文章编号:1004-0609(2007)04-560-07

电沉积法制备CuInSe2薄膜的组成与形貌

张治安,刘芳洋,吕 莹,赖延清,李 劼,刘业翔

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:采用电沉积法制备了CuInSe2薄膜材料,研究了制备工艺条件对材料组成、结构与性能的影响。研究结果表明:最佳的沉积电位范围为-0.6~-0.8 V(vs SCE);硒化退火是获得高质量CuInSe2薄膜的必要过程,硒化退火温度应控制在440~610 ℃范围内;在不同沉积电位和不同电解质浓度组成溶液中,通过电沉积并在500 ℃下硒化退火均可获得黄铜矿结构CuInSe2多晶薄膜;沉积电位的负移会使膜层中CuInSe2的相对含量增加,晶型完善,且杂相减少;随着电解质浓度的增加,电沉积CuInSe2退火后结晶程度变好,颗粒变得粗壮,致密性也有所改善;电沉积并硒化退火后薄膜中的铜铟摩尔比受沉积电位和电解质浓度影响较大,当沉积电位为-0.7和-0.8 V时,铜铟摩尔比约为1较为理想,且铜铟摩尔比的变化与电解液中CuCl2和InCl3的摩尔比变化一致。

关键词:CuInSe2(CIS);太阳电池; 薄膜; 电沉积;硒化退火

中图分类号:TM 914 文献标识码:A

Composition and morphology of CuInSe2 thin films by electrodeposition

ZHANG Zhi-an, LIU Fang-yang, L? Ying, LAI Yan-qing, LI Jie, LIU Ye-xiang

((School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: CuInSe2 thin films were obtained by electrodeposition, and the preparation conditions and their effect on performance of CuInSe2 films were investigated. The results show that the optimum ranges of potentials for electrodeposition and annealing temperature are about -0.6--0.8 V(vs SCE) and 440-610 ℃, respectively. Annealing is a necessary step for getting high-quality CuInSe2 thin films. CuInSe2 thin films can be prepared at different deposition potentials and electrolyte concentrations. As the potential moves to negative, the concentration of CuInSe2 increases, crystallinity and uniformity become better, and impurity phase decreases. The crystallinity and density improve, and the grains grow bulkier as the concentration of electrolyte increases. In all electrodeposited CuInSe2 thin films, the potential and electrolyte concentration can influence the mole ratio of Cu to In greatly. At the potentials of -0.7 and -0.8 V(vs SCE), the mole ratio of Cu to In is very reasonable at about 1. The change of mole ratio of Cu to In has the same trend as that of CuCl2 to InCl3 in electrolyte.

Key words: CuInSe2(CIS); solar cells; thin film; electrodeposition; selenized annealing

CuInSe2(CIS)薄膜太阳电池已成为最重要和最具发展前景的太阳电池之一[1-3]。CuInSe2薄膜是直接能隙半导体材料,能隙为1.05 eV,而且可以通过掺杂Ga形成Cu(In,Ga)Se2(CIGS)使能隙宽度在1.05~1.67 eV内连续调整,适合于太阳光的光电转换要求;它具有较高光吸收系数(达105),且性能稳定,不存在光衰效应(S-W效应),因此受到光伏界广泛关注[4-6]。

CuInSe2薄膜的制备方法很多,包括真空蒸镀[7]、电沉积[8]、溅射[9]、化学浴沉积[10]、金属有机物化学气相沉积[11]、分子束外延[12]、喷射热解[13]、封闭空间气相输运法(CsCVT)[14]等。其中美国NREL采用真空蒸镀法制备的CIS和CIGS太阳电池光电转换效率最高,分别达15.0%和19.5% [15]。我国CIS电池研究起步较晚,虽受条件限制,但也取得了一定的进展。南开大学孙云等[1, 16]利用蒸发硒化法制备的CIS薄膜电池效率目前达到9.13%,利用三步共蒸发法制备的CIGS太阳电池效率达到12.1%。在各种CIS制备方法中,溅射、真空蒸镀等物理气相沉积法(PVD)需要昂贵的真空设备和复杂的制备工艺,限制了该类方法的大规模应用。电沉积法由于具有非真空、廉价、简便、高效等优点,得到了广泛研究,并成为一种极具发展潜力和竞争力的CIS薄膜制备方法[17-20]。

