DOI:10.19476/j.ysxb.1004.0609.2019.11.07

热处理对砂型铸造Mg-4Sm-0.6Zn-0.4Zr合金显微组织和力学性能的影响

逯连文1,卜繁强1,刘晓琴1,王大臣1,孟 健2

(1. 中车长春轨道客车股份有限公司,长春 130062;

2. 中国科学院 长春应用化学研究所,长春 130022)

摘 要:本文研究了热处理对砂型铸造Mg-4Sm-0.6Zn-0.4Zr合金显微组织和力学性能的影响,并运用光学显微镜、X射线衍射、扫描电子显微镜、透射电子显微镜以及力学实验设备对该合金进行了表征与分析。结果表明:铸态合金主要有α-Mg和Mg3Sm组成;固溶处理之后,Mg3Sm相完全溶入到基体且晶粒并未发生明显长大。250 ℃峰时效合金中主要的析出相为基面γ″沉淀相。峰时效态合金展示了最好的力学性能,其抗拉强度、屈服强度和断后伸长率分别为210 MPa、153 MPa和4.0%。根据峰时效态合金的强化机制的定量分析结果,发现峰时效态合金主要的强化效果来自于弥散分布的细小的γ″的沉淀强化,其对屈服强度的贡献为120 MPa,约占总屈服强度的80%。

关键词:Mg-Sm;稀土镁合金;力学性能;砂型铸造

文章编号:1004-0609(2019)-11-2508-07 中图分类号:TG146.2 文献标志码:A

由于镁合金具有低密度、高比强度、良好的铸造性能以及优异的综合力学性能等优点,所以在汽车工业、航空航天、轨道列车以及电子消费品领域具有广阔的应用前景[1-5]。稀土添加到镁合金能够显著改善其铸造性能,提高拉伸性能和蠕变性能等。ZM6合金是我国自主研发的具有耐热、高强和良好铸造性能的稀土镁合金,被广泛用于航空领域,比如发动机机匣和飞机翼肋[6-7]。我国的ZM6合金属Mg-Nd-Zn-Zr合金,其研发历史先于目前商用铸造WE系稀土镁合金的。由于钕(Nd)价格昂贵[8],严重限制ZM6合金的在民用及轨道客车领域的广泛应用。因此,开发新的铸造合金,以替代昂贵钕成为亟待解决的问题。

钐(Sm)属于钇族轻稀土,是最廉价的稀土之一,具有独特的斜方结构,且在镁中的最大固溶度(质量分数)为5.7% [9],高于钕在镁中的固溶度(3.6%),这暗示钐在镁中具有良好的固溶强化效果和沉淀强化效果。早期,NISHIJIMA等[10]报道了Mg-0.99%Sm(摩尔分数)二元合金在200 ℃时效时的柱面析出相沉淀序列:过饱和固溶体(S.S.S.S)→Guinier Preston区(G.P.区,DO19结构,a=0.642 nm,c=0.521 nm)→ β′ (Mg5Sm,orthorhombic,a=0.642 nm,b=3.334 nm,c=0.521 nm)→ β1 (Mg3Sm,FCC,a=0.74 nm),并且认为β′是合金的主要强化相。另外,NIE等[11]和XIA等[12]认为,少量的锌(<1%,质量分数)添加能够改善镁合金的强度和蠕变性能,然而大量的锌(>1%)能够改变沉淀相的惯习面,即柱面( 或

