文章编号:1004-0609(2011)05-0995-08

蝶形模具挤压过程的数值模拟

和优锋, 谢水生, 程 磊, 黄国杰, 付 垚

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京100088)

摘 要:在Simufact9.0软件平台上,采用基于Euler网格描述的有限体积法,对蝶形模具非稳态挤压过程进行数值模拟,并与传统模具进行对比。数值模拟结果表明:当采用蝶形模具挤压方型管材时,金属的流动及变形较传统模具挤压时的更加均匀,分流桥上端及焊合室的死区减小;挤压力曲线平稳,没有明显的突变,突破分流孔的挤压力较传统模的降低约72.2%,最大挤压力降低约17.3%;模具的等效应力分布更加均匀,最大等效应力降低约11.2%,模具的使用寿命提高,且分流桥的弹性变形减小,模芯的稳定性提高。

关键词:蝶形模具;铝型材;有限体积法;数值模拟

中图分类号:TG146.2 文献标志码:A

Numerical simulation of butterfly die extrusion process

HE You-feng, XIE Shui-sheng, CHENG Lei, HUANG Guo-jie, FU Yao

(State Key Laboratory of Nonferrous Metals and Processes,

General Research Institute for Non-ferrous Metals, Beijing 100088, China)

Abstract: Based on Simufact9.0 commercial software the non-steady state extrusion process of butterfly die was investigated using finite volume method (FVM) of Euler mesh description and compared with the traditional porthole die extrusion. The simulation results show that when the square tube profile is extruded using the butterfly die, the metal flow and deformation are more homogeneous than those of the traditional die, and the dead metal zone at the top of dividing bridge and welding chamber decreases. Furthermore, the extrusion load curve is smoother and there is no obvious mutation change. The breaking portholes load and the maximum extrusion load of the butterfly die are reduced by 72.2% and 17.3%, respectively. The effective stress distribution is more uniform, and the maximum effective stress is reduced by 11.2%,which improves the die operating life. Moreover, the elastic deformation of the dividing bridge is lowered, and the stability of the die core is improved.

Key words: butterfly die; aluminium profiles; finite volume method (FVM); numerical simulation

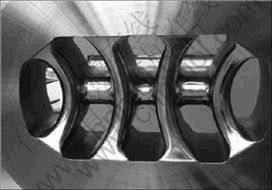

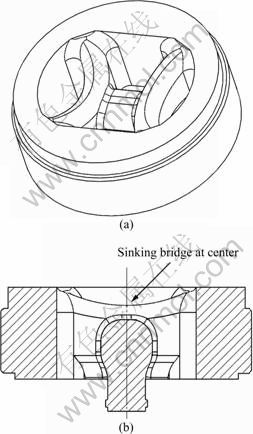

蝶形模具(Butterfly die)是一种新型结构的铝型材挤压模具。与传统模具不同,蝶形模圆形分流桥中心部位较低,用来减小突破挤压力,并帮助金属流入中心进料口。同时,分流桥设计为弯曲的弓形,改善了桥下金属的流动,从而使挤压生产力和多孔分流模的使用性能得到大幅提高。图1所示为应用在9 kt挤压机上的蝶形模具的上模结构[1]。

蝶形模具的概念最早是在20世纪90年代由意大利人提出的,后来,通过美国铝业公司的资深专家进一步开发,在Almax-Mori等公司逐渐得到应用。后来,意大利AlumarSrl公司也加入到了蝶形模具的开发中[1-2]。目前,蝶形模具已被AlumarSrl和Almax-Mori等公司的大多数欧洲客户普遍认同并采用。然而,目前国内尚未发现生产蝶形模具的厂家和研究报告,在蝶形模具挤压生产过程及模具结构设计方面的研究仍为空白。在铝型材非稳态挤压过程的数值模拟方面,国内外学者已进行不少研究[3-9],但主要是采用基于Lagrange网格描述的有限元法,且主要针对一些挤压比较小、型材断面简单的平模及对称性较好的分流组合模具,而采用有限体积法进行数值模拟的研究较少。由于挤压过程属于典型的材料大变形过程,给数值模拟及网格划分带来很大的困难。如采用基于Lagrange网格描述的有限元法,不可避免地会出现由于网格畸变引起的不断重划分及网格自接触问题,导致模拟精度降低或模拟计算无法进行。

