Cu/Al浇铸界面连接及拉伸性能的分子动力学模拟

来源期刊:中国有色金属学报2020年第12期

论文作者:钱相飞 郭巧能 杨仕娥 王明星 刘强 王杰芳

文章页码:2886 - 2901

关键词:分子动力学;浇铸;Cu/Al多层膜;界面扩散

Key words:molecular dynamics; casting; Cu/Al multilayer film; interface diffusion

摘 要:基于分子动力学方法研究不同浇铸温度和浇铸时间对Cu/Al多层膜连接过程界面扩散的影响,从力学性能和位错滑移方面,对比研究不同浇铸时间和浇铸温度下Cu/Al多层膜的拉伸变形,揭示微观原子结构对金属薄膜力学性能的影响。结果表明:随着浇铸温度和浇铸时间增加,界面区域的Cu、Al原子相互扩散数目增多,过渡层厚度增大,Cu/Al多层膜屈服强度和抗拉强度随浇铸时间增加先增加后降低,在浇铸温度为1013 K、浇铸时间为0.2 ns时,Cu/Al多层膜的力学性能最佳。

Abstract: The effects of different casting temperature and casting time on the interfacial diffusion of Cu/Al multilayer films were studied based on the molecular dynamics method. The tensile deformation of Cu/Al multilayer films under different casting time and casting temperature was compared from the aspects of mechanical properties and dislocation slip, and the effects of microatomic structure and the mechanical properties of metal films were revealed. The results show that the thickness of transition layer and the number of Cu and Al atoms diffusing each other near the interface both increase with the increase of casting temperature and casting time. The yield strength and tensile strength of Cu/Al multilayer films also increase at first and then decrease with the increase of casting temperature and casting time. When the casting temperature is 1013 K and the casting time is 0.2 ns, the mechanical properties of Cu/Al multilayers are the best.

DOI: 10.11817/j.ysxb.1004.0609.2020-37681

钱相飞,郭巧能,杨仕娥,王明星,刘 强,王杰芳

(郑州大学 物理学院,郑州 450001)

摘 要:基于分子动力学方法研究不同浇铸温度和浇铸时间对Cu/Al多层膜连接过程界面扩散的影响,从力学性能和位错滑移方面,对比研究不同浇铸时间和浇铸温度下Cu/Al多层膜的拉伸变形,揭示微观原子结构对金属薄膜力学性能的影响。结果表明:随着浇铸温度和浇铸时间增加,界面区域的Cu、Al原子相互扩散数目增多,过渡层厚度增大,Cu/Al多层膜屈服强度和抗拉强度随浇铸时间增加先增加后降低,在浇铸温度为1013 K、浇铸时间为0.2 ns时,Cu/Al多层膜的力学性能最佳。

关键词:分子动力学;浇铸;Cu/Al多层膜;界面扩散

文章编号:1004-0609(2020)-12-2886-15 中图分类号:TB331;TG111.6 文献标志码:A

随着科技的不断发展,传统单金属材料的性能越来越难以满足生产需要,在单层膜与复合膜的基础上发展起来的纳米多层膜兼具传统复合材料和现代纳米材料的优良性能,常用于大规模集成电路及微电子封装中应力工程的柔性互连[1]。纳米Cu/Al多层膜综合了Cu和Al各自优良的物理及化学性能,广泛用于大规模集成电路、微电机系统等方面[2-7]。微纳米器件在加工制备以及服役过程中往往会受到力、热、电、光等各种因素引起的应力作用,会使其力学性能下降,从而导致材料过早的断裂失效,因此研究不同温度和时间对Cu/Al多层膜界面扩散及其力学性能对保证微纳米器件的服役行为是至关重要的,为降低研究成本,缩短研究周期,选用大规模分子动力学数值模拟方法来研究纳米薄膜材料的微观机制和力学性能。常用的金属互连方法有很多,例如工业上常用的闪光焊和摩擦焊,但这两种方法操作不便,接头容易断裂;钎焊、爆炸焊等会在铜/铝界面形成过厚的脆性金属间化合物,使界面的结合强度降低;扩散焊连接的纳米材料界面结合良好,但耗时较长,效率较低;轧制复合法会因各组元基材的变形协调性影响到材料界面结合强度[8];浇铸法是通过金属液与预置块之间强烈的热作用,使两种金属在接触面上发生相互作用,形成良好的冶金结合,结合机理为熔化和扩散两部分,浇铸法能够解决Cu/Al表面氧化和杂质等问题,通过控制浇铸温度和浇铸时间从而减少金属间化合物的生成,增强Cu/Al结合强度。

Cu/Al多层膜材料作为功能材料广泛用于电子封装和集成电路中,研究Cu/Al材料的力学性能和变形机理对于Cu/Al材料互连的理论和实验研究具有重要意义[9-25]。在实验方面,谢军等[2-3]采用真空扩散连接技术实现Cu/Al薄膜连接,通过对温度、时间和压强等参数的控制,有效控制了界面扩散,防止了孔洞产生。李亚江等[9]采用真空扩散焊接技术研究了Cu/Al焊接工艺和界面扩散,结果表明,通过控制温度、时间和压强等参数,可以防止过渡区中Al含量超过10%,否则会产生脆性金属间化合物,影响材料结合性能。孟胶东等[10]研究了Cu/Al双金属复合结构的固相扩散连接工艺,发现连接工艺参数、Cu/Al材料组合形式以及母材的状态不同等都会影响Cu/Al连接性能。王征等[13]采用浇铸法制备Cu/Al复合材料,复合材料结合良好,浇铸温度与结合强度的关系呈现抛物线规律,当浇铸温度为720 ℃时,复合材料连接最佳。宋克兴等[14]研究了固-液复合法制备铜铝复合材料也得出了相同的结论。而蒋宇梅等[15]得出铝液的浇铸温度为700 ℃。张红安等[16]得出铝液的浇铸温度为680 ℃,且铝液温度不宜超过700 ℃。GAO等[17]在Cu/Al纳米线冷焊连接研究中发现连接接头具有超塑性,其接头甚至具有超过100%的总伸长率。

分子动力学模拟方面,刘浩等[18]模拟了Cu和Al的扩散焊接过程,结果发现界面处主要是Cu原子向Al侧扩散,Cu/Al试件结合强度比单晶Al和Cu的要小。CHEN等[20]对Cu/Al界面扩散连接进行了分子动力学模拟,结果表明界面区过渡层厚度随温度升高而增厚,扩散后界面结合良好,抗拉强度约为理想接触强度的88%。LI等[21]模拟了不同温度和时间下的Cu/Al界面原子扩散,随着时间增加和温度升高,原子数目增多,界面区域增厚,扩散最佳温度为750~800 K。罗龙等[22]模拟了Cu/Al热扎扩散过程中的界面原子扩散,低温时原子扩散不明显,800 K后原子发生明显的扩散,且扩散时主要是Cu原子向Al侧扩散。韩雪杰等[25]在温度和保温时间对铜/铝薄膜的界面扩散性能及力学性能影响的分子动力学模拟中也得出了相同的结论。

以上从实验和理论两方面对Cu/Al复合材料的互连进行了研究,实验从固-固、固-液、液-液方面研究了温度参数对材料力学性能的影响,对时间参数的研究较少,分子动力学模拟主要从固-固方面研究了扩散焊接温度和时间对Cu/Al复合材料力学性能的影响,固液方面的研究较少,因此,本文采用分子动力学方法研究浇铸温度和浇铸时间对Cu/Al多层膜界面扩散及力学性能的影响,能够有效的把试验温度与分子动力学模拟结合起来,且定性和定量分析浇铸时间对Cu/Al多层膜结合性能的影响,为材料的系统设计与优化提供理论依据。