或 ) β系列沉淀相消失,出现基面({0002}) γ系列沉淀相。相比β系列沉淀相,γ系列沉淀相对基面位错滑移的阻碍效果较弱,但是γ系列沉淀相具有更好的热稳定性。据报道[12],Mg-4Sm- 1Zn-0.4Zr (质量分数,%)合金的基面沉淀序列为:过饱和固溶体(S.S.S.S)→原子团簇→γ″(G. P.区Ⅰ,a= 0.556 nm,c=0.414 nm) → γ′(G. P. 区Ⅱ,a=0.556 nm,c=0.414 nm) (→层错)→γ (FCC,a=0.74 nm)。郑江等[13]系统研究了Mg-3Sm-0.5Zn-0.4Zr合金的铸态力学性能、压铸性能和蠕变性能,其结果表明Mg-3Sm-0.5Zn- 0.4Zr合金具有良好的力学性能和蠕变性能。苏昕等[14]研究了金属型铸造Mg-xSm-0.4Zn-0.3Zr (x=0.4~5)合金在175、200和225 ℃峰时效条件下合金的力学性能,其研究表明Mg-4Sm-0.4Zn-0.3Zr具有最佳的力学性能。

) β系列沉淀相消失,出现基面({0002}) γ系列沉淀相。相比β系列沉淀相,γ系列沉淀相对基面位错滑移的阻碍效果较弱,但是γ系列沉淀相具有更好的热稳定性。据报道[12],Mg-4Sm- 1Zn-0.4Zr (质量分数,%)合金的基面沉淀序列为:过饱和固溶体(S.S.S.S)→原子团簇→γ″(G. P.区Ⅰ,a= 0.556 nm,c=0.414 nm) → γ′(G. P. 区Ⅱ,a=0.556 nm,c=0.414 nm) (→层错)→γ (FCC,a=0.74 nm)。郑江等[13]系统研究了Mg-3Sm-0.5Zn-0.4Zr合金的铸态力学性能、压铸性能和蠕变性能,其结果表明Mg-3Sm-0.5Zn- 0.4Zr合金具有良好的力学性能和蠕变性能。苏昕等[14]研究了金属型铸造Mg-xSm-0.4Zn-0.3Zr (x=0.4~5)合金在175、200和225 ℃峰时效条件下合金的力学性能,其研究表明Mg-4Sm-0.4Zn-0.3Zr具有最佳的力学性能。

因此,以Mg-Sm-Zn-Zr为研究体系来改进原有的ZM6合金成份体系具有重要的研究价值;同时,Mg-Sm-Zn-Zr合金体系是具有良好铸造性能的合金,通常采用砂型铸造生产一些复杂形状的结构件。本研究以砂型铸造Mg-4Sm-0.6Zn-0.4Zr合金为研究对象,在苏昕等[14]的研究结果基础上,增加锌与锆含量来促进γ系列沉淀相的生成,达到强化合金的目的,同时研究该体系合金在不同状态下的力学性能,为Mg-4Sm-0.6Zn-0.4Zr合金进一步工业应用提供基础数据和参考依据。

1 实验

将工业纯镁、纯锌、Mg-20%Sm(质量分数)中间合金和Mg-30%Zr(质量分数)中间合金按照合金成分进行配料,然后除去各组分原料表面氧化皮并预热至250 ℃,同时清理铸铁坩埚并预热至550 ℃。加入镁锭,炉温升至730 ℃并通入V(SF6):V(CO2)=1:200的保护气体。待镁锭完全融化后,实测熔体温度在730~740 ℃时,撇去熔体表面浮渣,依次加入纯锌和Mg-20%Sm中间合金,待其完全融化后,升温至760 ℃;待实测熔体温度在(760±10) ℃左右时,撇去熔体表面浮渣,加入Mg-30%Zr中间合金,待其完全融化后,均匀搅拌10~15 min。然后降温至720 ℃并静置40 min。最后,将合金熔体浇铸到砂型模具。使用电感耦合等离子体光谱仪测定铸件的实际成分为 Mg-4.26Sm-0.58Zn-0.36Zr(质量分数,%)。

使用真空热处理炉(ZZG-250)对合金进行在固溶处理,具体工艺为520 ℃热处理6 h,并用热水淬火。然后,对固溶态合金进行250 ℃等温时效。采用FM-700型维氏硬度计进行硬度测试,载荷为50 N,保压时间为15 s,每个试样最少打10个点,取平均值作为有效数据。拉伸试样标距尺寸为15 mm×4 mm×2 mm,采用Instron 5869型万能材料试验机进行拉伸试验,应变速率为1×10-3 s-1。每个状态的试样至少测试5次。

