DOI: 10.11817/j.issn.1672-7207.2019.05.002

多功能铁水包熔化废钢的计算及分析

杨光1,邓帅1,徐安军1,戴晓庆2

(1. 北京科技大学 冶金与生态工程学院,北京,100083;

2. 中南大学 资源与安全工程学院,湖南 长沙,410083)

摘要:为了提高钢铁生产流程中的废钢比,在高炉接铁前向多功能铁水包中加入废钢,并通过热力学计算和数值模拟对多功能铁水包中的废钢熔化问题进行分析研究。研究结果表明:废钢在铁水包中有足够的时间升高至预热温度,高炉出铁口的铁水冲击能可有效促进大型废钢的熔化过程;当废钢比表面积为1.6 m2/t且预热温度为800 ℃时,每吨钢熔化时间约为11.5 min;铁水包中的废钢熔化受预热温度的影响,对于比表面积为3.3 m2/t的中型废钢,当其预热温度由300 ℃升高至800 ℃时,每吨钢熔化时间也由8.5 min缩短至6.8 min。

关键词:多功能铁水包;废钢;熔化过程;数值模拟

中图分类号:TF703.4 文献标志码:A 文章编号:1672-7207(2019)05-1021-07

Analysis and calculation of steel scrap melting in multifunctional hot metal ladle

YANG Guang1, DENG Shuai1, XU Anjun1, DAI Xiaoqing2

(1. School of Metallurgical and Engineering, University of Science and Technology Beijing, Beijing 100083, China

2. School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: In order to improve the scrap ratio in the steel production process, the scheme of adding scrap to the multifunctional hot metal ladle before loading to the blast furnace was proposed. The process of steel scrap melting in the multifunctional hot metal ladle was analyzed and studied by thermodynamic calculation and numerical simulation. The results show that the steel scrap has enough time to get the ideal preheating temperature in the ladle. The impact potential energy of hot metal, discharged from blast furnace tapping hole, can effectively promote the melting process of large scrap steel. When the specific surface area of the steel scrap is 1.6 m2/t and the preheating temperature is 800 ℃, the melting time per ton of steel scrap is about 11.5 min. Meanwhile, the melting of steel scrap in ladle is also greatly affected by the preheating temperature. For medium sized steel scrap with specific surface area of 3.3 m2/t, the melting time per ton of steel scrap decreases from 8.5 min to 6.8 min when the preheating temperature increases from 300 ℃ to 800 ℃.

Key words: multifunctional hot metal ladle; steel scrap; melting process; numerical simulation

铁矿石和废钢作为钢铁生产的2种重要原料,对钢铁工业的发展有着至关重要的影响。与有限的自然资源铁矿石不同,废钢是可回收利用的再生资源,使用废钢不仅能促进资源的循环利用和生产可持续发展,同时还能减少碳排放[1-3]和NOx等有害气体的产生,具有较好的经济效益和环保效益。根据文献[4-6]可知:使用废钢每生产1 t粗钢,铁矿石消耗减少4.3 t,冶炼能耗减少60%,用水量减少40%,废气排放减少86%,污水排放减少76%,废弃物产生减少97%。陆钟武[7-8]提出以废钢指数(S)作为衡量钢铁工业废钢资源充足程度的指标,并指出在钢铁产量下降后的若干年内,钢铁工业的废钢资源必然相对充足。从2015年至2017年底,由于钢铁工业产能过剩,在去产能、去库存和供侧给改革下,粗钢产量基本保持在8亿t左右。卜庆才等[9-12]对未来的废钢量进行了预测,根据钢铁制品的平均使用寿命和3类废钢的实际收得率,对我国废钢资源量和供需状况进行了分析,预测从2020—2030年废钢量将由1.2亿t左右逐年增至2.7亿t左右,废钢资源供给将得到改善,后续将进一步发展为废钢资源过剩。目前,国内钢铁厂使用的废钢多为轻薄废钢,易于熔化,但均需要购买;钢铁厂自产的废钢多为铸坯切削料,废钢成分相对较好,但厚度较大,属于中型废钢,熔化较为困难。由此可见,我国废钢量在未来将逐渐增多,废钢问题也将更加突出。为提高钢铁生产过程中的废钢比,本文作者提出铁水包中加废钢的方案,并对废钢熔化问题进行研究。

