DOI:10.19476/j.ysxb.1004.0609.2019.05.02

挤压对Mg-10Li-5Al-0.02Zr合金腐蚀行为的影响

贺玉卿,彭超群,王日初,冯 艳

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用X射线衍射(XRD)、电子探针(EPMA)、扫描电子显微镜(SEM)和X射线光电子能谱(XPS)研究挤压前后Mg-10Li-5Al-0.02Zr合金的微观组织及合金在3.5% NaCl(质量分数)溶液中的析氢和电化学腐蚀行为,并分析腐蚀膜结构。结果表明:Mg-Li-Al-Zr合金热挤压后物相由α-Mg相、不规则的AlLi相、弥散的MgLi2Al和β-Li基体组成。热挤压后,合金组织均匀,晶粒细化,第二相数量减少。铸态和挤压态样品的腐蚀速率(PH)分别为(2.74±0.2) mm/a和(1.47±0.2) mm/a,沿挤压方向形成的不连续带状组织和均匀组织减弱微电偶腐蚀,提高合金的耐蚀性。挤压态Mg-Li-Al-Zr合金在NaCl溶液中浸泡时,表面形成一层较致密的腐蚀表面膜,其由Mg(OH)2、LiOH、Li2CO3和MgO构成。

关键词: 镁锂合金;电化学测试;腐蚀行为

文章编号:1004-0609(2019)-05-0896-10 中图分类号:TG146.2 文献标志码:A

镁锂合金由于其高的比强度和比强度、超轻性能、优良的加工性能和抗震性能,因而广泛地应用于军事、航空航天、阳极材料和生物领域。镁锂合金的密度一般为1.35~1.65 g/cm3,是目前密度最小的金属材料。由于其优良的加工成型性和低密度的特性,镁锂合金在国民经济许多领域,尤其是航空航天及电子领域中更受人们青睐。少量Li元素的加入可以改变具有密排六方结构Mg的轴径比(a/c),提高镁合金的可加工性。当Li含量低于5.7%时,基体主要由α-Mg单相组成;Li含量高于10.3%时,基体主要由β-Li (BCC)单相组成;当Li含量为5.7%~10.3%时,合金由(α-Mg+β-Li)双相组成。在双相范围内,合金具有超塑性[1-3]。

近年来,许多学者对双相镁锂合金进行了大量力学性能方面的研究,比如通过添加合金化元素、塑性变形等方法来提高合金的力学性能[4-8]。但由于锂元素的化学活性比镁的更强,双相镁锂合金的耐腐蚀性能较差,从而限制了镁锂合金的使用。镁锂合金的耐腐蚀性能主要受合金元素、微观组织、表面膜形貌和合金所处环境的介质等影响。LIN等[9]研究了Al元素及其含量对镁锂合金耐腐蚀性能的影响。发现Al能与Li形成AlLi相,在腐蚀过程中该相能转化为Al颗粒来使腐蚀表面膜更致密,从而提高合金的耐腐蚀性能。XU等[10]也研究了在0.1 mol/L NaCl溶液中,β-Li单相Mg-Li 合金(Mg-10.95Li-3.29Al-0.59Y-0.19Zr)的腐蚀行为,发现该合金具有较优的耐腐蚀性能。结合XPS结果发现,由于合金具有弥散分布的纳米级的富Li相,使腐蚀表面膜表面生成致密而均匀的Li2CO3化合物层,从而阻碍溶液进一步腐蚀基体。但是WANG等[11]发现了Mg-8%Li在3.5% NaCl溶液中具有较差的耐腐蚀性能(阴极腐蚀电流密度为(197±19) μA/cm2), Cl-浓度的增加会加剧镁锂合金的腐蚀。

挤压可以使镁锂合金的基体组织和第二相细化,有利于提高其耐腐蚀性[12]。本文作者主要研究了热挤压对Mg-10Li-5Al-0.02Zr双相镁锂合金微观组织和腐蚀行为的影响,为提高合金耐腐蚀性能提供理论指导。

1 实验

1.1 熔炼铸造

实验合金制备:镁(Mg)、锂(Li)和铝(Al)以纯度为99.99%(质量分数)的金属加入,钇(Y)和锆(Zr)以中间合金加入(Mg-29.20% Y和 Mg-32.78% Zr)。考虑某些较活泼的元素在熔炼过程中有烧损,适量增加其烧损量。先对炉子排气至2.4 Pa,然后充入氩气至0.05 MPa。

如表1所列,将原料按成分逐一加入不锈钢坩埚中,保温30 min。待熔炼完成后,将熔体注入模具中,注入过程中保持熔体流动平稳且连续,去除底部残渣。冷却30 min后,泄压取出铸锭。将铸锭置于380 ℃下均匀化8 h,淬火后车去表面氧化皮,在260 ℃下预热2 h,挤压为板材,挤压比为19.22:1。其实际成分由电感耦合等离子体原子发射光谱(ICP-AES)检测,其名义成分、具体成分如表1所列。

表1 Mg-Li-Al- Zr合金的化学成分

Table 1 Chemical compositions of Mg-Li-Al- Zr

1.2 微观组织分析及物相鉴定

挤压样以挤压面作为工作面。在扫描电镜下进行观察。微观组织和腐蚀形貌采用扫描电镜(SEM,Quanta-200,附带EDS)进行观察。合金物相的确定采用X射线衍射仪(XRD,D/Max 2500),扫描范围为10°~80°,扫描步长为4°。合金元素分布图由电子探针显微分析仪(EPMA)分析得出。