采用日本Olympus GX71型金相显微镜、德国Bruker D8 Focus型X射线衍射仪、日本Hitachi S4800型场发射扫描电子显微镜且配备了EDAX GENESIS型能谱仪的TEM-EDS系统(图像采集操作电压为10 kV,能谱操作电压为20 kV)和美国FEI-TECNAI G2型的透射电子显微镜进行合金组织表征。金相和SEM样品均需要抛光和腐蚀处理,腐蚀液配方为35 mL酒精、2 mL冰醋酸、2.2 g苦味酸和3 mL去离子水。透射试样先制备一个厚度为30 μm左右、直径为3 mm的圆片,之后放入Gatan 691离子减薄仪中对样品进行减薄,采用液氮冷却,双面减薄,离子束能量为3~ 4 keV,离子双束设置为±4o,减薄时间约90 min。

2 实验结果

2.1 铸态和固溶态合金的显微组织

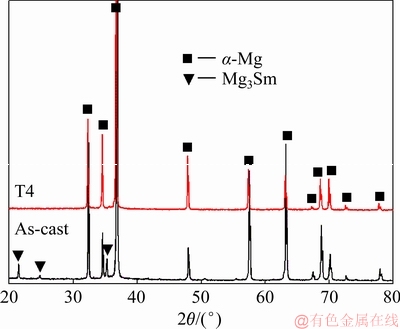

图1所示为Mg-4Sm-0.6Zn-0.4Zr合金铸态和固溶态合金的XRD谱。由图1可见,铸态合金主要由α-Mg和Mg3Sm(面心立方结构,a = 0.73 nm[12])组成。

