文章编号:1004-0609(2007)01-0111-07

往复挤压Mg-4Al-2Si镁合金的组织细化与力学性能

宋佩维1, 2,井晓天1,郭学锋1

(1. 西安理工大学 材料科学与工程学院, 西安710048;

2. 陕西理工学院 机械工程学院, 汉中723003)

摘 要:研究往复挤压变形对Mg-4Al-2Si合金组织和性能的影响性能,探讨基体组织和Mg2Si颗粒相的细化效果与细化机制,分析Mg2Si颗粒对再结晶的影响规律。结果表明:挤压过程中发生受位错攀移控制的动态再结 晶,通过晶界迁移、亚晶合并与转动机制形成细小的α(Mg)再结晶等轴晶;随着往复挤压道次的增加,动态再结晶速度加快,晶粒尺寸迅速减小;α(Mg)与Mg2Si的晶粒尺寸在铸态下分别为45和60 ?m,往复挤压6道次后,晶粒尺寸减小到3和1 ?m,形成了细小、均匀的α(Mg)等轴晶组织,Mg2Si颗粒呈细小、弥散分布;合金的力学性能随往复挤压道次的增加而显著提高。

关键词:Mg-4Al-2Si镁合金;往复挤压;动态再结晶;力学性能

中图分类号:TG 376.2 文献标识码:A

Structure refinement and mechanical properties of Mg-4Al-2Si Mg alloy by reciprocating extrusion

SONG Pei-wei1, 2, JING Xiao-tian1, GUO Xue-feng1

(1. School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China;

2. School of Mechanical Engineering, Shanxi University of Technology, Hanzhong 723003, China)

Abstract: The effects of reciprocating extrusion deformation on microstructures and properties of Mg-4Al-2Si alloys were studied, and the mechanisms of grain refinement of α(Mg) and Mg2Si particles, as well as the effect of Mg2Si particles on the recrystallization were investigated. The results show that dynamic recrystallization controlled by dislocation climbing takes place during the reciprocating extrusion process. The equiaxed grains are formed by crystal boundary migration, subgrain merge and twist rotation by recrystallization. The grain size decreases and the rate of dynamic recrystallization increases with increasing passes of reciprocating extrusion. The grain sizes of as-cast α(Mg) and Mg2Si particles decrease from 45 and 60 ?m to 3 and 1 ?m after 6 passes of reciprocating extrusion, respectively. Tthe microstructures are characterized by the fine equiaxed α(Mg) grain with homogeneous distribution of fine Mg2Si particles. The mechanical properties of alloys are improved obviously with increasing reciprocating extrusion passes.

Key words: Mg-4Al-2Si Mg alloy; reciprocating extrusion; dynamic recrystallization; mechanical properties

镁合金具有较高的比强度、比刚度和尺寸稳定 性,良好的减震性和易回收等优点,被誉为“21世纪绿色工程金属结构材料”,在汽车、航空航天等领域有着广阔的应用前景[1-2]。Mg-Al系是当前应用最广泛的镁合金,如AZ91D(Mg-9Al-0. 8Zn)合金具有优良的铸造性能、较高的室温强度和良好的抗腐蚀性能及成本较低等优点,但其高温力学性能差,长期使用温度不能超过120 ℃。因其沉淀强化相Mg17Al12的热稳定性较低(熔点437 ℃),在从室温加热到200 ℃时, Mg17Al12相的硬度便减少50%~60%[3]。

Mg-Al-Si合金是20世纪70年代德国大众汽车公司开发的压铸镁合金。170 ℃时,AS41的蠕变强度比AZ91和AM60好,它具有良好的伸长率、屈服强度和抗拉强度,应用于汽车发动机的变速箱、电动机架等。这种合金具有良好高温性能的主要原因是由于在晶界处形成细小弥散分布的稳定析出相Mg2Si[4],它具有高熔点(1 085 ℃)、与基体相近的低密度(1.9 g/cm3)、高弹性模量[5]等特点。然而,这种合金只能压铸,不能进行砂型或金属型铸造。因为在较慢的冷却速度下,脆性Mg2Si相呈粗大的汉字状,极大地降低了材料的伸长率和抗拉强度,恶化其力学性能[6]。