1.3 电化学测试

采用三电极体系进行电化学测试。合金试样作为工作电极,饱和KCl甘汞电极作参比电极,铂电极作辅助电极。电解液为3.5% NaCl(分析纯NaCl+蒸馏水)溶液,实验温度为恒定室温((25±1) ℃)。该测试于辰华电化学工作站(CHI660D)上进行。

动电位极化曲线(PDP)测试时,在3.5% NaCl溶液中静置5 min,待其电位稳定后进行测试,扫描速度为2 mV/s,扫描范围为-2~-1 V(vs SCE)。试样由极化曲线所得的阴极腐蚀电流密度Jcorr(mA/cm2)由CorrView软件中的Tafel外推法拟合得出。其相应的平均腐蚀速率Pi(mm/a)可由式(1)[13]得出:

Pi=22.85Jcorr (1)

在开路电位(OCP)下进行交流阻抗(EIS)测试,测试频率范围为100 kHz~10 mHz,振幅为20 mV。测得的曲线用Z-View软件进行拟合。

1.4 析氢自腐蚀测试

在室温((25±1) ℃)下将试样浸泡在3.5% NaCl溶液中测量其析氢自腐蚀速率。在烧杯中先倒入溶液后放入试样,倒扣玻璃漏斗,用滴定管装满溶液倒扣在漏斗上,用排水法收集合金与溶液反应后生成的氢气。实验开始未产生析氢时的读数为V1(mL),管内的液面下移,可通过一段时间t (h)排出的溶液体积读出产生的氢气量V0 (mL)。则析氢自腐蚀速率vH2(mL/(cm2×d))可由式(2)计算出:

(2)

(2)

该实验中,测试表面积A(cm2)为1,每隔1 h记录一次析氢量,最后描绘出其析氢量随时间变化曲线图。相应的腐蚀速率PH (mm/a)由式(3)[13]得出:

(3)

(3)

析氢实验和电化学测试均取3个平行样。

1.5 腐蚀表面膜分析

合金浸泡在3.5% NaCl溶液中1 h以后,采用带AlKα电子X射线光电子能谱分析仪(XPS, ESCALAB 250) 对合金腐蚀表面膜的元素信息进行分析,其功率设定为200 W。

在室温下将抛光后的试样浸泡26 h后,用铬酸溶液(200 g/L Cr2O3+10 g/L AgNO3)在超声波清洗机中去除表面腐蚀产物5 min,然后在无水乙醇中继续超声5 min,吹干。在扫描电镜二次电子下观察其未去除腐蚀产物的表面形貌,在背散射下观察其去除腐蚀产物的表面形貌。

2 结果与分析

2.1 微观组织

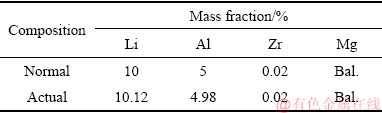

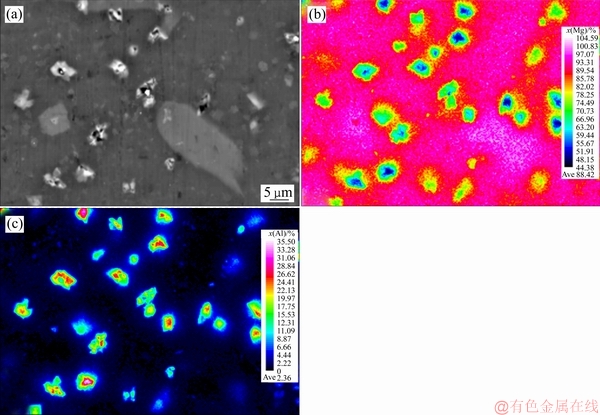

Mg-Li-Al-Zr合金热挤压前后的XRD谱如图1所示。可以看出,热挤压前后的合金未有物相的变化,都主要由β-Li相组成,此外还含有少量α-Mg、AlLi和极少量MgLi2Al 3种相组成。而与铸态相比,挤压后的AlLi和MgLi2Al相的含量稍多。

