DOI: 10.11817/j.issn.1672-7207.2018.06.013

圆盘浇铸机动态浇铸过程数值模拟

蒋朝辉,刘昕,桂卫华,阳春华,谢永芳

(中南大学 信息科学与工程学院,湖南 长沙,410083)

摘要:基于圆盘浇铸过程浇铸工具(中间包和浇铸包)的最优定量浇铸曲线的获取是决定浇铸质量的关键,而定量浇铸现场环境十分恶劣,无法通过现场反复实验来获得浇铸工具的最优定量浇铸曲线,应用Fluent软件对圆盘浇铸机的动态浇铸过程进行数值模拟,建立定量浇铸过程的数值仿真模型,编制UDF(用户自定义函数)设置浇铸工具的运动曲线,应用动网格模拟浇铸工具的刚体运动过程,并对浇铸过程进行气-液两相速度场计算。研究结果表明:数值仿真模型准确可靠;所获取的圆盘浇铸过程最优定量浇铸曲线直观地反映了中间包和浇铸包内铜液的速度场、气-液两相变化和浇铸工具刚体的运动,从而可对工业现场浇铸工具最优定量浇铸曲线的设置以及参数的优化提供参考。

关键词:浇铸工具;UDF(用户自定义函数);动网格;浇铸曲线

中图分类号:TP273 文献标志码:A 文章编号:1672-7207(2018)06-1403-11

Numerical simulation of casting tools in dynamic casting process

JIANG Zhaohui, LIU Xin, GUI Weihua, YANG Chunhua, XIE Yongfang

(School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Considering the fact that it is essential to obtain the most available casting motion curve of casting tools for casting, but it is difficult to verify the optimal casting motion curve by repeating field experiments because of the harsh industrial environments, CFD (computational fluid dynamics) software, i.e. Fluent, was used for three-dimension numerical simulation of the casting tools quantitative casting process to obtain numerical model which simulated the dynamic casting process. UDF (user-defined-function) was programed to set the motion curve for the casting tools, and dynamic mesh was used to simulate the casting tools dynamic casting process and Fluent software was used to study the gas-liquid two-phase flow of the casting tools. The results show that numerical simulation model is basically reliable, which can be used to obtain the best working curve of casting tools and to intuitively represent the distributions of the flow field in casting tools, and the change of gas-liquid two phase as well as the movement of casting tools can be investigated. Therefore, the technical guidance can be provided for the operation of setting casting motion curve and the parameter optimization.

Key words: casting tools; UDF (user-defined-function); dynamic mesh; casting motion curve

在铜冶炼过程中,铜阳极板质量直接影响整个铜冶炼流程的能耗和物耗[1]。圆盘浇铸机是生产铜阳极板的主流设备,而在对高品质电解铜需求量大增的背景下,对阳极板定量浇铸设备及其浇铸质量的要求越来越高[2-4]。圆盘浇铸机的最优定量浇铸曲线(即浇铸包和浇铸包的工作曲线)的设置是实现高精度、高效率定量浇铸的核心技术,其设置直接影响阳极板的质量和产量。长期以来,铜液的定量浇铸技术被国外公司所垄断,引进的装备与技术不仅成本昂贵,而且难以适应我国复杂多变的矿源[5-6]。为打破国外公司的垄断,我国正致力于开发并研制具有自主知识产权的定量浇铸装备及技术,以满足我国铜冶炼技术发展的需求[7]。最优定量浇铸曲线设计的目标是在满足工艺要求的基础上,使铜阳极板的单板质量、形状以及产量满足后续工序的需求。现有圆盘浇铸机浇铸包的定量浇铸曲线依靠人工经验设定和修改,人为干扰因素大,随机性强,易造成铜阳极板的质量波动大、浇铸产量低等问题[8]。由于圆盘浇铸机定量浇铸受现场高温、高尘、浓烟等恶劣环境的干扰,无法通过现场反复实验来获得浇铸工具的最优定量浇铸曲线。Fluent软件是基于计算流体动力学方法的求解流动问题的通用软件[9-11],采用Fluent软件数值模拟方法,通过计算机完成数值模拟计算过程,可以得到圆盘浇铸机浇铸过程基本物理量(如浇铸包和中间包的运动速度等)的分布以及对应物理量随时间的变化情况,可以形象、直观地对浇铸过程进行分析和评价,进而给出满足工艺条件约束和生产要求的浇铸包最优定量浇铸曲线。因此,需要采用Fluent软件对圆盘浇铸机浇铸工具的定量浇铸过程进行数值模拟,探寻不同工艺参数和浇铸结构对定量浇铸生产过程的影响,得到圆盘浇铸机浇铸工具的最优定量浇铸曲线。以中间包和浇铸包浇铸过程为研究对象,通过使用Fluent仿真软件对从中间包到浇铸包到铸模的整个工艺流程进行三维仿真模拟。通过Ansys仿真软件的DM模块,根据现场实际溜槽、浇铸包、中间包和母模等详细的几何尺寸建立实体模型。通过Meshing模块对建好的模型划分网格、离散化,以便于计算处理,并用几何重构的动网格划分模拟实际刚体的运动过程,利用UDF(用户自定义函数)设置中间包和浇铸包的运动状态研究刚体和流体的运动规律,构建铜液-空气两相流模型。控制参数时选择PSIO算法,并确定质量、动量和能量等方程的离散格式,对整个过程进行求解计算,得出浇铸结果,将计算的浇铸结果与预期的定量浇铸目标进行比较,若不满足便更改UDF。如此循环,直到满足浇铸目标的要求为止。通过此方法研究中间包和浇铸包浇铸过程铜液的运动规律,完成浇铸工作曲线的设置,以便为现场操作提供更可靠的信息,这对进一步提高浇铸过程的调控能力及精度具有重要意义。

