文章编号:1004-0609(2011)09-2068-07

用原位电阻法研究2A12铝合金的连续冷却转变

李红英1, 2, 宾 杰1, 王晓峰1, 唐 宜1

(1. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

2. 中南大学 航空航天学院,长沙 410083)

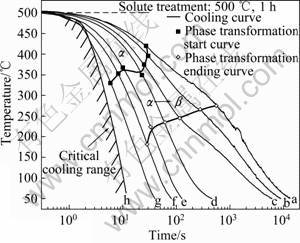

摘 要:采用原位电阻法测得以不同速率连续冷却2A12铝合金的电阻率—温度曲线,根据曲线斜率变化确定相变点及临界冷却速率,利用透射电镜观察连续冷却过程特征温度点的淬火组织,绘制出实验合金的连续冷却转变曲线(CCT图)。结果表明:2A12合金连续冷却相变主要集中在220~400 ℃的温度区间,随着冷却速率的增加,相变结束温度一直呈下降的趋势,但相变开始温度在达到某冷却速率时骤升,然后继续降低,抑制相变的临界冷却速率稍大于38 ℃/s。慢速连续冷却实验合金时,固溶度减小是引起电阻率变化的主要原因,固溶体脱溶的动力学行为与等温相变规律相似,可较好地用Johnson-Mehl-Avrami (JMA)方程描述。

关键词:2A12铝合金;原位电阻;相变;连续冷却转变

中图分类号:TG 151 文献标志码:A

Continuous cooling transformation of 2A12 aluminum alloy studied by using in-situ electrical resistivity measurement

LI Hong-ying1, 2, BIN Jie1, WANG Xiao-feng1, TANG Yi1

(1. Educational Key Laboratory of Non-ferrous Metal Material Science and Engineering,

Central South University, Changsha 410083, China;

2. School of Aeronautics and Astronautics, Central South University, Changsha 410083, China)

Abstract: The electric resistivity versus temperature curves of 2A12 aluminum alloy were recorded during continuous cooling using the in-situ electrical resistivity measurement. The phase transformation temperatures and critical cooling rate without phase transition of the alloy can be obtained from the relationships of electrical resistivity vs temperature curves. TEM was applied to the microstructure observation during the continuous cooling process. CCT diagrams of the tested samples can be established. The results show that the phase transformations of the tested alloy mainly take place between 220 ℃ and 400 ℃. The phase transformation finishing temperature decreases with the increase of cooling rates. While the phase transformation starting temperature increases suddenly until the cooling rate reaches some value, then decreases with the increase of cooling rates. The critical cooling rate for preventing phase transformation is above 38 ℃/s. The decrease of solid solubility is the main reason for variation of electric resistivity with a low cooling rate of the alloy. The decomposition of solid solution of the alloy is similar with the isothermal phase transformation, which can be well described by the Johnson-Mehl-Avrami (JMA) equation.

Key words: 2A12 aluminum alloy; in-situ electric resistivity; phase transformation; continuous cooling

可热处理强化铝合金的时效强化效果与淬火速率密切相关,提高淬火冷却速率可抑制冷却过程中第二相的析出,提高合金的强韧性和耐蚀性[1-2]。然而,淬火冷却速率过快会导致构件内部产生应力,使得较大构件的尺寸精度降低,或者引起变形和开裂,因此,合理控制淬火冷却速率十分重要[3]。铝合金相变动力学曲线(TTT、TTP、CCT图)是制定热处理工艺和调控铝合金组织的重要依据,其中CCT图有较大的实际意义,因为实际淬火过程一般是连续的。由于铝合金相变时引起的晶格常数和硬度变化小,难以通过膨胀法和硬度测试来获取相变信息,也难以通过组织观察方法区分相变状态。电阻率是组织敏感参量,电阻法在大块非晶材料[4]、铜基记忆合金[5]以及镍基合金[6]等的相变行为研究方面获得了较好应用。对于铝合金,脱溶转变早期形成的原子团簇、偏聚等细微结构变化都会导致显著的电阻变化,电阻法在铝合金预时效、低温时效研究中得到了较好的应用[7-10]。目前,电阻法多用作铝合金的一种静态研究手段,很少有将电阻法用于铝合金连续冷却相变研究的报道,大多数研究是在热处理之后逐个测量试样的电阻,很难获得准确的相变信息,而原位电阻测量能直观、迅速地反映相变信息。为此,作者开发出了一套在线连续测量电阻的装置,探索出了测量铝合金连续冷却相变点的原位电阻法,先后测绘出了7475、7A04和6082合金的CCT图[11-13]。基于前期研究基础,本文作者利用原位电阻法研究2A12铝合金的连续冷却转变过程,旨在阐明铝合金连续冷却相变的规律及其与电阻响应的相关性,为原位电阻表征铝合金组织演变奠定基础。