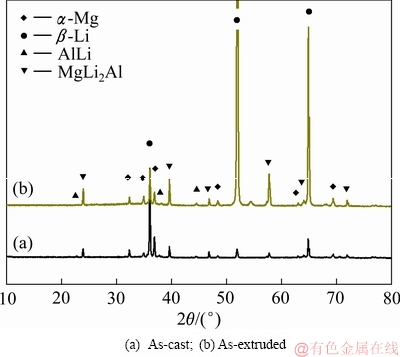

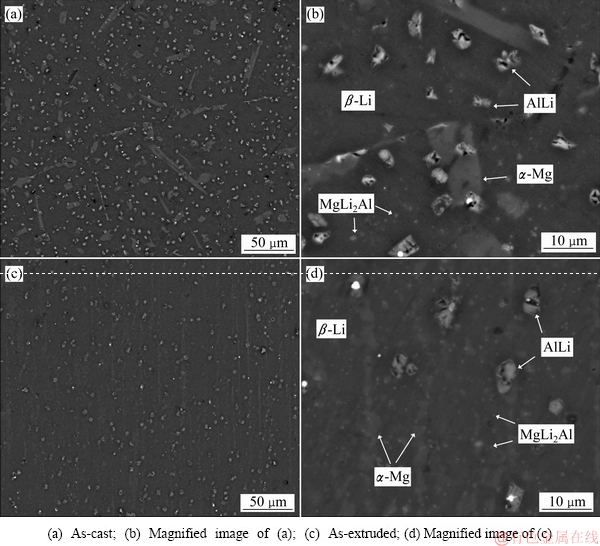

Mg-Li-Al-Zr合金热挤压前后的背散射照片如图2所示。由图2(a)可见,在铸态Mg-Li-Al-Zr合金中,较大亮色的长块状物分布在晶界和晶体内部。图3所示为铸态Mg-Li-Al-Zr合金的背散射照片和EPMA结果。由图3可见,暗色基体和较亮色长块状物主要由Mg元素组成,而后者的Mg含量明显高于前者的(Li为轻质元素,无法检测)。结合图1可知,暗色基体为β-Li相,较亮色的长块状物为α-Mg相。由文献[11-14]可知,当Mg-Li合金中Li含量为5.7%~10.3%时,合金主要由(α-Mg+β-Li)双相组成。由图2(b)可见,大小不均匀、直径约为1~5 μm的亮色不规则颗粒主要分布在暗色基体内和较大亮色的块状物中,结合图3可知其为富Al化合物,结合图1可知该相为AlLi相。WU等[15]发现在Li含量大于3%的Mg-Li合金中,Al元素能与Li形成AlLi相。从图2(b)中还能看到有白色细小的颗粒弥散分布在暗色基体中,由图3可知其主要由Mg、Al元素组成,结合图1可知该相为MgLi2Al相。由图2(c)和(d)可见,在挤压态Mg-Li-Al-Zr中,沿挤压方向出现明显的带状组织,较亮色的α-Mg相呈不连续条状分布在暗色基体中,而白色不规则的AlLi小颗粒趋于椭圆形,大小较均匀,直径约为3 μm,且与铸态Mg-Li-Al-Zr合金的相比,数量明显减少。而在图2(d)中,弥散分布的白色极细小颗粒为MgLi2Al相,与铸态Mg-Li-Al-Zr合金的相比,数量更少且分布更均匀。

因此,热挤压前后,Mg-Li-Al-Zr合金的物相未发生改变。而挤压后α-Mg相沿着挤压方向呈不连续的带状分布,且挤压后的AlLi和MgLi2Al相比铸态分布得更均匀,AlLi相数量更少。

图1 Mg-Li-Al-Zr合金的XRD谱

Fig. 1 XRD patterns of Mg-Li-Al-Zr alloys

2.2 腐蚀行为

2.2.1 析氢自腐蚀测试

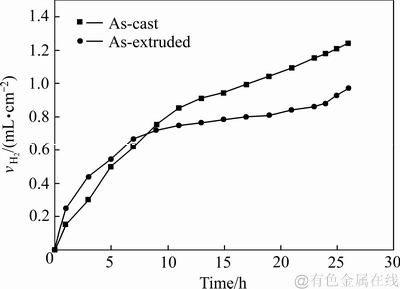

Mg-Li-Al-Zr合金热挤压前后在3.5% NaCl溶液中的析氢曲线如图4所示。由图4可知,合金在热挤压前后的析氢趋势一致:腐蚀初期,铸态的析氢速率随时间呈线性增长,而挤压态的析氢速率高于铸态的;腐蚀8~10 h时,铸态和挤压态样品的析氢速率均逐渐变慢,但依然增长,其中挤压态的析氢速率明显低于铸态的;腐蚀18~20 h左右时,两者的析氢速率均有增加,铸态的呈线性增长,而挤压态样品增幅较小。挤压前后Mg-Li-Al-Zr合金的析氢速率(VH2)及相应公式计算得出的平均腐蚀速率(PH)的结果如表2所列。铸态和挤压态样品的平均腐蚀速率分别为(2.35±0.2) mm/a和(2.12±0.2) mm/a,可知挤压后合金的析氢自腐蚀速率有所下降,耐腐蚀性能提高。

图2 Mg-Li-Al-Zr合金的背散射电子像

Fig. 2 Backscattered electron images of Mg-Li-Al-Zr alloys

图3 铸态Mg-Li-Al-Zr合金的背散射照片和在电子探针显微分析仪下相应的Mg和Al元素分布图

Fig. 3 Backscattered electron image of cast Mg-Li-Al-Y-Zr alloy(a) and corresponding elemental distribution maps of Mg(b), Al(c) under EPMA system

图4 Mg-Li-Al-Zr合金3.5% NaCl溶液中的析氢曲线

Fig. 4 Hydrogen evolution curves of Mg-Li-Al-Zr alloy immersed in 3.5% NaCl solution