1 铁水包加废钢方案设计

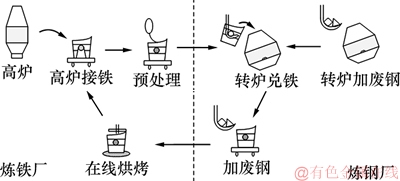

我国废钢消耗主要依靠长流程的转炉和短流程的电炉,由于长流程的钢铁生产过程不如电炉的能量来源直接可控,故废钢消耗量有限且还需要进行烘烤预热等操作[13-14]。由于废钢熔化需要有一定预热温度和其他熔化条件,在现有的多种钢铁厂铁钢界面运输模式中,“一包到底”模式下的多功能铁水包[15-16](以下简称铁水包)不需要倒罐,同样适合加入废钢。铁水包加废钢流程示意图如图1所示。

图1 铁水包加废钢流程示意图

Fig. 1 Schematic diagram of adding ladle in steel scrap

具体方案设计如下:铁水包在转炉兑铁完毕后,直接利用炼钢厂转炉加废钢的天车向铁水包中加入废钢,或使用抓钢机进行废钢加入;铁水包返回炼铁厂的铁水包烘烤位进行烤包及废钢预热;预热达一定温度(300 ℃以上)后,前往高炉出铁口等待接铁;利用高温铁水所具有的热能和势能熔化铁水包中的废钢。要实现铁水包中加废钢,关键问题在于废钢的加入对原有的生产工序是否产生不利影响,可分别从时间和温度上对此进行分析。

根据钢铁生产流程的特点并结合现场情况,对铁水包中加入废钢进行利弊分析。铁水包加入废钢具有以下优势:1) 充分吸收利用铁水热量,减少铁水热量无效耗散;2) 废钢吸收铁水的冲击势能,既能减小铁水对包底冲击区的冲刷危害、提高铁水包包龄,又能缩短废钢熔化时间[17];3) 增加钢铁全流程总废钢比和废钢加入量,节约钢铁生产成本;4) 解决钢铁厂自产的大量中型切削料废钢难以熔化的问题。同时,铁水包中加入废钢可能带来以下问题:1) 增加了铁水包中加废钢的操作,天车调度任务加大;2) 除极少量的铁水包废钢外,铁水包均需要进行在线烘烤[18]以提高铁水包热状态[19-22],同时使废钢达到足够的预热温度;3) 废钢熔化较慢或熔化不完全,影响铁水预处理。

为了证实本文方案的优点,同时分析方案中存在的问题并给出相应的解决办法,以首钢京唐钢铁公司300 t铁水包为例,对废钢熔化问题进行相关热力学分析和数值模拟。

2 铁水包中废钢熔化的热力学研究

2.1 废钢传热对流换热系数的确定

废钢在铁水包中的熔化受温度、表面传热系数等诸多因素的共同影响,且遵循牛顿冷却定律:

q=h·△t (1)

式中:q为热流密度,W/m2;h为对流换热系数,W/(m2·℃);△t为温差,℃。

研究废钢在铁水中熔化的热力学过程,关键在于废钢熔化过程中对流换热系数的确定。

(2)

(2)

(3)

(3)