1 实验

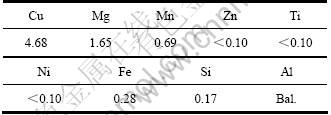

实验材料为8 mm厚的2A12热轧板,表1所示为实验合金的化学成分。

表1 实验合金的成分

Table 1 Chemical composition of tested alloy (mass fraction, %)

将试样进行500 ℃,1h固溶处理后,分别采用炉冷、空冷、风冷和液氮冷等不同方式冷却试样,利用自主开发的测量系统[12]连续测量试样冷却过程中的电阻和温度变化。将电阻换算成电阻率,得到不同冷却方式的电阻率—温度曲线,根据斜率变化判断相变开始点、相变结束点和临界冷却速率范围。固溶处理后,选定一个冷却速率,分别对试样冷却至相变开始前温度、相变开始后温度、相变结束前温度、相变结束后温度进行水淬,采用TecnaiG220型透射电子显微镜观察淬火试样的微观组织,并采用电镜自带的能谱仪对析出相进行成分分析,验证原位电阻测量获取的相变温度点的可靠性。透射电镜观察样品经机械减薄后双喷穿孔,电解液为30%硝酸甲醇溶液。

2 结果与分析

2.1 电阻率—温度曲线的测定与分析

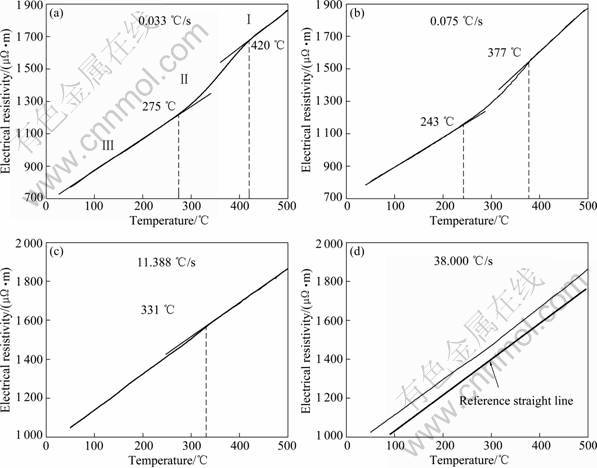

图1所示为实验合金在不同冷却速率下的典型电阻率—温度曲线,图中所标出的冷却速率均为平均冷却速率。当冷却速率较慢时,电阻率—温度曲线由直线、曲线、直线(I、Ⅱ、Ⅲ)三部分构成,如图1(a)和(b)所示。

在过饱和固溶体的连续冷却过程中,当材料内部组织没有变化时,固溶体电阻率减小主要由温度降低引起,电阻率—温度曲线近似为直线,由于原子分别以析出态和固溶态存在导致的电阻不同,一旦固溶体析出溶质原子,在晶内或晶界形成第二相,合金的电阻率将发生变化。因此,可根据电阻率—温度曲线变化规律获取相变信息,当冷却速率为0.033 ℃/s时,可以判断相变的开始温度和结束温度分别为420 ℃和275 ℃。当冷却速率为11.388 ℃/s时,电阻—温度曲线由两部分组成,如图1(c)所示,判断不出明确的相变结束点,这是因为较大的冷却速率能够抑制相变,在连续冷却过程中,第二相析出量有限,当冷却至较低温度时,虽然原子扩散速率较小,但因相变体积分数较低,固溶体过饱和度较高,相变驱动力大,合金在较低温度段仍有相变发生,电阻率向下偏离一直持续至室温,类似于自然时效[14]。图3(d)所示为液氮冷却对应的电阻率—温度曲线,图中的粗线为参比直线,但曲线整体近似直线,说明液氮的冷却速率已经接近临界冷却速率,因此判断2A12合金的临界冷却速率稍大于38 ℃/s。采用液氮进行冷却时,试样在很短时间内就冷到100 ℃,溶质原子来不及扩散,虽然基体有很大的过冷度,但材料内部相变量极小,难以判断相变开始点和结束点。