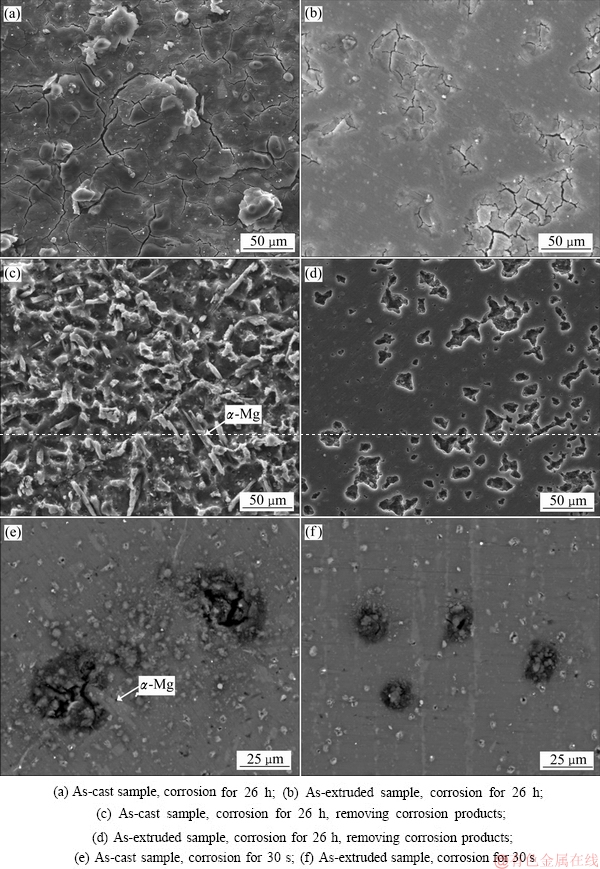

Mg-Li-Al-Zr合金热挤压前后在3.5% NaCl溶液中腐蚀后未去除腐蚀产物的表面形貌如图5所示。由图5(a)和(b)可知,浸泡26 h后挤压态合金比铸态合金的腐蚀表面光滑,且腐蚀产物膜上只有少量裂纹,而铸态合金的腐蚀产物较疏松,且表面容易剥落。这表明挤压后合金的腐蚀表面膜较致密且阻止溶液的局部腐蚀。图5(c)和(d)所示为合金挤压前后在3.5%NaCl溶液中浸泡26 h后去除腐蚀产物的表面形貌。由图5(c)可见,铸态合金的腐蚀表面不均匀,含有许多裸露的块状α-Mg相,晶内能看到较光滑的腐蚀圆坑,晶界上被腐蚀。由图5(d)可见,挤压态合金的腐蚀表面更光滑,且有少量腐蚀坑,其数量和密度均小于铸态合金的腐蚀表面。图5(e)和(f)所示为合金挤压前后在3.5% NaCl溶液中浸泡30 s后的表面形貌。由图5(e)和(f)可见,铸态合金的腐蚀坑数量少于挤压态合金的,但其腐蚀较严重,且点蚀开始于块状α-Mg和基体β-Li两相之间。挤压态合金的腐蚀主要发生在暗色基体β-Li相中,未明显沿着带状组织腐蚀,这说明α-Mg相的形貌和分布对合金的腐蚀有明显影响。

由此可知,在铸态样品中,分布在晶粒内和晶界上的α-Mg和β-Li基体组成了腐蚀原电池,且Li 的电位(-3.02 V (vs SHE))明显低于Mg的电位(-2.37 V (vs SHE))[16],而β-Li和α-Mg相元素上的主要区别是两相中的Mg和Li含量不同(β-Li相中Li含量高于Mg含量)。因此,β-Li相的电位低于α-Mg相的,两相间发生微电偶腐蚀,从而使β-Li相被腐蚀。而挤压态样品中,由于α-Mg相沿着挤压方面形成不连续的带状组织,因此弱化了β-Li和α-Mg两相间的微电偶腐蚀。因此,热挤压可以提高合金的耐腐蚀性能。

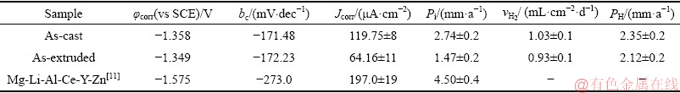

表2 Mg-Li-Al-Zr合金由析氢速率和极化曲线拟合得出的结果

Table 2 Electrochemical data calculated from polarization curve and hydrogen rate of Mg-Li-Al-Zr alloy

图5 Mg-Li-Al-Zr合金在3.5% NaCl溶液中浸泡后的腐蚀表面形貌

Fig. 5 Corrosion surface morphologies of Mg-Li-Al-Zr alloy after immersion in 3.5% NaCl solution

2.2.2 动电位极化曲线测试

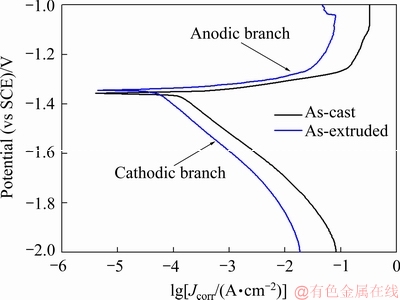

热挤压前后的Mg-Li-Al-Zr合金在3.5% NaCl溶液中的动电位极化曲线如图6所示。由图6可见,两条极化曲线皆由两部分组成:与析氢还原反应有关的阴极支和与电极的阳极溶解有关的阳极支。两个样品中的阴极支和阳极支左右两侧明显不对称,其中阳极区的电流密度较大是由于镁合金的电位极负,在阳极区也会发生析氢反应,形成了负差数效应。由CorrView软件中的Tafel外推的腐蚀电位(φcorr)更负,在120~250 mV范围内的阴极支得到了相应的腐蚀电流密度(Jcorr)。当低于腐蚀电位(φcorr)时,阴极支呈现线性关系,挤压态的阴极腐蚀电流密度小于铸态。随着电位从腐蚀电位φcorr (vs SCE)往正扫时,腐蚀电流密度急剧增加且两个样品中都未出现明显的点蚀电位(φp)。这表明了样品发生了快速腐蚀,该腐蚀的过程是由两方面引起的。首先,在阳极极化条件下合金的腐蚀加剧。其次,腐蚀膜的保护性是有限的。PARDO等[17]研究了Mg(OH)2 腐蚀膜在pH<11.5的3.5% NaCl溶液中不稳定且容易脱落,从而使合金进一步被腐蚀。超过腐蚀电位(φcorr)后腐蚀电流密度(Jcorr)急剧增加。其中铸态的阳极支光滑且并未出现明显的点蚀电位(φp),但未出现钝化现象。而挤压态样品中在阳极支随着电位正扫,出现一定程度地波动,这可能是由于样品表面的腐蚀产物剥落。

