变压精馏和萃取精馏分离乙腈和水工艺模拟及优化

余美琼1,杨金杯1,郑志功2

(1. 福建师范大学 福清分校,福建 福州,350300;

2. 中海油山东化学工程有限责任公司,山东 济南,250013)

摘要:基于乙腈与水的共沸特性分析,提出变压精馏和萃取精馏分离乙腈与水的工艺方法,并对2种分离工艺可行性进行研究。利用Aspen Plus软件对2种分离工艺进行模拟并优化,以Wilson活度系数方程为物性计算方法,其二元相互参数由汽液相平衡数据回归,考察理论板数、进料位置和回流比等因素对分离的影响,得到2种分离工艺的较佳工艺参数,并进行能耗比较。研究结果表明:2种分离工艺均能较好地实现乙腈和水的分离,乙腈产品纯度均能达到 99.5%;在相同的处理量及分离要求下,萃取精馏比变压精馏节省能耗,更适合乙腈和水共沸体系的分离,为该共沸物分离的设计与改造提供了依据。

关键词:乙腈;Aspen Plus软件;变压精馏;萃取精馏;节能

中图分类号:TQ028 文献标志码:A 文章编号:1672-7207(2014)09-2966-06

Simulation and optimization for separation of acetonitrile and water by pressure swing distillation and extractive distillation

YU Meiqiong1, YANG Jinbei1, ZHENG Zhigong2

(1. Fuqing Branch, Fujian Normal University, Fuzhou 350300, China;

2. CNOOC Shandong Chemical Engineering Co. Ltd, Jinan 250013, China)

Abstract: Pressure swing distillation and extractive distillation for separation of acetonitrile and water were investigated based on the characteristics of the azeotropic composition. The two separation processes were simulated by Aspen Plus software using the physical property model Wilson with binary parameters obtained by experimental data of vapor liquid equilibrium (VLE). The factors, such as theoretical plates, feed location and reflux ratio, that affected the separation efficiency and energy consumption were analyzed. The results show that acetonitrile and water are both efficiently separated by pressure swing distillation and extractive distillation, and the purity of acetonitrile both can reach 99.5% by these two processes. The two processes evaluated are optimized independently from each other, and the optimal conditions are obtained. For the binary system acetonitrile and water, the extractive distillation is more attractive than the pressure swing distillation because of its energy saving, which provides an effective method for the design and retrofit of separation of azeotropic system.

Key words: acetonitrile; Aspen Plus software; pressure swing distillation; extractive distillation; energy-saving

乙腈是一种重要的有机化工原料,作为溶剂或反应物广泛应用于制药领域,在溶剂回用过程经常需要从水中分离乙腈[1],在丙烯氨氧化法生产丙烯腈过程中也副产乙腈,需从水溶液中提纯[2],乙腈产量约占主产物丙烯腈产量的 3%,同时在硫酸二甲酯水相法生产乙腈的产品精制过程中也涉及到乙腈与水的分离问题[3]。由于乙腈和水存在共沸[4],在常压下共沸点为76.3 ℃,其中乙腈质量分数为84%,要达到《SHT 1627.1—1996 工业用乙腈》优等品纯度 99.5% 要求,采用普通精馏无法实现。共沸体系的分离一般是利用消除共沸或改变共沸组成的方法进行分离提纯,常用的方法有共沸精馏、萃取精馏、液液萃取、变压精馏、吸附及渗透汽化等[5-10]。目前文献报道的乙腈与水分离方法主要是间歇萃取精馏、间歇加盐萃取精馏、间歇变压精馏和渗透汽化等。周金波等[11]以乙二醇为分离乙腈-水体系的萃取剂,常压下测定了乙腈-乙二醇物系的汽液平衡数据,并测定了乙二醇存在下乙腈-水物系的汽液平衡数据,结果表明以乙二醇为萃取剂能够消除乙腈-水物系的共沸点,同时进行了乙腈-水物系的间歇萃取精馏试验,回流比为 2,萃取剂流量与回流量之比(溶剂比) 为 4,塔顶产品中乙腈的摩尔分数达到 98.8%,乙腈的回收率为 75%。崔现宝等[12]通过实验表明氯化钙乙二醇溶液作为萃取剂可消除乙腈-水的共沸点,并进行乙腈-水物系的间歇加盐萃取精馏实验,以氯化钙质量分数为 10% 的乙二醇溶液为萃取剂,回流比为 2,萃取剂流量和回流量之比为 1,塔顶产品中乙腈的摩尔分数达到 99%,回收率为 85%。Repke等[13]利用间歇变压精馏分离乙腈-水,间歇变压精馏由高压塔和低压塔组成,通过实验表明高压塔塔釜可得到高纯度的乙腈,并建立了数学模型,模型计算值与实验值能很好地吻合。张庆武等[14]以渗透汽化陶瓷膜,对乙腈脱水过程进行了实验研究,结果表明,以乙腈-水的共沸液为原料进行渗透汽化脱水,得到的乙腈产品中水的质量分数小于 0.1%,收率达到 98%,但装置的处理量较小,操作时间较长。上述几种分离方法中萃取精馏和变压精馏在实际工业生产过程中应用较广泛,本文作者针对乙腈-水体系,运用化工模拟软件Aspen Plus,采用萃取精馏和变压精馏2种工艺连续操作,对处理量 8 kt/a的乙腈水溶液分离工艺进行模拟与优化(年操作时间 8000 h),规定乙腈产品纯度达到 99.5%,废水中乙腈质量分数小于 0.5%。考察2种分离工艺的各参数对分离和能耗的影响,提出2种分离工艺的较佳方案,并进行对比,以便为乙腈与水共沸体系的分离与节能提供依据。