1 浇铸过程描述和浇铸工具运动分析

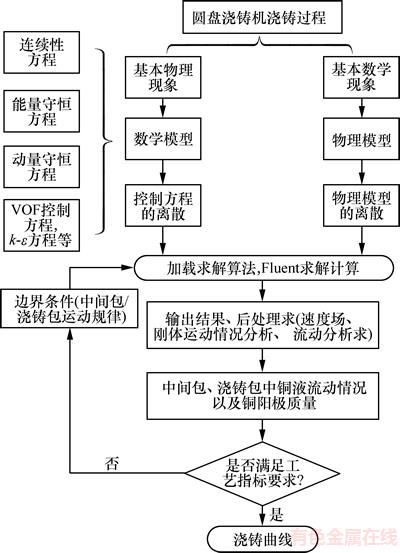

本文采取的研究方案如图1所示。在电解铜冶炼的整个生产过程中,将熔融状态的铜液定量浇铸成符合电解要求的铜板,符合要求的铜板在电解作用下将会产生高纯度的电解铜。铜经过熔化、氧化-还原除杂精炼后,打开阳极炉出铜口,铜液经溜槽注入中间包。中间包承接阳极炉溜槽中的铜液,存储并将铜液按一定量交替倾倒在两边定量浇铸包中,以便进行极板定量浇铸[12]。中间包在倾倒铜液时,由驱动装置来驱动中间包翻转倾倒。中间包浇铸曲线将按包中铜液量设定其倾倒速度与角度,从而使中间包在规定时间内,将铜液平稳无冲击地倾倒在浇铸包中。

图1 整体研究方案

Fig. 1 Scmeme of total solution

浇铸包承接中间包倾倒的铜液,存储并将铜液按一定量浇铸在模具中,进行极板定量精确浇铸。浇铸包质量控制由其下部所装称质量的传感器完成[13]。极板质量为380 kg,误差控制在±3.8 kg以内。浇铸包在浇铸铜液时,由驱动装置来驱动浇铸包倾倒。浇铸包将按浇铸曲线设定的倾倒速度与角度,在规定时间内,将包中铜液平稳地浇铸在模具中,实现铜极板精确浇铸。

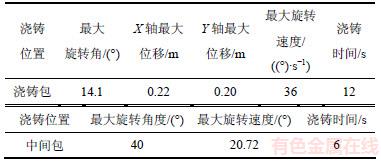

浇铸工具包括中间包和浇铸包[14]。中间包与浇铸包的运动状态不同,浇铸的精度也不相同。中间包工作时铜液容量为(3 500±850) kg。每次向浇铸包倾倒铜液用时6 s,每次倾倒铜液量(380±20) kg,如图2(a)所示。中间包的运动比较简单,主要是Θ轴旋转运动,受最大旋转角度、最大旋转速度和浇铸时间的限制,如表1所示。浇铸包工作时铜液容量为(650±80) kg。浇铸包每次向模具倾倒铜液用时12.0 s,每次倾倒铜液量为(380±3.8) kg。浇铸包的初始位面与水平面最大倾转角度为2°,极限位面与水平面最大倾转角度为12°。浇铸包的运动十分复杂,为后滑移运动。如图2(b)所示,将浇铸包包体运动分解为Θ轴的旋转运动以及X轴和Y轴的平移运动。浇铸包的运动也受极限位、运动速度和浇铸时间的限制,如表1所示。

图2 浇铸工具的运动分析图

Fig. 2 Analysis schematics of casting tools motion

表1 浇铸工具的运动参数

Table 1 Motion parameters of casting tools

2 浇铸过程数值仿真模型

2.1 假设条件

为了更好地研究浇铸工具内流场的流动,根据实际问题略去或简化一些次要因素,确定过程的主要特征和影响因素,并进行一些合理假设,可使复杂的现实过程简化为较简单、清晰的模型。进行如下假设:

1) 连续浇铸过程正常稳定运行,无溢流等异常工况。高温铜液是不可压缩的牛顿流体。

2) 铜液流动过程中各向同性,密度、黏性系数等物性参数各向相同。

3) 忽视浇铸工具内高温铜液的凝固现象,整个流场内高温铜液保持液体状态。

4) 浇铸工具呈水平正常放置,初始状态时液面是水平的。

2.2 控制方程

浇铸工具内高温铜液的流动是湍流流动。以下数学模型用于描述三维不可压缩非稳态流动的过程。

2.2.1 流体体积函数(Volume of fluid,VOF)模型

VOF方法用于解决自由表面的问题,用单流体模型解决多相流问题[15]。该理论认为,对于气-液两相流场,假设在同一单元中的气体、液体或者两者的混合体具有相同的速度,即满足同一组动量方程,两相流的流场就可以用单相流的一系列等式来表示,但它们的体积分数在整个流场中都作为单独变量[16]。在每个单元中,气-液两相体积分数之和为1,体积分数αw定义为1个单元内液体的体积分数,单元内气体的体积分数为1-αw。若αw=1,则表示该单元内全部为液体;若αw=0,则表示该单元内全部为气体;若0<αw<1,则表示该单元内界面为气-液交界面[17-19]。只要流场中各个单元的气-液两相体积分数都已知,则其他气-液共有的变量如流速、流量、压力都可用体积分数的加权平均来表示。气-液交界面的跟踪可以通过下列方程实现[20]:

(1)

(1)

其中:t为时间,s;ui为速度分量,m/s;xi为直角坐标系分量,m。

在Fluent软件中,VOF模型通过求解单独的动量方程和处理穿过区域的每一流体的容积比来模拟多种不能混合的流体[21]。在仿真中,可以用VOF模型给定不同计算域内高温铜液和空气的位置与体积分数。

2.2.2 铜液-空气两相流动模型

该模型用来描述黏性的铜液-空气两相的流动,包括质量守恒方程和动量方程。

质量守恒方程:

(2)

(2)

动量守恒方程:

(3)

(3)

式中:t为时间(s);x为位移(m);i和j为三维直角坐标系下的坐标方向;ui和uj分别为xi和xj方向上的速度分量(m/s);p为压强(Pa);ρ为流体密度(kg/m3);μeff为有效黏度,为μ和μt之和,μ为分子动力学黏度(Pa·s),μt为湍流动力黏度(Pa·s),μt=Cμρ/ε。Cμ为流动黏度系数,其值如表2所示。

表2 控制方程中的常数

Table 2 Constants in governing equations

2.2.3 湍流模型

湍流动能方程:

(4)

(4)

湍流耗散率方程:

(5)

(5)

式中:G为由于平均速度梯度引起的湍动能k的产生项,

(6)

(6)

ui为xi方向上的速度分量(m/s);ρ为流体密度(kg/m3);μ为流体的分子动力学黏度(Pa·s);k为湍动能(m2/s2);ε为湍动耗散率 (m2/s3);p为压力(Pa);C1ε与C2ε分别为湍流生成项与耗散项常数;σε和σε分别为k和ε湍流Prandtl数。在标准k-ε模型中,根据Launder等的推荐值及实验验证,模型常数C1ε,C2ε,σk和σε见表2。

VOF模型中,关于流量的函数式(2)~(6)中的ρ和μ变成了变量,可以表示为体积分数的加权平均值:

(7)

(7)

(8)

(8)

式中:ρw和ρa分别为铜液和空气的密度(kg/m3);μw和μa分别为铜液和空气的动力黏度(Pa·s)。可以通过对αw求解,得出ρ和μ。

2.3 几何物理模型和离散化

2.3.1 几何物理模型

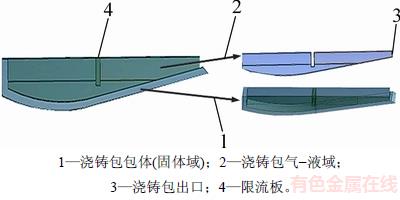

通过Ansys仿真软件的DM模块,根据现场实际的溜槽、浇铸包、中间包和母模等详细的几何尺寸等建立实体模型。溜槽和中间包的几何结构见图3。中间包的长为2.960 m,宽为0.960 m,高为0.600 m。中间包气-液域的体积为0.930 m3,其中初始状态下铜液域的体积为0.393 m3(对应初始状态下铜液质量3 500 kg)。浇铸包的仿真模型结构如图4所示。浇铸包长为1.850 m,宽为0.590 m,高为0.191 m。浇铸包气-液域的体积为0.220 m3,其中初始状态下铜液域的体积为0.073 m3(对应初始状态下铜液质量650 kg)。铸模的仿真模型结构如图5所示,其中,浇铸包的长为1.160 m,宽为0.960 m,高为0.080 m。

图3 中间包仿真模型结构图

Fig. 3 Schematic of computational domain of tundish

图4 浇铸包仿真模型结构图

Fig. 4 Schematic of computational domain of casting ladle

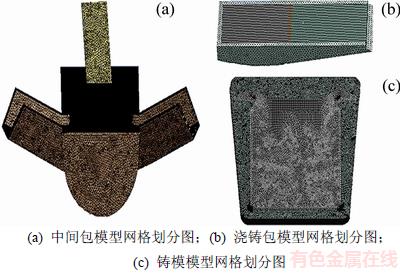

2.3.2 计算区域离散化

通过Ansys仿真软件的Meshing模块对建立的物理模型划分网格,采取混合网格技术对计算区域进行离散化,如图6所示。由于中间包、浇铸包和铸模的部分流动区域由规则的长方体组成,其适宜用六面体网格进行离散化;中间包、浇铸包入口出口端和铸模挂耳处等的几何结构不规则,适宜用四面体网格离散化。为了提高计算精度,可以适当加密入口出口端和气-液交界面的网格。整体模型网格数量为102万,网格最差畸变度在0.790以下,网格质量良好。