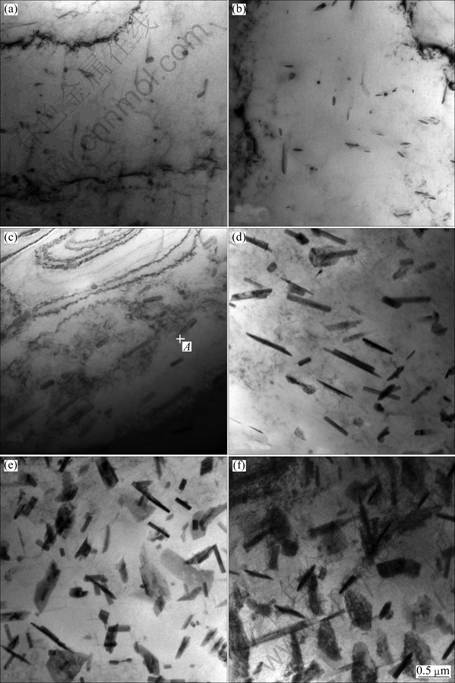

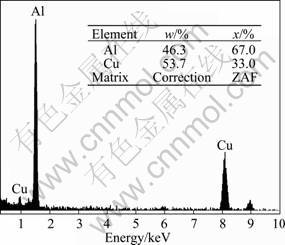

重复图1(a)对应的冷却过程,分别将试样冷却至500、430、410、285、265和50 ℃淬火,图2所示为各淬火试样的微观组织。试样在500 ℃淬火时(图2(a)),仅有一些没有完全固溶到基体中的高温难溶相;当温度降低到430 ℃时(图2(b)),仍没有观察到析出相;当温度降低到410 ℃时(图2 (c)),析出呈杆状的粗大第二相,发生了明显的相变,随着温度降低至 285 ℃(图2 (d)),析出相更粗大,数量也有所增加。对图2(c)出现的杆状相A进行能谱分析,结果如图3所示,析出相A中Al与Cu摩尔比约为2:1,应该是2×××铝合金中常见的θ(CuAl2)相,第二相的析出和长大导致电阻率—温度曲线发生变化。图2(e)和(f)所示为相变结束点附近以及50 ℃淬火的组织。对比发现,析出相的形貌及数量都没有明显的变化,说明期间没有相变发生。分析表明,透射电镜观察的结果与原位电阻法对相变点的判断是吻合的。

图1 不同速率冷却时的电阻率—温度曲线

Fig.1 Representative electrical resistivity—temperature curves at different cooling rates: (a) 0.033 ℃/s; (b) 0.075 ℃/s; (c) 11.388 ℃/s; (c) 38 ℃/s

2.2 连续冷却转变曲线的绘制与分析

根据电阻率—温度曲线确定相变点,表2列出了不同冷却速率对应的相变点,将不同冷却速率的冷却曲线、相变开始温度和结束温度绘制在温度—时间对数坐标系中,并将临界冷却速率范围和固溶工艺标示出来,得到图4所示的CCT图,图4中β相泛指连续冷却过程中可能析出的第二相。

表2 不同冷却速率对应的相变温度

Table 2 Phase transformation temperatures at different cooling rates

图2 不同温度淬火试样的TEM像

Fig.2 TEM images of samples quenched at different temperatures: (a) 500 ℃; (b) 430 ℃; (c) 410 ℃; (d) 285 ℃; (e) 265 ℃; (f) 50 ℃