1 乙腈-水体系热力学参数回归

过程模拟计算的准确性主要取决于汽液相平衡数据的可靠性以及热力学模型的正确选择。对于变压精馏只涉及乙腈与水,萃取精馏则涉及乙腈、水和萃取剂三个物质,后续分析选用乙二醇作为萃取剂。由于乙腈和水存在共沸,为高度非理想体系,选用Wilson方程校正液相非理想性,RK方程校正汽相非理想性。Wilson方程为

(1)

(1)

式中:g为活度系数;x为摩尔分数;N为组分数;i和j为组分;k为序数(k=1~N),

;aij和bij为体系物质间的相互作用参数;Vi和Vj分别为纯物质i与j在计算温度下的浓度,m3/mol。

;aij和bij为体系物质间的相互作用参数;Vi和Vj分别为纯物质i与j在计算温度下的浓度,m3/mol。

利用韩世均[4]测定乙腈-水二元体系在常压下汽液相平衡数据和周金波等[11]测定乙腈-乙二醇二元体系在常压下汽液相平衡数据,通过Aspen中的Data Regression模块分别回归得到乙腈-水、乙腈-乙二醇的Wilson方程的二元相互作用参数,另外乙二醇和水的二元相互作用参数直接使用Aspen数据库中的参数,结果如表 1 所示。

表1 Wilson方程二元相互作用参数

Table 1 Wilson binary interaction parameters

为了验证Wilson方程参数回归的可靠性,对模型计算值和实验值进行比较。对常压下乙腈-水、乙腈-乙二醇体系,已知体系压力及液相组成,利用回归的模型参数分别预测汽相中乙腈的组成和体系温度,结果表明:对于乙腈-水体系汽相中乙腈组成的平均相对误差为0.65%,体系温度的平均相对误差为 0.08%;对于乙腈-乙二醇体系汽相中乙腈组成的平均相对误差为 0.76%,体系温度的平均相对误差为 0.33%。上述计算表明:利用回归的Wilson方程参数预测的计算值能较好地与实验值吻合,说明所选的Wilson方程适合该分离体系,且所回归的模型参数准确可靠,为分离过程的模拟提供可靠的理论依据。

2 2种分离工艺可行性分析

2.1 分离要求

待分离物料工况:进料量为1 t/h,进料温度为25 ℃,乙腈质量分数为72%,水质量分数为28%。经分离要求乙腈产品纯度为 99.5%,废水中乙腈质量分数小于 0.5%。