1 实验

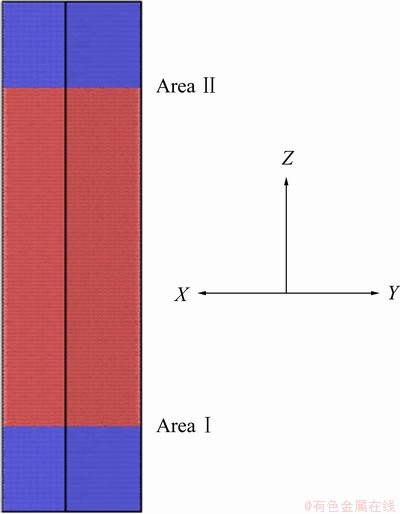

运用MS建模软件构建初始原子结构模型,模型是上、下层为Cu原子,而中间层为Al原子的单晶结构。模型Cu、Al原子之间存在两个界面区,如图1所示,将模型的下界面区定义为区域Ⅰ,上界面区定义为区域Ⅱ,X方向为[100]晶向,Y方向为[010]晶向,Z方向为[001]晶向,模型由28a1×28a1×28a1、25a2×25a2×99a2及28a1×28a1×28a1组成,其中a1(a1=0.3615 nm)是Cu的晶格常数,a2(a2=0.4050 nm)是Al的晶格常数,本文将临界特征方法[11,24]用到铜/铝薄膜上,再考虑到温度、时间等因素,故取铜铝薄膜厚度为60 nm,考虑到满足周期性条件的方向上不同尺度的原胞容易导致模拟误差,参照文献[19, 21, 25],模型长度和宽度均取为10 nm。模型有423116个原子,原子的运动轨迹遵从牛顿运动定理,运动方程的数值求解采用verlet算法,时间步长设为2 fs。模型在X,Y方向采用周期性边界条件,Z轴采用自由边界条件,设Z轴为单轴拉伸方向,上层Cu薄膜的上表面和下层Cu薄膜的下表面分别固定3层原子,以组成一个界面偶。模型的原子初速度由麦克斯韦速率分布给出,本文所使用的势函数为CAI等[26]提出的EAM势。该模型势函数已用于(铝、银、铜、镍、铅、金、铀)等面心立方(FCC)金属及其合金中,且计算了以七种金属系的A3B、AB、AB3、AB2型金属间化合物的形成热,计算结果符合第一性原理和Miedema合金理论[25-26],目前该势函数已广泛用于计算铜铝材料热力学性质[4, 19, 21, 25-26],七系金属溶液的溶解热也能很好用该EAM势来表示[26],并且文献[19, 21, 25]分别用该势函数从单轴拉伸及循环加载方面计算模拟了铜/铝薄膜的力学性能。因此,本文选用该势函数来模拟研究铜/铝浇铸界面连接的力学性能。

图1 模型的初始原子结构(上下层蓝色是Cu原子,中间层红色是Al原子)

Fig. 1 Initial atomic structure of model (upper and lower blue area for Cu atoms, middle red area for Al atoms)

本文采用大规模并行计算软件LAMMPS[27]进行计算模拟,模拟系综采用NPT系综,模拟压强为1个大气压。模型原子排列遵循FCC晶格结构,实际模拟中模型结构并不稳定,存在较大的预应力,需要对模型进行驰豫,降低原子势能。首先,将模型置于1 K温度下,运行40 ps,使系统充分驰豫,原子处于平衡状态,其次,让系统中Cu基体升温至673 K并保温一段时间使Cu达到预热目的,之后,让系统中Al基体升温至浇铸温度(953、973、993、1013和1033 K) 并保温一段时间使之成为Al液,然后让Al液和固态Cu接触达到浇铸目的,在浇铸条件下,研究浇铸温度对界面扩散的影响。然后使Cu/Al模型降温至300 K,并运用Nose/Hoover热浴法[28]在300 K下对模型进行保温,最后对不同浇铸温度所形成的Cu/Al多层膜在300 K下沿Z轴拉伸,研究浇铸温度对Cu/Al薄膜力学性能的影响,以及在恒定温度下,对浇铸时间为(0.1、0.2、0.4、0.5、0.6和0.8 ns)的模型进行单抽拉伸,用以研究不同浇铸时间对铜铝多层膜强度的影响,最后采用可视化软件The Open Visualization Tool (OVITO)[29]分析其塑性变形机理。

2 结果与分析

2.1 浇铸温度对Cu/Al多层膜扩散的影响

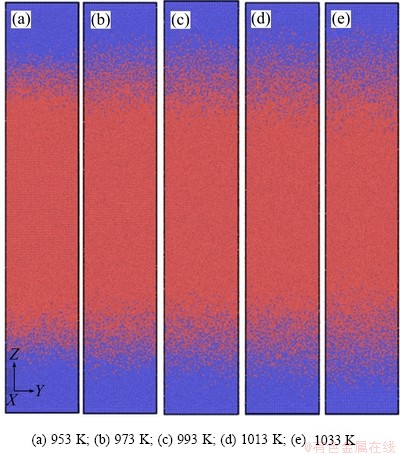

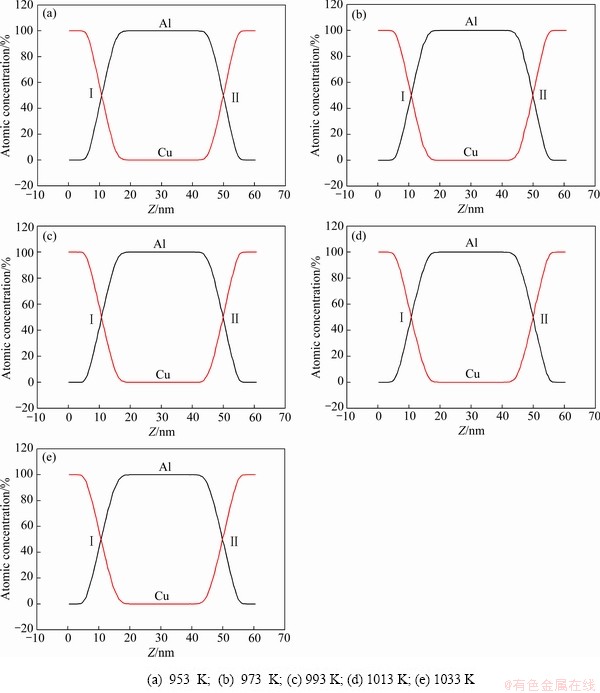

采用Cu/Al/Cu三层膜的原子模型,如图1所示,其中蓝色代表Cu原子,红色代表Al原子。图2所示为浇铸时间为0.2 ns时Cu/Al多层膜在(953、973、993、1013、1033 K)浇铸温度下的原子扩散图。结果表明,在浇铸状态下,Cu原子能够扩散到Al原子层内部,同时Al原子也能扩散到Cu原子层内部,且随着浇铸温度升高,Cu、Al原子互扩散数量增多。

原子的扩散遵循爱因斯坦扩散定律,可用均方位移(Mean square displacement, MSD)随时间的变化曲线来表征:

(1)

(1)

式中:DMS为MSD值; 是i原子t时刻的位移矢量;

是i原子t时刻的位移矢量; 是i原子0时刻的位移矢量;N为模型总原子数;〈〉为时间相关性算符。

是i原子0时刻的位移矢量;N为模型总原子数;〈〉为时间相关性算符。

图2 953~1033 K的浇铸温度下Cu、Al原子的扩散

Fig. 2 Diffusion of Cu and Al atoms at casting temperature of 953-1033 K

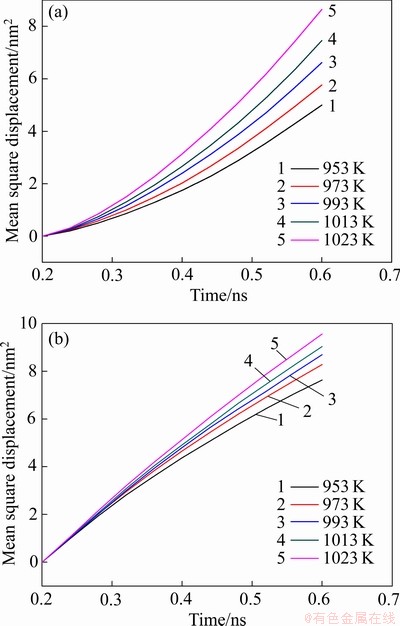

图3 铝原子和铜原子的均方位移随时间变化曲线

Fig. 3 Variation curve of mean square displacement of Al(a) and Cu(b) atoms with time

图3所示为0.2 ns时不同浇铸温度(953、973、993、1033 K)下Cu、Al原子均方位移随时间的变化曲线。从图3中可以看出,Al原子的MSD值随着浇铸温度升高呈先缓后快趋势增加,铜原子的MSD值随浇铸温度升高不断增大。随浇铸温度升高,界面附近固态Cu原子大量脱落,与熔融态的Al液融合,原子MSD值增大。分析Cu、Al原子在各个浇铸温度下的均方位移曲线,得出浇铸阶段的Cu原子MSD值总是大于Al原子,分析原因得出:一方面,Al的原子半径为2.886  ,大于Cu的原子半径2.556