图1 应用在9 kt挤压机上的蝶形模具的上模结构[1]

Fig.1 Upper die structure of butterfly die for 9 kt press[1]

因此,本文作者采用基于Euler网格描述的有限体积法,在Simufact9.0软件平台上,对蝶形模具非稳态挤压过程进行数值模拟,详细分析蝶形模具在挤压过程中金属的流动变形行为,并与传统分流组合模挤压过程中金属的流动、挤压力、模具应力及变形进行对比,为蝶形模具结构设计及开发提供指导。

1 有限体积模型的建立

1.1 模具结构设计

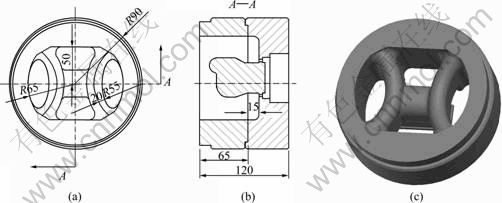

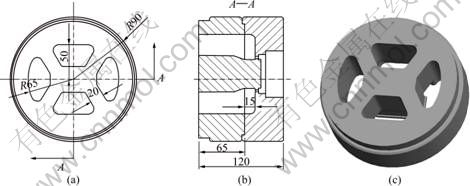

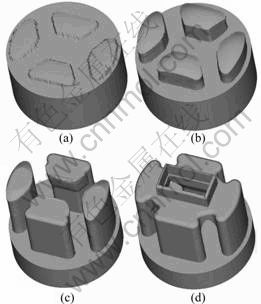

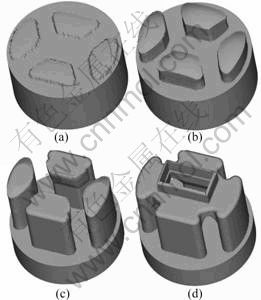

以壁厚为3 mm、截面外形尺寸为66 mm×36 mm的矩形方管为例,设计蝶形模具结构,如图2所示。同时,为了更好地研究蝶形模具与传统模具在挤压过程中金属的流动变形行为,设计一套传统的分流组合模具,如图3所示。为了便于对比分析金属流动、挤压力大小及模具应力场分布,蝶形模具与传统模具的分流孔面积、分流桥宽度、焊合室面积及高度都分别基本一致。

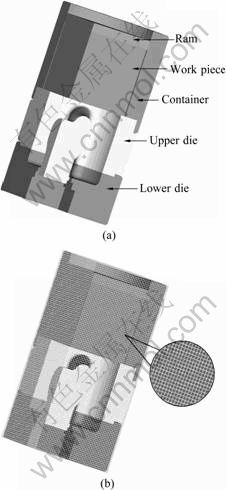

1.2 几何模型的建立

基于Simufact9.0软件平台,采用Euler网格描述的有限体积法,建立蝶形模具挤压数值模拟模型,如图4所示。由于型材截面对称,为节省计算时间及成本,取其1/4进行计算。与Lagrange网格描述的有限元法不同,有限体积法采用Euler网格描述,如图4(b)所示。Euler网格固定在空间不动,材料流动时,网格并不变化,无论材料发生多大的变形,不需进行网格重划,避免了Lagrange网格由于畸变导致网格不断重划分引起的计算精度降低问题。而且材料的流动边界能够与其自身的边界接触并融合在一起,解决了有限元模拟分流组合模具挤压时由于网格的自接触引起网格摺叠而无法计算的问题[10-12]。