2.2 变压精馏分离可行性

当共沸物组成对压力变化灵敏时,由压力不同的2个精馏塔串联组成的变压精馏能有效地分离共沸 物[15-16]。将上述回归的Wilson方程参数输入Aspen Plus软件,计算不同压力下乙腈与水的汽液相平衡数据,得到相平衡图及局部放大如图 1 所示,不同压力下共沸组成如表 2 所示。

图1 不同压力下乙腈(1)和水(2)二元体系汽液相平衡图

Fig. 1 VLE diagram of acetonitrile (1) and water (2) binary system at different pressures

表2 不同压力下乙腈与水共沸组成的计算值

Table 2 Calculated azeotropic compositions of acetonitrile and water at different pressures

由图 1 和表 2 可知:常压下乙腈和水共沸组成计算值能很好地与实验值较吻合,说明由汽液相平衡回归的参数准确可靠。增大操作压力,共沸物的乙腈质量分数减少,水质量分数增多,偏离了常压下的共沸。压力为 50 kPa时,二元的共沸组成为:乙腈 0.870 9,水 0.129 1,共沸点56.9 ℃;当压力增大至 300 kPa时,二元的共沸组成为:乙腈 0.786 1,水 0.213 9,共沸点相应增大至 110.8 ℃。基于此特性,可用变压精馏分离乙腈和水,塔顶得到操作压力下的共沸物,塔釜得到高纯产品。

变压精馏工艺流程如图 2 所示,该工艺由减压塔(T101)和加压塔(T102)组成。考虑到热量集成的可操作性及塔顶物料避免使用冷冻水,减压塔 T101 操作压力 50 kPa,塔釜为纯水,温度为 81.4 ℃,T102 操作压力 300 kPa,塔顶温度即为该压力下共沸点温度 110.8 ℃,两者温差29.4 ℃。可利用加压塔 T102 塔顶的蒸汽作为减压塔 T101 再沸器的热源,构成热集成变压精馏系统,可节省能耗。

乙腈和水的混合物流 S101 与 T102 塔釜物流 S109 换热后,与 T102 塔顶循环物流 S108 混合后进入 T101 塔, T101 塔釜物流 S102 排出废水;T101 塔顶的共沸物汽相物流 S103 冷凝后经泵 P101 加压分成2股,物流 S104 回流,物流 S105 进入 T102;加压塔 T102 塔顶汽相共沸物料作为 T101 再沸器的热源,冷凝后经泵 P102 加压,物流 S107 回流,物流 S108 循环至 T101;T101 不足热源由再沸器 E104 提供,T102 塔釜物流 S109 经换热后采出即为高纯度的乙腈产品。

图2 变压精馏工艺流程图

Fig. 2 Process diagram of pressure swing distillation

选用Aspen Plus软件中的Radfrac严格精馏模型及Heater换热模型建立图 2 流程,以循环物流 S108 作为决策变量,塔釜乙腈和水的纯度为约束变量,分离能耗最低为目标函数建立计算模型。根据物料衡算及不同压力下的共沸组成,将物流S108设为撕裂流并赋初值,进行初步模拟。在此基础上,应用Aspen Plus软件的灵敏度工具,优化工艺参数,对两塔的理论板数、进料位置和回流比进行模拟优化。初始模拟条件,T101操作压力为50 kPa,回流比为1.5,第 10 块板进料(由上至下,下同),塔顶采出流量为1 779.6 kg/h;T102操作压力为300 kPa,回流比为1.5,第 10 块板进料,塔顶采出流量为1 057.4 kg/h。T102塔釜物流S109用于预热进料。模拟过程中规定进入 T101再沸器的物流S106流量,其冷凝潜热等于 T101再沸器所需的热量。

2.3 萃取精馏分离可行性

萃取精馏的关键是选择一种适合的萃取剂提高共沸物的相对挥发度(共沸物相对挥发度为 1),消除体系的共沸达到分离目的,因此,萃取剂的选择是萃取精馏的关键因素[17]。萃取剂的选择标准是通过比较不同萃取剂中共沸物的相对挥发度变化情况。相对挥发度值越高,说明越容易分离。相对挥发度的定义为

(2)

(2)

式中:i和j为组分, 为在萃取剂存在下组分i与j的相对挥发度;