目前采用电沉积法制备CuInSe2薄膜主要存在成分偏离理想化学计量比严重、膜层质量较PVD法差等问题,这使得基于电沉积的CIS或CIGS薄膜太阳电池效率较低,阻碍了该电沉积法的推广和应用。针对这些问题,本文作者以采用电沉积法制备太阳电池用黄铜矿结构CuInSe2薄膜为目标,在确定合适的沉积电位范围和硒化退火温度的基础上,研究了沉积电位和电解质浓度对薄膜的物相组成、组织形貌与化学成分的影响规律,以探求高质量的太阳电池用CuInSe2薄膜的制备工艺,推动促进电沉积制备CuInSe2薄膜的大规模应用。

1 实验

1.1 电沉积工艺

实验系统采用三电极体系,以金属钼为基底(d 8 mm)电沉积制备薄膜。参比电极为饱和甘汞电极(SCE),对电极为大面积Pt片电极;由 PRINCETON APPLIED RESEARCH Potentiostat/Galvanostat Model 273A提供恒电位;电解液组分为:5~10 mmol/L CuCl2,100 mmol/L InCl3,10~20 mmol/L SeO2,500 mmol/L KCl(支持电解质),500 mmol/L 柠檬酸钠(络合剂和缓冲剂)。用浓盐酸调整pH值为1.50±0.01,无搅拌电沉积。通过线性电位扫描分析,确定沉积电位范围。其他条件为:25 ℃,常压,电沉积时间60 min。

1.2 硒化退火工艺

适当的热处理可以改善CIS薄膜的结晶度和组分均匀性,减少缺陷,对薄膜的各种性能有较大的影响。本研究采用硒化退火的方式对电沉积制备的薄膜样品进行退火处理。

将电沉积制备的样品进行热分析,确定合适的退火温度。然后将样品放入管式炉中,在合适的退火温度下和氩气保护气氛中退火1 h,以形成黄铜矿结构CuInSe2多晶薄膜并改善结晶程度和化学计量比。为了在退火过程中减少Se的过度挥发和杂质氧元素的引入,将样品和1 g Se粉置于带盖石墨坩埚中,以获得弱还原性气氛。

1.3 CIS薄膜表征

采用SDTQ-600同步热分析仪(DTA-TGA)分析升温过程中样品中物相的演变等物理化学性质变化,升温速率为10 ℃/min,测试温度范围为室温至1 100 ℃,Ar气氛。

采用日本理学Rigaku3014型X射线衍射仪(XRD)表征样品的物相组成,测试条件如下:电压40 kV,电流300 mA,扫描速度10(?)/min,步宽0.02?,扫描区间10?~90?,Cu Kα靶。

采用日本电子公司JSM-6360型扫描电镜(SEM)观察材料的表面形貌,测试电压为20 kV。

采用美国EDAX公司EDX-GENESIS 60S型X射线能谱分析仪(EDX)检测薄膜中的化学组分及元素分布,工作电压为15 kV。

2 结果与讨论

2.1 沉积电位范围与退火温度的确定

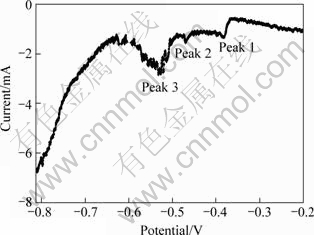

采用线性电位扫描法来确定每一组分的氧化还原电势,分析电沉积过程中的电化学反应,确定最佳沉积电位范围。图1所示为线性电位扫描I—φ曲线。

图1 扫描速率为5 mV/s时线性电位扫描I—φ曲线

Fig.1 I—φ curve of linear potential scan with scanning rate of 5 mV/s(Electrolyte composition: 8 mmol/L CuCl2, 100 mmol/L InCl3, 16 mmol/L SeO2, 500 mmol/L Na-citrate, 500 mmol/L KCl, pH=1.50±0.01)

从图1可以看出,Cu2+/Cu、SeO32-/Se、In3+/In的还原电位分别为-0.38、-0.47和-0.55 V(vs SCE),分别对应图1中的还原峰1、2和3,各还原电位比较接近,能实现共沉积[21];当沉积电位大于-0.8 V时,开始有氢气的析出。因此,电沉积CuInSe2薄膜的最佳沉积电位应为-0.55~-0.8 V。本研究选取在-0.6~-0.8 V范围内来进行CuInSe2的电沉积制备。