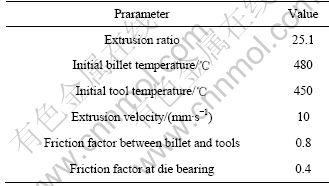

1.3 模拟参数的设定

选取挤压筒直径为140 mm、挤压比为25.1、坯料材料为Al6061铝合金,模具材料采用H13钢。在铝型材挤压模拟中常采用剪切摩擦模型:

f = mk (1)

式中:f为摩擦应力;k为剪切屈服应力;m为摩擦因数。

图2 蝶形模结构设计示意图

Fig.2 Structured schematic diagram of butterfly die (mm): (a) Die assembly drawing; (b) Sectional drawing; (c) Upper die 3D drawing

图3 传统模结构设计示意图

Fig.3 Structural schematic diagram of traditional die (mm): (a) Die assembly drawing; (b) Sectional drawing; (c) Upper die 3D drawing

图4 有限体积法数值模拟模型

Fig.4 Numerical simulation model of FVM: (a) Geometry model; (b) Euler mesh model

在实际生产中,铝型材成形一般采用热挤压,且坯料与工作模具之间没有润滑。在高温高压下,坯料与工模具之间几乎粘结在一起,其摩擦因数取0.8;由于工作带非常光滑且长度较短,挤压时坯料与工作带之间有一定的滑动,因此,取其摩擦因数为0.4[13-15]。其他挤压工艺及数值模拟参数见表1。

表1 数值模拟用挤压工艺参数

Table 1 Extrusion processing parameters in numerical simulation

2 模拟结果与分析

2.1 挤压过程中的金属流动

图5所示为传统模具在挤压过程中金属的流动,其中:S为挤压杆的行程。由图5可以看出,在挤压开始阶段,坯料在挤压力的作用下被分流桥直接劈分为4股金属,然后流入分流孔中,直到S=32.228 1 mm时分流孔中的金属接触到焊合室底部,开始向径向 流动填充焊合室,分流的金属在焊合室的高温、高压下重新融合在一起,最终完全挤出工作带形成挤压 产品。

与传统模具挤压不同,蝶形模具挤压过程中金属的流动如图6所示。从图6可以看出:在开始挤压阶段,当S=3.503 2 mm时,坯料首先填充上模下沉部分(如图7所示);当S=12.501 3 mm时,坯料填充满上模下沉部分后开始接触到圆形分流桥,随着挤压的继续进行,流动金属被中间分流桥劈分为4股金属;当S=32.552 7 mm时,坯料已完全进入分流孔中,随后与传统分流模一样,金属流入焊合室融合在一起,然后挤出工作带。正是因为蝶形模具的分流桥中心下沉,使得金属开始挤压的流动阻力明显减低;其次,蝶形模具的圆形分流桥也使金属的摩擦面积显著减小,金属的变形更加均匀。

图5 传统模具挤压过程中金属的流动

Fig.5 Metal flow in extrusion process of traditional die: (a) S=4.503 2 mm; (b) S=13.501 3 mm; (c) S=32.228 1 mm; (d) S=41.302 3 mm

图6 蝶形模具挤压过程中金属的流动

Fig.6 Metal flow in extrusion process of butterfly die: (a) S=3.503 2 mm; (b) S=12.501 3 mm; (c) S=32.552 7 mm; (d) S=44.562 9 mm

图7 上模结构示意图

Fig.7 Schematic diagram of upper die structure: (a) 3D drawing; (b) Sectional drawing