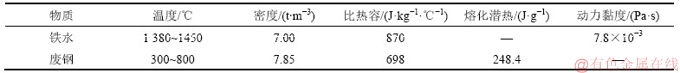

式中:Re为雷诺数;ρ为铁水密度,kg/m3;u为铁水流速,m/s;d为出铁口铁水液柱直径,m;Pr为普朗特数;ν为运动黏度,m2/s;α为热扩散系数,m2/s;μ为动力黏度,Pa·s;cp2为铁水比热容,J/(kg·℃);k为热导率,W/(m·℃)。假设高炉出铁口距铁水包底6 m,铁水冲击包底流速约为11 m/s,铁水液柱直径为80 mm;铁水和废钢的热物性参数如表1所示。

表1 铁水和废钢的热物性参数

Table 1 Thermophysical properties of hot metal and steel scrap

铁水冲击废钢为强制对流换热,其雷诺数Re≈ 5.6×105,满足Dittus-Boelter对流换热实验关联式[23-24]的适用范围,同时,联合努塞尔准数(Nu)表达式确定铁水与废钢的对流换热系数:

(4)

(4)

式中:ct为修正系数,此处取ct=0.95。

(5)

(5)

式中:L为废钢厚度,m。

由式(1)~(4)可得对流换热系数h为

(6)

(6)

废钢在铁水包中的对流换热可分为2种情况:第1种为初始接铁时刻,铁水液柱对废钢直接冲击;第2种为高炉接铁一段时间后,废钢完全浸入铁水中进行对流换热。根据式(6)可计算出受铁水冲击时的表面对流换热系数h1约为2 046 W/(m2·℃),浸入铁水后的表面对流换热系数h2约为863 W/(m2·℃),由此可见高炉铁水直接冲击废钢阶段的对流换热系数为浸入铁水中对流换热系数的2~3倍。

2.2 废钢熔化过程分析

废钢在铁水包中首先经烘烤预热达到一定温度,后在高炉接铁时吸收铁水热量达到其熔点后开始逐渐熔化。废钢的熔点与其自身碳质量分数有关,碳质量分数越高,其熔点越低。但废钢自身碳质量分数较低,一般在2%以下,熔点为1 430~1 480 ℃;但高炉铁水碳质量分数相对较高,废钢与铁水接触会出现渗碳,即铁水中的碳原子向废钢中渗透,提高废钢中的碳质量分数,熔点也将降低。

铁水在接触废钢后,废钢由于熔点较高吸收铁水热量先出现表面结壳,短时间内由于铁水的渗碳作用,废钢碳质量分数升高、熔点降低,开始熔化。整个熔化过程如下:废钢表面结壳,而后渗碳与熔化过程同时进行。根据文献[25-27]可知:渗碳达到一定程度所需时间较短,结壳再熔化时间约为2 min。故假设熔化时碳质量分数为3.3%,根据铁-碳相图可知此时废钢熔点为1 260℃。废钢熔化能量守恒方程如下:

(7)

(7)

(8)

(8)

(9)

(9)

式中:Q为废钢熔化所需热量,J;Qt为废钢升温至熔点所需热量,J;cp1为废钢比热容,J/(kg·℃);Qm为废钢的熔化潜热所需总热量,J;θm为废钢熔化温度,℃;θh为废钢预热温度,℃;q1为废钢熔化潜热,kJ/kg;m1为废钢的质量,kg。

由于废钢熔化时间还与废钢和铁水的接触面积有关,此处以重型废钢为例,在可熔化情况下,废钢完全熔化时间t的表达式为

(10)

(10)

式中:t1为冲击阶段持续时间,s;S为废钢的比表面积(S=s/m),m2/t;s为废钢总表面积,m2。

由式(10)可以看出废钢熔化时间主要受废钢预热温度θh和废钢的比表面积共同影响。以长×宽×高分别为2.0 m×1.5 m×0.2 m的废钢进行计算,可知其质量为4.7 t,比表面积为1.6 m2/t。若其预热温度为800 ℃,根据高炉出铁速率,厚度小于0.2 m的废钢完全浸入铁水的时间t1仅需1~2 min,此废钢完全熔化时间约为25.8 min,每吨钢熔化时间为5.5 min。