由图4可以看出,2A12合金在连续冷却过程中的相变主要发生在220~400 ℃之间,相变结束温度随冷却速率增加而降低,但是,相变开始温度偏离了冷却速率越快,相变开始温度越低的规律,当冷却速率增加到一定程度时(曲线e),相变开始温度突然升高,然后随冷却速率的增加而再次下降。连续冷却过程较为复杂,当冷却速率极其缓慢时,会析出平衡相,当冷却速率极快时,相变来不及发生,高温组织保持至室温,得到过饱和固溶体,当冷却速率介于极快与极慢之间时,可能发生平衡相、亚稳相、GP区等的独立和复合析出,不同冷却速率对应的相变类型和相变程度都不一样,电阻率—温度曲线表现出不同的变化规律。冷却速率较慢时,相变开始和结束温度随冷却速率增加而降低,这是因为对于同一种类型的相变,冷却速率越大,原子扩散越不充分,相变开始温度较低,相变发生的程度也相应降低,与较慢冷却速率相比,当冷至一定温度时,基体的过饱和程度更高,相变结束温度相应更低。当冷却速率较快时(曲线e),实验合金相变开始温度发生激增,很可能是材料内部析出了非平衡相,如GP区、过渡相θ′和S′等。相变初期,界面能起决定性作用,相比平衡相,非平衡相的结构与基体差别较小,界面能小,形核功小,相变更容易发生,因此相变温度更高,导致相变开始点突然升高。相变开始温度骤升后,随冷却速率的继续增加,过饱和固溶体脱溶受到抑制的程度加剧,使相变温度再次降低,当冷却速率达到足够大时,相变完全被抑制。

图3 2A12合金中析出相的能谱

Fig.3 Energy spectrum of coarse precipitated phases in 2A12 alloy

图4 2A12合金的CCT图

Fig.4 CCT diagram for 2A12 aluminum alloy

在实际生产中,大尺寸及复杂铝合金构件淬火存在冷却不均匀的问题,冷却不均匀将导致淬火应力而使制件变形,站在减小淬火应力的角度,应当降低冷却强度以减小温度梯度,站在抑制第二相析出的角度,则需增加冷却强度以减少在相变敏感温度区的停留时间,两者相互矛盾。CCT图既包含了冷却过程的温度变化信息,也包含了与温度变化相关的相变信息,根据其对淬火工艺进行指导,可在减少淬火应力的同时最大限度抑制第二相的析出。在需要减小淬火应力的场合,可以根据CCT图制定分级淬火工艺,由图4所示的2A12合金的CCT图可以看出,220~400 ℃的中温阶段为淬火敏感区,对工件淬火时,在高温区间可适当慢冷,经过淬火敏感区应该急冷,为抑制相变的发生,冷却速率应尽可能达到或超过临界冷却速率38 ℃/s。

2.3 慢速连续冷却过程的相变分析

根据RAEISINIA的研究结果[7],合金相变过程电阻率可用修正的Matthiessen公式表示,即

(1)

(1)

式中:ρ0表示合金电阻率随温度变化的部分; 表示固溶组元对电阻率的贡献值;

表示固溶组元对电阻率的贡献值; 为固溶组元i的质量分数;

为固溶组元i的质量分数; 为固溶组元i增加1%(质量分数)时引起电阻率的改变量;D/λ1/2表示析出相对电阻率的贡献;λ为析出相间距;D为实验常数。

为固溶组元i增加1%(质量分数)时引起电阻率的改变量;D/λ1/2表示析出相对电阻率的贡献;λ为析出相间距;D为实验常数。

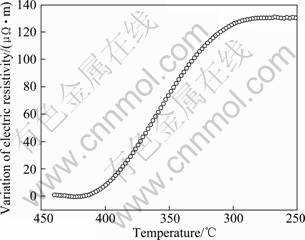

由图1(a)可知,当冷却速率为0.033 ℃/s,连续冷却过程Ⅰ阶段没有发生固溶体脱溶,若忽略温度对电阻温度系数的影响,电阻率与温度呈线性关系,则实验合金在不发生相变时电阻率随温度变化可用ρ0来表示,Ⅱ阶段发生了固溶体脱溶,电阻率变化可用ρ表示,固溶体脱溶引起的电阻率变化量Δρ=ρ0-ρ。图5所示为相变引起的电阻率变化量Δρ与温度的变化曲线。由图5可知,Δρ随着温度的降低持续增加,相变结束后Δρ不再发生变化。