2.2 挤压过程中的载荷—行程曲线

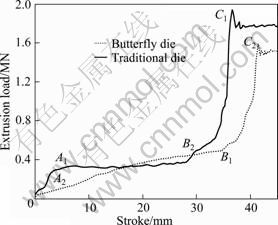

图8所示为蝶形模具与传统模具在挤压过程中的载荷—行程曲线。从图8可以看出,在整个挤压过程中,挤压力曲线变化与分流组合模具挤压中金属的流动变形相对应,主要经过分流、焊合和成形3个阶段。开始阶段,坯料受到挤压杆的压力后首先被镦粗完全充满挤压筒,同时坯料的下端开始突破分流桥的阻力,流入分流孔内。在这个阶段,挤压力迅速上升到A点,然后坯料在分流孔内刚性平移,直到在B点接触到焊合室底部后,挤压力基本不发生变化。坯料接触到焊合室底部后向侧向流动,逐渐填满焊合室,焊合室内的金属开始互相接触而发生焊合。由于金属在焊合过程中焊合室内累积的金属不断增加,其静水压力也不断升高,导致挤压力也急剧上升,在C点达到峰值,由于这一过程极为短暂,所以,挤压力曲线上升梯度非常大。坯料在焊合室中完全焊合后从下模模孔流 出,随着型材完全挤出工作带,挤压进入稳态流动过程,挤压力逐渐趋于平稳。

图8 蝶形模具与传统模具在挤压过程中的挤压载荷—行程曲线比较

Fig.8 Comparison of extrusion load—stroke curves for butterfly die and traditional die

然而,当采用蝶形模具挤压时,挤压力曲线平稳上升,没有明显的突变,其突破分流孔的挤压力在A2点仅为0.1 MN,较传统模具A1点的0.36 MN显著降低,下降约72.2%,减弱了开始挤压阶段坯料对模具的冲击。且最大挤压力也有所降低,传统模具最大挤压力在C1点为1.910 MN,蝶形模具的最大挤压力在C2点为1.580 MN,下降约17.3%。由于蝶形模具模桥中心部分下沉(如图7所示),坯料开始发生变形的阻力较传统模具的减小,因此,蝶形模具的突破挤压力较传统模具的明显降低。其次,由于蝶形模具的分流桥为弓形,且桥上端为圆形,同时,坯料、下沉部分及分流孔组合在一起,改善了桥下隐蔽部分金属的流动,使得桥下死区减少,金属的变形更加均匀,因此,蝶形模具的最大挤压力较传统模具的有所降低。

2.3 不同变形阶段金属的速度场分布

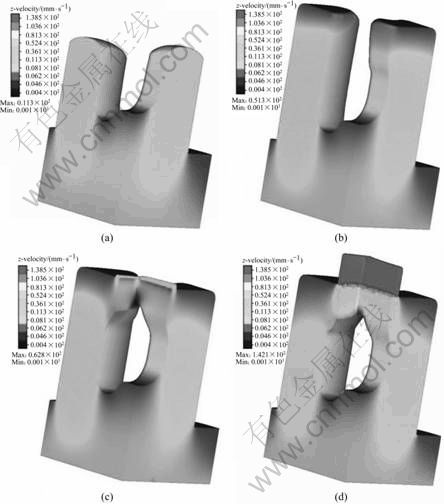

图9所示为蝶形模具在挤压过程中不同变形阶段坯料的速度场分布。当S=29.765 0 mm时,坯料被分流桥劈分后进入分流孔内,各分流孔中心金属由于受到的摩擦力较小,因此,流速明显快于分流孔边缘处的,造成分流孔中心部分金属凸起。由于上模上端的阻碍及挤压筒内壁的摩擦作用,坯料将在挤压筒底部沿着边缘部分形成一个死区,此处金属的流动速度几乎为零,不参与变形。同时,与分流桥上部接触的金属因分流桥的阻碍作用流动速度减缓。随着挤压的继续进行,当S=39.361 5 mm时,分流孔的金属开始接触到焊合室底部,端部金属受到模具限制,沿挤压方向的流动受阻,金属的流动速度降低。当S=42.240 5 mm时,接触到焊合室底部的金属被迫产生侧向流动,在焊合室底部转角处形成第二个死区。金属在径向的速度明显增大,金属将填充满焊合室,同时,剪切变形加剧,进入成形阶段。当S=45.844 9 mm时,坯料被完全挤出工作带,焊合面上的金属停止径向流动,开始沿挤压方向迅速流出模孔,这时,流出模孔的金属流速达到最大值,型材断面出口速度均匀,为138 mm/s。

图9 不同变形阶段金属的速度场分布

Fig.9 Metal velocity field distribution at different deformation phases: (a) S=29.765 0 mm; (b) S=39.361 5 mm; (c) S=42.240 5 mm; (d) S=45.844 9 mm