3 废钢熔化的控制

3.1 废钢种类对废钢熔化的影响

为了保证废钢加入不影响铁水预处理,废钢完全熔化时间必须小于铁水包从接铁开始到预处理站的时间。根据生产调研结果可知,铁水包从高炉接铁至预处理站的时间为45~70 min,为保证铁水包在到达预处理站时废钢熔化完全,取最小周转时间45 min。由式(10)可以看出每吨钢的熔化时间仅与预热温度和废钢比表面积有关,在分析废钢预热温度对熔化速率的影响时,需控制另一变量,即废钢的比表面积。3种典型废钢参数如表2所示。

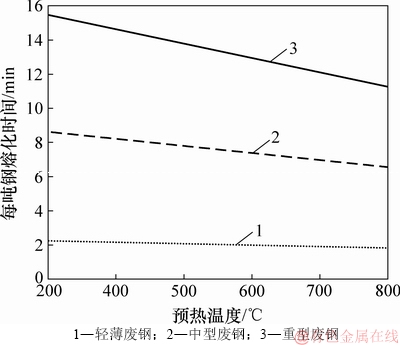

图2所示为废钢预热温度与熔化时间的关系。由图2可以看出:每吨钢的熔化时间与废钢的预热温度呈线性相关;废钢预热温度越高,废钢熔化速率越大,每吨钢的熔化时间越短;随着废钢预热温度升高,废钢熔化时间缩短;废钢比表面积越小,预热温度对废钢熔化速率的改善效果越明显;废钢比表面积越大,预热温度对废钢熔化速率的影响较小。以废钢3为例,当预热温度达到800 ℃时,每吨钢熔化时间为11.5 min,总熔化时间约为54 min,超出铁水包运输至铁水预处理的安全时间45 min。由此可见,比表面积极小的重型废钢,即使预热温度达800 ℃,仍然难以保证在进行铁水预处理之前熔化完全。

表2 废钢参数

Table 2 Parameters of steel scrap

图2 每吨钢预热温度与熔化时间的关系

Fig. 2 Relationship between preheating temperature and melting time per ton of scrap steel

根据比表面积将废钢分为3类:第Ⅰ类为轻薄废钢,比表面积大于5 m2/t;第Ⅱ类为中型废钢,比表面积为2~5 m2/t;第Ⅲ类为重型废钢,比表面积小于2 m2/t。每吨钢熔化时间与比表面积关系如图3所示,其中区域Ⅰ,Ⅱ和Ⅲ分别对应轻薄废钢、中型废钢和重型废钢。由图3可以看出:每吨钢的熔化时间与废钢的比表面积呈反比,当比表面积小于5 m2/t时,增大比表面积能有效提高废钢熔化速率,即缩短每吨钢的熔化时间;当比表面积大于5 m2/t时,比表面积不再是废钢熔化的限制性因素,提高比表面积对熔化速率影响较小。比表面积与预热温度对每吨钢熔化时间的影响如图4所示。

图3 每吨钢比表面积与熔化时间的关系

Fig. 3 Relationship between specific surface area and melting time per ton of scrap steel

图4 比表面积与预热温度对每吨钢熔化时间的影响

Fig. 4 Effects of the specific surface area and preheating temperature on the melting time per ton of steel scrap

3.2 模拟验证试验

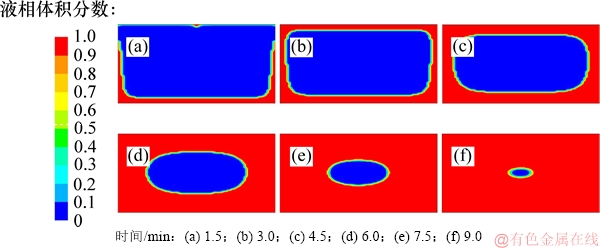

采用数值模拟方法验证分析计算的准确性。模拟熔化过程采用长×宽×高分别为0.6 m×0.6 m×0.3 m的块状废钢,总质量为0.85 t,比表面积为1.7 m2/t。数值模拟采用二维模型进行计算,以块状废钢的轴对称面进行观察,铁水包中熔化废钢示意图见图5。