可见,细化组织对提高力学性能具有十分重要的意义。采用微合金化或快速凝固技术细化组织,尤其是细化Mg2Si相是目前研究较多的一个方面。在砂型铸造时,袁广银等[6-8]通过在Mg-Al-Zn-Si合金中加入0.5%Sb或0.2%Ca,形成Mg3Sb2或CaSi2相作为非均质形核核心,细化了基体组织和粗大的Mg2Si 相颗粒,提高其力学性能。但Carbonneau等[5]发现,在含量为0.18% Ca的组织中出现另外一针状正交晶体结构的MgCaSi相, 损害了合金的强度和韧性。黄晓锋等[9]在Mg-5Al-1Si 中添加微量Nd后,形成了棒条状Al11Nd3相,细化了Mg2Si相和基体组织,大大提高了合金的室温与高温性能。采用快速凝固法制备Mg-Al-Zn-Si合金[10],也使基体组织得到细化,Mg2Si相颗粒呈细小弥散状分布,提高了合金的力学性能。此外,还有采用机械合金化、热挤压等方法细化含Si镁合金。尽管上述方法在细化组织、提高性能方面取得了效果,但也存在不足。如合金化会使材料的抗腐蚀性能下降,快速凝固在制备大体积块材方面有很大的困难等。往复挤压是一种新的晶粒细化方法,材料在进行正挤压的同时又受到镦粗变形。挤压前后试样的形状保持不变,可往复多次挤压变形,产生大的累积应变,同时发生动态再结晶,获得超细的等轴晶组织,使材料具有优异的力学性能[11-12]。采用往复挤压工艺,Yeh等[11]对Al–20%Si(质量分数)合金、Chu等[13-14]对含Al4C3的复合材料以及陆文林等[12]对Zn-Al合金进行研究,取得了较好的效果,但未对组织细化机制进行深入研究。

采用往复挤压工艺对Mg-Al-Si合金的组织进行细化、尤其是细化粗大的脆性Mg2Si相颗粒,这方面的研究目前还未见报道。本文作者研究了Mg-4Al-2Si合金经过不同道次往复挤压后组织与性能的变化规律,重点探讨了往复挤压工艺对组织细化的影响规律。

1 实验

1.1 铸态试样制备

研究所用Mg-4Al-2Si合金的名义成分为Al 4.0,Si 2.0,余量Mg。该合金中Si是以自制的Al-Si中间合金形式加入。合金在SG2-5-10型井式坩埚炉中采用工业专用保护剂进行熔炼。当熔体温度达到740 ℃时加入中间合金,用石墨棒搅拌熔体约3 min,然后保温10 min使中间合金充分溶解,使Al、Si 的含量达到设计要求。再经过精炼后于720 ℃下保温20 min浇注到石墨模中,铸成d50 mm×120 mm的铸锭。对铸锭进行420 ℃保温12 h的均匀化处理。

1.2 往复挤压铸态试样

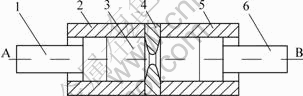

在3 150 kN液压机上,使用专用模具对铸态试样进行往复挤压。图1所示为往复挤压机构示意图。将试样3 装入挤压桶内,在350 ℃、4 MPa下进行预挤压,使试样充满型腔,然后再升温进行正式挤压。挤压温度为380 ℃,压力为8 MPa, 挤压比为12.7?1,挤压速度为1.2 mm /min。施加压力使两顶杆A、B以相同速度向同一方向运动,挤压桶静止不动。当试件3被完全压入桶5内时挤压停止,这时就完成了一次挤压。在此挤压过程中,试样在桶2内受到了正挤压变形,而在桶5内受到了镦粗变形[12]。