图1 铸态和固溶态合金的XRD谱

Fig. 1 XRD patterns of as-cast and solid solution alloys

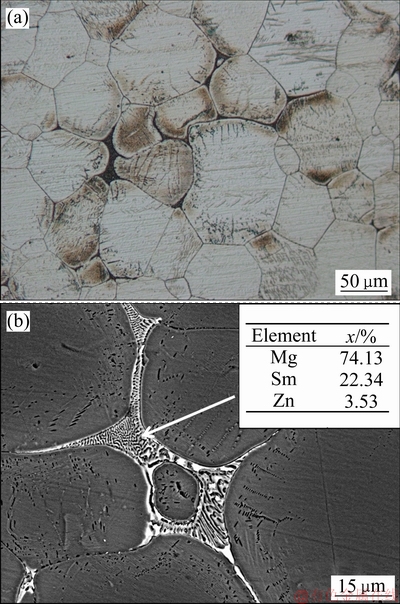

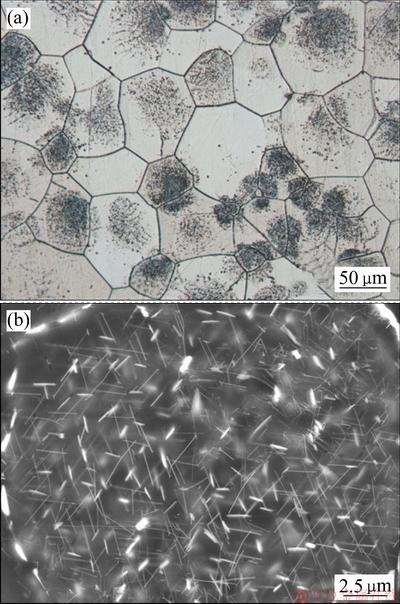

图2所示为铸态合金的微观组织。从图2(a)可以看出,铸态合金的平均晶粒尺寸约50 μm,晶界上断续分布着第二相。从图2(b)可以更加清晰地看出,该相呈白色层片状并分布在晶界处,与基体α-Mg形成是典型的离异共晶。根据相应的EDS分析结果可知,该相的成分为Mg74.13Sm22.34Zn3.53,与XRD分析的结果相符,即Mg3Sm相中富集了少量的锌元素(见图2(b))。固溶态合金的XRD结果显示,固溶合金中只有α-Mg,无其他相的衍射峰出现;但从固溶态合金的金相照片与背散射扫描照片中发现(见图3),固溶后合金的晶粒中心部位析出大量长条状第二相,且在长条状相周围有块状与短杆状相析出。根据FU等[15]和GAO等[16]的报道,块状颗粒为ZrH2相(立方结构,a=0.478 nm),短杆状和长条状颗粒为Zn2Zr3相(四方结构,a= 0.768 nm和c=0.699 nm),且这些析出相对力学性能影响尚不明确。另外,固溶合金晶粒间的Mg3Sm相完全溶解,平均晶粒尺寸为52 μm,晶粒并未发生明显长大。

图2 铸态合金的微观组织

Fig. 2 Optical microstructure(a) and BSE-SEM image(b) and corresponding EDS results of as-cast alloy

图3 固溶态合金的微观组织

Fig. 3 Optical microstructure(a) and BSE-SEM image(b) for solid solution alloy

2.2 时效硬化行为和峰时效态合金的组织

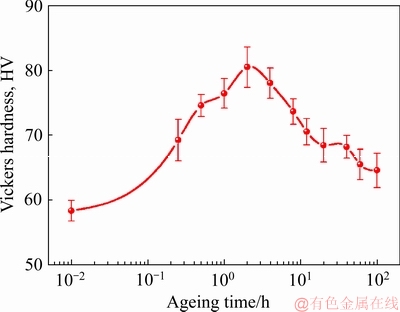

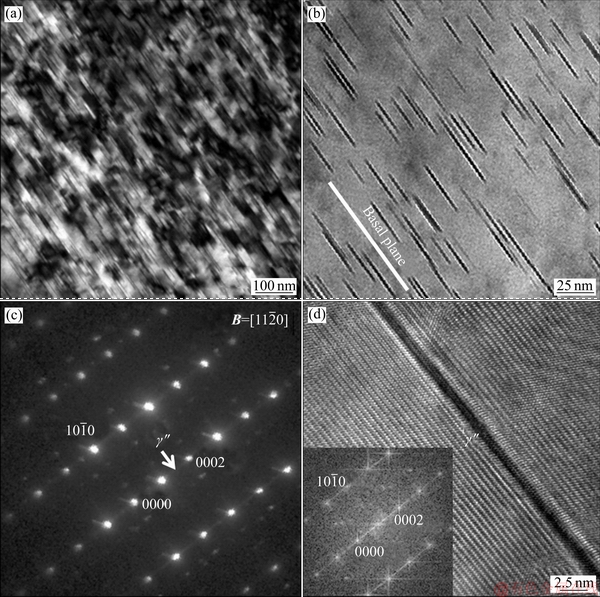

图4所示为Mg-4Sm-0.6Zn-0.4Zr合金在250 ℃等温时效过程中的硬度与时效时间的关系。由图4可以清晰看到,时效态合金表现出显著的时效硬化效果,这暗示强的沉淀强化。固溶态合金的硬度为57HV,在时效2 h后达到了峰值硬度,其值为81HV。进一步时效,硬度表现出明显的下降趋势,称之为过时效,其主要原因是沉淀相长大。图5给出了峰时效合金的TEM相关表征。图5(a)和(b)所示为明场TEM像,可以看到峰时效合金的析出相仅有一种,其宽度约为1 nm,长度方向约为50 nm,长宽比为50:1。根据选区电子衍射照片(见图5(c))可知,这种析出相的惯习面为基面,且沿着[0002]方向出现微弱的衍射条纹。这种衍射特征也在Mg-Gd-Zn-Zr合金[11]和Mg-Sm-Zn-Zr合金[12]中有过报道,并且NIE等[11-12]认为,这种衍射特征主要是由γ″(Mg4REZn 类型)引起,γ″是一种有序的六方结构,晶格参数为a=0.556 nm和c=0.444 nm。另外γ″与镁基体通常呈共格关系,具体位向关系如下: //