图5 铁水包中熔化废钢示意图

Fig. 5 Diagram of melting process of steel scrap in hot metal ladle

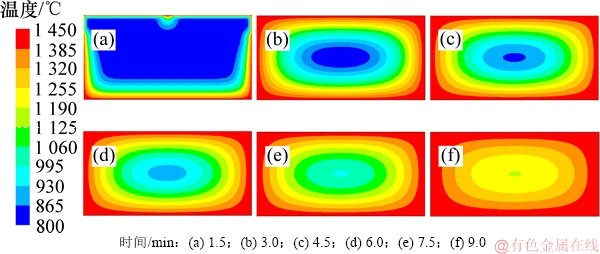

数值模拟使用Fluent软件进行计算,废钢初始的预热温度设置为800 ℃,高炉出铁温度设置为1 450 ℃.由于铁水黏度较大,湍流模型选择SST k-ω模型。对废钢对称面每隔1.5 min监测1次,其中包括废钢块的温度场分布以及剩余废钢液相体积分数。图6所示为废钢熔化过程中的温度场分布。由图6可知:初始1.5 min内铁水液柱直接冲击废钢上表面,底部的铁水液面也逐渐升高;废钢中心温度始终最低,废钢整体温度随着时间逐渐升高,在接铁9.0 min时废钢基本温度均超过1 260 ℃。

图7所示为废钢熔化过程中的液相体积分数云图。由图7可知:接铁初始时刻铁水冲击废钢造成废钢上表面形成凹坑,随着铁水包内铁水液位逐渐升高,废钢下部开始熔化;接铁9.0 min时废钢基本熔化完全,前4.5 min主要为废钢吸热升温过程,温差大,热流密度大,但废钢熔化质量较少,熔化速率较慢;后4.5 min废钢基本达到熔化温度,主要为吸热熔化,熔化速率较大。模拟中0.85 t废钢在10.0 min时完全熔化,废钢的平均熔化时间为11.7 min,模拟结果与计算结果相对误差小于2%,证实了计算过程的准确性。

3.3 铁水包中废钢加入质量的控制

由于铁水熔化废钢后的整体温度仍需满足铁水预处理的安全温度:

(11)

(11)

式中:m2为铁水质量。

联合式(7),(8),(9)和(11)可得废钢加入质量表达式为

(12)

(12)

图6 废钢熔化温度场分布

Fig. 6 Temperature fields in steel scrap melting process

图7 废钢熔化过程中液相体积分数分布云图

Fig. 7 Liquid volume fraction cloud pictures of melting process of steel scrap

式中:θf为高炉出铁温度,℃;θs为铁水预处理安全温度,℃;θd为铁水由高炉至预处理站的运输温降,℃;mmax为铁水包中的最大废钢加入质量,t。由于铁水运输温降基本固定[28-29],高炉出铁温度波动不大,废钢加入质量的影响因素主要为废钢预热温度所影响的熔化时间。

在满足铁水预处理站前完全熔化且达到预处理安全温度的条件下,废钢的最大加入质量的目标函数如下:

(13)

(13)

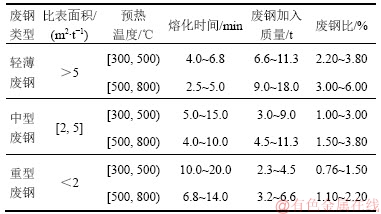

式中:t0为铁水包接铁开始至预处理站的时间,此处取最小值45 min;tm为废钢在铁水中结壳渗碳过程的总时间,tm≈2 min; 为每吨钢熔化时间,min。根据式(12)计算受铁水热量所限制的最大废钢加入质量,取废钢预热温度θh=300 ℃,可得最大废钢加入质量约为30 t,故铁水热量不是限定废钢加入质量的关键因素,熔化时间对废钢加入质量影响较大。由此可以计算出3类典型废钢在不同预热温度范围内的废钢安全加入量和熔化情况,如表3所示。