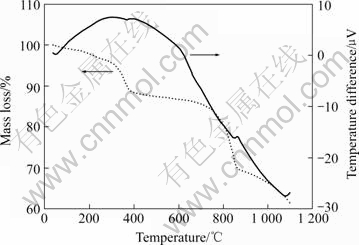

对电沉积所得薄膜进行了DTA—TGA分析,结果如图2所示,实线为DTA曲线,虚线为TGA曲线。由于CuInSe2熔点为987 ℃,当温度低于665 ℃时,CuInSe2为结晶的黄铜矿结构;当温度高于810 ℃时,CuInSe2为非晶的闪锌矿结构;当温度在665~810 ℃之间时CuInSe2为过渡结构[22]。为获得具有黄铜矿结构的CuInSe2薄膜,本研究考查电沉积所得薄膜在665 ℃以下温度区间的物理化学变化情况。

图2 电沉积CuInSe2的差热—热重分析曲线

Fig.2 DTA—TGA curves of electrodeposited CuInSe2

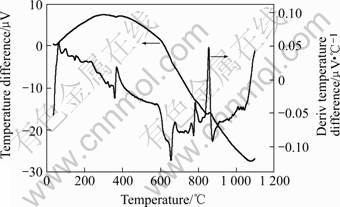

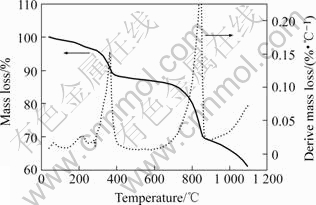

分别对DTA和TGA曲线作一阶微商,以获取更多的信息用于解析。图3和4所示分别为DTA、TGA曲线及两者对温度作一阶微商。

图3 电沉积薄膜的DTA曲线及其一阶微商曲线

Fig.3 DTA and its derivative(temp) curves of electrodeposited film

图4 电沉积薄膜的TGA曲线及其一阶微商曲线

Fig.4 TGA and its derivative(temp) curves of electrodeposited film

根据薄膜的DTA—TGA曲线及两者的一阶微商曲线,可大致将整个热处理过程分为如下3个阶段。

第一个阶段为室温至281.4 ℃,这一阶段总的变化趋势是向Cu-Se二元相(CuSe、Cu2Se)和In-Se二元相(InSe、In2Se3 )演化。第二个阶段为301 ℃至440.3 ℃,这可能是由二元相向CuInSe2三元相演变的一个驰豫过程。第三阶段为440.3 ℃至610 ℃左右,这一阶段主要是CuInSe2的晶体进一步长大和完善的过程,晶型为黄铜矿结构。当温度大于610 ℃时,CuInSe2的化学键断裂、晶体结构破坏,CuInSe2开始向非晶的闪锌矿结构过渡。

从上述分析可以大致确定退火的温度为440~610℃,这个温度范围有利于具有黄铜矿晶型结构的CuInSe2的形成和长大。因此,本研究采用的退火温度为500 ℃。

2.2 电沉积薄膜退火前后的组成与形貌变化

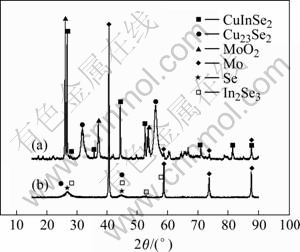

在CuCl2、InCl3、H2SeO3、Na-citrate、KCl的浓度分别为8、100、16、500、500 mmol/L以及恒电位为-0.7 V条件下制备了电沉积薄膜,并对比了电沉积薄膜退火前后的物相结构(见图5),发现电沉积薄膜退火前CuInSe2相不明显,为Cu2-x Se、In2Se3和Se的混合物,这三者的衍射峰不强并有重叠,导致分辨较为困难;且各衍射峰的半高宽峰宽较大,表明样品结晶较差。而硒化退火后则出现大量具有黄铜矿结构的CuInSe2相,薄膜在(112)、 (220)、(312)、(332)面(2θ分别为26.68?、44.22?、52.44?、70.98?)具有优先生长的趋势。退火后衍射峰增强,半高宽减小。由Scherrer公式可知,随着半高宽的减小,薄膜沿c轴方向的晶粒尺寸增大,晶形变好,这也可以从图6所示电沉积CIS薄膜的表面形貌得到证实。上述结果表明退火的重要性和必要性。

图5 电沉积制备的CuInSe2退火前后的XRD谱

Fig.5 XRD patterns of electrodeposited CuInSe2: (a) After annealing; (b) Before annealing

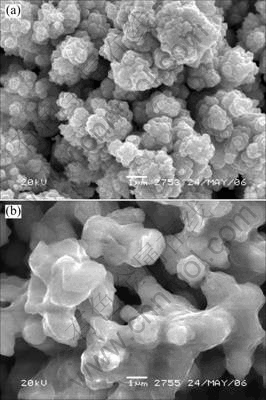

图6 电沉积CIS薄膜退火前后的表面形貌

Fig.6 Morphologies of electrodeposited CIS thin films before and after annealing: (a) After annealing; (b) Before annealing