,大于Cu的原子半径2.556  ,半径越大原子间隙越大,半径较小的Cu原子更容易进入半径较大的Al原子层中;另一方面,Cu为固态,Al为液态,界面附近大量Cu原子脱落,进入Al层深处与Al原子融合,部分Al原子在Cu层深处融合,所以界面处Cu原子MSD值大于Al原子。并且Cu、Al原子MSD值随时间的增加而增大,随着浇铸时间增加,界面处Cu的温度越来越高,脱落的Cu原子增多,Cu、Al融合更充分,Cu、Al原子MSD值会越来越接近。

,半径越大原子间隙越大,半径较小的Cu原子更容易进入半径较大的Al原子层中;另一方面,Cu为固态,Al为液态,界面附近大量Cu原子脱落,进入Al层深处与Al原子融合,部分Al原子在Cu层深处融合,所以界面处Cu原子MSD值大于Al原子。并且Cu、Al原子MSD值随时间的增加而增大,随着浇铸时间增加,界面处Cu的温度越来越高,脱落的Cu原子增多,Cu、Al融合更充分,Cu、Al原子MSD值会越来越接近。

扩散系数D与温度T呈指数关系[23]:

(2)

(2)

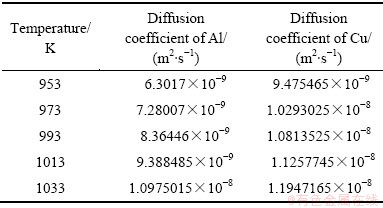

式中:D是扩散系数(nm2/ns);D0是扩散常数;Q是激活能(eV);K是玻尔兹曼常数(J/K);T是温度(K)。不同浇铸温度下Cu、Al原子在界面处的扩散系数值如表1所列,分析表1中的数据得出Al的扩散系数小于Cu的,Cu原子的扩散速度大于Al原子的,浇铸条件下,固态Cu原子与液态Al原子的扩散机制导致 Cu原子扩散速度大于Al原子的。

分子动力学模拟中将原子扩散浓度大于5%的区域定义为过渡区[18-21],浓度均大于5%的原子在Z轴

表1 不同温度下铝和铜的扩散系数

Table 1 Diffusion coefficient of Al and Cu under different temperatures

坐标的差值即为原子界面扩散过渡层厚度。本文的Cu/Al/Cu模型存在两个界面区,图4(a)~(e) 5个图给出了Cu/Al多层膜在不同温度(953、973、993、1013、1033 K)下沿Z轴的原子浓度图。分析图5可以得出在过渡区内,Cu原子扩散到Al层内部,Al原子同样能扩散到Cu层内部,界面在过渡区中间,向Cu、Al侧移动现象不明显,并且随着温度升高,Cu、Al原子相互扩散原子数目增多,过渡层厚度增大[2, 18, 21-23, 32]。

图4 不同浇铸温度下Cu/Al多层膜原子沿Z方向的原子浓度图

Fig. 4 Concentration image of Cu/Al multilayer film atoms along Z direction at casting temperatures

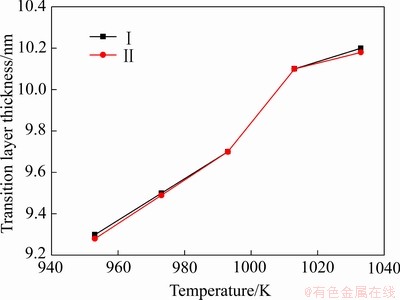

图5所示为Cu/Al多层膜过渡层厚度随浇铸温度的变化曲线,从图5中可以看出,随着浇铸温度的升高,过渡层厚度增大。两个过渡区的过渡层厚度都在9 nm以上,当温度在1013 K以下时,过渡层厚度呈快速增大状态,而在1013 K后,过渡层厚度增大变缓。

图5 过渡层厚度随浇铸温度的变化曲线

Fig. 5 Variation curve of thickness of transition layer with casting temperature

2.2 浇铸温度对Cu/Al多层膜拉伸力学性能的影响

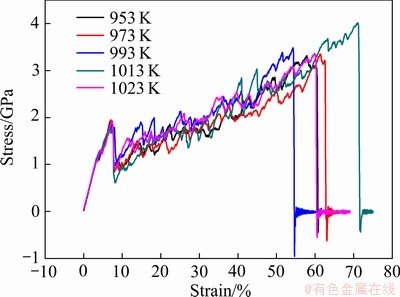

不同浇铸温度(953、973、993、1013和1033 K)下的应力-应变曲线如图6所示,应力应变曲线分为三个阶段:弹性阶段,应力随应变增加呈线性增加,达到屈服点后,塑性变形开始,应力先下降,后呈锯齿波状增加,达到抗拉强度后,应力快速下降,材料断裂。

图6 不同浇铸温度下Cu/Al多层膜单轴拉伸的应力-应变曲线

Fig. 6 Tensile stress-strain curves of Cu/Al multilayer film at different casting temperatures

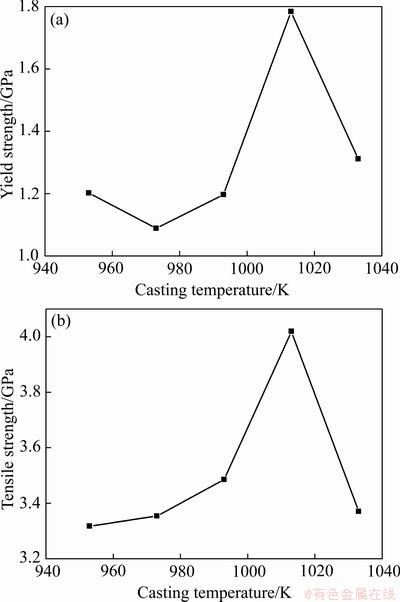

Cu/Al多层膜材料的浇铸温度(953、973、993、1013和1033 K)与屈服强度和抗拉强度的关系曲线如图7所示。当浇铸温度从953 K升高到1013 K时,多层膜的屈服强度在973 K时略有减小,之后随温度升高而增大,抗拉强度则随浇铸温度的升高而增大,1013 K后随着温度升高,屈服强度和抗拉强度均降低,在1013 K时屈服强度和抗拉强度均达到最大值,屈服强度为1.78 GPa,抗拉强度为4.02 GPa,与实验结果得出的固-液最佳复合温度993 K接近[13-14, 30]。

图7 Cu/Al多层膜的屈服强度、抗拉强度随浇铸温度的变化曲线

Fig. 7 Change curves of yield strength(a) and tensile strength(b) of Cu/Al multilayer film with casting temperature

Cu/Al多层膜的屈服应变和抗拉应变随浇铸温度(953、973、993、1013和1033 K)的变化如图8所示,温度从973 K升高到1013 K时屈服应变随温度升高先减小后增加,1013 K时达到最大值6.75%,之后随温度升高屈服应变减小,而抗拉应变则呈折线型变化,在993 K前随浇铸温度的升高先增大后减小,993 K后变化趋势仍是呈先增大后减小趋势,1013 K时的抗拉应变值最大,为71.01%。研究结果表明浇铸温度不应过高或者过低,浇铸温度过低,Cu/Al原子互扩散不充分,无法形成良好的界面冶金结合,过高则会形成脆性金属间化合物,同样对材料的结合不利,浇铸温度为1013 K时最佳。浇铸条件下Cu、Al线膨胀系数差异大[13],冷却过程中界面会产生很大的应力,容易产生裂纹和孔洞等缺陷,也会降低界面结合性能。

图8 Cu/Al多层膜的屈服应变、抗拉应变随浇铸温度的变化曲线

Fig. 8 Change curves of yield strain(a) and tensile strain(b) of Cu/Al multilayer film with casting temperature