为每吨钢熔化时间,min。根据式(12)计算受铁水热量所限制的最大废钢加入质量,取废钢预热温度θh=300 ℃,可得最大废钢加入质量约为30 t,故铁水热量不是限定废钢加入质量的关键因素,熔化时间对废钢加入质量影响较大。由此可以计算出3类典型废钢在不同预热温度范围内的废钢安全加入量和熔化情况,如表3所示。

表3 不同预热温度下铁水包废钢加入质量

Table 3 Steel scrap mass added in hot metal ladle under different preheating temperatures

对于300 t铁水包而言,当预热温度达到最高温度800 ℃时,该方案中轻薄废钢、中型废钢和重型废钢最大加入质量分别为18.0,11.3和6.6 t,3类废钢的铁水包废钢比分别为2.20%~6.00%,1.00%~3.80%和0.76%~2.20%。

在钢铁厂首次试行该方案时,由于钢铁厂生产环境复杂,工序与工序之间衔接紧凑度难以保证,铁水包中加废钢的操作可能存在部分隐患,出现状况时可采取以下应对措施:1) 铁水包周转率过低或高炉出铁备包数太少,可不必保证100%的铁水包加废钢;2) 需要冶炼高品质或其他特殊钢种时,不添加废钢或添加筛选合格的废钢;3) 若由于废钢加入过多或预处理等待时间过长,导致预处理时铁水温度不够,可适当加入辅热剂;4) 对于加入废钢的铁水包,在高炉接铁时应尽量避免出铁口的第1包铁水,防止由于铁水沟所导致的首包铁水温度偏低,同时也应避免出铁口的最后1包铁水,避免因出现尾包(即半包铁)而继续等待接铁,从而影响废钢熔化的情况。

4 结论

1) 提出在多功能铁水包中添加废钢的方案,并通过数值模拟方法进行验证。该方案减少了高炉接铁过程中铁水液柱对铁水包包底的冲刷,提高了铁水包包龄及钢铁生产流程中总的废钢加入质量,降低了钢铁生产成本。

2) 铁水包的在线烘烤和废钢的比表面积对废钢熔化有着重要影响。当重型废钢比表面积为1.6 m2/t,废钢预热温度由300 ℃提高至800 ℃时,每吨钢熔化时间由15.5 min缩短至11.5 min;当预热温度均为800 ℃时,对于比表面积为3.3 m2/t的中型废钢,每吨钢熔化时间为6.8 min,而对于比表面积为26.1 m2/t的轻薄废钢,每吨钢熔化速率为2.3 min。

3) 对于容量为300 t的铁水包,铁水包中添加轻薄废钢、中型废钢和重型废钢的最大质量分别为18.0,11.3和6.6 t,铁水包废钢比最高分别为6.0%,3.8%和2.2%。

4)分析铁水包中添加废钢可能存在的影响,并提出应对措施,为后续相关研究提供参考。

参考文献:

[1] YAMAZAKI M. Effects of CO2 emissions trading on steel scrap recycling: a simulation analysis using a computable general equilibrium model[J]. Materials Transactions, 2011, 52(3): 498-506.

[2] 卢鑫, 白皓, 赵立华, 等. 钢铁企业能源消耗与CO2减排关系[J]. 工程科学学报, 2012, 34(12): 1445-1452.

LU Xin, BAI Hao, ZHAO Lihua, et al. The relationship between energy consumption and CO2 emissions in iron and steel making[J]. Chinese Journal of Engineering, 2012, 34(12): 1445-1452.