图5 铸模仿真模型结构图

Fig. 5 Schematic of computational domain of casting mould

图6 各物理模型网格的划分图

Fig. 6 Schematic of mesh structure of casting tools

2.4 边界条件

初始条件:中间包和浇铸包铜液域内铜液的体积分数为1,空气的体积分数为0;空气域内空气的体积分数为1,铜液的体积分数为0;铸模气-液域内空气体积分数为1,铜液的体积分数为0。

高温铜液的入口边界条件:在重力作用下,高温铜液以一定流量从溜槽进入中间包内,入口流速是定值,故将入口边界条件设置为速度入口,为0.220 m/s。入口边界处铜液的体积分数为1。

高温铜液的出口边界条件:高温铜液从处于大气环境中的中间包和浇铸包出口处流出,故可采取压力出口边界,压力设为大气压。

无滑移边界条件:中间包、浇铸包和铸模的固体域中无铜液流动,设置为Wall壁面。问题描述为刚体的运动导致液体的流动,在固体边界上对速度取无滑移边界条件。

动区域:设置动网格区域模拟浇铸过程中浇铸工具的运动,用UDF设置运动状态。

在整个浇铸过程中,高温铜液的密度为8.9 t/m3,经试验检测,动力黏度为0.038 Pa·s。

3 浇铸过程数值仿真结果分析

3.1 中间包仿真结果分析

中间包承接阳极炉溜槽中的铜液,根据中间包下的质量传感器,当中间包内的铜液达到3.5 t时,中间包开始工作。对于中间包仿真,设定中间包的长度方向为Z轴,宽度方向为X轴,高度方向为Y轴。通过UDF设置中间包运动状态,用动网格实现中间包的运动过程,通过Fluent软件仿真得到满足要求的计算 结果。

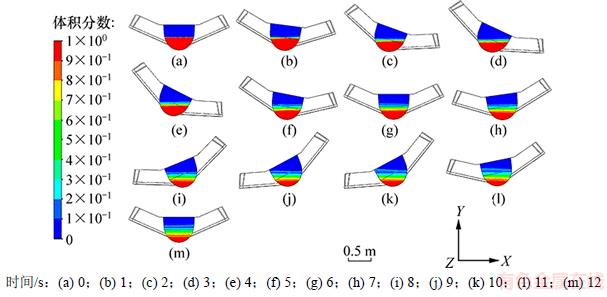

图7所示为沿Z轴正向观测时,中间包浇铸过程铜液的体积分数云图,表3所示为中间包在不同时间流出的铜液量。从图7(a)~(c)可见:中间包在浇铸过程中先沿顺时针作旋转运动,从0 s时的初始位开始转动,在2.0 s左右达到最大倾角,中间包旋转了26°。从图7(d)~(g)可见:中间包保持最大倾角,浇铸2.6 s后快速返回初始位,中间包内铜液的体积分数在此期间快速减少,整个顺时针旋转浇铸时间为6.00 s。从图7(h)和图7(i)可见:中间包返回初始位后,再沿逆时针作旋转运动,在2.00 s左右达到最大倾角。由于逆时针旋转浇铸时,中间包内铜液相对于顺时针浇铸时较少。为了达到精度要求,逆时针旋转浇铸最大倾角相对于顺时针浇铸时更大,中间包在逆时针浇铸时旋转28.5°。从图7(j)~(m)可见:中间包同样保持最大倾角浇铸2.6 s后快速返回初始位,整个逆时针旋转浇铸时间为6.0 s。顺时针旋转浇铸和逆时针旋转浇铸组成了中间包的1个浇铸周期。在1个周期内,中间包分别往两边的浇铸包浇铸铜液量为380 kg,误差为±20 kg。

图7 各时间内中间包内铜液的体积分数

Fig. 7 Copper liquid volume fractions of tundish

表3 中间包在不同时间流出的铜液量

Table 3 Copper liquid flow from tundish in different time

图8所示为沿Y轴正向观测时,中间包浇铸过程最初的气-液交界面速度矢量图。从图8可见:中间包在浇铸过程中入口和出口的速度较大,顺时针和逆时针浇铸时出口处速度分别在3.0 s和9.0 s左右达到最大,流速为1.3 m/s左右。由于中间包快速转动的惯性作用,顺时针浇铸时右侧壁面速度较大,并形成回流。逆时针浇铸时左侧壁面较大,并形成回流。由于初始时刻中间包内的液体较多,中间包入口处进入的铜液往四周扩散,液体域内的铜液流速较小。