图6 Mg-Li-Al-Zr合金的动电位极化曲线

Fig. 6 Potentiodynamic polarization curves of Mg-Li-Al-Zr alloy

由极化曲线阴极支拟合所得的析氢数据和有关公式计算出的结果如表2所列。为了比较Mg-Li-Al-Zr合金的腐蚀性能,同时也给出了在3.5% NaCl 溶液中的Mg-8%-Li-3%Al-1%Ce-1%Y-1%Zn (Mg-Li-Al-Ce- Y-Zn)[11]的结果。铸态和挤压态样品的腐蚀速率(Pi)分别为(2.74±0.2) mm/a和(1.47±0.2) mm/a。铸态和热挤压的腐蚀电流密度(Jcorr)分别为(119.75±8) μA/cm2和(64.16±11) μA/cm2。两个样品的Jcorr结果均明显小于由Mg-Li-Al-Ce-Y-Zn得出的数据(Jcorr=(197±19) μA/cm2)。而腐蚀电流密度越小则意味着拥有更好的耐腐蚀性能[18-19],因此热挤压可提高Mg-Li-Al-Zr合金的耐腐蚀性能,且优于Mg-Li-Al-Ce-Y-Zn合金的。由极化曲线的阴极腐蚀电流密度所得阴极腐蚀速率和由析氢速率所得的腐蚀速率略有不同。这是由于后者得到的是一段时间内的平均腐蚀速率(PH),而前者所得的腐蚀速率(Pi)则表示为合金的瞬时腐蚀速率[13]。在分析镁合金腐蚀行为时,如析氢这样的长周期测试是十分必要的。

2.2.3 交流阻抗测试

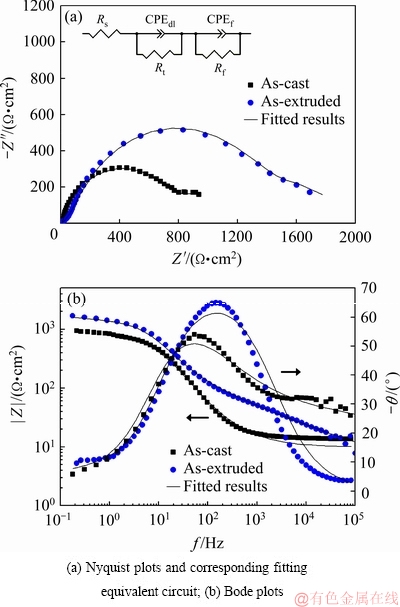

图7 Mg-Li-Al-Zr合金在开路电位下(OCP)的交流阻抗图谱

Fig. 7 Electrochemical impedance spectra (EIS) at OCPs of Mg-Li-Al-Zr alloy

图7所示为Mg-Li-Al-Zr合金在3.5%NaCl溶液中开路电位(OCP)下的交流阻抗图谱(EIS)。热挤压前后样品的交流阻抗Nyqiust图均由两个大小不等的容抗弧组成,且其Bode中也包括两个相对应的容抗弧峰。在高频区中,较大容抗弧与双电层的电极/电解质界面有关,而低频区中较小的容抗弧与电极表面的腐蚀膜有关。由图7(a)可知,挤压态样品的两个容抗弧半径均明显大于铸态样品的。热挤压前后样品的等效电路图和相应的拟合结果如图7和表3所示。为了便于比较,Mg-8Li-3Al-1Ce-1Y-1Zn合金在3.5% NaCl溶液中的交流阻抗拟合结果也列于表3中。在图7中,Rs表示溶液电阻,Rt表示电荷转移电阻,Rf表示膜电阻。在高频区中,平行于电荷转移电阻(Rf)的较大容抗弧与电极/电解液界面的双电层有关,低频区较小的容抗弧则与工作电极表面的Mg(OH)2膜有关[20-21]。CPEdl表示双电层的常相位角元件,而CPEf表示Mg(OH)2的常相位角元件[22-23]。而常相位角元件(CPE)一般表示非理想的电容和补偿系统的非均匀性[24-25] ,其出现与电极表面的微观粗糙度有关[26]。CPE可以根据Y和n两个参数并由式(4)[27]计算得出,式中的ωm表示容抗虚部达最大值是所对应的角频率。

C = Y·(ωm)n-1 (4)

从表3可以看出,铸态和挤压态合金在高频区的电荷转移电阻(Rt)分别为748.70 Ω·cm2和1095.00 Ω·cm2,即挤压态的Rt较大,这表明了溶液中的电子比较不易穿过电极表面的双电层。在低频区,挤压态样品的膜电阻(Rf)值为1466.00 Ω·cm2,铸态样品的为350.00 Ω·cm2,而Mg-Li-Al-Ce-Y-Zn合金未出现小的容抗弧。这表明了挤压态Mg-Li-Al-Zr合金表面的Mg(OH)2膜有利于抑制其腐蚀的扩展,而Mg-Li-Al-Ce-Y-Zn合金的腐蚀膜不能保护镁合金基体[27-28]。由式(5)[20-29]计算出极化电阻(Rp):

(5)

(5)

在镁合金中,极化电阻(Rp)值越大,则腐蚀速率越低,合金的耐腐蚀性能越好。由表3中可知,Mg-Li-Al-Zr铸态和挤压态样品的极化电阻(Rp)分别为2569.60和1112.10 Ω·cm2,Mg-Li-Al-Ce-Y-Zn合金的极化电阻(Rp)分别为1112.1和232.0 Ω·cm2,这表明挤压后的Mg-Li-Al-Zr合金比铸态的耐腐蚀性能好,且两者都明显比Mg-Li-Al-Ce-Y-Zn合金的耐腐蚀性能好,这与析氢和极化曲线测试所得结论一致。