// and

and  //

// 。图5(d)所示为γ″相的典型高分辨照片,其快速傅里叶变换照片与选取电子衍射照片(见图5(c))高度吻合,再次证明了γ″的存在。因此,合金在250 ℃峰时效的主要强化相为基面γ″沉淀相。

。图5(d)所示为γ″相的典型高分辨照片,其快速傅里叶变换照片与选取电子衍射照片(见图5(c))高度吻合,再次证明了γ″的存在。因此,合金在250 ℃峰时效的主要强化相为基面γ″沉淀相。

图4 固溶态合金在250 ℃等温时效过程中的硬度演变

Fig. 4 Hardening evolution of solid solution alloy as a function of ageing time during isothermal aged at 250 ℃

2.3 力学性能

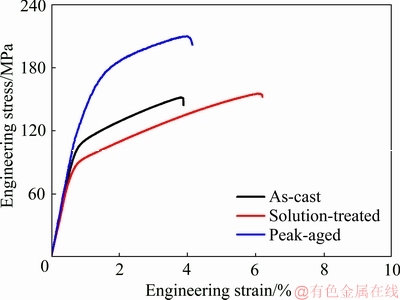

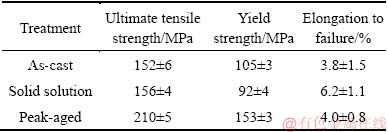

图6所示为铸态、固溶态、峰时效态合金在室温条件下的工程应力-应变曲线,相应的抗拉强度(UTS)、拉伸屈服强度(TYS)和断后伸长率(EL)列于表1中。从中可以看出铸态合金的强度和塑性均比较低,铸态合金的抗拉强度、拉伸屈服强度和断后伸长率分别为152 MPa、105 MPa和3.8%。但是固溶处理之后,合金的拉伸屈服强度下降,断后伸长率明显改善,达到了6.2%。峰值时效之后,合金的强度显著增加,拉伸屈服强度高达153 MPa,抗拉强度高达210 MPa,同时断后伸长率保持在4.0%。

图5 峰时效态合金的TEM组织

Fig. 5 BF-TEM micrographs((a), (b)), their corresponding SAED patterns(c) and high resolution TEM images(d) with corresponding digital FFT patterns of precipitates in peak-aged Mg-4Sm-0.6Zn-0.4Zr alloy (Electron beam for all images is parallel to  zone axis)

zone axis)

图6 铸态、固溶态、峰时效态合金在室温的工程应力-工程应变曲线

Fig. 6 Engineering stress-engineering strain curves of as-cast, solid solution, peak-aged alloy at room temperature

表1 Mg-4Sm-0.6Zn-0.4Zr合金的力学性能

Table 1 Mechanical properties of Mg-4Sm-0.6Zn-0.4Z alloy

3 讨论

由于铸态合金中存在粗大的第二相,在变形过程中容易在第二相处产生应力集中导致裂纹的产生,并且不利于协调变形,因此铸态合金断后伸长率较低且抗拉强度也不高。铸态合金经固溶后,粗大的第二相完全固溶到基体中,由此产生一定程度的固溶强化。值得注意的是,虽然固溶态合金中出现一些与锆有关的相组份,但是这些生成相对合金力学性能的影响至今不清楚,同时,这些相主要在晶内部分析出,占比不大,与铸态合金中的第二相比较,对晶界的阻碍无作用[15],因此对力学性能的贡献不予考虑。固溶态合金在拉伸过程中晶间变形更加容易,展示了较高的塑性。由于晶界第二相强化消失,固溶强化比第二相强化作用效果低,使得固溶合金的拉伸屈服强度低于铸态合金的。峰时效合金表现出优异的力学性能,这主要是γ″(Mg4REZn 类型)相产生的沉淀强化作用,这些细小弥散的沉淀相能够有效阻碍位错运动,从而显著改善了合金的力学性能。为了进一步理解沉淀强化效果,本文采用定量分析的方法讨论沉淀强化。峰时效态合金的屈服强度( )可用下式表示:

)可用下式表示:

(1)

(1)

式中: 为纯镁的屈服强度,其值为21 MPa[17];

为纯镁的屈服强度,其值为21 MPa[17]; 为晶界强化效果;

为晶界强化效果; 为沉淀强化效果。为了便于分析,可以认为峰时效之后,固溶强化效果可忽略不计。

为沉淀强化效果。为了便于分析,可以认为峰时效之后,固溶强化效果可忽略不计。

晶界强化根据经典的Hall-Petch关系式可表示为[17-18]

(2)

(2)

式中:k为Hall-Petch系数,其值可取为188 MPa·μm-1/2[19];d为平均晶粒尺寸。由于时效造成晶粒在一定程度上缓慢长大,其平均晶粒尺寸取值为55 μm。所以晶界强化的贡献约为25 MPa。

由于峰时效合金中的析出相主要为基面析出相。因此,当dt>>tt(dt和tt分别为沉淀相的长度和宽度),根据NIE[20]提出基面沉淀相Orowan强化效果定量分析公式,可知γ″的强化效果:

(3)

(3)

式中: 为基面沉淀相γ″对屈服强度的贡献;M为Taylor因子(M=4.5[21]);G为纯镁的剪切模量(G=16.6 GPa[19]);b为镁的柏格斯矢量的模(b=0.32 nm[17]);

为基面沉淀相γ″对屈服强度的贡献;M为Taylor因子(M=4.5[21]);G为纯镁的剪切模量(G=16.6 GPa[19]);b为镁的柏格斯矢量的模(b=0.32 nm[17]); 为镁的泊松比(

为镁的泊松比( =0.35[21]);f是沉淀相的体积分数。根据图5可知,dt和f的值分别被估算为50 nm和2.2%。基于式(3),沉淀强化对屈服强度的贡献估算值约为120 MPa。

=0.35[21]);f是沉淀相的体积分数。根据图5可知,dt和f的值分别被估算为50 nm和2.2%。基于式(3),沉淀强化对屈服强度的贡献估算值约为120 MPa。

由定量分析可知,峰时效态合金的屈服强度约为166 MPa,略微高于实验值153 MPa。这可能是因为选择相关参数的误差以及对合金中一些缺陷的忽略所致。但我们仍可以在分析结果中看到,晶界强化的贡献仅约为25 MPa,而沉淀强化的贡献约为120 MPa。因此,峰时效态合金的主要强化机制为沉淀强化。

4 结论

1) 铸态合金主要有α-Mg和Mg3Sm组成,平均晶粒尺寸为50 μm。固溶处理之后,晶界Mg3Sm相完全溶入到基体中,且晶粒并未发生明显的长大。固溶态合金在250 ℃等温时效过程中,表现出良好的时效强化效果。时效合金中析出的主要强化相为基面γ″沉淀相。

2) 铸态合金的抗拉强度、拉伸屈服强度和断后伸长率分别为152 MPa、105 MPa和3.8%。固溶处理之后,屈服强度略有下降,抗拉强度变化不大,而断后伸长率明显改善,达到了6.2%。进一步峰时效处理,合金的强度显著增加,拉伸屈服强度高达153 MPa,抗拉强度高达210 MPa,同时断后伸长率保持在4.0%。

3) 对峰时效态合金的强化机制进行了定量分析,发现主要的强化效果来自于γ″的沉淀强化,其对屈服强度的贡献为120 MPa,约占总屈服强度的80%,远高于晶界强化效果。

REFERENCES

[1] 张洪杰, 孟 健, 唐定骧. 高性能镁-稀土结构材料的研制、开发与应用[J]. 中国稀土学报, 2004, 22(1): 40-47.

ZHANG Hong-jie, MENG Jian, Tang Ding-xiang. Investigation, exploitation and application of magnesium- rare earth alloy as a structure material[J]. Journal of The Chinese Rare Earth Society, 2004, 22(1): 40-47.