图8 中间包内铜液速度矢量图

Fig. 8 Copper liquid velocity vectors of tundish bag

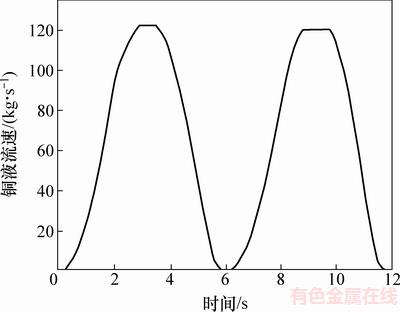

图9和图10所示分别为中间包浇铸过程中1个周期内,出口处流速的变化和中间包内铜液质量的变化。中间包入口处速度设为匀速浇铸,流速为19 kg/s。从图9可见:顺时针浇铸时,铜液浇铸速度在2.9 s时达到最大值,流速为122.6 kg/s;逆时针浇铸且铜液浇铸速度为9.0 s时,达到最大值,流速为120.8 kg/s。由于逆时针浇铸时中间包内铜液量较少且浇铸的角度较大,前期浇铸速度增加较慢,保持最大速度浇铸的时间更久,后期浇铸速度减少较快。从图10可见:由于顺时针和逆时针浇铸刚开始和快结束时浇铸速度较小,浇铸包内铜液量在前1.0 s和后1.0 s时会增加。顺时针浇铸铜液量在1.9 s时开始快速减少,逆时针浇铸铜液量在8.3 s时开始快速减少。中间包每秒流出的铜液量如表3所示,其中顺时针浇铸铜液量为393.62 kg。逆时针浇铸铜液量为380.13 kg,均满足(380±20) kg的误差要求。

图9 浇铸过程中中间包出口处铜液流速

Fig. 9 Copper liquid flow rate of tundish outlet

图10 浇铸过程中中间包内铜液质量

Fig. 10 Copper liquid mass of tundish during the casting process

3.2 浇铸包仿真结果分析

浇铸包承接中间包倾倒的一定量的铜液,根据浇铸包下的质量传感器,当浇铸包内的铜液达到650 kg时,浇铸包开始工作。对于浇铸包浇铸过程的仿真,从浇铸包开始工作算起。对于浇铸包仿真,设定中间包的长度方向为X轴,宽度方向为Z轴,高度的方向为Y轴。通过UDF设置浇铸包运动的运动状态,用动网格实现中间包的运动过程,通过Fluent软件仿真得到满足要求的计算结果。

图11所示为沿Z轴正向观测时,浇铸包浇铸过程铜液的体积分数云图,显示出浇铸包浇铸过程浇铸包的运动情况及浇铸包内铜液的体积分数的变化情况。从图11(a)~(m)可见:浇铸包作后滑移运动。由于浇铸包浇铸的精度要求很高,浇铸包的1个浇铸周期一般分解为4个运动阶段,即快速启动浇铸包—慢速浇铸—快速浇铸—快速收起浇铸包。从图11(a)~(c)可见:浇铸包的初始位面与水平面角度为2°,为了提高工作效率,先快速启动浇铸包,浇铸包旋转和平移的速度较大,使浇铸包达到浇出铜液的临界位,时间持续约2.0 s。由图11(d)和图11(e)可见:在浇铸包即将达到临界位时,铸模为空模,浇铸速度过大会导致铜液溅出,浇铸包进入慢速浇铸阶段,此时,浇铸包旋转和平移速度较小,慢慢达到临界位并开始浇铸,时间持续约2.00 s。从图11(f)和图11(g)可见:在慢速浇铸一段时间后,铸模内有一定的铜液,慢慢提高浇铸速度,提高生产效率,并在6 s时浇铸包浇铸达到极限位。由图11(g)~(k)可见:随着浇铸包到达极限位,浇铸包进入快速浇铸阶段,时间持续约4.0 s;在6.0~10.0 s内,浇铸包内铜液体积分数快速降低。从图11(l)和图11(m)可见:为了提高浇铸精度,达到浇铸要求,快速收起浇铸包使浇铸包到达起始位。浇铸包1个浇铸周期为12.0 s,在1个周期内往铸模内浇铸铜液量380 kg,误差为±3.8 kg。

图12所示为沿Z轴正向观测时,浇铸包浇铸过程铜液的速度矢量图。从图12(a)可见:在3.8 s时,铜液从浇铸包中流出,此时,根据设置的UDF函数,浇铸包旋转6.1°,即浇铸包上平面与水平面角度为4.1°,浇铸包内铜液开始缓慢流出。从图12(b)可见:在6.0 s时,浇铸包达到浇铸的最大位置,浇铸包内的铜液开始快速流出,浇铸包出口和限流板左侧近壁面的流速较大。从图12(c)可见:在8.2 s时,浇铸包达到浇铸的最大速度,出口处最大处速度达1.7 m/s左右。隔板左侧近壁面形成回流区,隔板右侧和下侧近壁面速度均较大。从图12(d)可见:在10.2 s时,浇铸包开始快速返回。由于浇铸包内铜液量减少和浇铸包浇铸角度变小,浇铸包浇铸的速度慢慢减小。从图12(e)可见:在12.0 s时,浇铸包返回初始位,浇铸包出口速度减为0 kg/s。由于浇铸包快速返回的惯性作用,在隔板右侧近壁面有回流铜液拍打形成回旋。