[3] 陆钟武, 岳强, 高成康. 论单位生产总值钢产量及钢产量、钢铁行业的能耗、物耗和排放[J]. 中国工程科学, 2013, 15(4): 23-29.

LU Zhongwu, YUE Qiang, GAO Chengkang. Study on steel output per unit GDP and steel production, energy consumption, materials consumption & wastes emission of steel industry[J]. Engineering Sciences, 2013, 15(4): 23-29.

[4] WANG Minxi, GU Shanlu, GUO Yan. Steel scrap’s discovery and utilization: based on China[J]. Acta Geologica Sinica, 2015, 88(S2): 1294-1295.

[5] FUT

P, PRIBULOV

P, PRIBULOV A, FEDORKO G, et al. Influence of steel scrap in the charge on the properties of gray cast iron[J]. ISIJ International, 2017, 57(2): 374-379.

A, FEDORKO G, et al. Influence of steel scrap in the charge on the properties of gray cast iron[J]. ISIJ International, 2017, 57(2): 374-379.

[6] IGARASHI Y, DAIGO I, MATSUNO Y, et al. Estimation of the change in quality of domestic steel production affected by steel scrap exports[J]. ISIJ International, 2007, 47(5): 753-757.

[7] 陆钟武. 关于钢铁工业废钢资源的基础研究[J]. 金属学报, 2000, 36(7): 728-734.

LU Zhongwu. A study on the steel scrap resources for the steel industry[J]. Acta Metallurgica Sinica, 2000, 36(7): 728-734.

[8] 陆钟武. 论钢铁工业的废钢资源[J]. 钢铁, 2002, 37(4): 66-70.

LU Zhongwu. On steel scrap resources for steel industry[J]. Iron and Steel, 2002, 37(4): 66-70.

[9] 卜庆才, 吕江波, 李品芳,等. 2020—2030年中国废钢资源量预测[J]. 中国冶金, 2016, 26(10): 45-49.

BU Qingcai, LU Jiangbo, LI Pinfang, et al. Prediction of Chinese steel scrap resources quantity in 2020—2030[J]. China Metallurgy, 2016, 26(10): 45-49.

[10] IGARASHI Y, KAKIUCHI E, DAIGO I, et al. Estimation of steel consumption and obsolete scrap generation in Japan and Asian countries in the future[J]. ISIJ International, 2008, 93(12): 782-791.

[11] HATAYAMA H, DAIGO I, MATSUNO Y, et al. Outlook of the world steel cycle based on the stock and flow dynamics[J]. Environmental Science & Technology, 2010, 44(16): 6457-6463.

[12] NAKAJIMA K, UCHIYAMA Y, HALADA K. Investigation of processing scraps of steel for the developing materials flow of recycling system[J]. Journal of the Japan Institute of Metals, 2002, 66(9): 917-920.

[13] PAK Y A, FILIPPOV G A, GLUKHIKH M V. Converter smelting of steel with preliminary scrap heating to reduce hot-metal consumption[J]. Steel in Translation, 2016, 46(9): 657-661.

[14] SUGIURA S, DEMUKAI N. Melting of direct reduced iron in a non-electric power scrap melting furnace[J]. ISIJ International, 2006, 28(12): 1014-1020.

[15] 杨光, 徐安军, 贺东风, 等. 多功能铁水包加盖保温效果分析[J]. 钢铁, 2017, 52(7): 96-103.

YANG Guang, XU Anjun, HE Dongfeng, et al. Analysis on heat preservation of multifunctional hot metal ladle[J]. Iron and Steel, 2017, 52(7): 95-103.

[16] 张龙强, 田乃媛, 徐安军,等. 实现铁水包多功能技术的研究[J]. 工程科学学报, 2007, 29(4): 424-427.

ZHANG Longqiang, TIAN Naiyuan, XU Anjun, et al. Research on realization of ladle multifunction[J]. Chinese Journal of Engineering, 2007, 29(4): 424-427.