图1 往复挤压结构示意图

Fig.1 Schematic diagram of reciprocating extrusion apparatus: 1 Ram A; 2 Container A; 3 Billet; 4 Neck die; 5 Container B;6 Ram B

然后杆A、B再以相同速度同时反向运动,完成第二次挤压。如此反复进行挤压,使材料的组织得到细化。最后去掉一端的顶杆(如杆A),挤出试件。

1.3 组织与性能检验

试样浸蚀剂为60 mL乙醇+20 mL醋酸+19mL H2O+1 mL HNO3;显微组织观察在Olympus 光学显微镜上进行;硬度检验在HV-120维氏硬度计上进行;拉伸实验采用d6 mm×30 mm标准短试样在WDW3100电子万能拉伸机上进行;用JSM-6700F型扫描电镜观察断口形貌。

2 结果与讨论

2.1 显微组织细化

2.1.1 Mg2Si相颗粒细化

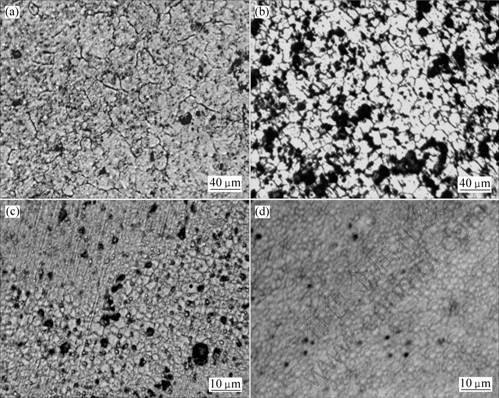

图2所示为Mg-4Al-2Si合金中Mg2Si相在往复挤压过程中组织细化的情况。可见,铸态下汉字状共晶Mg2Si与初生多边形块状Mg2Si颗粒比较粗大,最大尺寸约60 ?m, 如图2(a);随挤压道次的增加,粗大的Mg2Si颗粒逐渐变得细小,见图2(b)~(d)。当挤压道次为2时,汉字状共晶Mg2Si已被细化,同时粗大的初生多边形块状Mg2Si颗粒得到初步破碎,但分布不均匀,如图2(b)。当挤压道次为4时,已被细化的共晶Mg2Si颗粒更加细小;多边形块状Mg2Si颗粒也得到显著细化,分布趋于均匀,如图2(c)。挤压道次为6时,共晶Mg2Si颗粒已非常细小,分布十分均匀;多边形块状Mg2Si颗粒也呈细小、弥散分布,颗粒平均尺寸约为1 ?m,如图2(d)所示。

图2 往复挤压过程中Mg-4Al-2Si合金中Mg2Si相的显微组织变化

Fig.2 Variation of microstructures of Mg2Si in Mg-4Al-2Si alloys during reciprocating extrusion: (a) As-cast; (b) 2 passes; (c) 4 passes; (d) 6 passes

2.1.2 基体组织细化

图3示出了α(Mg) 基体组织在往复挤压过程中的变化。均匀化处理后铸态的晶粒比较粗大,晶粒的平均尺寸在45 ?m左右,如图3(a)所示。随着往复挤压道次的增加,动态再结晶晶粒尺寸逐渐减小,如图3(b)~(d)所示。往复挤压2道次后,基体组织被细化到10 ?m左右,如图3(b)所示,但组织的均匀性和等轴性较差;往复挤压4道次后,等轴晶的尺寸变得更小,约为6 ?m,组织的均匀性和等轴性大幅提高,如图3(c)所示;往复挤压6道次后,得到了非常细小、均匀分布的等轴晶组织,晶粒尺寸约为3 ?m,如图3(d)所示。

图3 α(Mg)基体组织在往复挤压过程中的变化

Fig.3 Variation of microstructures of α(Mg) phase during reciprocating extrusion: (a) As-cast; (b) 2 passes; (c) 4 passes;(d) 6 passes

