网络首发时间: 2016-07-13 16:58

稀有金属 2017,41(10),1082-1086 DOI:10.13373/j.cnki.cjrm.xy16050024

Al-5Ti-1B-4Sr中间合金对Al-8Si合金同时细化和变质效果

王宝山 冯义成 郭育阳 王丽萍 郭二军 姜文勇

哈尔滨理工大学工程训练中心

哈尔滨理工大学材料科学与工程学院

摘 要:

采用氟盐法和对掺法成功制备了Al-5Ti-1B-4Sr中间合金, 采用X射线衍射 (XRD) 和扫描电镜 (SEM) 分析了Al-5Ti-1B-4Sr中间合金的组织及相组成。通过改变Al-5Ti-1B-4Sr中间合金细化变质保温时间, 采用微观组织分析和宏观组织分析方法, 研究了Al-5Ti-1B-4Sr中间合金对Al-8Si亚共晶铝硅同时细化和变质的效果。研究结果表明, Al-5Ti-1B-4Sr中间合金中含有Al3Ti相、TiB2相和Al4Sr相, Al-5Ti-1B-4Sr中间合金对亚共晶铝硅合金有良好的同时细化变质效果。Al-5Ti-1B-4Sr中间合金可使共晶硅从针状或板片状形貌转变为纤维状或块状。与未变质试样相比, 细化变质时间为10 min时, Al-8Si合金中针状或板片状共晶硅显著减少;变质时间超过20 min时, 看不到针状或板片状共晶硅存在;当变质时间达到80 min时, 部分针状或板片状共晶硅再次出现。随着Al-5Ti-1B-4Sr细化变质保温时间的变化, α-Al的二次枝晶臂间距和共晶团尺寸先减小后增大, 细化变质保温时间为30 min时效果最好。Al-5Ti-1B-4Sr中间合金对亚共晶铝硅合金细化变质的孕育期为1020 min, 衰退期为60 min。

关键词:

细化剂;变质剂;中间合金;亚共晶铝硅合金;

中图分类号: TG146.21

作者简介:王宝山 (1961-) , 男, 黑龙江哈尔滨人, 学士, 实验师, 研究方向:高性能铝合金, E-mail:1324664896@qq.com;;冯义成, 副教授, 电话:0451-86392518, E-mail:fyc7806067@163.com;

收稿日期:2016-05-27

基金:黑龙江省自然科学基金项目 (ZD2016011) 资助;

Simultaneous Refinement and Modification of Al-8Si Alloy with Al-5Ti-1B-4Sr Master Alloy

Wang Baoshan Feng Yicheng Guo Yuyang Wang Liping Guo Erjun Jiang Wenyong

Engineering Training Center, Harbin University of Science and Technology

School of Materials Science and Engineering, Harbin University of Science and Technology

Abstract:

The Al-5Ti-1B-4Sr master alloy was prepared successfully by complex halide salts and direct reaction with molten aluminum methods. The microstructure was observed and analyzed by X-ray diffraction ( XRD) and scanning electron microscope ( SEM) .The effect of simultaneous refinement and modification of Al-5Ti-1B-4Sr master alloy on Al-8Si alloy was studied by microstructure and macrostructure analysis with various addition and holding time. The experimental results showed that the Al-5Ti-1B-4Sr master alloy contained Al3Ti, TiB2 and Al4Sr phases, which had a good effect of simultaneous refinement and modification on Al-8Si alloy. The eutectic Si was changed from needle-like or flaky to fibrous or bulky. When the refining and modifying time was 10 min, the needle-like or flaky eutectic Si in Al-8Si alloy became less than that in unmodified Al-8Si alloy. When the refining and modifying time was longer than 20 min and shorter than 80 min, the needle-like or flaky eutectic Si in Al-8Si vanished. When the refining and modifying time was longer than 80 min, the needle-like or flaky eutectic Si in Al-8Si appeared again. The second dendrite arm space ( SDAS) and eutectic cell size decreased firstly and then increased with holding time increasing. The refinement and modification efficiency was best when the holding time was 30 min. The refinement and modification of Al-5Ti-1B-4Sr master alloy on Al-8Si alloy had a 10 ~ 20 min incubation stage and faded more than 60 min.