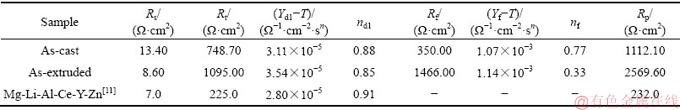

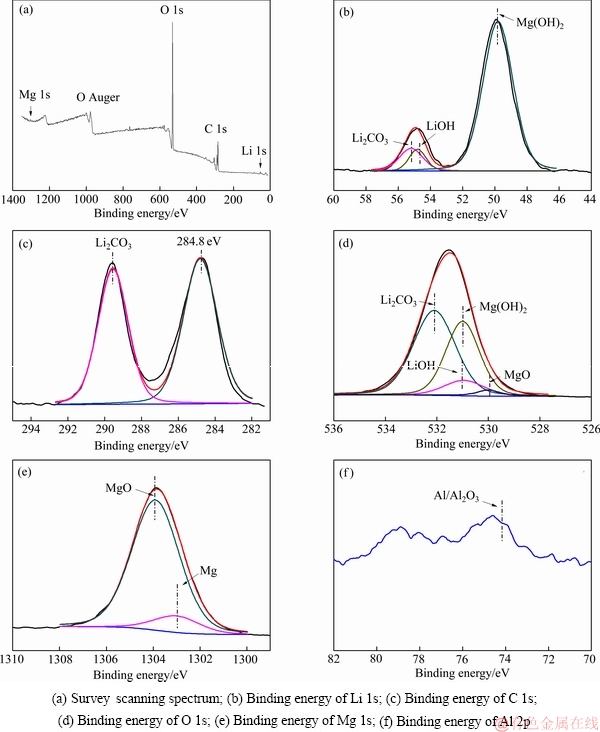

2.2.4 腐蚀膜层分析

挤压态Mg-Li-Al-Zr合金在3.5% NaCl溶液中腐蚀1 h后XPS谱如图8所示。由图8可以看出,合金腐蚀膜主要由Mg、Li、C和O元素组成,未出现Al或含Al的化合物,主要化合物为:Mg(OH)2(结合能:EMg-1s=1304 eV,EO-1s=531 eV),Li2CO3(结合能:ELi-1s=55.2 eV,EC-1s=289.9 eV,EO-1s=531.9 eV),LiOH(结合能:ELi-1s=54.9 eV,EO-1s=530.9 eV),很少量的MgO(结合能:EMg-1s=1303.9 eV,EO-1s=530 eV)和Mg(结合能:EMg-1s=1303 eV)。

由图8可知,挤压态合金的表面腐蚀产物主要为Mg(OH)2、LiOH、Li2CO3和MgO。由图5(b)可知,挤压态合金的表面腐蚀膜较铸态合金致密。LIN等[9]研究了含9% Al(质量分数)的Mg-Li-Al-Zn合金在MgCl2的腐蚀表面产物主要是Mg(OH)2/Al混合物,合金中AlLi相转变而来的Al颗粒能使腐蚀产物层变得更致密连续,提高合金的耐腐蚀性能。而在Mg-Li-Al-Zr合金的腐蚀产物主要为Mg(OH)2、LiOH、Li2CO3和MgO,并未发现有Al或Al的化合物生成。这可能是由于其Al含量较低,挤压态合金中的AlLi颗粒数量减少,在腐蚀过程中未能有效嵌在腐蚀膜层中来阻止溶液的渗入。XU等[10]发现在Mg-11%Li基合金中含有纳米级的β-Li相,表面极易生成一层致密的Li2CO3化合物,能有效保护基体不被进一步腐蚀。相比而言,挤压态Mg-Li-Al-Zr合金腐蚀产物中的Li2CO3化合物使腐蚀膜层更致密,从而阻碍溶液的局部腐蚀。有文献[10-30]表明Li极易在空气中氧化并进一步与CO2反应生成Li2CO3,如式(6)和(8)所示。Mg也容易氧化为MgO,如式(7)所示。大量腐蚀产物在α-Mg相周围聚集,且有少量的裂纹产生,说明溶液可以沿着裂纹向基体内部渗透,使α-Mg和β-Li相之间发生微电偶腐蚀。因此,β-Li相中的Li和Mg腐蚀生成Mg(OH)2和LiOH且有氢气溢出,如式(9)~(12)所示:

4Li+O 2→2Li2O (6)

2Mg+O2→2MgO (7)

Li2O+CO2→Li2CO3 (8)

MgO+H2O→Mg2(OH) (9)

Li2O+H2O→2LiOH (10)

Mg+2H2O→Mg(OH)2+H2 (11)

2Li+2H2O→2LiOH+H2 (12)

表3 由交流阻抗图谱拟合有关等效电路图中数据的结果

Table 3 Results of fitting Nyquist plots from equivalent circuit

图8 挤压态 Mg-Li-Al-Y-Zr 合金浸泡在3.5% NaCl后腐蚀表面的XPS谱

Fig. 8 XPS spectra of corrosion surface film on extruded Mg-Li-Al-Y-Zr alloy after immersion in 3.5% NaCl solution

3 结论

1) 挤压态Mg-10Li-5Al-0.02Zr合金由β-Li基体、AlLi相、弥散的MgLi2Al以及沿挤压方向呈带状分布的α-Mg相组成。相比铸态合金,挤压态合金的第二相数量减少,晶粒和第二相明显细化,组织更均匀。

2) 挤压态合金中的α-Mg相沿挤压方向呈不连续带状分布,弱化了微电偶腐蚀,均匀的组织也提高了挤压态Mg-10Li-5Al-0.02Zr合金的耐蚀性,铸态和挤压态合金的腐蚀速率分别为(2.74±0.2) mm/a和(1.47±0.2) mm/a,且挤压态合金的腐蚀膜较致密,腐蚀产物主要由Mg(OH)2、LiOH、Li2CO3和MgO组成。

REFERENCES

[1] LIU Xu-he, ZHAN Hai-bo, GU Shi-hai, QU Zhi-kun, WU Rui-zhi, ZHANG Mi-lin. Superplasticity in a two-phase Mg-8Li-2Zn alloy processed by two-pass extrusion[J]. Materials Science & Engineering A, 2011, 528(19/20): 6157-6162.