图6所示为电沉积CIS薄膜退火前后的表面形貌。由图可见,退火前膜由大量小颗粒附聚在一起,颗粒粒径比较均匀,在0.5 μm左右,粒子之间存在大量界面和空隙,表面均匀性和致密性均不理想;退火后薄膜呈鱼齿状,均匀性和致密性均有所改善,颗粒之间的界面大大减少甚至消失,颗粒变得粗大,结晶程度大大提高。

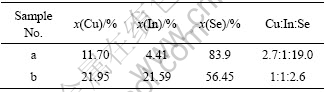

表1所列为EDX检测的膜层化学成分在退火前(No.a)和退火后(No.b)的变化对比。结果表明,退火可改善膜层的化学计量比,使之接近Cu?In?Se=1?1?2的理想化学组成。

表1 电沉积CuInSe2退火前后化学组成

Table 1 Composition of CIS thin films before and after annealing

综合上述XRD、SEM及EDX分析结果,表明对电沉积的样品进行退火处理是获得具有黄铜矿结构、结晶程度高、晶粒粗壮、致密、接近理想化学计量比的CuInSe2薄膜的一道十分必要的步骤。

2.3 沉积电位对薄膜组成与形貌的影响

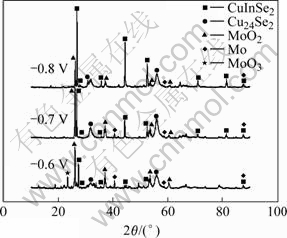

图7所示是不同电位下恒电位沉积CIS薄膜退火后的XRD谱。制备样品时,电解液组成中CuCl2、InCl3、H2SeO3、Na-citrate、KCl的浓度分别为8、100、16、500、500 mmol/L。由图可见,不同电位下电沉积制备的CuInSe2为黄铜矿结构,其在面(112)、(204)、(312)、(332)的特征峰均可以从谱中检出,其中(112)面的衍射峰最强。

图7 不同电位下沉积CIS薄膜退火后的XRD谱

Fig.7 XRD patterns of electrodeposited CIS thin films at different potentials after annealing

从图7中还可以看出,随着沉积电位的增大,薄膜中CuInSe2的衍射峰强度逐渐增强。这表明随着沉积电位的增大,具有黄铜矿晶型的CuInSe2在薄膜中的相对含量逐渐增加,且晶体结构更为完善。此外从图7中还发现有Cu2-xSe化合物的衍射峰,这可能是电沉积及硒化退火过程中,富余的Cu和Se反应生成的Cu2-xSe二元化合物;而且可以看出随着沉积电位的负移,薄膜中杂相的衍射峰强度和数目均减少,表明杂相含量随沉积电位负移而减少。

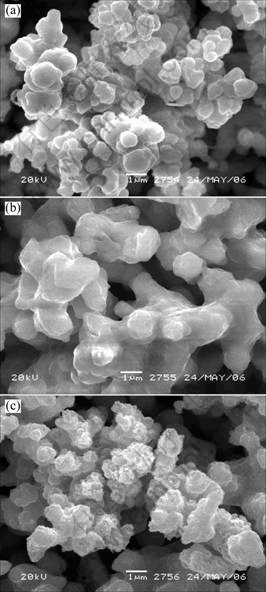

图8所示是不同沉积电位下制得的CuInSe2薄膜的表面形貌。由图可见,不同沉积电位下制备的CuInSe2在相同条件硒化退火后的表面形貌有一定的差异。主要表现在颗粒间融合(或界面消失)的程度不同、颗粒长大的程度不同和颗粒尺寸的不同。

图8 不同沉积电位下制得的CuInSe2薄膜表面形貌

Fig.8 Morphology of electrodeposited CIS thin films at different potentials: (a) -0.6 V; (b) -0.7 V; (c) -0.8 V

从图8(a)可以看出,CuInSe2结晶程度较好,颗粒间界面基本消失,融合成鱼齿状,连续性和致密性较好,颗粒最为粗壮。从图8(a)和(c)可见,CuInSe2呈颗粒状,颗粒之间仍互相连接,表现出界面消失和颗粒长大的趋势,与图8(b)相比,CuInSe2颗粒连接不紧密,结晶程度和致密性也较差。总的来说,各薄膜样品的平整性和致密性均不理想,需要进一步优化制备工艺条件。