Keyword:

refinement; modification; master alloy; hypoeutectic Al-Si alloy;

Received: 2016-05-27

铸造铝硅系合金具有优良的综合性能, 在机械、航空、航天、军工、交通运输等领域应用广泛[1]。亚共晶铝硅合金的初生α-Al晶粒尺寸、二次枝晶臂间距、共晶硅尺寸及形貌对其力学性能有重要影响[2,3,4]。未经变质的共晶硅为粗大片状, 严重割裂铝基体, 恶化铝硅合金性能。目前, 含Sr变质剂为铝硅合金中常见、有效的共晶硅变质剂[5,6,7,8], 可使粗大片状共晶硅转变为细长纤维状。含Ti或和B的细化剂对亚共晶铝硅合金的初生α-Al晶粒尺寸、二次枝晶臂间距具有显著细化作用[9,10,11,12,13,14]。因此, 对亚共晶铝硅合金同时进行晶粒细化和共晶硅变质具有重要意义。若生产一种含Ti, B和Sr的中间合金, 可实现对亚共晶铝硅同时进行晶粒细化和共晶硅变质的效果[15,16]。目前生产中, Sr的加入量范围为0.02%~0.04%时, 对共晶硅具有较好的变质效果[17]。因此, 本文采用氟盐法和对掺法成功制备了Al-5Ti-1B-4Sr中间合金, 通过改变Al-5Ti-1B-4Sr中间合金加入量及细化变质保温时间, 进行Al-5Ti-1B-4Sr中间合金对亚共晶铝硅同时细化和变质效果研究。

1 实验

Al-5Ti-1B-4Sr中间合金采用氟盐法和对掺法相结合的方法制备。采用的原材料有工业纯铝、氟钛酸钾、氟硼酸钾和Al-10Sr中间合金。采用工业纯铝、氟钛酸钾、氟硼酸钾在800℃制备出Al-TiB中间合金, 然后将Al-10Sr中间合金加入到AlTi-B中间合金熔体中, 保温10 min, 制备出Al-5Ti-1B-4Sr中间合金。采用荷兰飞利浦公司的Rigaku Rotaflex D/MA X射线衍射分析仪 (XRD) 对制备的Al-5Ti-1B-4Sr中间合金进行相分析, 采用FEI公司Quanta 200扫描电子显微镜 (SEM) 对Al-5Ti-1B-4Sr中间合金进行组织分析。采用Al-8Si合金验证制备的Al-5Ti-1B-4Sr中间合金对亚共晶铝硅合金同时细化变质效果。Al-8Si采用工业纯铝和Al-20Si中间合金在电阻炉中熔配而成, 熔配温度为780℃。Al-5Ti-1B-4Sr中间合金加入量为1%, 改变中间合金加入时间, 表征Al-5Ti-1B-4Sr中间合金对亚共晶铝硅的同时细化变质效果。

金相组织观察试样采用OLYMPUS-GX71观察, 腐蚀剂为0.5%HF溶液。细化变质宏观组织观察试样采用60%HCl+30%HNO3+5HF+5%H2O混合溶液腐蚀。采用截线法定量分析试样的晶粒尺寸及二次枝晶臂间距。