[2] LIU Xu-he, WU Rui-zhi, NIU Zhong-yi, ZHANG Jing-huai, ZHANG Mi-lin. Superplasticity at elevated temperature of an Mg-8%Li-2%Zn alloy[J]. Journal of Alloys & Compounds, 2012, 541(1): 372-375.

[3] DONG S L, IMAI T, LIM S W, KANETAKE N, SAITO N. Superplasticity evaluation in an extruded Mg-8.5Li alloy[J]. Journal of Materials Science, 2007, 42(13): 5296-5298.

[4] SUN Yue-hua, WANG Ri-chu, PENG Chao-qun, FENG Yan, YANG Ming. Corrosion behavior and surface treatment of superlight Mg-Li alloys[J]. Transaction of Nonferrous Metal Society of China, 2017, 27(7): 1455-1475.

[5] ZHANG Jing-huai, ZHANG Li, LENG Zhe, LIU Shu-juan, WU Rui-zhi, ZHANG Mi-lin. Experimental study on strengthening of Mg-Li alloy by introducing long-period stacking ordered structure[J]. Scripta Materialia, 2013, 68(9): 675-678.

[6] 李瑞红, 蒋 斌, 陈志军, 潘复生. 超轻Mg-Li-Al系变形镁合金挤压板材的组织及性能[J]. 中国有色金属学报, 2016, 26(1): 31-36.

LI Rui-hong, JIANG Bin, CHEN Zhi-jun, PAN Fu-sheng. Microstructure and mechanical properties of as-extruded ultra-light Mg-Li-Al sheet[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 31-36.

[7] FU H, GE B, XIN Y, WU R, FERNANDEZ C, HUANG J, PENG Q. Achieving high strength and ductility in magnesium alloys via densely hierarchical double contraction nanotwins[J]. Nano Letters, 2017, 17(10): 6117-6124.

[8] KIM Y H, SON H T. Effects of Li addition on microstructure and mechanical properties of Mg-6Al-2Sn-0.4Mn alloys[J]. Transaction of Nonferrous Metal Society of China, 2016, 26(3): 697-703.

[9] LIN M C, TSAI C Y, UAN J Y. Electrochemical behaviour and corrosion performance of Mg-Li-Al-Zn anodes with high Al composition[J]. Corrosion Science, 2009, 51(10): 2463-2472.

[10] XU Wan-qiang, BIRBILIS N, SHA Gang, WANG Yu, DANIELS J, YANG Xiao, FERRY MICHAEL. A high- specific-strength and corrosion-resistant magnesium alloy[J]. Nature Materials, 2015, 14(12): 1229-1235.

[11] WANG Nai-guang, WANG Ri-chu, FENG Yan, XIONG Wen-hui, ZHANG Jun-chang, DENG Min. Discharge and corrosion behaviour of Mg-Li-Al-Ce-Y-Zn alloy as the anode for Mg-air battery[J]. Corrosion Science, 2016, 112: 3-24.

[12] 董 鹏, 陈 鼎, 陈振华, 章 凯. 新型Mg-8Li-5Al-5Ca合金的微观组织、力学及耐腐蚀性能[J]. 材料导报, 2017, 31(18): 64-71.

DONG Peng, CHEN Ding, CHEN Zhen-hua, ZHANG Kai. Microstructure, Mechanical Properties and Corrosion Resistance of a Novel Mg-8Li-5AI-5Ca Alloy[J]. Materials Review, 2017, 31(18): 64-71.

[13] SHI Zhi-ming; LIU Ming; ATRENS A. Measurement of the corrosion rate of magnesium alloys using Tafel extrapolation[J]. Corrosion Science, 2010, 52(2): 579-588.

[14] DONG Han-wu, WANG Li-dong, WU Yao-ming, WANG Li-min. Preparation and characterization of Mg-6Li and Mg-6Li-1Y alloys[J]. Journal of Rare Earth, 2011, 29(7): 645-649.

[15] WU R Z, QU Z K, ZHANG M L. Reviews on the influences of alloying elements on the microstructure and mechanical properties of Mg-Li base alloys[J]. Reviews on Advanced Materials Science, 2010, 24 (1): 35-43.

[16] PAN Ying-cai, WU Guo-qing, CHENG Xu, ZHANG Zong-ke, LI Mao-yuan, JI Su-dong, HUANG Zheng. Galvanic corrosion behaviour of carbon fibre reinforced polymer/magnesium alloys coupling[J]. Corrosion Science, 2015, 98: 672-677.

[17] PARDO A, MERINO M C, COY A E, VIEJO F, ARRABAL R, FELIU S Jr. Influence of microstructure and composition on the corrosion behaviour of Mg/Al alloys in chloride media[J]. Electrochimica Acta, 2008, 53(27): 7890-7902.

[18] LIU Xiao-yan, WANG Zhao-peng, FU Bao-gang, LONG Liang, ZHANG Xi-liang, CUI Hao-xuan. Effects of Mg content on the mechanical properties and corrosion resistance of Al-Cu-Mg-Ag alloy[J]. Journal of Alloys & Compounds, 2016, 685: 209-215.