2.3 浇铸时间对Cu/Al多层膜界面扩散的影响

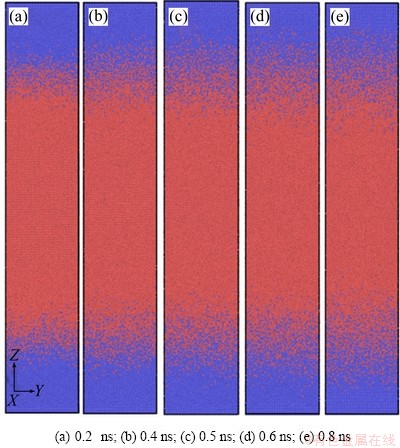

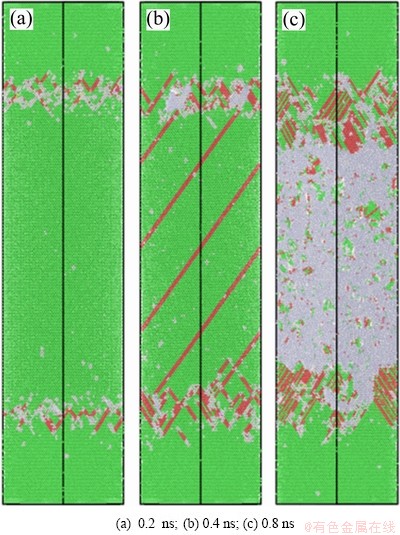

有色金属研究中浇铸温度对于铸件性能好坏的实验研究很多,对浇铸时间的研究较少,实际上浇铸时间对材料的性能影响是很显著的,浇铸温度为1013 K时,Cu/Al多层膜单轴拉伸力学性能达到最佳,可选用1013 K作为浇铸温度来讨论不同浇铸时间对Cu/Al多层膜材料力学性能的影响,图9所示为Cu/Al多层膜在1013 K下不同浇铸时间(0.2、0.4、0.5、0.6和0.8 ns)的原子扩散,从图9中可看出,随着浇铸时间增加,固态 Cu原子和液态Al原子越过界面,彼此相互扩散融合,导致界面消失,过渡层厚度增大。

图9 不同浇铸时间下的Cu、Al原子相互扩散图

Fig. 9 Diffusion of Cu and Al atoms at casting time

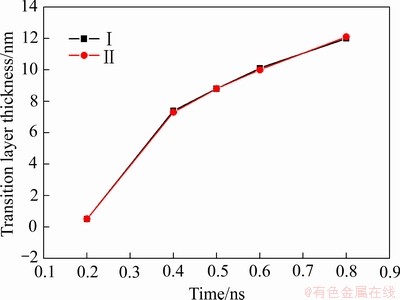

Cu/Al多层膜在1013 K浇铸温度下过渡层厚度随浇铸时间的变化如图10所示,过渡层厚度随着浇铸时间增加呈先快后缓的增大趋势,0.4 ns前,过渡层厚度随时间呈快速线性增加;0.4 ns后,过渡层厚度的增大缓慢减小。

图10 过镀层厚度随浇铸时间的变化曲线

Fig. 10 Variation curve of thickness of transition layer with casting time

2.4 浇铸时间对Cu/Al多层膜拉伸力学性能的影响

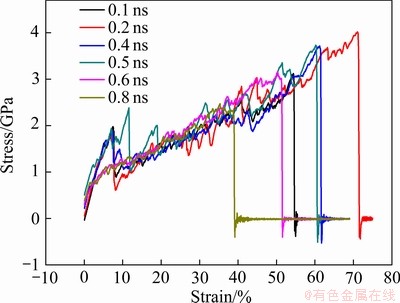

浇铸温度为1013 K,浇铸时间为0.1、0.2、0.4、0.5、0.6和0.8 ns时,应变率为0.9375 /Ps下Cu/Al多层膜单轴拉伸的应力-应变曲线如图11所示,Cu/Al多层膜的拉伸变形可分为三个阶段:第一阶段即弹性阶段,应力随应变增加呈线性增加;第二阶段是塑性

强化阶段,Cu/Al多层膜发生屈服后,应力-应变曲线继续呈锯齿波形状继续增加,直至达到最大应力值即抗拉强度;第三阶段是断裂失效阶段,材料出现裂纹,裂纹扩展直至材料断裂失效,应力急剧下降。

图11 不同浇铸时间下Cu/Al多层膜单轴拉伸的应力-应变曲线

Fig. 11 Tensile stress-strain curves of Cu/Al multilayer film at different casting time

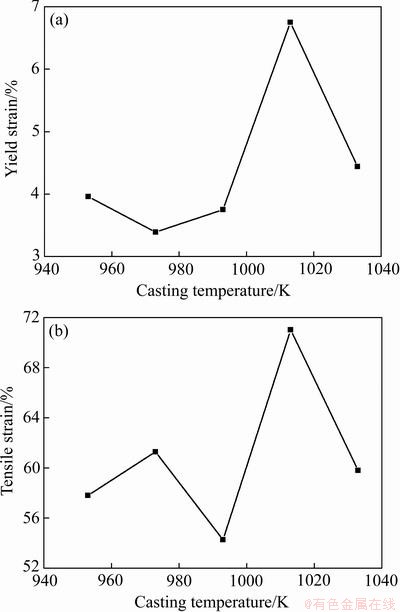

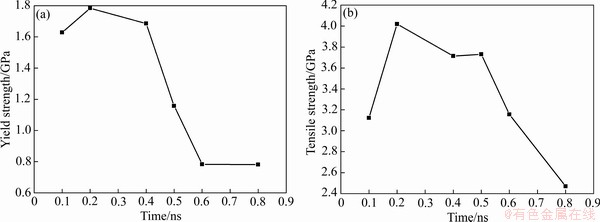

浇铸时间为0.1、0.2、0.4、0.5、0.6和0.8 ns时Cu/Al多层膜的屈服强度、抗拉强度与浇铸时间的关系如图12所示。由图12可看出,屈服强度随浇铸时间的增加呈先增加后减小趋势,0.6 ns后基本保持不变,0.2 ns时屈服强度值最大为1.78 GPa;抗拉强度亦随浇铸时间的增加先增加后逐渐减小,0.2 ns时达到最大值4.02 GPa。CHEN等[20]采用分子动力学方法模拟出理想接触Cu-Al连接强度是3.6 GPa,只考虑温度时,扩散焊接的Cu/Al薄膜抗拉强度可达理想接触Cu/Al的88%,韩雪杰等[25]结合保温温度和保温时间所构建出的Cu/Al薄膜抗拉强度达到了理想接触Cu/Al的96%,本文采用不同浇铸时间和浇铸温度构建出的Cu/Al薄膜的抗拉强度是理想接触Cu/Al的111.67%。

图12 Cu/Al多层膜的屈服强度、抗拉强度随浇铸时间的变化曲线

Fig. 12 Change curves of yield strength(a) and tensile strength(b) of Cu/Al multilayer film with casting time

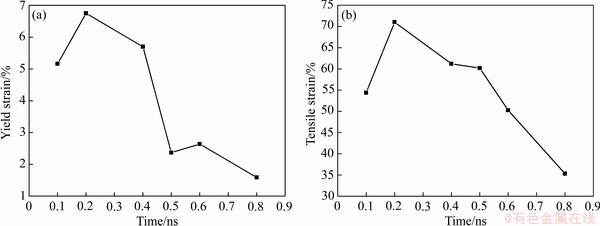

图13 Cu/Al多层膜的屈服应变、抗拉应变随浇铸时间的变化曲线

Fig. 13 Change curves of yield strain(a) and tensile strain(b) of Cu/Al multilayer film with casting time

图13所示为Cu/Al多层膜的屈服应变、抗拉应变随浇铸时间的变化曲线。由图13可看出,屈服应变随浇铸时间的增加先增加后呈折线形减小,0.2 ns时屈服应变值最大ε=6.75%;抗拉应变亦随着浇铸时间的增加先增加后减小,0.2 ns时抗拉应变值最大,为71.01%。分析图11、12和13得出,Cu/Al多层膜的结合强度随浇铸时间增加变化显著,0.5 ns前,随着浇铸时间增加,抗拉强度和抗拉应变减小较缓;0.5 ns后,Cu/Al多层膜抗拉强度和抗拉应变随时间增加快速减小,屈服强度与屈服应变则随时间增加呈折线形减小,0.2 ns时屈服强度、屈服应变和抗拉强度、抗拉应变均达到最大值。浇铸时间不能过长也不能过短,浇铸时间过短,Cu、Al原子扩散数目少,Cu/Al多层膜连接不够充分,过长则会产生过厚的金属间化合物[31-35],从而导致Cu/Al多层膜结合强度降低。0.2 ns时浇铸时间最佳。