[17] 袁飞, 杨光, 徐安军,等. 基于不同保温措施下的铁水包热状态模拟分析[J]. 工程科学学报, 2018, 40(1): 31-40.

YUAN Fei, YANG Guang, XU Anjun, et al. Thermal state simulation analysis of molten iron ladle based on different insulation measures[J]. Chinese Journal of Engineering, 2018, 40(1): 31-40.

[18] KLIMANCHUK V V, KOSOLAP N V, GLADKII P A, et al. Ladle heating of hot metal on discharge from the blast furnace[J]. Steel in Translation, 2011, 41(11): 918-923.

[19] GLASER B, G RNERUP M, SICHEN D. Thermal modelling of the ladle preheating process[J]. Steel Research International, 2011, 82(12): 1425-1434.

RNERUP M, SICHEN D. Thermal modelling of the ladle preheating process[J]. Steel Research International, 2011, 82(12): 1425-1434.

[20] ZHANG Xinghe, TAKAHASHI R, NOGAMI H, et al. Numerical simulation of the moving bed furnace for iron scrap melting[J]. ISIJ International, 2002, 42(S1): 23-27.

[21] 欧俭平, 萧泽强, 蒋绍坚,等. 蓄热式钢包烘烤装置的热工特性[J]. 中南大学学报(自然科学版), 2004, 35(2): 217-221.

OU Jianping, XIAO Zeqiang, JIANG Shaojian, et al. Thermal performance of regenerative ladle heater[J]. Journal of Central South University(Science and Technology), 2004, 35(2): 217-221.

[22] VOLKOVA O, JANKE D. Modelling of temperature distribution in refractory ladle lining for steelmaking[J]. ISIJ International, 2003, 43(8): 1185-1190.

[23] YUAN Zhongxian, TAO Wenquan, WANG Qqiuwang. Numerical prediction for laminar forced convection heat transfer in parallel-plate channels with streamwise-periodic rod disturbances[J]. International Journal for Numerical Methods in Fluids, 2015, 28(9): 1371-1387.

[24] XIE Weian, XI Guannan. Geometry effect on flow fluctuation and heat transfer in unsteady forced convection over backward and forward facing steps[J]. Energy, 2017, 132: 49-56.

[25] LI J, PROVATAS N, BROOKS G. Kinetics of scrap melting in liquid steel[J]. Metallurgical & Materials Transactions B, 2005, 36(2): 293-302.

[26] WU Yongke, LACROIX M. Numerical study of melting of scrap metal[J]. Numerical Heat Transfer Applications, 1993, 24(4): 413-425.

[27] GUTHRIE R I L, STUBBS P. Kinetics of scrap melting in baths of molten pig iron[J]. Canadian Metallurgical Quarterly, 2013, 12(4): 465-473.

[28] 杨光, 徐安军, 贺东风. 高炉-转炉区段铁水运输温降综述[J]. 中国冶金, 2018,28(4): 1-6.

YANG Guang, XU Anjun, HE Dongfeng. Review on temperature of hot metal from BF to BOF[J]. China Metallurgy, 2018, 28(4): 1-6.

[29] JIANG Zhaohui, PAN Dong, GUI Weihua, et al. Temperature measurement of molten iron in taphole of blast furnace combined temperature drop model with heat transfer model[J]. Ironmaking & Steelmaking, 2018,45(3): 1-9.

(编辑 伍锦花)

收稿日期:2018-06-06;修回日期:2018-08-06

基金项目(Foundation item):国家重点研发计划项目(2016YFB0601301); 国家自然科学基金资助项目(51674030)(Project(2016YFB0601301) supported by the National Key Research and Development Program of China; Project(51674030) supported by the National Natural Science Foundation of China)

通信作者:徐安军,博士,教授,从事冶金流程工程学以及钢铁流程整体优化研究;E-mail: anjunxu@126.com