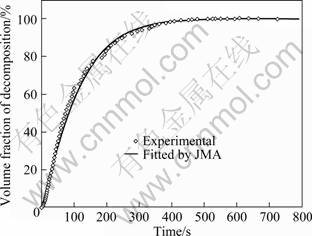

由式(1)可知,合金的电阻率与其析出相间距的平方根成反比,当析出相间距大于100 nm时,析出相对电阻率的影响则可以忽略[7]。经500 ℃,1 h固溶处理后,以0.033 ℃/s冷却实验材料,固溶体发生脱溶,结合图2的组织观察结果,析出相间距远大于100 nm,因此,析出的第二相对电阻率的影响很小,固溶度减小是引起Δρ变化的主要原因。设固溶体脱溶完成时,引起电阻率的最大变化量为Δρmax,则固溶体脱溶的相对质量分数变化可用Δρ/Δρmax表示,参比连续冷却过程的冷却曲线,可以得到固溶体脱溶量随时间的变化曲线,如图6所示。

图5 相变引起的电阻率变化量与温度的关系

Fig.5 Relationship between electric resistivity caused by phase transition and temperature

图6 实验合金以0.033 ℃/s冷却时固溶体脱溶的动力学 曲线

Fig.6 Decomposition kinetic curve of tested alloy at cooling rate of 0.033 ℃/s

在连续冷却过程中,新相的形核率和长大速率独立地随温度而变化,因此,非等温转变的相变分析较等温转变困难得多。对于较慢速率的连续冷却过程,合金的相转变量与温度、时间的关系满足式(2)所示的JMA方程[15]。

(2)

(2)

式中:n为Avrami常数,与相变类型有关;K(T)为依赖于温度的相变速率常数,如式(3)所示。

(3)

(3)

式中:K0为频率常数;E为相变激活能;R为摩尔气体常数;T为相变温度,对于等温相变过程,K(T)为常数。由图6可知,与等温转变的规律相似,JMA方程与实验结果吻合较好,表明JMA方程可以较好地描述实验材料以较慢速率冷却的相变动力学过程。对实验结果进行拟合,得到固溶体脱溶体积分数

,其中Avrami常数

,其中Avrami常数

n=1.16,对于铝合金过饱和固溶体的脱溶过程,n为1.0~1.5可用于描述转变初期的形核以及针片状析出相的增厚过程[16],这与之前的组织观察吻合较好。对于很慢的冷速条件,连续冷却过程可以视作多个短时等温相转变的叠加,而每一个短时等温过程都符合JMA关系,因此可以用JMA方程描述实验合金慢速连续冷却过程的动力学行为。在较快的冷却速率下,溶质原子来不及扩散,固溶体脱溶量减少,过饱和程度提高,相变驱动力增大,析出相的类型、体积分数、间距都可能与慢速冷却时的情况不一样,有待进一步探讨。此外,连续冷却过程中固溶体和析出相如何影响相对电阻值、不同冷却速率下析出相(GP区、亚稳相) 如何影响电阻值等问题也有待深入探讨。

3 结论

1) 根据原位测量的电阻率—温度曲线,得到以不同速率连续冷却2A12铝合金的相变开始点和结束点,确定了实验合金的临界淬火速率范围,建立了2A12合金的CCT图,结合组织观察,验证了原位电阻法获取相变信息的有效性。

2) 在500 ℃固溶1 h后以不同速率连续冷却实验合金,相变开始温度先随着冷却速率的加快降低,冷却速率增加到一定程度时发生激增,随后随着冷却速率的增加而降低,相变主要在220~400 ℃之间,抑制相变发生的临界淬火速率大于38 ℃/s。

3) 以较慢的速率连续冷却实验合金时,固溶度降低是引起电阻率变化的主要原因,固溶体脱溶的动力学行为与等温相变规律相似,可用JMA方程较好地描述。

REFERENCES

[1] SHANG B C,YIN Z M,WANG G,LIU B,HUANG Z Q. Investigation of quench sensitivity and transformation kinetics during isothermal treatment in 6082 aluminum alloy[J]. Materials & Design, 2011, 32(7):3818-3822.

[2] 贺永东, 张新明, 游江海, 叶凌英, 刘文辉. 淬火无析出区Al-Zn-Mg-Cu合金断裂行为的影响[J]. 中国有色金属学报, 2006, 16(3): 392-399.

HE Yong-dong, ZHANG Xin-ming, YOU Jiang-hai, YE Ling-ying, LIU Wen-hui. Effect of precipitate free zone quench-induced on fracture behaviour of Al-Zn-Mg-Cu alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 392-399.