2 结果与讨论

2.1 Al-5Ti-1B-4Sr中间合金的XRD图谱

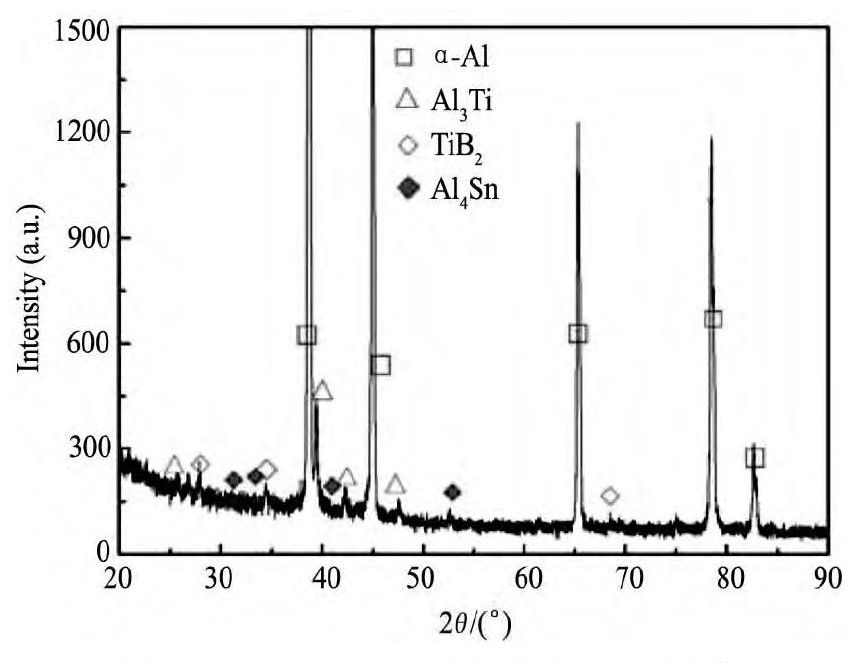

图1是Al-5Ti-1B-4Sr中间合金的X射线衍射 (XRD) 图谱。从图1中可以看出, Al-5Ti-1B-4Sr中间合金中除了α-Al相外, 还含有Al3Ti相、Ti B2相和Al4Sr相, 这些相具有较好的细化变质效果。文献[18]指出, B和Sr之间会发生相互反应, 形成Al Ti Sr相和Sr B6相, 影响中间合金细化效果和变质效果。从XRD分析看, 本研究所制备的Al-5Ti-1B-4Sr中间合金中没有形成Sr B6相。

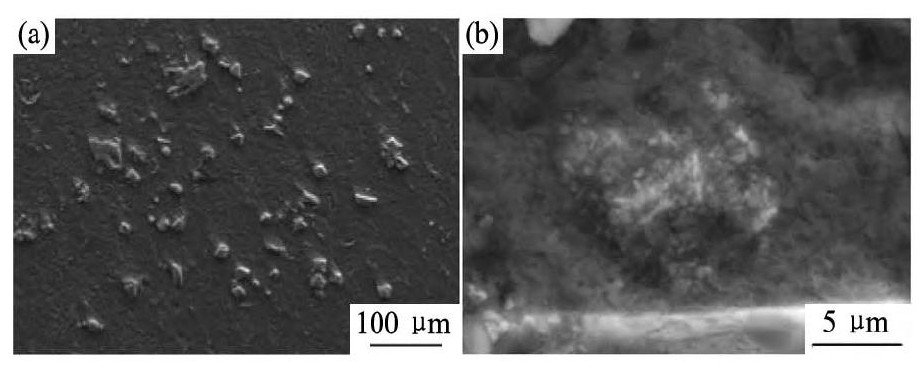

Al-5Ti-1B-4Sr中间合金的扫描电子显微镜 (SEM) 照片如图2所示。图2 (a) 为低倍组织, 图2中块状物质为Al3Ti相和Al4Sr相, 这两种相形态相似, 比较难以区分。图2 (b) 为高倍组织, 片状物质主要为Ti B2相。Al-5Ti-1B-4Sr中间合金中Al3Ti相、Ti B2相和Al4Sr相的尺寸和形貌适宜于作为优良的细化变质剂。

图1 Al-5Ti-1B-4Sr中间合金XRD图谱Fig.1 XRD pattern of Al-5Ti-1B-4Sr master alloy

图2 Al-5Ti-1B-4Sr中间合金SEM照片Fig.2 SEM images of Al-5Ti-1B-4Sr master alloy (a) Low magnification; (b) High magnification

