍互相独立、塑性差、没有连续变形的能力,不具有发泡性。即,几种加热炉温下Tp都小于Tf 。当试样温度>Tp、气体压力大于周围环境压力时,试样在气体的作用下发生断裂。加热炉温低时,试样升温熔化慢,使TiH2有更多时间分解积聚压力,压力平衡温度Tp越低,试样的可变形性越差。随着炉温的升高,试样加热速度加快,平衡温度Tp提高,试样具备了一定的发泡性。所以炉温为725 ℃时,试样断开分成了几段;炉温为750 ℃和800 ℃时,试样没有断开而是出现了裂缝,气体从裂缝逸出,发泡结束。

2) 热压法

炉温为725 ℃时,没有发泡,试样裂开;炉温为750 ℃和800 ℃时试样发泡成功;如3.1节所分析,热压时,粉末颗粒之间结合较冷压法紧密,部分地方由于原子的热扩散作用,形成冶金结合,预制体强度提高,但颗粒表面氧化膜仍然存在。所以,试样的可发泡温度Tf较冷压法降低。炉温低时(725 ℃),加热速度慢,Tp仍小于Tf ,当试样温度>Tp时,气体压力将使试样裂开、气体逸出、发泡失败;随炉温升高,加热速度增快,Tp将大于Tf,当试样温度>Tp时,在气体压力的作用下,实现发泡;炉温进一步提高,Tp越高,TiH2分解速率提高,发泡时间相对减少,合并和逸出的机会也减少,所以发泡效果更好,孔隙率高、气泡也更为均匀。但炉温过高,试样容易达到很高的温度,引起气泡的迅速合并逸出,甚至塌陷,使发泡效果变差甚至失败。

3) 挤压法

在各个炉温时,试样均能发泡。如3.1节所分析,这是因为挤出法所获预制体试样组织致密,颗粒之间为冶金结合,强度高,塑性好,且导热快。所以试样很容易变软熔化,具有连续变形膨胀的能力,即可发泡温度Tf较低;另一方面,从强度角度分析,其压力平衡温度较高,在几种加热方式下Tp都大于Tf,所以各试样都实现了发泡。但不同的升温速度下,试样的发泡组织有所不同,升温速度越高,TiH2分解形成气泡的速率也越快,气泡更为均匀、圆整。但炉温过高,试样容易达到很高的温度,粘度过小,会引起气泡的迅速合并逸出,甚至塌陷,使发泡效果变差甚至失败。这一点和热压法的规律相似。

4 结 论

1) 预制体的加热发泡过程是TiH2分解以及母材的强度和塑性等性能变化、并相互作用的结果。发泡过程中,存在压力平衡温度Tp和可发泡温度Tf两个影响因素,可用其相对大小定性判断试样的发泡情况。

2) 预制体制备方式对PCM法泡沫铝的发泡效果和行为有显著影响。冷压法时,几种加热方式下Tp都小于Tf,均不能发泡;热压法的发泡效果随加热速度而异,炉温为725 ℃下,Tp<Tf时没有发泡,试样裂开;炉温为750 ℃和800 ℃时,Tp>Tf,试样发泡成功;挤压法 在各个炉温时,Tp都大于Tf,试样均能发泡,挤压法效果最好。预制体制备方式对发泡行为影响的原因在于其所引起的粉末颗粒之间结合形式的不同以及预制体的强度和塑性的差别。

3) 加热速度对于预制体的发泡行为影响也很大,并和预制体制备方式相互作用。加热速度越快,压力平衡温度Tp越高,越容易实现发泡且发泡效果变好,但过快时试样容易达到很高的温度,而引起塌陷。加热速度的影响效果主要是因为TiH2分解速度受时间和温度两方面的影响,加热速度快使分解时间相对减少,从而使压力平衡温度Tp提高。

REFERENCES

[1] Ashby M F, Evans A G, Fleck N A, Gibson L J, Hutchinson J W, Wadley H N G. Metal foams: A design guide[M]. Boston: Butter-Worth-Heinemann, 2000.

[2] Banhart J. Manufacture, characterization and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46: 559-632.

[3] Seeliger H W. Aluminum foam sandwich (AFS)—ready for market introduction[C]//Cellular Metals: Manufacture, Properties and Applications. Bremen: MIT-Verlag, 2003: 5-12.

[4] Baumister J, Lehmhus D. Commercially available products made of PM aluminum foams-status and products[C]//Cellular Metals: Manufacture, Properties and Applications. Bremen: MIT-Verlag, 2003: 13-18.