[2] 王渠东, 丁文江. 镁合金研究开发现状与展望[J]. 世界有色金属, 2004(7): 8-11.

WANG Qu-dong, DING Wen-jiang. The status and outlook of magnesium alloy research and exploration[J]. World Nonferrous Metals, 2004(7): 8-11.

[3] 黄正华, 刘汪涵博, 戚文军, 徐 静. Sm对AZ91D合金显微组织与力学性能的影响[J]. 中国有色金属学报, 2015, 25(10): 2649-2655.

HUANG Zheng-hua, LIU Wang-hanbo, QI Wen-jun, XU Jing. Effects of Sm on microstructure and mechanical property of AZ91D alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2649-2655.

[4] HUANG Z H, QI W J, XU J, CAI C. Microstructures and mechanical properties of Mg-Al-Sm series heat-resistant magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 22-29.

[5] 石洪吉, 邓运来, 张 凯, 杨 柳, 陈明安. Nd含量对Mg-6Gd-2.5Y-0.5Zr合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2017, 27(9): 1785-1793.

SHI Hong-ji, DENG Yun-lai, ZHANG Kai YANG Liu, CHEN Ming-an. Effects of Nd addition on microstructure and mechanical properties of Mg-6Gd-2.5Y-0.5Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1785-1793.

[6] WU D, CHEN R S, KE W. Microstructure and mechanical properties of a sand-cast Mg-Nd-Zn alloy[J]. Materials and Design, 2014, 58: 324-331.

[7] 王狂飞, 周志杰, 王有超, 米国发. 铸造镁合金ZM6砂型铸造工艺研究[J]. 热加工工艺, 2011, 40(19): 39-40.

WANG Kuang-fei, ZHOU Zhi-jie, WANG You-chao, MI Guo-fan. Sand casting technology for ZM6 alloy[J]. Hot Working Technology, 2011, 40(19): 39-40.

[8] CHE C, CHENG L, TONG L, CAI Z, ZHANG H. The effect of Gd and Zn additions on microstructures and mechanical properties of Mg-4Sm-3Nd-Zr alloy[J]. Journal of Alloys and Compounds, 2017, 706: 526-537.

[9] 张 玉, 黄晓锋, 马振铎, 李 雅, 马 颖, 郝 远. 热处理工艺对Mg-6Zn-2Sm-0.4Zr镁合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2017, 27(10): 1961-1969.

ZHANG Yu, HUANG Xiao-feng, MA Zhen-duo, LI Ya, MA Ying, HAO Yuan. Effects of heat-treatment technology on microstructure and mechanical properties of Mg-6Zn-2Sm- 0.4Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(10): 1961-1969.

[10] NISHIJIMA M, HIRAGA K, YAMASAKI M, KAWAMURA Y. Characterization of precipitates in Mg-Sm alloy aged at 200 ℃, studied by high-resolution transmission electron microscopy and high-angle annular detector dark-field scanning transmission electron microscopy[J]. Materials Transaction, 2009 50(7): 1747-1752.

[11] NIE J F, OH-ISHI K, GAO X, HONO K. Solute segregation and precipitation in a creep-resistant Mg-Gd-Zn alloy[J]. Acta Materialia, 2008, 56(20): 6061-6076.

[12] XIA X, LUO A A, Stone D S. Precipitation sequence and kinetics in a Mg-4Sm-1Zn-0.4Zr (wt%) alloy[J]. Journal of Alloys and Compounds, 2015, 649: 649-655.

[13] 郑 江. Mg-Sm-Zn-Zr合金的微观组织、力学性能和蠕变机制研究[D]. 上海: 上海交通大学, 2010: 82-109.

ZHENG Jiang. Microstructure, mechanical properties, and creep deformation mechanisms of Mg-Sm-Zn-Zr alloys[D]. Shanghai: Shanghai Jiao Tong University, 2010: 82-109.