2.2 显微组织

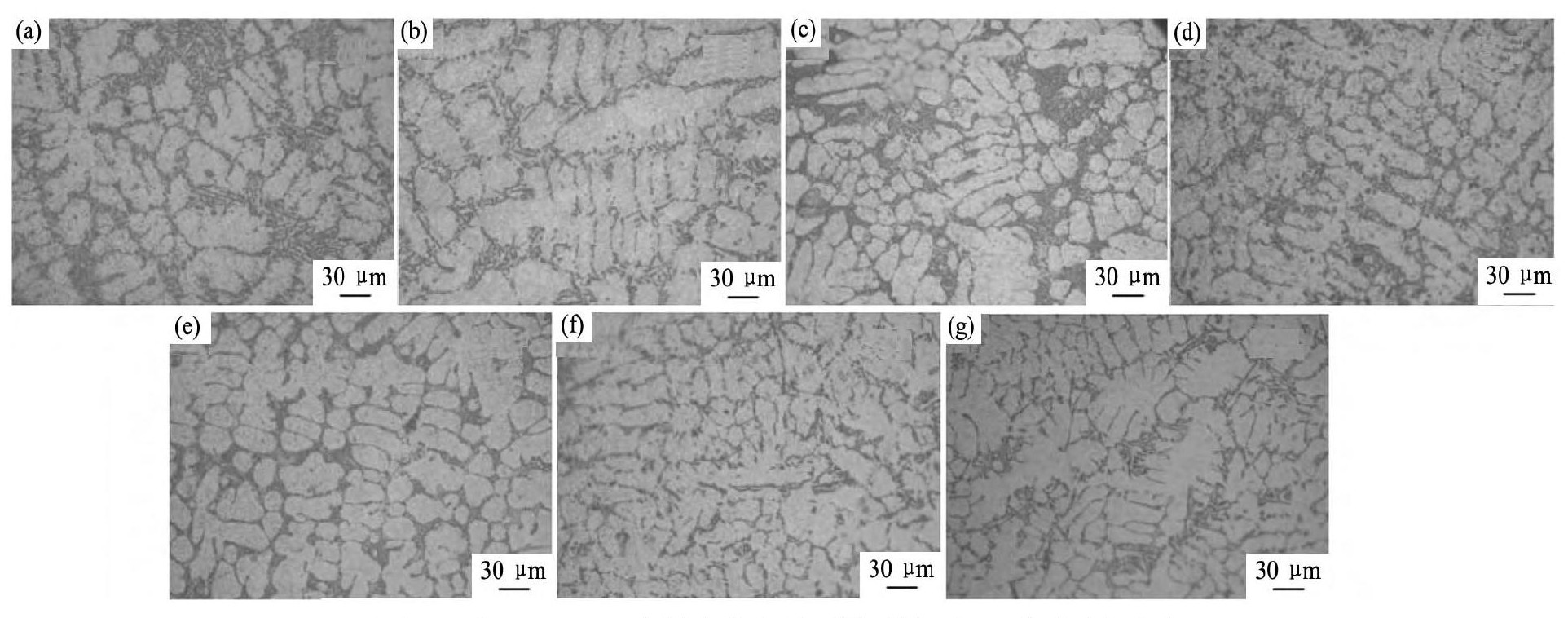

Al-5Ti-1B-4Sr中间合金不同细化变质时间的Al-8Si合金试样显微组织如图3所示。未经Al-5Ti-1B-4Sr中间合金细化变质处理的Al-8Si合金显微组织如图3 (a) 所示。从图3 (a) 可以看出, Al-8Si合金中的共晶硅以粗大针状或板片状形貌存在。经变质处理后, 共晶硅形貌得到良好变质, 呈纤维状存在。随着细化变质时间的延长, 共晶硅从针状或板片状形貌转变为纤维状或块状。与未变质试样相比, 细化变质时间为10 min时, Al-8Si合金中针状或板片状共晶硅显著减少;变质时间超过20min时, 看不到针状或板片状共晶硅存在。当变质时间达到80 min时, 部分针状或板片状共晶硅再次出现。以上试验结果表明, Al-5Ti-1B-4Sr中间合对共晶硅有良好的变质效果, 对共晶硅变质的孕育期为10~20 min, 衰退时间为80 min。