[5] Banhart J. Industrialization of aluminum foam technology[C]// Proceedings of the 9th International Conference on Aluminum Alloys. Austria: Brisbane, 2004: 764-770.

[6] Baumeister J, Banhart J, Weber M. Aluminum foams for transport industry[J]. Materials & Design, 1997, (18): 217-220.

[7] Schaffler P, Rajner W. Process stability in the serial production of aluminum foam panels and 3-dimensional parts[C]//Cellular Metals: Manufacture, Properties and Applications. Bremen: MIT-Verlag, 2003: 39-42.

[8] Arnold M, Korner C, Singer R F. PM aluminum foams: stabilizing mechanisms and optimization[C]//Cellular Metals: Manufacture, Properties and Applications. Bremen: MIT-Verlag, 2003: 71-76.

[9] Stanzick H, Banhart J. Process control in aluminium foam production using real-time X-ray radioscopy[J]. Advanced Engineering Materials, 2002, 4(10): 814.

[10] Duarte I, Weigand P, Banhart J. Foaming kinetics of aluminum alloys[C]//Metal Foams and Porous Metal Structure. Bremen: MIT Verlag, 1999: 97.

[11] Knnedy A R, Lopez V H, Asavavisithchai S. The effect of TiH2 oxidation on gas release and foaming in compacted Al—TiH2 powder precursors[C]//Cellular Metals: Manufacture, Properties and Applications. Bremen: MIT-Verlag, 2003: 95-100.

[12] 周向阳, 刘希泉, 李 劼. 采用新型发泡剂制备泡沫铝[J]. 中国有色金属学报, 2006, 16(11): 1983-1986.

ZHOU Xiang-yang, LIU Xi-quan, LI Jie. Preparation of aluminum foam using novel foaming agent[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1983-1986.

[13] 王 芳, 王录才. 粉体发泡法泡沫铝制备工艺及性能的研究[J]. 铸造设备研究, 2002, 41(1): 16.

WANG Fang, WANG Lu-cai. Research on the producing methods and properties of aluminum foams made by powder metallurgy[J]. Research and Studies on Foundry Equipment, 2002, 41(1): 16

[14] 魏 莉, 唐 骥, 姚广春. 粉末冶金法制备泡沫铝材料发泡过程中孔形态的演变[J]. 铸造, 2004, 53(6): 459-462.

WEI Li, TANG Ji, YAO Guang-chun. Evolution of morphology the aluminum foam in the foaming process by the powder metallurgy method[J]. Foundry, 2004, 53(6): 459-462.

[15] 高洪吾, 刘士魁, 赵彦波, 刘顺华, 李长茂. 加热氧化处理对TiH2释氢行为的影响[J]. 中国有色金属学报, 2005, 15(3): 363-368.

GAO Hong-wu, LIU Shi-kui, ZHAO Yan-bo, LIU Shun-hua, LI Chang-mao. Effect of heat oxidation treatment on gas release behavior of TiH2[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 363-368.

[16] 朱勇刚, 陈 锋, 梁晓军, 何德坪. 粉末冶金发泡时泡沫铝孔结构及泡壁微观组织的演变[J]. 中国有色金属学报, 2004, 14(7): 1106-1112.

ZHU Yong-gang, CHEN Feng, LIANG Xiao-jun, HE De-ping. Evolution of pore morphology and cell wall microstructure of aluminum foam during powder metallurgical foaming[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1106-1112.

[17] 宝鸡有色金属材料研究所. 粉末冶金多孔材料[M]. 北京: 冶金工业出版社, 1978.

Baoji Research Institute of Nonferrous Metal Materials. Powder metallurgy porous materials[M]. Beijing: Metallurgical Industry Press, 1978.

[18] 黄利军, 虞炳西, 高树浚. 钛吸氢和放氢过程[J]. 金属功能材料, 1998, 5(3): 24-26.

HUANG Li-jun, YU Bing-xi, GAO Shu-jun. Kinetics of hydrogen absorption and desorption by titanium[J]. Metal Functional Materials, 1998, 5(3): 24-26.

[19] Akiyama M. The property and application of aluminum foams[J]. Hitatsu Shipbuilding News, 1988(4): 1245-1246. (in Japanese)

[20] Sawata Y K, Kimake S O. Foaming property of aluminum foam made by powder metallurgy[J]. Powder and Powder Metallurgy, 1997, 44(4): 323-328. (in Japanese)

(编辑 龙怀中)

基金项目:山西省留学归国人员科技基金(200540)

收稿日期:2006-07-20;修订日期:2007-06-28

通讯作者:王录才,教授;电话:0351-6999221; E-mail: zsby2@yahoo.com.cn; porous2005@sina.com.cn