为在萃取剂存在下组分i与j的相对挥发度; 和

和 分别为组分i与j的在萃取剂中的无限稀释活度。

分别为组分i与j的在萃取剂中的无限稀释活度。

所有沸点较高的溶剂都可能用于分离乙腈和水的共沸物,本文选用较常见的4种萃取剂进行研究:乙二醇(EG),二甲基亚砜(DMSO),N,N-二甲基甲酰胺(DMF),N-甲基吡咯烷酮(NMP)。利用Wilson方程计算 82 ℃下乙腈和水在不同萃取剂中的无限稀释活度,并得到不同萃取剂中乙腈-水的相对挥发度,结果如表 3 所示。由表 3 可知:对乙腈和水共沸体系,4种萃取剂的加入消除了体系的共沸( 均大于1),且在乙二醇体系中共沸物的相对挥发度最大(13.02),因此,乙二醇是最适合作为乙腈-水体系分离的萃取剂,相对挥发度越大分离所需的费用越低。

均大于1),且在乙二醇体系中共沸物的相对挥发度最大(13.02),因此,乙二醇是最适合作为乙腈-水体系分离的萃取剂,相对挥发度越大分离所需的费用越低。

萃取精馏工艺流程如图 3 所示。该工艺由萃取精馏塔(T201)和溶剂回收塔(T202)组成,其中T201为常压塔和T202为减压塔。乙腈水溶液物流S201与T202塔釜物流S207换热后进入萃取精馏塔T201,T201塔顶得高纯度的乙腈产品;水在塔中被乙二醇萃取,T201塔釜物料乙二醇和水混合物物流S204经泵加压进入T202,水和萃取剂乙二醇在溶剂回收塔 T202精馏分离,塔顶分离出水,塔釜的乙二醇物流S207加压后经换热器E201和E202冷却后进入T201循环使用。

采用Aspen Plus软件中的Radfrac严格精馏模型及Heater换热模型建立图3所示流程。以乙腈和水的纯度为约束变量,分离能耗最低为目标函数建立计算模型,进行初步模拟,再通过灵敏度分析进行工艺参数优化,对两塔的理论板数、进料位置、溶剂比和回流比模拟优化。初始模拟条件如下:T201操作压力为101 kPa,回流比为1.2,乙腈溶液第10块板进料,萃取剂乙二醇第5块板进料,溶剂比(萃取剂与乙腈溶液进料量比值)为1.5,塔顶采出流量为722.2 kg/h;T202操作压力为30 kPa,回流比为1.0,第10块板进料,塔顶采出流量为277.8 kg/h。T202塔釜物流S207用于预热进料。

表3 乙腈(1)-水(2)萃取精馏萃取剂的选择

Table 3 Entrainer selection for extractive distillation system

图3 萃取精馏工艺流程图

Fig. 3 Process diagram of extractive distillation

3 结果与讨论

3.1 变压精馏工艺模拟结果

通过模拟优化,得到变压精馏分离乙腈与水的较佳工艺条件如表4所示,该条件下的各物流如表5所示,各换热器的热负荷如表6所示。由表5可知:当循环物流S108流量为1 057.4 kg/h时,能将全部的乙腈以共沸物的形式带出 T101,T101塔釜得高纯度的水。T102塔顶汽相的冷凝潜热全部应用于T101的再沸器E103中,实现了能量的综合利用。

表4 变压精馏较佳工艺条件

Table 4 Optimal condition of pressure swing distillation

表5 变压精馏较佳条件下的物流

Table 5 Stream results of pressure swing distillation at optimal conditions

表6 变压精馏换热器热负荷

Table 6 Heat duty of heat exchanger of pressure swing distillation

3.2 萃取精馏分离模拟结果

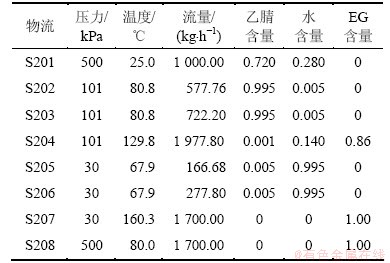

通过模拟优化,得到萃取精馏分离乙腈与水的较佳工艺条件如表 7 所示,该条件下的物流表如表 8 所示,各换热器的热负荷如表 9 所示。由表 8 可知:当循环物流 S208 即萃取剂流量为 1 700 kg/h,即能将全部的水带到 T201 塔釜,T201 塔顶则得高纯的乙腈产品。