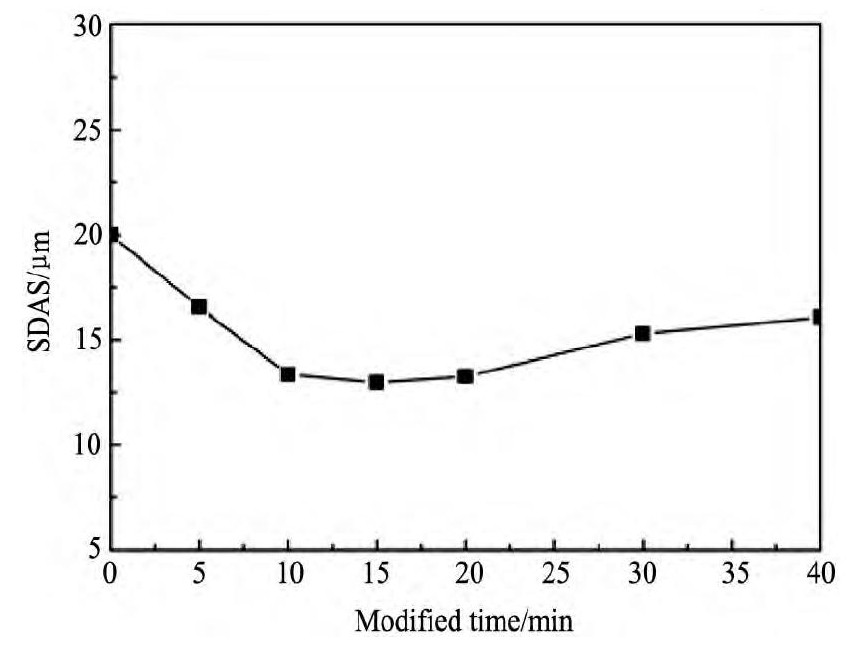

Al-5Ti-1B-4Sr中间合金不同时间细化变质时间的Al-8Si合金的二次枝晶臂间距如图4所示。从图4可以看出, 随着细化变质时间的延长, Al-8S合金的二次枝晶臂间距先减小后增大。当细化变质时间为30 min时, Al-8Si合金的二次枝晶臂间距最小, 其值为12.97μm。在细化变质时间范围内, Al-8Si合金的二次枝晶臂间距大小变化不明显, Al-5Ti-1B-4Sr中间合金对亚共晶铝硅合金的枝晶长大有显著的抑制效果。