图11 浇铸包内铜液的体积分数

Fig. 11 Copper liquid volume fractions of casting ladle

图12 浇铸包内铜液速度矢量图

Fig. 12 Copper liquid velocity vector of casting ladle

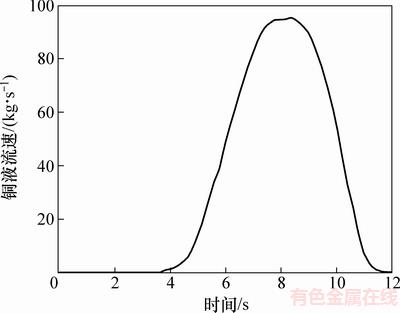

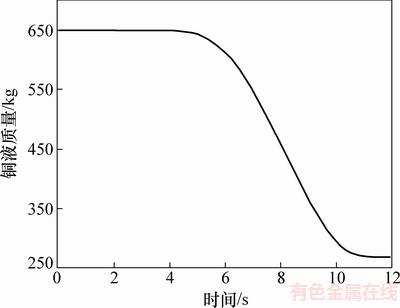

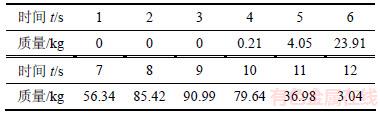

图13和图14所示分别为浇铸包浇铸过程中1个周期内,出口处流速的变化和浇铸包内铜液质量的变化。从图13可见:由于刚开始浇铸包处于快速起包阶段,在3.8 s时铜液流出速度开始增加,在4.8 s时流出速度开始快速增加,浇铸包在6.0 s左右达到极限位,由于限流板的影响,在8.2 s时才达到浇铸速度最大值,流速为95.1 kg/s;随着浇铸包内铜液量减少和浇铸包返回,在10.2 s时流出速度开始迅速减少,在11.7 s左右流出速度减少为0 kg/s,此时,由于铜液液面下降,浇铸速度减少,受限流板的影响不大。从图14可见:由于浇铸包未达到浇铸极限位以及受限流板的影响,在5.5 s之前,浇铸包内铜液量减少非常缓慢;在5.5 s之后,铜液量开始快速减少。由于浇铸包的快速返回和铜液量减少,在10.4 s后,浇铸包内的铜液量又缓慢地减少,此时,由于铜液液面下降,铜液减少的速度受限流板的影响不大。浇铸包在不同时间流出的铜液量如表4所示,其中浇铸铜液量为380.58 kg,满足(380±3.8) kg的误差要求。

3.3 铸模仿真结果分析

铸模承接浇铸包倾倒的一定量铜液,以形成特定形状的阳极板。对于铸模仿真,设定铸模的长度方向为Y轴,宽度方向为X轴,高度方向为Z轴。

图13 浇铸过程中浇铸包出口处铜液流速

Fig. 13 Copper liquid flow rate of casting ladle outlet

图14 浇铸过程中浇铸包内铜液质量

Fig. 14 Copper liquid mass of casting ladle

表4 浇铸包在不同时间流出的铜液量

Table 4 Copper liquid flow from casting ladle in different time

图15所示为沿Z轴反向观测时,铸模在浇铸过程中铜液体积分数云图,显示浇铸过程中铸模内铜液体积分数的变化情况。从图15(a)可见铸模在4.1 s左右开始有铜液注入。从15(a)~(i)可见:铜液从铸模中间位置处注入铸模中,随着浇铸包后滑移运动,铜液注入铸模的位置也发生改变;从4.1 s开始,铜液注入铸模的位置往Y轴的负方向偏移,在6.4 s左右达到最大偏移,与浇铸包在6.0 s左右达到极限位相对应;在最大偏移位置注入铜液4.0 s左右,铸模内铜液的体积分数快速增大;从10.2 s开始,铜液注入位置随着浇铸包的返回开始往Y轴正方向移动;铜液进入铸模后,从中间位置往四周扩散;在8.0~12.0 s时,铸模后端的铜液体积分数相对于前端较大;在浇铸的整个过程中,由于离铜液注入位置远以及铜液的流入通道窄,铸模挂耳处铜液的体积分数始终最低。

图16所示为沿Z轴反向观测时,铸模浇铸过程中铜液的速度矢量。从图16(a)可见:在4.1 s左右,铸模内速度开始发生变化,流速为1 m/s左右,铜液注入铸模内。从16(a)~(d)可见:在整个浇铸过程中,铸模内铜液流速最大处位于铜液注入铸模的位置;刚开始铸模内没有铜液,铸模内铜液的流速较大,并随着浇铸包浇铸速度增加,铸模内铜液的流速缓慢变大;当铸模内的铜液快速增加时,铸模内铜液的流速不断减小。从16(c)和图16(d)可见:当铸模内铜液较多时,铜液在注入位置的两边形成螺旋状流动。从16(e)可见:浇铸包快要返回初始位,铸模内无铜液注入,铸模内最大速度出现在铸模的两侧,流速为0.3 m/s左右。