表7 萃取精馏较佳工艺条件

Table 7 Optimal condition of extractive distillation

表8 萃取精馏较佳条件下的物流

Table 8 Stream results of extractive distillation at optimal conditions

表9 萃取精馏换热器热负荷

Table 9 Heat duty of heat exchanger of extractive distillation

3.3 2种分离工艺比较

由表 6 和表 9 可知:变压精馏和萃取精馏2种分离工艺,其冷凝器和再沸器消耗的能量总和如表 10 所示。由表 10 可知:对于乙腈-水体系,相同的处理量达到相同的分离要求,萃取精馏工艺更节能,与变压精馏工艺相比,冷凝器节省循环水 54.8%,再沸器节省加热蒸汽 51.2%。且由表 4 和表 7 可知:萃取精馏工艺两塔塔径均比变压精馏工艺小,可节省设备投资费用。这是由于变压精馏工艺中水是从塔顶采出,水的潜热很大,所需能耗较大,而萃取精馏工艺中水是从塔釜采出,能耗较变压精馏低。因此萃取精馏工艺更适合于分离乙腈-水体系。但由于萃取精馏引入第3组分,产品可能夹带第3组分,也存在一定不足。

表10 2种分离工艺能耗对比

Table 10 Comparison of energy consumption of two separation processes kW

4 结论

1) 利用乙腈和水二元体系的汽液相平衡数据,回归Wilson方程的二元相互作用参数,相平衡数据的模型计算值和实验值较吻合。

2) 根据乙腈和水共沸组成随压力变化灵敏的特性,由加压塔和减压塔组成的变压精馏工艺可实现乙腈和水分离;通过萃取剂的筛选,采用萃取精馏工艺,乙二醇是较适合乙腈-水体系分离的萃取剂。

3) 通过Aspen Plus软件模拟计算,表明采用减压塔和加压塔组成的变压精馏工艺和采用萃取塔和回收塔组成的萃取精馏工艺都能有效地实现乙腈和水共沸物的分离,得到2种分离工艺较佳的工艺参数,萃取精馏比变压精馏节约能耗,其中冷凝器节省循环水 54.8%,再沸器节省加热蒸汽 51.2%,更适合该共沸体系的分离,为共沸物分离的设计与改造提供了依据。

参考文献:

[1] 马文婵, 孙建杰, 魏洪普, 等. 萃取法分离乙腈-乙酸乙酯和水混合物的研究[J]. 应用化工, 2010, 38(5): 781-782.

MA Wenchan, SUN Jianjie, WEI Hongpu, et al. Study on separation of acetonitrile and ethyl acetate mixture by extractive distillation[J]. Applied Chemical Industry, 2010, 38(5): 781-782.

[2] 魏奇业, 杨树林, 魏毓良. 乙腈精制过程优化研究[J]. 化工自动化及仪表, 2011, 38(9): 1104-1106.

WEI Qiye, YANG Shulin, WEI Yuliang. Study on acetonitrile purification optimization[J]. Control and Instruments in Chemical Industry, 2011, 38(9): 1104-1106.

[3] 孙小方, 蔡亦军, 夏陆岳, 等. 高纯乙腈连续精制工艺及计算机智能控制系统设计与应用[J]. 化工自动化及仪表, 2010, 37(4): 33-35.

SUN Xiaofang, CAI Yijun, XIA Luyue, et al. Design and application of continuous refining process of high purity acetonitrile and its computer intelligent control system[J]. Control and Instruments in Chemical Industry, 2010, 37(4): 33-35.

[4] 韩世均. 丙烯腈-乙腈-水三元体系汽液平衡的研究[J]. 化工学报, 1980, 31(3): 241-254.

HAN Shijun. The relationship of vapor-liquid equilibria in acrylonitrile-acetonitrile-water ternary systems[J]. Journal of Chemical Industry and Engineering, 1980, 31(3): 241-254.