2.3 宏观组织

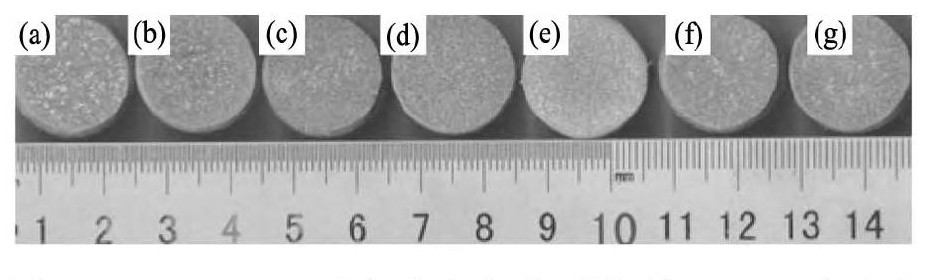

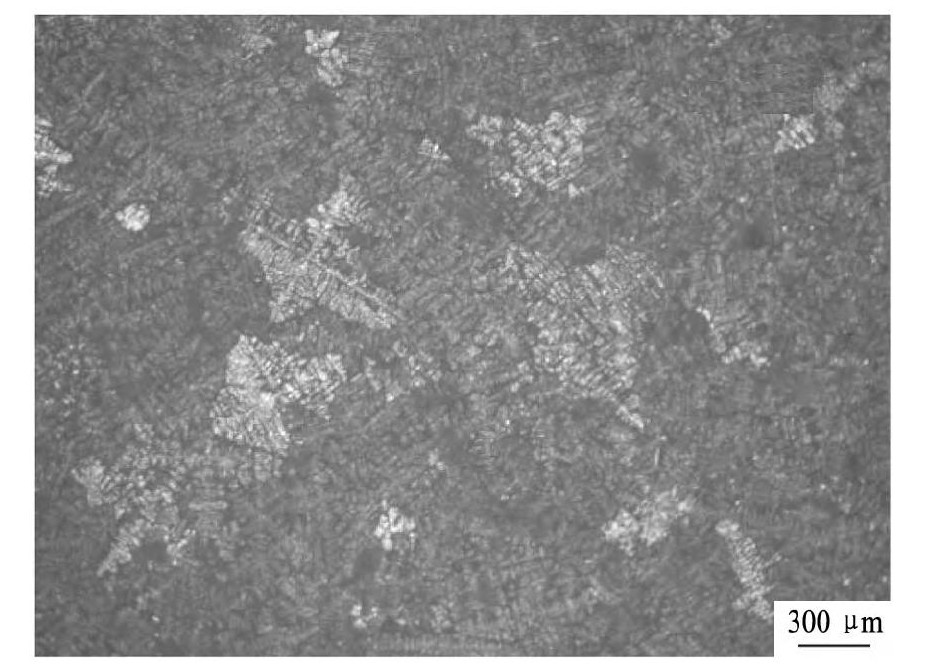

Al-5Ti-1B-4Sr中间合金不同时间细化变质时间的Al-8Si合金宏观组织如图5所示。从图5中可以看出, 随着细化变质时间的增加, Al-8Si合金的宏观晶粒尺寸 (可看作共晶团尺寸) 先减小然后稍微增加, 细化变质时间为30 min时宏观晶粒尺寸最小。典型宏观组织试样放大50倍的金相组织如图6所示。从图6中可以明显看出每个宏观晶粒为一个共晶团。

图3 Al-5Ti-1B-4Sr中间合金变质不同时间Al-8Si合金金相组织Fig.3 Microstructure of Al-8Si alloy modified by Al-5Ti-1B-4Sr master alloy with different time (a) 0 min; (b) 10 min; (c) 20 min; (d) 30 min; (e) 40 min; (f) 60 min; (g) 80 min

图4 Al-8Si合金变质时间与二次枝晶臂间距关系曲线Fig.4 Effect of modified time on SDAS in Al-8Si alloy

图5 Al-5Ti-1B-4Sr中间合金变质不同时间Al-8Si合金宏观组织Fig.5Macrostructure of Al-8Si alloy modified by Al-5Ti-1B-4Sr master alloy with different time

(a) 0 min; (b) 10 min; (c) 20 min; (d) 30 min; (e) 40 min; (f) 60 min; (g) 80 min