为了与实验作对比,将本文的模型带入式(3),式(3)是刘文川等[36]在常用的金属铸造生产经验公式的基础上,导入壁厚等参数后推导出的平板型铝合金通用浇铸时间公式:

(3)

(3)

式中:tA为铸件有效浇铸时间,s;m为铸件质量kg;δ为铸件壁厚,mm;n为平板件数。

m为Cu层和Al层薄膜的质量和为1.9738×10-20 kg,壁厚δ是Cu层薄膜的厚度为1×10-8 m,n为3,带入(3)式计算得tA为5×10-10 s,即0.5 ns,分子动力学模拟得出的结果与实验公式计算出的结果接近。

为了深入研究浇铸时间对Cu/Al多层膜强度的影响,本文在1013 K浇铸温度下的5个浇铸时间中选取0.2 ns、0.5 ns和0.8 ns三个浇铸时间进行讨论,采用OVITO可视化软件来识别模型的原子结构类型,如图15所示,为了对比3个时间下模型的力学性能和讨论拉伸过程中的原子结构演化,以及分析造成力学性能差异的原因,采用位错分析(Dislocation analysis, DXA)对塑性变形阶段的位错原子进行提取分析。如图14(a)所示,当浇铸时间为0.2 ns时,Cu/Al多层膜界面附近出现了少量OTHER原子和HCP原子,如图14(b)所示,当浇铸时间为0.5 ns时,Cu/Al多层膜界面附近的OTHER原子和HCP原子数目略有增多,并且在Al薄膜内形成内禀层错,薄膜内部应力得到释放,如图14(c)所示,当浇铸时间为0.8 ns时,Cu/Al多层膜界面附近OTHER原子和HCP原子数目增多,并且Al薄膜内出现大量的OTHER原子和HCP原子,这是由于Cu、Al原子互扩散过程中产生了柯肯达尔效应,使得Cu/Al多层膜界面空隙缺陷增多[19],其次Cu、Al热膨胀差异系数过大,Cu的小于Al的,冷却过程中由于Cu、Al的冷却量不同,会使界面产生很大的应力[13],亦使得界面附近产生大量缺陷,导致FCC结构向HCP结构和OTHER结构转变,材料结构改变。

图14 不同浇铸时间下未加载时的Cu、Al原子结构分析(红色代表HCP结构,绿色代表FCC结构,白色代表OTHER结构)

Fig. 14 Analysis of Cu and Al atomic structures without loading at different casting time (red for HCP structure, green for FCC structure, white for OTHER structure)

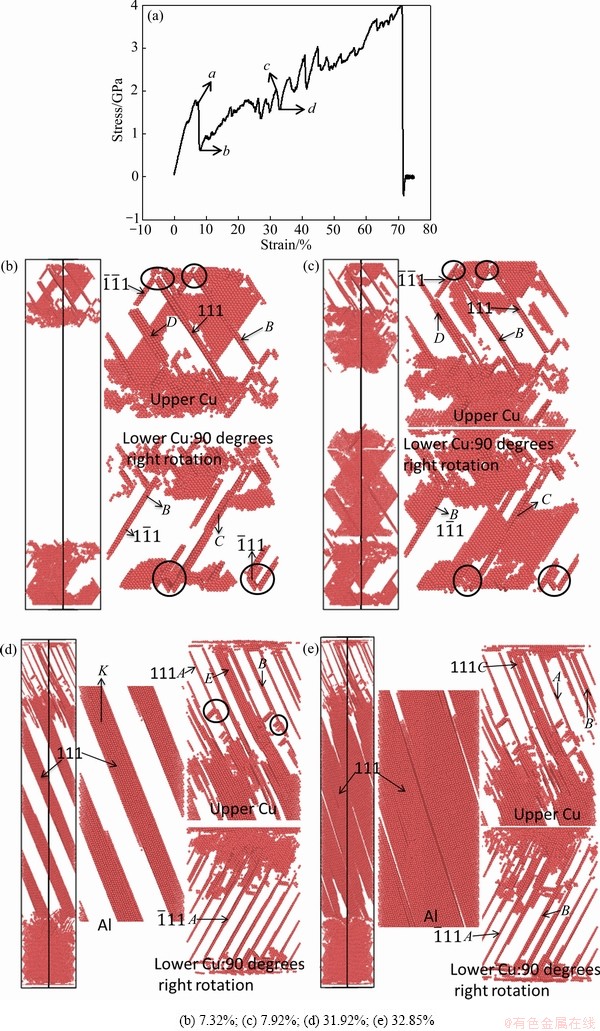

FCC结构晶体中的HCP原子可表示为不同的平面缺陷:单层HCP原子为孪晶结构,相邻两层的HCP是内禀层错[37-38]。图中的A、B、C、D、E、F等箭头指向部分分别为孪晶、内禀层错、3层、4层、5层以及6层的HCP结构,K表示12层HCP结构,圆圈表示压杆位错。图15所示为0.2 ns浇铸时间时不同应变的Cu/Al多层膜去除FCC原子和OTHER原子后的HCP层错原子结构图和局部放大图。当应变为7.5%时,如图15(b)所示,Cu层{111}面形成了内禀层错和3层、4层的HCP结构,不同{111}面上的部分层错发生交截形成压杆位错,当应变达到8.1%时,如图15(c)所示,Cu层薄膜内层错滑移增多,同时Al层薄膜内多个滑移系统连续启动,导致应力降至b点[39],应变增加到31.92%时,如图15(d)所示,Cu层薄膜的(111)面内形成孪晶和5层HCP结构,在 面形成大量的孪晶,并且Cu层薄膜有层错交截形成压杆位错,Al薄膜层其它面的层错消失,而在(111)面形成4个12层的HCP结构,使得应力增大,而当应变达到32.85%时,如图15(e)所示,薄膜层

面形成大量的孪晶,并且Cu层薄膜有层错交截形成压杆位错,Al薄膜层其它面的层错消失,而在(111)面形成4个12层的HCP结构,使得应力增大,而当应变达到32.85%时,如图15(e)所示,薄膜层 面层错滑移启动,大量孪晶消失逐渐转化为内禀层错,Al层薄膜(111)面的HCP原子层不断滑移增多,应力降低。

面层错滑移启动,大量孪晶消失逐渐转化为内禀层错,Al层薄膜(111)面的HCP原子层不断滑移增多,应力降低。

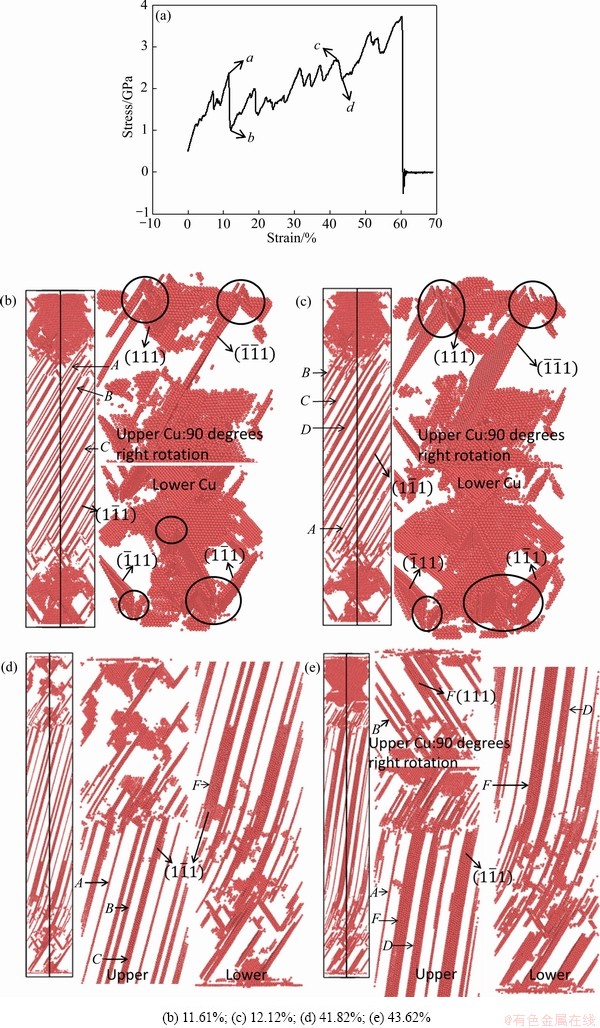

图16所示为0.5 ns浇铸时间时不同应变下的Cu/Al多层膜的位错结构。如图14(b)所示,拉伸之前,0.5 ns浇铸时间的模型界面附近和Al薄膜内已经有层错形成,当应变为11.61%时,如图16(b)所示,Al薄膜内 面大量的内禀层错、孪晶和3层HCP结构滑移启动,同时上下层Cu薄膜层的不同{111}面内大量层错交截形成压杆位错,此时应力处在一个峰值点;当应变为12.12%时,如图16(c)所示,Al薄膜层