2.1.3 组织演变与细化机制

往复挤压的实质是多次的拔长、镦粗变形。在不断的拔镦过程中,块状Mg2Si和汉字状Mg2Si不断地变形、破碎、细化,并趋向于均匀、弥散分布;同时基体组织也随累积应变量的持续增加,而经历了多次的动态再结晶,逐渐转变为均匀、细小的等轴晶;均匀、弥散分布的第二相既促进了基体再结晶的形核,又有效抑制了再结晶晶粒的异常长大。

从动力学分析,由于Mg的层错能较低, 其扩展位错很宽,位错难以从位错网中解脱出来,也难以通过交滑移和攀移而相互抵消;此时,变形开始阶段形成的亚组织中位错密度很高,且亚晶尺寸很小,胞壁中有较多位错缠结,在一定的应力和变形温度下,当材料在变形中储存能积累到足够高时,就会导致动态再结晶的发生。

金属再结晶过程分为形核和长大两个阶段。在高温时(300~450 ℃),镁合金的塑性变形激活能与晶内自扩散激活能相当,此时位错攀移成为塑性变形的控制机制。新晶粒主要通过原始晶粒晶界的迁移来形核。发生晶界迁移时,晶界所扫过的区域位错实现重排并形成小角度晶界,这些小角度晶界可通过不断吸收新的位错而转变成大角度晶界[15]。即在挤压应力的作用下, 首先沿晶界形成亚晶结构, 进而通过亚晶合并机制形成较大尺寸的大角度亚晶;随后,通过晶界迁移、亚晶进一步合并和转动, 发生动态再结晶,最终形成细小的大角度晶粒。

在往复挤压Mg-4Al-2Si合金过程中,随挤压道次的增加,累积应变量增大,晶内位错密度进一步增加、晶格畸变加剧,再结晶速度加快,从而使新晶粒形核数目增多,新晶粒所占体积分数增大,使晶粒得到明显细化,形成更加细小的再结晶等轴晶;同时,Mg2Si第二相颗粒也得到充分细化和均布。而且,Mg2Si第二相颗粒对动态再结晶也产生了很大的影响。关于第二相颗粒对动态再结晶的影响,ZHANG等[16]在Mg-Zn-Y-Zr合金研究中发现,在300 ℃ 挤压时,合金中并未发生动态再结晶,原因是第二相颗粒密集分布,钉扎潜在动态再结晶晶粒的晶界,提高了动态再结晶的温度。粗大的脆性第二相(W相)在300 ℃和 350 ℃挤压时难以破碎,在400 ℃时才破碎成细颗粒。此时动态再结晶得以充分进行,许多动态再结晶晶粒在第二相周围形成,而且沿扭曲的晶界、孪晶界及位错线生长,形成了细小(平均尺寸为2 ?m)、均布的动态再结晶晶粒。同时,由于细小第二相颗粒的钉扎作用,使动态再结晶颗粒的生长受到抑制,在400 ℃高温下也几乎未有反常的晶粒生长。

由上述结果可知,在往复挤压Mg-4Al-2Si合金过程中,铸态下粗大密集的Mg2Si相颗粒(尺寸约60 ?m,见图2(a))在塑性变形过程中由于对潜在动态再结晶晶粒晶界的钉扎,使合金发生动态再结晶的温度升高,阻碍动态再结晶过程的进行。随往复挤压到道次的增加,Mg2Si 颗粒由部分细化逐渐变为全部细化并均匀分布(最终尺寸约1 ?m,见图2(d));同时,基体组织也发生多次动态再结晶而充分细化,见图3(b)~(d)。其中部分动态再结晶的晶粒产生于细小的Mg2Si 颗粒周围。这时的Mg2Si 颗粒促进了动态再结晶过程的进行;同时细小的Mg2Si 颗粒还能有效抑制再结晶晶粒的异常长大。