[19] SONG D, MA A B, JIANG J H, LIN P H, YANG D H, FAN J F. Corrosion behaviour of bulk ultra-fine grained AZ91D magnesium alloy fabricated by equal-channel angular pressing[J]. Corrosion Science, 2011, 53(1): 362-373.

[20] LI Jia-run, JIANG Quan-tong, SUN Hu-yuan, LI Yan-tao. Effect of heat treatment on corrosion behavior of AZ63 magnesium alloy in 3.5wt.% sodium chloride solution[J]. Corrosion Science, 2016, 111: 288-301.

[21] BARIL G, BLANC C, PEEBEERE N. AC impedance spectroscopy in characterizing time-dependent corrosion of AZ91 and AM50 magnesium alloys characterization with respect to their microstructures[J]. Journal of the Electrochemcal Society, 2001, 148(12): B489-B496.

[22] LIU Wen-juan, CAO Fa-he, CHEN An-na, CHANG Lin-rong, ZHANG Jian-qing, CAO Chu-nan. Corrosion behaviour of AM60 magnesium alloys containing Ce or La under thin electrolyte layers. Part 1: Microstructural characterization and electrochemical behaviour[J]. Corrosion Science, 2010, 52(2): 627-638.

[23] SHI Yin-chun, PENG Chao-qun, FENG Yan, WANG Ri-chu, WANG Nai-guang. Microstructure and electrochemical corrosion behavior of extruded Mg-Al-Pb-La alloy as anode for seawater-activated battery[J]. Material & Design, 2017, 124: 24-33.

[24] CAO Dian-xue, WU Lin, WANG Gui-ling, Lü Yan-zhuo. Electrochemical oxidation behavior of Mg-Li-Al-Ce-Zn and Mg-Li-Al-Ce-Zn-Mn in sodium chloride solution[J]. Journal of Power Sources, 2008, 183(2): 799-804.

[25] WANG Nai-guang, WANG Ri-chu, XIONG Wen-hui, ZHANG Jun-chang, FENG Yan. Electrochemical discharge performance of Mg-Al-Pb-Ce-Y alloy as anode for Mg-air battery[J]. Journal of Materials Chemistry A, 2016, 4(22): 8658-8668.

[26] SONG Y W, SHAN D Y, CHEN R S, HAN E H. Corrosion resistance of Mg-8.8Li alloy compared with AZ91[J]. Corrosion Engineering Science & Technology, 2014, 46: 719-723.

[27] WANG Nai-guang, WANG Ri-chu, PENG Chao-qun, PENG Bing, FENG Yan, HU Cheng-wang. Discharge behaviour of Mg-Al-Pb and Mg-Al-Pb-In alloys as anodes for Mg-air battery[J]. Electrochimica Acta, 2014, 149: 193-205.

[28] LI C Q, XU D K, CHEN X B, WANG B J, WU R Z, HAN E H, BIRBILLS N. Composition and microstructure dependent corrosion behaviour of Mg-Li alloys[J]. Electrochimica Acta, 2017, 260: 55-64.

[29] SHI Yin-chun, PENG Chao-qun, FENG Yan, WANG Ri-chu, WANG Nai-guang. Enhancement of discharge properties of an extruded Mg-Al-Pb anode for seawater-activated battery by lanthanum addition[J]. Journal of Alloys & Compounds. 2017, 721: 392-404.

[30] ZENG Rong-chang, SUN Lu, ZHENG Yu-feng, CUI Hong-zhi, HAN En-hou. Corrosion and characterisation of dual phase Mg-Li-Ca alloy in Hank’s solution: The influence of microstructural features[J]. Corrosion Science, 2014, 79: 69-82.

Effect of extrusion on corrosion behavior of Mg-10Li-5Al-0.02Zr alloy

HE Yu-qing, PENG Chao-qun, WANG Ri-chu, FENG Yan

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Microstructure of Mg-10Li-5Al-0.02Zr alloy and the effects of extrusion on hydrogen and electrochemical corrosion behavior of Mg-Li-Al-Zr alloy in 3.5% NaCl(mass fraction) solution and the corrosion film structure were studied by X-ray diffractometry(XRD), electron probe micro-analyze(EPMA), scanning electron microscopy(SEM) and X-ray photoelectron spectroscopy(XPS). The results indicate that the Mg-Li-Al-Zr alloy after extrusion consists mainly of α-Mg, irregular AlLi, dispersed MgLi2Al and β-Li phases. After extrusion, the structure of Mg-Li-Al-Zr alloy becomes more evenly, the grain size of Mg-Li-Al-Zr alloy refines, the number of second phases decreases. The average corrosion rates(PH) of Mg-Li-Al-Zr alloys before and after extrusion are (2.74±0.2) mm/a and (1.47±0.2) mm/a, respectively. A discontinuous banded structure forming along the extrusion direction and the uniform microstructure can weaken effectively micro-galvanic corrosion and increase corrosion resistance. After the extruded Mg-Li-Al-Zr alloy is immersed in NaCl solution, a dense and compact corrosion coating which consists mainly of Mg(OH)2, LiOH, Li2CO3 and MgO forms on the surface.

Key words: Mg-Li alloy; electrochemical measurement; corrosion behavior

Foundation item: Project(51101171) supported by the National Natural Science Foundation of China

Received date: 2018-04-08; Accepted date: 2018-10-22

Corresponding author: FENG Yan; Tel: +86-731-88836638; E-mail: fengyanmse@csu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51101171)

收稿日期:2018-04-08;修订日期:2018-10-22

通信作者:冯 艳,副教授,博士;电话:0731-88836638;E-mail:fengyanmse@csu.edu.cn