图15 铸模内铜液体积分数

Fig. 15 Copper liquid volume fraction of casting mould

图16 铸模内铜液的速度矢量图

Fig. 16 Copper liquid velocity vectors of casting mould

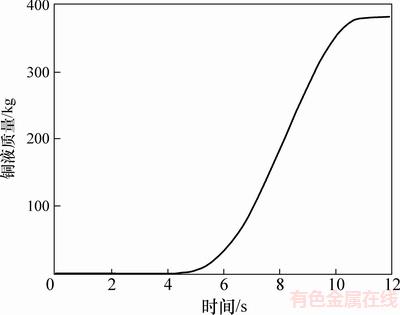

图17所示为浇铸过程中1个周期内铸模铜液的变化。从图17可见:由于浇铸包未达到浇铸极限位以及受限流板的影响,在5.8 s之前,铸模内铜液量增加非常缓慢;在5.8 s后,铜液量开始快速增加。由于浇铸包快速返回和铜液量减少,在10.8 s之后,铸模内的铜液量又缓慢增加。铸模在不同时间注入的铜液量如表5所示,可见在7~10 s时铸模注入的铜液较多,铸模内注入的铜液量共为380.58 kg,满足(380±3.8) kg的误差要求。

图17 浇铸过程中铸模内铜液质量

Fig. 17 Copper liquid mass of casting mould

表5 铸模内在不同时间注入的铜液量

Table 5 Copper liquid flow into casting mould in different time

4 结论

1) 通过数值模拟仿真技术,用UDF设置浇铸工具在浇铸过程中的运动状态,用动网格实现浇铸包运动过程,用VOF模型设置气-液两相分布和变化情况,分析了浇铸过程中浇铸包内铜液流场和体积分数变化。通过不断修正UDF,得到1条满足工业生产需求的最优化工作曲线,该曲线可为现场中确定浇铸包浇铸曲线的设置提供参考。仿真结果在工业现场中得到了实验验证。

2) 仿真方法可以为其他熔融金属的定量浇铸提供参考。

3) 中间包顺时针浇铸在2.9 s时浇铸速度最大,流速为122.6 kg/s。逆时针浇铸时,在9.0 s左右浇铸速度最大,流速为120.8 kg/s。中间包逆时针浇铸旋转角度更大,保持最大速度浇铸时间更长。中间包在1个周期内顺时针浇铸铜液量为393.62 kg,逆时针浇铸铜液量为380.13 kg。

4) 浇铸包在3.8 s开始流出铜液,在5.5 s开始铜液开始迅速减少,在8.2 s浇铸速度最大,流速为95.1 kg/s。浇铸包的浇铸速度受限流板的影响明显,并在限流板近壁面形成回流。浇铸包在1个周期内的浇铸铜液量为380.58 kg。

5) 铜液进入铸模后,从中间位置往四周扩散。铸模后端的铜液体积分数相对于前端较大,铸模挂耳处铜液的体积分数始终最低。铸模内的铜液流速随着铸模内铜液的增多而下降,并在注入铜液位置处两边形成回流。

参考文献:

[1] 李明周, 黄金堤, 童长仁. 铜电解槽内电解液流场的数值模拟[J]. 中国有色金属学报, 2015, 25(8): 2259-2267.

LI Mingzhou, HUANG Jindi, TONG Changren. Numerical simulation of electrolyte flow in copper electrolytic cell[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2259-2267.

[2] 王文祥, 刘志宏. 影响电解铜质量因素分析[J]. 有色矿冶, 2001, 17(5): 25-28.

WANG Wenxiang, LIU Zhihong. Influencing factors of electrolytical copper quality[J]. Non-ferrous Mining and Metallurgy, 2001, 17(5): 25-28.

[3] 刘晓花. M18单圆盘铜浇铸机控制系统研究与设计[D]. 长沙: 中南大学信息科学与工程学院, 2010: 1-6.

LIU Xiaohua. The research and design of M18 copper casting wheel control system[D]. Changsha: Central South University. School of Information Science and Engineering, 2010: 1-6.

[4] 何梅松, 田勇. 圆盘浇铸系统的运行状况与改进[J]. 有色冶金设计与研究, 2015, 36(6): 16-19.

HE Meisong, TIAN Yong. Operating Condition and improvement of casting wheel system[J]. Nonferrous Metals Engineering & Research, 2015, 36(6): 16-19.

[5] 蒋晓敏, 夏柳飞. 双圆盘浇铸机喷涂系统改进[J]. 铜业工程, 2009(1): 41-43.

JIANG Xiaomin, XIA Liufei. Modification of spray coating systemon casting wheel[J]. Copper Engineering, 2009(1): 41-43.

[6] ZHANG Jing, GAO Ying, GAO Jingna, et al. Numerical simulation of fluid flow in thin slab continuous casting mould[C]//2009 International Conference on Measuring Technology and Mechantronics Automation. Zhangjiajie, China, 2009: 267-270.