与传统的正向挤压相比,往复挤压又有其独特之处。往复挤压集挤压与镦粗于一体,挤压前后试样的形状不发生变化,通过多道次的往复挤压,累积大的应力与应变,使合金的组织得到细化,从而在试样的纵、横截面上均可获得细小的再结晶等轴晶组织,力学性能表现出各向同性[12]。而正向挤压变形的基本特征是形成了挤压平行流线和沿挤压方向的再结晶等轴晶组织[17],往往表显出各向异性。显然,往复挤压在细化组织、提高性能方面更具优势。

2.2 力学性能

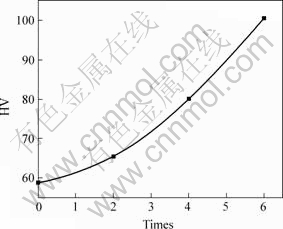

图4所示为合金硬度与挤压道次的关系曲线;图5所示为合金力学性能与挤压道次的关系曲线。

图4 Mg-4Al-2Si合金硬度与挤压道次的关系

Fig.4 Relationship between hardness of Mg-4Al-2Si alloy and reciprocating extrusion times

图5 Mg-4Al-2Si合金力学性能与挤压道次的关系

Fig.5 Relationship between mechanical properties of Mg- 4Al-2Si alloy and reciprocating extrusion times

由图4可见,随挤压道次的增加,合金硬度不断提高。原因在于基体晶粒和第二相颗粒越来越细小,位错密度越来越大,从而导致合金硬度的升高。由图5可见,随挤压道次的增加,合金的抗拉强度、屈服强度和伸长率不断提高。从铸态到挤压2道次时,合金的抗拉强度σb从铸态的113 MPa提高到挤压态的210 MPa,屈服强度σ0. 2从铸态的86 MPa提高到挤压态的171 MPa;当挤压道次从2增加到4时,σb 的增幅趋于减小,σ0. 2 的增幅更小;当挤压道次增加到6时,σb达到271 MPa,σ0. 2 达到264 MPa,此时,伸长率δ5从铸态的4.1% 提高到挤压态的14.6%。与铸态相比,σb、σ0. 2和δ5分别提高了140%、207%和256%。优于AS41的力学性能(σb=240 MPa,σ0. 2=140 MPa,δ5=8%)。

往复挤压后合金的抗拉强度、屈服强度和伸长率的大幅度提高,得益于基体组织和第二相的双重细化所产生的细晶强化和弥散强化作用。根据Hall-Petch关系式:σs=σb+kd-1/2可知,晶粒越细,屈服强度就越高;细小的晶粒也可提高合金的塑性。这与本实验结果一致。

第二相颗粒对材料力学性能的影响也至关重 要。在Mg-4Al-2Si合金中,Mg2Si相的性质、形状、大小、数量和分布对合金的力学性能起到了重要的作 用[6]。铸态合金中,粗大的脆性Mg2Si相在塑性变形过程中易产生应力集中,在应力作用下,微裂纹沿Mg2Si相与基体的界面处扩展,从而导致合金的力学性能骤然降低[6]。经过多道次的往复挤压后,Mg2Si相呈细 小、弥散形式均匀分布于基体组织中,产生了弥散强化作用。