面大量的内禀层错、孪晶和3层HCP结构滑移启动,同时上下层Cu薄膜层的不同{111}面内大量层错交截形成压杆位错,此时应力处在一个峰值点;当应变为12.12%时,如图16(c)所示,Al薄膜层 面的滑移系启动,孪晶部分消失,逐渐转化为内禀层错和4层的HCP结构,应力下降;随着应变增加,应力呈锯齿波形增加,孪晶、层错不断形核、滑移、湮没,直至材料断裂。当应变为41.82%时,如图16(d)所示,Cu/Al薄膜内的大面积层错逐渐消失,Al薄膜层

面的滑移系启动,孪晶部分消失,逐渐转化为内禀层错和4层的HCP结构,应力下降;随着应变增加,应力呈锯齿波形增加,孪晶、层错不断形核、滑移、湮没,直至材料断裂。当应变为41.82%时,如图16(d)所示,Cu/Al薄膜内的大面积层错逐渐消失,Al薄膜层 面层错部分转化成孪晶,部分转化成6层HCP结构,Cu层薄膜不同{111}面上的层错交截形成压杆位错,对应的应力增大;应变进一步增大到43.62%时,如图16(e)所示,Cu、Al薄膜层层错再次滑移启动,Al层薄膜和下层Cu薄膜的

面层错部分转化成孪晶,部分转化成6层HCP结构,Cu层薄膜不同{111}面上的层错交截形成压杆位错,对应的应力增大;应变进一步增大到43.62%时,如图16(e)所示,Cu、Al薄膜层层错再次滑移启动,Al层薄膜和下层Cu薄膜的 面的6层和4层HCP结构滑移长大,上层Cu薄膜(111)面的滑移系再次启动,形成内禀层错和4层HCP结构,此时应力下降。

面的6层和4层HCP结构滑移长大,上层Cu薄膜(111)面的滑移系再次启动,形成内禀层错和4层HCP结构,此时应力下降。

图15 浇铸时间为0.2 ns的Cu/Al多层膜在单轴拉伸加载下塑性变形阶段不同应变的位错结构图

Fig. 15 Curve graph(a) and dislocation structures((b)-(e)) of Cu/Al multilayers with casting time of 0.2 ns under uniaxial tensile loading at different strain stages

图16 浇铸时间为0.5 ns的Cu/Al多层膜在单轴拉伸加载下塑性变形阶段不同应变的位错结构图

Fig. 16 Curve graph(a) and dislocation structures((b)-(e)) of Cu/Al multilayers with casting time of 0.5 ns under uniaxial tensile loading at different strain stages

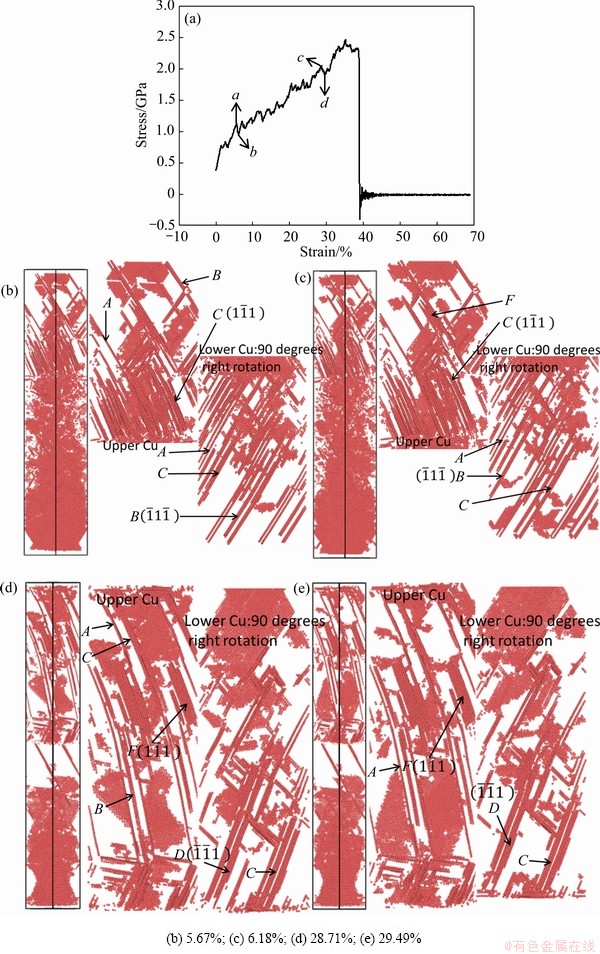

图17所示为0.8 ns浇铸时间时不同应变下的Cu/Al多层膜的位错结构。当应变为5.67%和6.18%时Al薄膜内存在大量的HCP缺陷原子和原子团,使得层错只能在界面附近和Cu薄膜中滑移,如图17(b)和(c)所示,在界面附近和Cu薄膜的{111}滑移面形成大量的内禀层错、孪晶和3层HCP结构;当应变达到28.71%时,如图17(d)所示,层错穿过Al薄膜内HCP原子和原子团,Al内HCP原子和原子团消失,在上层Cu薄膜和Al薄膜的 面形成内禀层错、部分3层和6层HCP结构,下层Cu薄膜和Al薄膜的

面形成内禀层错、部分3层和6层HCP结构,下层Cu薄膜和Al薄膜的 面形成3层和4层的HCP结构且在{111}内有层错交截形成压杆位错,此时应力增大;随着应变增加到29.49%时,如图17(e)所示,Cu薄膜内

面形成3层和4层的HCP结构且在{111}内有层错交截形成压杆位错,此时应力增大;随着应变增加到29.49%时,如图17(e)所示,Cu薄膜内 面的 5层和4层HCP结构转变为3层,应力略有降低。

面的 5层和4层HCP结构转变为3层,应力略有降低。

结合图11~17,对比浇铸时间为0.2 ns和0.5 ns时的单轴拉伸的应力-应变曲线和微观原子结构可知,塑性变形过程中,Cu/Al多层膜的变形机理主要是层错的形核和运动。压杆位错、孪晶和多层HCP结构对位错的阻碍作用极易引起塑性阶段应力随应变呈锯齿波状增加[39]。位错滑移需要克服孪晶、压杆位错和多层HCP结构的阻碍作用,随着HCP层错厚度增加和数目的增多,克服层错所需应力也会增大。0.2 ns时,有孪晶、3层、4层和5层HCP结构形成,且在Al薄膜内形成4个12层HCP结构贯穿Al薄膜。0.5 ns时,有孪晶、3层、4层、5层以及6层HCP结构在Cu、Al薄膜内生成,并且0.2 ns时的多层HCP结构大于0.5 ns时的,因此,0.2 ns的薄膜结合强度高于0.5 ns的。而浇铸时间为0.8 ns时,由于浇铸时间过长,Cu、Al原子扩散数目过多使得Cu/Al多层膜产生晶格畸变,薄膜原子结构改变,导致材料结合强度降低。

图17 浇铸时间为0.8 ns的Cu/Al多层膜在单轴拉伸加载下塑性变形阶段不同应变的位错结构图

Fig. 17 Curve graph(a) and dislocation structures((b)-(e)) of Cu/Al multilayers with casting time of 0.8 ns under uniaxial tensile loading at different strain stages

3 结论

1) 随着浇铸时间和浇铸温度的增加,Cu原子扩散到Al侧的数目比Al原子扩散到Cu侧的多,Cu、Al原子互扩散至对方深处,Cu/Al多层膜界面逐渐消失。

2) 随着浇铸温度的升高,Cu和Al原子的扩散系数均增大,界面区过渡层厚度也在不断增大,铜的扩散系数大于铝的扩散系数,导致Cu/Al多层膜力学性能发生变化,抗拉强度随浇铸温度的升高先增加后减小,在浇铸温度1013 K下,其抗拉强度达到最大值4.02 GPa。

3) 浇铸温度为1013 K时,随着浇铸时间的增加,过渡层厚度增大,抗拉强度和抗拉应变随着浇铸时间增加逐渐减小,0.2 ns时,抗拉强度达到最大值4.02 GPa,在1013 K下保温0.2 ns时Cu/Al多层膜力学性能最佳。

4) 对比不同浇铸时间下的Cu/Al多层膜塑性变形阶段的位错结构得出,当浇铸时间等于0.2 ns时,薄膜内层错、孪晶、多层HCP结构的形成和它们的数量增加使得薄膜强度最大,当浇铸时间大于0.5 ns后,由于浇铸时间过长,Cu、Al原子扩散数目过多,材料结构发生改变,使得Cu/Al多层膜结合强度快速降低。

REFERENCES

[1] 莫里斯. 纳米封装: 纳米技术与电子封装[M]. 罗小兵, 陈明祥, 译. 北京: 机械工业出版社, 2013: 394-419.