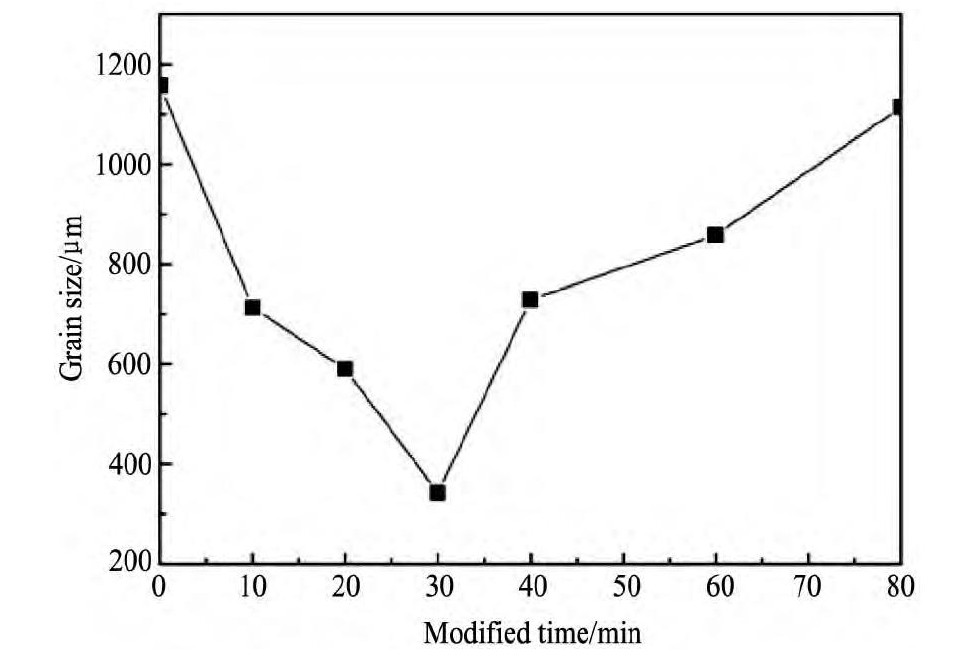

采用截线法对Al-8Si合金试样共晶团尺寸进行定量分析, 分析结果如图7所示。从图7中可以看出, 未加细化变质剂时, Al-8Si合金共晶团尺寸较大, 其值为1157.14μm。随着细化变质时间的增加, 共晶团尺寸先减小后增加, 当变质时间为30 min时, 共晶团尺寸最小, 其值为342.86μm。当细化变质时间达到80 min时, 共晶团尺寸长大, 几乎接近未细化变质处理的水平, 共晶团尺寸为1114.29μm。Sun等[19]研究认为, 一个共晶团中的Si相和Al相都不是单晶体, 而是由不同位相的小晶粒构成的。并且初生铝的形核影响共晶相形核及生长。Al-5Ti-1B-4Sr中间合金中的Al3Ti和Ti B2相对α-Al有显著的细化作用, 从而对共晶形核及生长有重要的影响, 进而表现为Al-8Si合金共晶团尺寸的影响。

图6 典型的Al-8Si合金变质组织Fig.6 Typical microstructure in modified Al-8Si alloy

图7 Al-8Si合金变质时间与共晶团尺寸关系曲线Fig.7Effect of modified time on eutectic cell size of Al-8Si alloy

3 结论

1.Al-5Ti-1B-4Sr中间合金对亚共晶铝硅合金具有良好的同时细化和变质效果。

2.Al-5Ti-1B-4Sr中间合金的细化变质孕育期为10~20 min, 超过60 min时, 出现细化变质衰退。

3.Al-5Ti-1B-4Sr中间合金对亚共晶铝硅合金的二次枝晶臂间距细化效果不明显, 对共晶团细化效果显著。当细化变质时间超过40 min时, 共晶团尺寸开始长大。

参考文献

[1] Yan H, Zhang J Q, Zhang S.Research progress on rare earth aluminium alloy modification[J].Materails Review, 2013, 27:285. (闫洪, 张敬奇, 张苏.稀土对铝合金变质处理的研究进展[J].材料导报, 2013, 27:285.)

[2] Yan H, Song X C, Huang X.Preparation of Al-La master alloy by ultrasonic method and modification on Al alloy[J].Rare Met., 2015, 34 (7) :457.

[3] Sathyapal Hegde, Prabhu K Narayan.Modification of eutectic silicon in Al-Si alloys[J].Journal of Materials Science, 2008, 43 (9) :3009.

[4] Sheng M, Tao Z D, Jia P, Leng J F, Geng H R.Effects of Y and Y combined with Al-5Ti-1B on the microstructure and mechanical properties of hypoeutectic Al-Si alloy[J].JOM, 2015, 67 (2) :330.

[5] Ali Mazahery, Mohsen Ostad Shabani.Modification mechanism and microstructural characteristics of eutectic Si in casting Al-Si alloys:a review on experimental and numerical studies[J].JOM, 2014, 66 (5) :726.