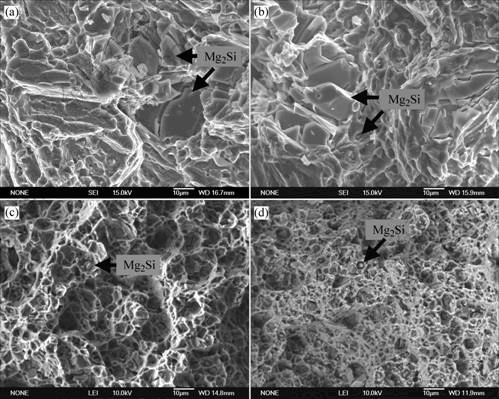

2.3 断口形貌

图6所示为Mg-4Al-2Si合金在不同状态下的室温拉伸断口SEM形貌。可见,铸态时Mg2Si相颗粒非常粗大,结合图3(a)可知基体组织的晶粒也很粗大,断口上有河流花样和解理台阶,如图6(a)所示,力学性能很差;经过2道次的往复挤压后,多边形块状Mg2Si相颗粒得到了初步细化,汉字状Mg2Si也已经较细 小,基体组织迅速细化,如图2(b)和3(b)所示,这时的断口形貌为准解理脆性断裂,如图6(b)所示;经过4道次的往复挤压后,基体组织细化程度进一步提高,Mg2Si相颗粒呈细小、弥散分布,断口韧窝比较小、密度大,Mg2Si颗粒存在于韧窝底部,为韧性断裂,如图6(c)所示;经过6道次的往复挤压后,基体组织更加细密,Mg2Si相颗粒呈非常细小、弥散状分布于基体组织中,断口韧窝也更加细小、密度非常大,细小的Mg2Si颗粒存在于韧窝底部,为韧性断 裂,如图6(d)所示。这时的力学性能也得到进一步的提高,如图4和5所示。

图6 不同状态Mg-4Al-2Si合金试样的拉伸断口SEM形貌

Fig.6 SEM images of Mg-4Al-2Si alloys at different states: (a) As-cast; (b) 2 passes; (c) 4 passes; (d) 6 passes

3 结论

1) 往复挤挤压过程中发生了受位错攀移控制的动态再结晶,形成了细小的α(Mg)再结晶等轴晶和 细小均布的Mg2Si颗粒相。随着往复挤压道次的增加,动态再结晶速度加快,晶粒尺寸迅速减小。

2) 往复挤压可显著细化Mg-4Al-2Si合金的组织。随挤压道次的增加,α(Mg)基体组织与Mg2Si相组织均被细化,α(Mg)基体再结晶晶粒的均匀性与等轴性不断提高。α(Mg)与Mg2Si的晶粒尺寸在铸态下分别为45和60 ?m,往复挤压6道次后,晶粒尺寸分别减小到3和1 ?m。形成了非常细小、均匀的再结晶等轴晶组织,Mg2Si相呈细小、弥散形式分布于基体组织中。

3) 往复挤压可使Mg-4Al-2Si合金的硬度、抗拉强度、屈服强度和伸长率迅速提高。合金力学性能提高的主要原因在于基体组织的细晶强化和Mg2Si相的弥散强化作用。

4) 合金室温拉伸的断裂形式随往复挤压道次的增加而发生变化。铸态和往复挤压2道次时合金的拉伸断裂形式为解理和准解理脆性断裂;往复挤压4道次和6道次时,合金拉伸断裂形式为微孔聚合型韧性断裂。

REFERENCES

[1] Friedrich H, Schumann S. Research for a “new age of Magnesium” in the automotive industry[J]. J Mater Process Tech, 2001, 117: 276-281.

[2] Aghion E, Bronfin B, Eliezer D. The role of the magnesium industry in protecting the environment[J]. J Mater Process Tech, 2001, 117: 381-385.

[3] 袁广银, 孙扬善. Bi 对铸造镁合金组织和力学性能的影响[J]. 铸造, 1998(5): 5-7.

YUAN Guang-yin, SUN Yang-shan. Effect of bismuth on microstructure and machanical properties of cast magnesium alloy[J]. Foundry, 1998(5): 5-7.

[4] Humble P. Towards a cheap resistant magnesium alloy[J]. Materaials Forum, 1997, 21: 4556-4562.

[5] Carbonneau Y, Couture A, Van Neste A. Communications the observation of a new ternary MgSiCa phase in Mg2Si alloys[J]. Metall Mater Trans A, 1998, A29(6): 1759-1763.

[6] 袁广银, 刘满平, 王渠东, 朱燕萍, 丁文江. Mg-Al-Zn-Si合金的显微组织细化[J]. 金属学报, 2002, 38(10): 1105-1108.