[7] LIAO E B, TAY A A O, ANG S S, et al. Numerical analysis on compliance and electrical behavior of multi-copper-column flip-chip interconnects for wafer-levelpackaging[J]. IEEE Transactions on Advanced Packaging, 2006, 29(2): 343-353.

[8] ZSCHECH E, HO P S, SCHMEISSER D, et al. Geometry and microstructure effect on EM-induced copper interconnect degradation[J]. IEEE Transactions on Device and Materials Reliability, 2009, 9(1): 20-30.

[9] 鲍文, 李伟鹏. 基于 FLUENT/MATLAB 接口的分布参数系统闭环控制仿真[J]. 系统仿真学报, 2008, 20(11): 2851-2854.

BAO Wen, LI Weipeng. Closed-loop control simulation technology of distributed parameter system based on Fluent/Matlab interface[J]. Journal of System Simulation, 2008, 20(11): 2851-2854.

[10] 屈天鹏, 韩志伟. 多流T型中间包流场和温度分布模拟研究[J]. 连铸, 2012(5): 16-21.

QU Tianpeng, HAN Zhiwei. Modeling on fluid flow and thermal distribution in multi-strand T-tundish[J]. Continuous Casting, 2012(5): 16-21.

[11] 彭彦平, 邢相伟. 基于FLUENT软件沾浆机内部流场的模拟研究[J]. 铸造技术, 2014, 6: 90.

PENG Yanping, XING Xiangwei. Research of simulating inner fluid field of slurry mixer by FLUENT[J]. Foundry Technology, 2014, 6: 90.

[12] 陈荣, 张文汉. 铜冶炼过程中的圆盘定量浇铸系统与设备[J]. 江西有色金属, 2009, 23(2): 41-43.

CHEN Rong, ZHANG Wenhan. Disc casting machine system in copper metallurgy[J]. Jiangxi Nonferrous Metals, 2009, 23(2): 41-43.

[13] 黄金堤, 李静. 废杂铜精炼过程中动态多元多相平衡热力学模型[J]. 中国有色金属学报, 2015, 25(12): 3513-3522.

HUANG Jindi, LI Jing. Dynamic multicomponent and multiphase equilibrium thermodynamics model during scrap copper refining process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3513-3522.

[14] 刘威, 龙鹏. 基于两种烧嘴的铜精炼阳极炉内燃烧过程数值模拟[J]. 过程工程学报, 2015, 15(2): 259-265.

LIU Wei, LONG Peng. Numerical simulation of gaseous combustion process in anode furnace of copper refining with two types of burner[J]. The Chinese Journal of Process Engineering, 2015, 15(2): 259-265.

[15] 周萍, 李昊岚. 锌电解槽内气液两相流动的数值模拟[J]. 东北大学学报(自然科学版), 2015, 36(8): 1136-1140.

ZHOU Ping, LI Haolan. Numerical simulation of gas-liquid two-phase flow in zinc electrowinning[J]. Journal of Northeastern University(Natural Science), 2015, 36(8): 1136-1140.

[16] 陈卓, 周萍, 李鹏, 等. 机械搅拌式锌浸出槽内固液两相流的数值模拟与结构优化[J]. 中国有色金属学报, 2012, 22(6): 1835-1841.

CHEN Zhuo, ZHOU Ping, LI Peng, et al. Numerical simulation and structure optimization of solid-liquid two-phase flow field in mechanical stirred zinc leach tank[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1835-1841.

[17] WANG X, LOU J, WU H, et al. A VOF based numerical simulation of initial flow field of underwater gas jet[C]//Remote Sensing, Environment and Transportation Engineering (RSETE). Nanjing, China: IEEE, 2011: 3794-3797.

[18] WANG X, WANG C, AN J, et al. Numerical simulation of water-filling process in long-distance diversion tunnel with free flow[C]//Computer Science and Computational Technology. Shanghai, China: IEEE, 2008: 499-503.

[19] YOKOI K. Efficient implementation of THINC scheme: a simple and practical smoothed VOF algorithm[J]. Journal of Computational Physics, 2007, 226(2): 1985-2002.

[20] HIRT C W, NICHOLS B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225.

[21] XING X Q, BUTLER D L, YANG C. Lattice Boltzmann-based single-phase method for free surface tracking of droplet motions[J]. International Journal for Numerical Methods in Fluids, 2007, 53(2): 333-351.

(编辑 陈灿华)

收稿日期:2017-07-12;修回日期:2017-09-14

基金项目(Foundation item):国家自然科学基金资助项目(61773406);国家自然科学基金委创新研究群体科学基金资助项目(61621062);国家杰出青年科学基金资助项目(61725306)(Project(61773406) supported by the National Natural Science Foundation of China; Project(61621062) supported by the Innovative Research Groups of the National Natural Science Foundation of China; Project(61725306) supported by the National Science Foundation for Distinguished Young Scholars of China)

通信作者:蒋朝辉,博士,副教授,从事复杂工业过程建模与优化控制,工业图像处理研究;E-mail:jzh0903@csu.edu.cn