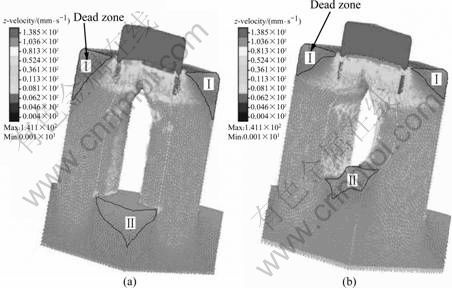

图10所示为坯料完全被挤出工作带达到稳态阶段时蝶形模具与传统模具的速度场矢量分布图对比。由图10可以看出,在挤压过程中坯料与模具接触的地方都有两个明显的死区,一个是沿着焊合室底部边缘形成的死区Ⅰ,另一个是分流桥上端对坯料流动的阻碍形成的死区Ⅱ。由于蝶形模具的分流桥上端为圆形,且分流桥中心下沉,使其对金属流动的摩擦阻力较传统模具的显著减小,因此,蝶形模具死区Ⅱ的体积较传统模具的小。其次,由于蝶形模具的分流桥形状为弓形,且采用两级分流结构,改善了桥下及焊合室内金属的流动,因此,蝶形模死区Ⅰ的体积较小。

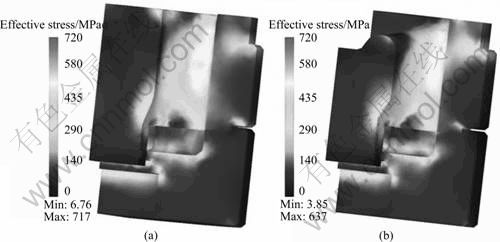

2.4 模具应力分析对比

图11所示为传统模具及蝶形模具在稳态挤压过程中的等效应力分布图。从图11可以看出,在挤压过程中,模具的等效应力分布很不均匀,在模芯根部与分流桥下部连接处应力集中明显,因此,在挤压过程中容易产生裂纹,这与实际生产出现的情况完全吻合。根据模拟结果可知,蝶形模具在挤压中模具的最大等效应力为642 MPa, 较传统模具的717 MPa显著降低,下降约11.2%,这对提高模具的使用寿命非常有利。从图12在挤压方向上模具的弹性变形分布图可以看出,在挤压过程中,模具的最大弹性变形出现在靠近挤压筒中心部位的上模模桥处,根据模拟结果,蝶形模具在挤压方向的最大弹性变形量为0.382 mm,传统模具的为0.437 mm,说明蝶形模具结构提高了分流桥的抗弯性能,且使模芯的稳定性提高,保证了型材尺寸的精度。

图10 稳态挤压阶段金属的速度矢量图对比

Fig.10 Comparison of velocity vector at steady state extrusion: (a) Traditional die; (b) Butterfly die

图11 模具等效应力分布图对比

Fig.11 Comparison of effective stress distribution of die: (a) Traditional die; (b) Butterfly die

图12 模具的弹性变形量分布图对比

Fig.12 Comparison of elastic deformation distribution of dies: (a) Traditional die; (b) Butterfly die

3 结论

1) 采用基于Euler网格描述的有限体积法,对蝶形模挤压方型管材的非稳态挤压过程进行数值模拟,并与传统模挤压过程进行对比。数值模拟结果表明,蝶形模具结构对模具中金属流动、挤压力、模具应力场及弹性变形都有显著影响。

2) 当采用蝶形模具挤压方型管材时,金属的流动及变形较传统模具挤压时的更加均匀,分流桥上端及焊合室死区减小。

3) 蝶形模具的挤压载荷—行程曲线平稳,没有明显的突变,突破挤压力较传统模具的降低约72.2%,有效地降低了开始挤压时坯料对模具的冲击,最大挤压力降低约17.3%。

4) 蝶形模具的等效应力分布均匀,分流桥下的应力集中减小,最大等效应力较传统模的降低约11.2%,且分流桥的弹性变形减小,模芯的稳定性提高。

REFERENCES

[1] MEERBUSCH B R. High-tech ‘butterflies’ from Italy[J]. International Journal for Industry, Research and Application, 2008, 84: 46-49.