YUAN Guang-yin, LIU Man-ping, WANG Qu-dong, ZHU Yan-ping, DING Wen-jiang. Microstructure refinement of Mg-Al-Zn-Si alloys[J]. Acta Metallurgica Sinica, 2002, 38(10): 1105-1108.

[7] YUAN G Y, LIU Z, WANG Q D, ZHU Y P, DING W J. Microstructure refinement of Mg-Al-Zn-Si alloy[J]. Materials Letters, 2002, 56: 53-58.

[8] YUAN Guang-yin, LIU Man-ping, DING Wen-jiang, Akihisa I. Microstructure and mechanical properties of Mg-Zn- Si-based alloys[J]. Mater Sci Eng A, 2003, A357: 314-320.

[9] 黄晓锋, 王渠东, 曾小勤, 朱燕萍, 卢 晨, 丁文江. 钕对Mg-5Al-1Si高温蠕变及组织性能的影响[J]. 中国稀土学报, 2004, 22(3): 361-364.

HUANG Xiao-feng, WANG Qu-dong, ZENG Xiao-qin, ZHU Yan-ping, LU Chen, DING Wen-jiang. Effect of neodymium on microstructure and high temperature creep properties of Mg-5Al-1Si magnesium alloy[J]. Journal of the Rare Earth Society, 2004, 22(3): 361-364.

[10] Mabuchi M, Higashj K. Strengthening mechanisms of Mg-Si alloys[J]. Acta Mater, 1996, 44(11): 4611-4618.

[11] Yeh J W, Yuan S Y, Peng C H. A reciprocating extrusion process for producing hypereutectic Al–20wt.% Si wrought alloys[J]. Mater Sci Eng A, 1998, A252: 212-221.

[12] 陆文林, 王 勇, 冯泽舟, 海锦涛. 采用沙漏挤压工艺制备超细晶材料[J]. 热加工工艺, 2001, 2: 10-12.

LU Wen-lin, WANG Yong, FENG Ze-zhou, HAI Jing-tao. Production of the ultrafine-grained materials by sand glass extrusion process[J]. Hot Working Technology, 2001, 2: 10-12.

[13] Chu H S, Liu K S, Yeh J W. An in situ composite of Al (graphite, Al4C3) produced by reciprocating extrusion[J]. Mater Sci Eng A, 2000, A277: 25-32.

[14] Chu H S, Liu K S, Yeh J W. Aging behavior and tensile properties of 6061Al-0.3 μm Al2O3p particle composites produced by reciprocating extrusion[J]. Scripta Material, 2001, 45: 541-546.

[15] Galiyv A, Kaiby R, Gottstein G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

[16] ZHANG Ya, ZENG Xiao-qin, LIU Liu-fa, CHEN Lu, ZHOU Han-tao, LI Qiang, ZHU Yan-ping. Effects of yttrium on microstructure and mechanical properties of hot-extrusion Mg-Zn-Y-Zr alloys[J]. Mater Sci Eng A, 2004, A373: 320-327.

[17] 于 翔, 丁培道, 彭 健, 杨春楣. 挤压变形对MB15 镁合金及组织性能的影响[J]. 金属成形工艺, 2004, 22(1): 41-45.

YU Xiang, DING Pei-dao, PENG Jian, YANG Chun-mei. Research on the extrusion and properties of MB15 magnesium alloy[J]. Metal Forming Technology, 2004, 22(l): 41-45.

基金项目:国家自然科学基金资助项目(50271054); 陕西省自然科学基金资助项目(2002E110); 凝固技术国家重点实验室基金资助项目(200301)

收稿日期:2006-03-16;修订日期:2006-11-28

通讯作者:宋佩维, 高级工程师, 博士研究生; 电话: 13891825600; E-mail: spwsyh@yahoo.com.cn

(编辑 龙怀中)