MORRIS J E. Nanopackaging nanotechnologies and electronics packaging[M]. LUO Xiao-bing, CHEN Ming-xiang, transl. Beijing: Machinery Industry Press, 2013: 394-419.

[2] 谢 军, 吴卫东, 叶成钢, 黄丽珍, 袁光辉. Al/Cu 薄膜真空扩散连接技术[J]. 强激光与粒子束, 2004, 16(5): 607.

XIE Jun, WU Wei-dong, YE Cheng-gang, HUANG Li-zheng, YUAN Guang-hui. Vacuum diffusion bonding technology of aluminum/copper films[J]. High Power Laser and Particle Beams, 2004, 16(5): 607.

[3] 谢 军, 吴卫东, 杜 凯, 郑凤成, 叶成钢, 黄丽珍, 袁光辉. Al/Cu 微米级厚度薄膜扩散连接工艺及显微组织分析[J]. 原子能科学技术, 2004, 38(7): 120-124.

XIE Jun, WU Wei-dong, DU Kai, ZHENG Feng-cheng, YE Cheng-gang, HUANG Li-zheng, YUAN Guang-hui. Process and microstructure analysis in vacuum diffusion bonding of aluminum and copper films[J]. Atomic Energy Science and Technology, 2004, 38(7): 120-124.

[4] NI Z L, YE F X. Effect of lap configuration on the microstructure and mechanical properties of dissimilar ultrasonic metal welded copper-aluminum joints[J]. Journal of Materials Processing Technology, 2017, 245: 180-192.

[5] CHEN S Y, WU Z W, LIU K X, LI X J, LUO N, LU G X. Atomic diffusion behavior in Cu-Al explosive welding process[J]. Journal of Applied physics, 2013, 113(4): 044901.

[6] ZHOU Q, LI S, HUANG P, XU K W, WANG F, LU T J. Strengthening mechanism of super-hard nanoscale Cu/Al multilayers with negative enthalpy of mixing[J]. APL Materials, 2016, 4(9): 096102.

[7] JIANG H G, DAI J Y, TONG H Y, DING B Z, SONG Q H, HU Z Q. Interfacial reactions on annealing Cu/Al multilayer thin films[J]. Journal of Applied Physics, 1993, 74(10): 6165-6169.

[8] 张清东, 李 硕, 张勃洋, 谢 璐, 李 瑞. 金属轧制复合过程微观变形行为的分子动力学建模及研究[J]. 金属学报, 2019, 55(7): 919-927.

ZHANG Qing-dong, LI Shuo, ZHANG Bo-yang, XIE Lu, LI Rui. Molecular dynamics modeling and studying of micro-deformation behavior in metal[J]. Acta Metallurgica Sinica, 2019, 55(7): 919-927.

[9] 李亚江, 吴会强, 陈茂爱, 杨 敏, 冯 涛. Cu/Al 扩散焊工艺及结合界面的组织性能[J]. 焊接, 2001(10): 7-10.

LI Ya-jiang, WU Hui-qiang, CHEN Mao-ai, YANG Min, FENG Tao. Vacuum diffusion welding procedure of copper/ aluminum and microstructure analyses bond interface[J]. Welding & Joining, 2001(10): 7-10.

[10] 孟胶东, 曲文卿, 庄鸿寿. Al-Cu 双金属复合结构的扩散连接试验研究[J]. 材料工程, 2003(1): 34-37.

MENG Jiao-dong, QU Wen-qing, ZHUANG Hong-shou. Experimental study on diffusion bonding of Al-Cu bimetal composite structure[J]. Journal of Materials Engineering, 2003 (1): 34-37.

[11] GRUBER P A, SOLENTHALER C, ARZT E, SPOLENAK R. Strong single-crystalline Au films tested by a new synchrotron technique[J]. Acta Materialia, 2008, 56(8): 1876-1889.

[12] 赵鸿金, 王 达, 秦 镜, 张迎晖. 铜/铝层状复合材料结合机理与界面反应研究进展[J]. 热加工工艺, 2011, 40(10): 84-87.

ZHAO Hong-jin, WANG Da, QIN Jing, ZHANG Ying-hui. Research progress on bonding mechanism and interface reaction of Cu/Al laminated composite[J]. Hot Working Technology, 2011, 40(10): 84-87.

[13] 王 征, 刘 平, 刘新宽. 浇铸法制备铜铝复合材料及其性能研究[J]. 上海有色金属, 2015, 36(2): 61-64.

WANG Zheng, LIU Ping, LIU Xin-kuan. Research of casted Cu-Al composite materials on performance[J]. Nonferrous Metal Materials and Engineering, 2015, 36(2): 61-64.

[14] 宋克兴, 张 亚, 张彦敏, 国秀花. 铜/铝固-液复合研究[J]. 铸造, 2014, 63(7): 655-658.

SONG Ke-xing, ZHANG Ya, ZHANG Yan-min, GUO Xiu-hua. Study on solid-liquid bonding of Cu/Al composites[J]. Foundry, 2014, 63(7): 655-658.

[15] 蒋宇梅. 铜/铝复合材料及其界面研究[J]. 中国科技信息, 2009(19): 40-41.

JIAMG Yu-mei. Study on Cu/Al composite and its interface[J]. China Science and Technology Information, 2009(19): 40-41.

[16] 张红安, 陈 刚. 铜/铝复合材料的固-液复合法制备及其界面结合机理[J]. 中国有色金属学报, 2008, 18(3): 41-47.

ZHANG Hong-an, CHEN Gang. Fabrication of Cu/Al compound materials by solid-liquid bonding method and interface bonding mechanism[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 41-47.

[17] GAO J, WANG K F, FU X Q, CHEN S J, ZHANG Z J, WANG Q N, LI J J, YU Q. Super plasticity in a cold-welded Al-Cu joint[J]. Applied Physics Letters, 2019, 114(6): 063101.

[18] 刘 浩, 柯孚久, 潘 晖, 周 敏. 铜-铝扩散焊及拉伸的分子动力学模拟[J]. 物理学报, 2007, 56(1): 407-412.

LIU Hao, KE Fu-jiu, PAN Hui, ZHOU Ming. Molecular dynamics simulation of the diffusion bonding and tensile behavior of a Cu-Al interface[J]. Acta Physica Sinica, 2007, 56(1): 407-412.

[19] 刘 强, 郭巧能, 钱相飞, 王海宁, 郭睿林, 肖志杰, 裴海蛟. 循环载荷下纳米铜/铝薄膜孔洞形核、生长及闭合的分子动力学模拟[J]. 物理学报, 2019, 68(13): 133101.

LIU Qiang, GUO Qiao-neng, QIAN Xiang-fei, WANG Hai-ning, GUO Rui-lin, XIAO Zhi-jie, PEI Hai-jiao. Molecular dynamics simulation of void nucleation, growth and closure of nano-Cu/Al films under cyclic loading[J].Acta Physica Sinica, 2019, 68(13): 133101.

[20] CHEN S, KE F J, ZHOU M, BAI Y L. Atomistic investigation of the effects of temperature and surface roughness on diffusion bonding between Cu and Al[J]. Acta Materialia, 2007, 55(9): 3169-3175.

[21] LI C, LI D, TAO X M, CHEN H M, OUYANG Y F Molecular dynamics simulation of diffusion bonding of Al-Cu interface[J]. Modelling and Simulation in Materials Science and Engineering, 2014, 22(6): 065013.