[2] PINTER T. Butterfly dies–increase extrusion speed through innovative porthole[C]//Proceedings of International Conference of Extrusion Technology. Orlando, 2008: 42-45.

[3] LOF J, BLOKHUIS Y. FEM simulations of the extrusions of complex thin-walled aluminum sections[J]. Journal of Materials Processing Technology, 2002, 122: 344-354

[4] LEE J M, KIM B M, CHUNG G K. Effects of chamber shapes of porthole die on elastic deformation and extrusion process in condenser tube extrusion[J]. Materials and Design, 2005, 26(4): 327-336.

[5] DONATI L, TOMESANI L. The effect of die design on the production and seam weld quality of extruded aluminium profiles[J]. Journal of Materials Processing Technology, 2005, 164/165: 1025-1031.

References and further reading may be available for this article. To view references and further reading you must purchase this article.

[6] CHENG Lei, XIE Shui-sheng, HUANG Guo-jie, WU Peng-yue, HE You-feng. Non-steady FE analysis in the porthole dies extrusion of aluminum harmonica-shaped tube[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(S1): 32-36.

[7] 方 刚, 王 飞, 雷丽萍, 曾 攀. 铝型材挤压数值模拟的研究进展[J]. 稀有金属, 2007, 31(5): 682-688.

FANG Gang, WANG Fei, LEI Li-ping, ZENG Pan. Review of numerical simulation for extrusion process of aluminum alloy profile[J]. Chinese Journal of Rare Metals, 2007, 31(5): 682-688

[8] CHEN F K, CHUANG W C, TORNG S. Finite element analysis of multi-hole extrusion of aluminum-alloy tubes[J]. Journal of Materials Processing Technology, 2008, 201(1/3): 150-155.

[9] FANG G, ZHOU J, DUSZCZYK J. FEM simulation of aluminium extrusion through two-hole multi-step pocket dies[J]. Journal of Materials Processing Technology, 2009, 209(4): 1891-1900.

[10] LOU Shu-mei, ZHAO Guo-quan, WANG Rui, WU Xiang-hong. Modeling of aluminum alloy profile extrusion process using finite volume method [J]. Journal of Materials Processing Technology, 2008, 206(1/3): 481-490.

[11] WU X H, ZHAO G Q, LUAN Y G, MA X W. Numerical simulation and die structure optimization of an aluminum rectangular hollow pipe extrusion process[J]. Materials Science and Engineering A, 2006, 435/436: 266-274.

[12] 黄光法, 林高用, 蒋 杰, 王 芳, 杨立斌, 彭大署. 大挤压比铝型材挤压过程的数值模拟[J]. 中国有色金属学报, 2006, 16(5): 887-893.

HUANG Guang-fa, LIN Gao-yong, JIANG Jie, WANG Fang, YANG Li-bin, PENG Da-shu. Numerical simulation of extrusion process of aluminum profile with large extrusion ratio[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 887-893

[13] MA X, de ROOIJ M B, SCHIPPER D J. Modelling of contact and friction in aluminium extrusion[J]. Tribology International, 2010, 43: 1138-1144.

[14] FLITTA I, SHEPPARD T. Material flow during the extrusion of simple and complex cross-sections using FEM[J]. Material Science and Technology, 2005, 21: 648-656

[15] BAKHSHI M. A theoretical and experimental study of friction in metal forming by the use of forward extrusion process [J]. Journal of Material Processing Technology, 2002, 125/126: 369-374.

(编辑 陈卫萍)

基金项目:国家“十一五”科技支撑计划项目(2007BAE38B00)

收稿日期:2010-05-10;修订日期:2010-07-02

通信作者:谢水生,教授; 电话: 010-82241265; E-mail: xiess@grinm.com