[6] Li S S, Tang J L, Zeng D B.Incubation and fading of Sr modification in hypoeutectic Al-Si alloys[J].Foundry, 2005, 54 (4) :344. (李双寿, 唐靖林, 曾大本.亚共晶铝硅合金锶变质处理的孕育和衰退[J].铸造, 2005, 54 (4) :344.)

[7] Hanque M M.Effect of strontium on the structure and properties of aluminum-silicon alloys[J].Journal of Material Processing Technology, 1995, 55 (3-4) :193.

[8] Zhao H L, Bai H L, Wang J, Guan S K.Preparation of Al-Ti-C-Sr master alloys and their refining efficiency on A356 alloy[J].Materials Characterization, 2009, 60:377.

[9] Reddy N S, Rao A K Prasada, Krishnaiah J, Chakraborty M, Murty B S.Design of an ideal grainrefiner alloy for Al-7Si alloy using artificial neural networks[J].J.Mater.Engin.Perform., 2013, 22 (3) :696.

[10] Zhu M, Yang G C, Yao L J, Cheng S L, Zhou Y H.Influence of Al-Ti-B addition on the microstructure and mechanical properties of A356 alloys[J].Rare Met., 2009, 28 (2) :181.

[11] Birol Y.A novel Al-5Ti-1B alloy for grain refining AlSi foundry alloys[J].Journal of Alloys and Compounds, 2009, 486 (1-2) :219.

[12] Birol Y.Efficiency of binary and ternary alloys from Al-5Ti-1B system in grain refining aluminium foundry alloys[J].International Journal of Cast Metals Research, 2013, 26 (5) :283.

[13] Jigajinni S M, Venkateswarlu K, Kori S A.Effect of a grain refiner cum modifier on mechanical properties of Al-7Si and Al-11Si alloys[J].Met.Mater.Int., 2013, (2) :171.

[14] Ren J, Tao Q G, Ma Y.Manufacture of Al-Ti-B grain refiner by reaction of complex halide salts with molten aluminum in B2O3alternative KBF4[J].Chinese Journal of Rare Metals, 2016, 40 (2) :188. (任峻, 陶钦贵, 马颖.B2O3替代KBF4用氟盐法制备Al-Ti-B晶粒细化剂的研究[J].稀有金属, 2016, 40 (2) :188.)

[15] Amir Hassani, Khalil Ranjbar, Sattar Sami.Microstructural evolution and intermetallic formation in Al-8wt%Si-0.8 wt%Fe alloy due to grain refiner and modifier additions[J].Int.J.Miner.Metall.Mater., 2012, 19 (8) :739.

[16] Mallapur D G, Kori S A, Udupa K Rajendra.Influence of Ti, B and Sr on the microstructure and mechanical properties of A356 alloy[J].J.Mater.Sci., 2011, 46:1622.

[17] Liao H C, Ding Y, Sun G X.Effect of strontium on growth ofαdendrite in near-eutectic Al-Si alloys[J].Acta Metallurgica Sinca, 2002, 38 (3) :245. (廖恒成, 丁毅, 孙国雄.Sr对近共晶Al-Si合金中α枝晶生长行为的影响[J].金属学报, 2002, 38 (3) :245.)

[18] Li J G, Ma H T, Zhang B Q, Fang H S, Ma X H.The combination effect of Al-3Ti-4B and Al-10Sr master alloy on ZL104 alloy[J].Acta Metallurgica Sinca, 2000, 36 (6) :579. (李建国, 马洪涛, 张柏清, 方鸿生, 马晓华.Al-3Ti-4B细化剂和Al-10Sr变质剂对ZL104合金的联合作用[J].金属学报, 2000, 36 (6) :579.)

[19] Sun Y, Pang S P, Liu X R, Yang Z R, Sun G X.Nucleation and growth of eutectic cell in hypoeutectic Al-Si alloy[J].Trans.Nonferrous Met.Soc.China, 2011, 21:2186.