[14] SU X, LI D J, XIE Y C, ZENG X Q, DING W J. Effect of Sm on the microstructure and mechanical property of Mg-xSm-0.4Zn-0.3Zr alloys[C]//HAN Y. Materials Science Forum. Switzerland: Trans Tech Publications Inc, 2013: 238-244.

[15] FU P, PENG L, JIANG H, CHANG J, ZHAI C. Zr-containing precipitates in Mg-3wt%Nd-0.2wt%Zn- 0.4wt%Zr alloy during solution treatment at 540 ℃[C]// HAN Y. Materials Science Forum. Switzerland: Trans Tech Publications Inc, 2007: 97-100.

[16] GAO X, MUDDLE B C, NIE J F. Transmission electron microscopy of Zr-Zn precipitate rods in magnesium alloys containing Zr and Zn[J]. Philosophical Magazine Letters, 2009, 89(1): 33-43.

[17] ROKHLIN L L. Magnesium alloys containing rare earth metals: Structure and properties[M]. London: Taylor & Francis, 2003: 2-15.

[18] GUAN K, YANG Q, BU F, QIU X, SUN W, ZHANG D, ZHENG T, NIU X, LIU X, MENG J. Microstructures and mechanical properties of a high-strength Mg-3.5Sm-0.6Zn- 0.5Zr alloy[J]. Materials Science and Engineering A, 2017, 703(4): 97-107.

[19] ARGON A S. Strengthening mechanisms in crystal plasticity[M]. Oxford: Oxford University Press, 2007: 32-45.

[20] NIE J F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys[J]. Scripta Materialia, 2003, 48(8): 1009-1015.

[21] CACERES C H, LUKAC P. Strain hardening behaviour and the Taylor factor of pure magnesium[J]. Philosophical Magazine, 2008, 88(7): 977-989.

Effect of heat treatment on microstructure and mechanical properties of sand-cast Mg-4Sm-0.6Zn-0.4Zr alloy

LU Lian-wen1, BU Fan-qiang1, LIU Xiao-qin1, WANG Da-chen1, MENG Jian2

(1. CRRC Changchun Railway Vehicles Co., Ltd., Changchun 130062, China;

2. Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Changchun 130022, China)

Abstract: In this work, the effects of heat treatment on microstructure and mechanical properties of sand-cast Mg-4Sm-0.6Zn-0.4Zr alloy were investigated through the microstructure analysis by optical microscopy(OM), X-ray diffractometry(XRD), scanning electron microscopy(SEM) and transmission electron microscopy(TEM) and mechanical properties testing. The results indicate that the as-cast alloy is mainly comprised of α-Mg matrix and eutectic Mg3Sm phase. After solution treatment, the coarse second phases are almost dissolved into Mg matrix and the grains do not grow significantly. The dominant precipitates of the alloy peak-aged at 250 ℃ are identified as basal γ″ phase. Also, the peak-aged alloy displays the best mechanical properties with ultimate tensile strength of 210 MPa, yield strength of 153 MPa, and elongation to failure of 4.0%. In addition, the dominant strengthening effect in peak-aged alloy is considered as precipitation strengthening induced by the dispersed fine γ″ precipitate based on the quantitative analysis results of the strengthening mechanism. The contribution of precipitation strengthening to yield strength is 120 MPa, accounting for about 80% of the total yield strength.

Key words: Mg-Sm; rare-earth Mg alloy; mechanical properties; sand casting

Foundation item: Project(2016SYHZ0006) supported by the National Science and Technology Program of China

Received date: 2018-12-09; Accepted date: 2019-04-04

Corresponding author: BU Fan-qiang; Tel: +86-13600406114; E-mail: bufanqiang@cccar.com.cn

(编辑 何学锋)

基金项目:国家科技计划项目(2016SYHZ0006)

收稿日期:2018-12-09;修订日期:2019-04-04

通信作者:卜繁强,工程师,博士;电话:13604406114;E-mail:bufanqiang@cccar.com.cn