[5] Donis I R, Esquijarosa J A, Gerbaud V, et al. Separation of n-hexane–ethyl acetate mixtures by azeotropic batch distillation with heterogeneous entrainers[J]. Chemical Engineering and Processing, 2005, 44(1): 131-137.

[6]  R, Montón J B, Burguet M C, et al. Separation of isobutyl alcohol and isobutyl acetate by extractive distillation and pressure-swing distillation: Simulation and optimization[J]. Separation and Purification Technology, 2006, 50(2): 175-183.

R, Montón J B, Burguet M C, et al. Separation of isobutyl alcohol and isobutyl acetate by extractive distillation and pressure-swing distillation: Simulation and optimization[J]. Separation and Purification Technology, 2006, 50(2): 175-183.

[7] Modla G, Lang P. Feasibility of new pressure swing batch distillation methods[J]. Chemical Engineering Science, 2008, 63(11): 2856-2874.

[8] LEI Zhigang, ZHOU Rongqi, DUAN Zhanting. Application of scaled particle theory in extractive distillation with salt[J]. Fluid Phase Equilibria, 2002, 200(1): 187-201.

[9] Kiminori S, Kazunori S, Takashi N. Separation of ethanol-ethyl acetate mixture by pervaporation at 100-130 °C through NaY zeolite membrane for industrial purpose[J]. Microporous and Mesoporous Materials, 2008, 115(1): 170-175.

[10] Asheh S A, Banat F, Lagtah N A. Separation of ethanol–water mixtures using molecular sieves and biobased adsorbents[J]. Chemical Engineering Research and Design, 2004, 82(7): 855-864.

[11] 周金波, 崔现宝, 董炳利, 等. 间歇萃取精馏分离乙腈-水体系[J]. 化学工业与工程, 2009, 26(6): 482-486.

ZHOU Jinbo, CUI Xianbao, DONG Bingli, et al. Separation of acetonitrile-water mixture by batch extractive distillation[J]. Chemical Industry and Engineering, 2009, 26(6): 482-486.

[12] 崔现宝, 李 杨, 冯天扬, 等. 加盐萃取精馏分离乙腈-水物系[J]. 石油化工, 2007, 36(12): 1229-1233.

CUI Xianbao, LI Yang, FENG Tianyang, et al. Separation of acetonitrile-water by saline extractive distillation[J]. Petrochemical Technology, 2007, 36(12): 1229-1233

[13] Repke J U, Klein A, Bogle D, et al. Pressure swing batch distillation for homogeneous azeotropic separation[J]. Chemical Engineering Research and Design, 2007, 85(4): 492-501.

[14] 张庆武, 曹蕊. 乙腈脱水新工艺的研究[J]. 过滤与分离, 2011, 21(1): 42-44.

ZHANG Qingwu, CAO Rui. A new technical research of acetonitrile dehydration[J]. Journal of Filtration & Separation, 2011, 21(1): 42-44.

[15] Estela L, Juan B M, Macruz B. Separation of di-n-propyl ether and n-propyl alcohol by extractive distillation and pressure-swing distillation: Computer simulation and economic optimization[J]. Chemical Engineering and Processing, 2011, 50(11): 1266-1274.

[16] 杨德明, 王新兵, 孙磊. 热集成变压精馏分离甲苯-异丙醇的模拟[J]. 化学工程, 2011, 39(2): 10-13.

YANG Deming, WANG Xinbing, SUN Lei. Simulation of heat-integrated pressure swing distillation for separation of toluene-isopropyl alcohol[J]. Chemical Engineering, 2011, 39(2): 10-13.

[17] WANG Qiaoyi, YU Baoru, XU Chunjian. Design and control of distillation system for methylal/methanol separation. Part 1: Extractive distillation using DMF as an entrainer[J]. Industrial & Engineering Chemistry Research, 2012, 51(3): 1281-1292.

(编辑 陈爱华)

收稿日期:2013-11-03;修回日期:2014-03-22

基金项目:福建省教育厅科研资助项目(JA12355)

通信作者:余美琼(1981-),女,福建福清人,硕士,讲师,从事化工传质与分离研究;电话:13599079339;E-mail: joan091600@126.com