[22] 罗 龙, 王宝峰, 李丽荣. 铜/铝热轧扩散复合界面扩散的分子动力学模拟[J]. 热处理技术与装备, 2011, 32(2): 55-60.

LUO Long, WANG Bao-feng, LI Li-rong. Molecular dynamics simulation of diffusion behavior at the interface of hot rolling-diffusion bonding of Cu/Al[J]. Heat Treatment Technology and Equipment, 2011, 32(2): 55-60.

[23] 尹海龙, 李世春. Al-Cu扩散偶的界面反应[J]. 热加工工艺, 2008, 37(24): 1-4.

YI Hai-long, LI Shi-chun. Interfacial reactions in Al-Cu diffusion couples[J]. Hot Working Technology, 2008, 37(24): 1-4.

[24] 郭巧能, 曹义刚, 孙 强, 刘忠侠, 贾 瑜, 霍裕平. 温度对超薄铜膜疲劳性能影响的分子动力学模拟[J]. 物理学报, 2013, 62(10): 107103.

GUO Qiao-neng, CAO Yi-gang, SUN Qiang, LIU Zhong-xia, JIA Yu, HUO Yu-ping. Temperature dependence of fatigue properties of ultrathin copper films: molecular dynamics simulations[J].Acta Physica Sinica, 2013, 62(10): 107103.

[25] 韩雪杰, 郭巧能, 杨仕娥, 王明星, 王杰芳, 刘 强, 王鲁钰, 古 干, 钱相飞. 温度和保温时间对铜/铝薄膜的界面扩散性能及力学性能影响的分子动力学模拟[J]. 热加工工艺, 2019, 48(14): 102-107.

HAN Xue-jie, GUO Qiao-neng, YANG Shi-e, WANG Ming-xing, WANG Jie-fang, LIU Qiang, WANG Lu-yu, GU Gan, QIAN Xiang-fei. Molecular dynamics simulation of effect of temperature and holding time on interface diffusion performance and mechanical properties of copper/aluminum film[J]. Hot Working Technology, 2019, 48(14): 102-107.

[26] CAI J, YE Y Y. Simple analytical embedded-atom-potential model including a long-range force for fcc metals and their alloys[J]. Physical Review B, 1996, 54(12): 8398.

[27] PLIMPTON S. Fast parallel algorithms for short-range molecular dynamics[J]. Journal of Computational Physics, 1995, 117(1): 1-19.

[28] EVANS D J, HOLIAN B L. The nose-hoover thermostat[J]. The Journal of Chemical Physics, 1985, 83(8): 4069-4074.

[29] STUKOWSKI A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool[J]. Modelling and Simulation in Materials Science and Engineering, 2009, 18(1): 015012.

[30] 于宝义, 乔 刚, 陈 岩, 刘春雨. 热浸镀法 Cu/Al 液固复合的研究[J]. 特种铸造及有色合金, 2010(6): 581-583.

YU Bao-yi, QIAO gang, CHEN Yan, LIU Chun-yu. Preparation of Cu/Al liquid-solid compound bimetallic composites by hot-dipping technology[J]. Special Casting & Nonferrous Alloys, 2010(6): 581-583.

[31] 王 超. 铜-铝两相材料固液成型的分子动力学模拟[D]. 武汉: 华中科技大学, 2015.

WANG Chao. Molecular dynamic simulation on solid-liquid compound of copper and aluminum two-phase materials[D]. Wuhan: Huazhong University of Science and Technology, 2015.

[32] 杨 睿, 李世春, 宋玉强. Al/Cu 扩散偶相界面的实验研究[J]. 中国石油大学学报(自然科学版), 2007, 31(2): 110-113.

YANG Rui, LI Shi-chun, SONG Yu-qiang. Experimental study on interface of Al/Cu diffusion couple[J]. Journal of China University of Petroleum(Edition of Natural Science), 2007, 31(2): 110-113.

[33] 张建宇, 马 强, 廉 影, 李河宗, 马 聪, 张家硕. Cu/Al 复合材料退火过程中的界面组织演变[J]. 金属热处理, 2017, 42(7): 131-136.

ZHANG Jian-yu, MA Qiang, LIAN Ying, LI He-zong, MA Cong, ZHANG Jia-shuo. Interfacial microstructure evolution of Cu/Al composites during annealing[J]. Heat Treatment of Metals, 2017, 42(7): 131-136.

[34] 叶 政, 羊 浩, 黄继华, 陈树海. 保温时间对铝/铜钎焊接头界面化合物和力学性能的影响[J]. 焊接学报, 2016, 37(12): 9-12.

YE Zheng, YANG Hao, HUANG Ji-hua, CHEN Shu-hai. Influence of dwelling time on interfacial compounds and mechanical properties of aluminum/copper brazing joints[J]. Transactions of the China Welding Institution, 2016, 37(12): 9-12.

[35] 王利华, 乔 刚. 退火处理对铜铝复合材料扩散层组织和性能的影响[J]. 金属热处理, 2013, 38(12): 68-71.

WANG Li-hua, QIAO Gang. Effects of annealing on microstructure and mechanical properties of Cu/Al composite materials diffusion layer[J]. Heat Treatment of Metals, 2013, 38(12): 68-71.

[36] 刘文川, 刘晓烈. 有色金属铸件有效浇注时间计算公式探讨[J]. 特种铸造及有色合金, 1999(6): 37-39.

LIU Wen-chuan, LIU Xiao-lie. Discussion on calculating formula for efficient pouring time of non-ferrous metal castings[J]. Special Casting & Nonferrous Alloys, 1999(6): 37-39.

[37] FU T, PENG X, WENG S, ZHAO Y B, GAO F S, DENG L J, WANG Z C. Molecular dynamics simulation of effects of twin interfaces on Cu/Ni multilayers[J]. Materials Science and Engineering A, 2016, 658: 1-7.

[38] ZHANG Z, WANG B, HUANG S, WEN B, YANG S, ZHANG B, LIN C T, JIANG N, JIN Z M, GUO D M. A novel approach to fabricating a nanotwinned surface on a ternary nickel alloy[J]. Materials & Design, 2016, 106: 313-320.

[39] 徐 爽, 郭雅芳. 纳米铜薄膜塑性变形中空位型缺陷形核与演化的分子动力学研究[J]. 物理学报, 2013(19): 388-394.

XU Shang, GUO Ya-fang. Generation and evolution of vacancy-type defects in nano-Cu films during plastic deformation by means molecular dynamics[J]. Acta Physica Sinica, 2013(19): 388-394.

QIAN Xiang-fei, GUO Qiao-neng, YANG Shi-e, WANG Ming-xing, LIU Qiang, WANG Jie-fang

(School of Physics, Zhengzhou University, Zhengzhou 450001, China)

Abstract: The effects of different casting temperature and casting time on the interfacial diffusion of Cu/Al multilayer films were studied based on the molecular dynamics method. The tensile deformation of Cu/Al multilayer films under different casting time and casting temperature was compared from the aspects of mechanical properties and dislocation slip, and the effects of microatomic structure and the mechanical properties of metal films were revealed. The results show that the thickness of transition layer and the number of Cu and Al atoms diffusing each other near the interface both increase with the increase of casting temperature and casting time. The yield strength and tensile strength of Cu/Al multilayer films also increase at first and then decrease with the increase of casting temperature and casting time. When the casting temperature is 1013 K and the casting time is 0.2 ns, the mechanical properties of Cu/Al multilayers are the best.

Key words: molecular dynamics; casting; Cu/Al multilayer film; interface diffusion

Foundation item: Project(11372283) supported by the National Natural Science Foundation of China; Project (13A140674) supported by the Foundation of Henan Educational Committee, China; Project(17A430001) supported by the Research Foundation of the Higher Education Institutions of Henan Province, China

Received date: 2019-12-02; Accepted date: 2020-08-31

Corresponding author: GUO Qiao-neng; Tel: +86-15136275356; E-mail: gqiaoneng@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(11372283);河南省教育厅科学技术研究重点项目(13A140674);河南省高等学校重点科研项目(17A430001)

收稿日期:2019-12-02;修订日期:2020-08-31

通信作者:郭巧能,教授,博士;电话:15136275356;E-mail:gqiaoneng@163.com