[3] LIU S D, ZHONG Q M, ZHANG Y, LIU W J, ZHANG X M, DENG Y L. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams[J]. Materials and Design, 2010, 31: 3116-3120.

[4] GUO J, ZU F, CHEN Z, ZHENG S, YUAN Y. Exploration of a new method in determining the glass transition temperature of BMGs by electrical resistivity[J]. Solid State Communications, 2005, 135(1/2): 103-107.

[5] FURLANI A M, STIPCICH M, ROMERO R. Phase decomposition in a β Cu-Zn-Al-Ti-B shape memory alloy[J]. Materials Science and Engineering A, 2005, 392(1/2): 386-393.

[6] MATSUMOTO H. Irreversibility in transformation behavior of equiatomic nickel–titanium alloy by electrical resistivity measurement [J]. Alloys and compounds Design, 2004, 368(1/2): 182-186.

[7] RAEISINIA B, POOLE W J, LLOYD D J. Examination of precipitation in the aluminum alloy AA6111 using electrical resistivity measurements[J]. Materials Science and Engineering A, 2006, 420(1/2): 245-249.

[8] 袁生平, 蒲 雄, 张国君, 刘 刚, 王瑞红, 孙 军, 陈康华. 多重时效析出第二相对Al-Mg-Si 合金电导率的影响[J]. 中国有色金属学报, 2010, 20(11): 2070-2074.

YUAN Sheng-ping, PU Xiong, ZHANG Guo-jun, LIU Gang, WANG Rui-hong, SUN Jun, CHEN Kang-hua. Effects of multiple precipitates on electrical conductivity of aged Al-Mg-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2070-2074.

[9] HOSSEIN S, DMITRIJ G, PETER M, HATEM S Z. Study of the early stages of clustering in Al-Mg-Si alloys using the electrical resistivity measurements[J]. Materials Science and Engineering A, 2009, 525(1/2): 186-191.

[10] ESMAEILI S, LLOYD D J, POOLE W J. Modeling ofprecipitation hardening for the naturally aged Al-Mg-Si-Cu alloy AA6111[J]. Acta Materialia, 2003, 51(12): 3467-3481.

[11] 李红英, 唐 宜, 曾再得, 王法云, 孙 远. Al-Zn-Mg-Cu连续冷却曲线的测量[J]. 中国有色金属学报, 2008, 18(9): 1613-1621.

LI Hong-ying, TANG Yi, ZENG Zai-de, WANG Fa-yun, SUN Yuan. Testing of continuous cooling transformation curve of Al-Zn-Mg-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1613-1621.

[12] 李红英, 王晓峰, 唐 宜, 邓云吉, 黄 愉, 孙 远, 王法云. 7A04铝合金连续冷却转变曲线的测定[J]. 中国有色金属学报, 2010, 20(4): 640-646.

LI Hong-Ying, WANG Xiao-feng, TANG Yi, DENG Yun-ji, HUANG Yu, WANG Fa-yun. Measurement of continuous cooling transformation curves of 7A04 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 640-646.

[13] 李红英, 赵延阔, 唐 宜, 王晓峰. 6082铝合金CCT图的测定及应用[J]. 金属学报, 2010, 46(10): 1237-1243.

LI Hong-ying, ZHAO Yan-kuo, TANG Yi, WANG Xiao-feng. Determination and application of CCT diagram for 6082 aluminum alloy[J]. Acta Metallurgica Sinica, 2010, 46(10): 1237-1243.

[14] MILKEREIT B, KESSLER O, SCHICK C. Recording of continuous cooling precipitation diagrams of aluminium alloys[J].Thermochimica Acta, 2009, 492(1/2): 73-78.

[15] KEMPEN A T W, SOMMER F, MITTEMEIJER E J. Determination and interpretation of isothermal and non-isothermal transformation kinetics: The effective activation energies in terms of nucleation and growth[J]. Journal of Materials Science, 2002, 37: 1321-1332.

[16] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 401.

ZHENG Zi-qiao. Fundamentals of material science[M]. Changsha: Central South University Press, 2005:401.

(编辑 龙怀中)

收稿日期:2011-04-18;修订日期:2011-06-22

通信作者:李红英,教授,博士;电话: 0731-88836328;E-mail: lhying@mail.csu.edu.cn