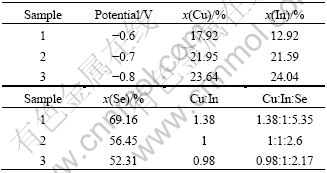

表2所示为不同电位下电沉积CuInSe2薄膜退火后样品经EDX检测的化学组成。从表2可以看出,样品1中Se的相对含量很高,且较样品2和3要高得多;而且样品1的铜铟摩尔比远大于1,这可能是在-0.6 V时各组分的析出速率为Se?Cu?In,表明沉积电位不够负,离最佳沉积电位较远。样品2和3的Cu/In均在1?1附近,较为理想,但样品2的Se相对含量过高,样品3中则虽Se仍过量,但有所改善。

表2 不同电位下电沉积CuInSe2薄膜退火后的化学组成

Table 2 Composition of electrodeposited CuInSe2 thin films at different potentials

各样品均表现为Se过量,对比各样品可见,在-0.8 V下电沉积制备的CuInSe2最接近理想的化学计量比。

2.4 电解质浓度对薄膜组成与形貌的影响

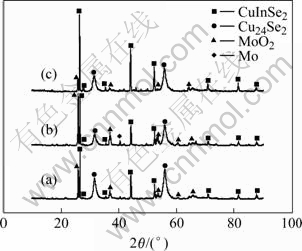

图9所示为不同电解质浓度下电沉积并硒化退火获得CIS膜的XRD谱。由图可见,采用不同电解质组成的电解液体系在相同沉积电位(-0.7 V)下电沉积并硒化退火均可得到具有黄铜矿结构的CuInSe2,其在面(112)、(204)、(312)、(332)的特征衍射峰均可以从谱中检出(2θ分别为26.68?、44.22?、52.44?、70.98?),其中(112)面的衍射峰最强;在(424)和(512)面(2θ分别为81.43?、87.62?)的衍射峰也比较明显,这进一步说明电沉积制备的CuInSe2在各个方向结晶较好,晶型较为完整;随着电解质浓度(Cu2+、SeO3-2)的增加,各薄膜中CuInSe2的衍射线强度有所增大,但增幅不大。

图9 不同电解质浓度下恒电位(-0.7 V)电沉积CIS膜退火后的XRD谱

Fig.9 XRD patterns of electrodeposited CIS thin films at -0.7 V with different electrolyte concentrations(mmol/L):

(a) CuCl2?InCl3?H2SeO3:N-acitrate?KCl=5?100?10?500?500;

(b) CuCl2?InCl3?H2SeO3:Na-citrate?KCl=8?100?16?500?500;

(c) CuCl2?InCl3?H2SeO3:Na-citrate?KCl=10?100?20?500?500

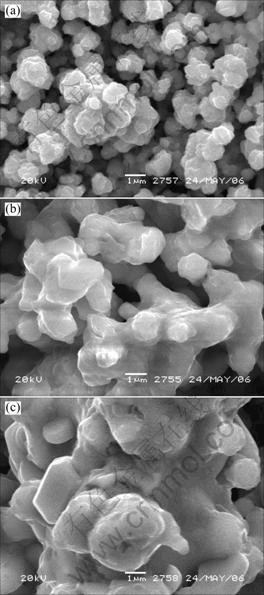

图10所示为不同电解质浓度下恒电位沉积CIS薄膜退火后的表面形貌。从图10可以看到,在不同电解质浓度及恒电位(-0.7 V)下沉积并退火获得的CuInSe2膜层结晶良好,颗粒呈球状或齿状,较为均匀和粗壮,致密性较好;随着电解质浓度(Cu2+、 )的上升,电沉积CuInSe2颗粒尺寸逐渐增大,膜层致密性增强。这可能是由于电解质浓度的增加会促进成核与生长。但各薄膜的均匀性均不理想,表面起伏不平,这可能是电流密度不均匀以及电解液的均镀能力不佳等造成。

)的上升,电沉积CuInSe2颗粒尺寸逐渐增大,膜层致密性增强。这可能是由于电解质浓度的增加会促进成核与生长。但各薄膜的均匀性均不理想,表面起伏不平,这可能是电流密度不均匀以及电解液的均镀能力不佳等造成。

图10 不同电解质浓度下恒电位沉积CIS薄膜退火后的表面形貌

Fig.10 Morphology of electrodeposited CIS thin films at different electrolyte concentrations(mmol/L): (a) CuCl2?InCl3? H2SeO3:N-acitrate?KCl=5?100?10?500?500; (b) CuCl2?InCl3? H2SeO3:Na-citrate?KCl=8?100?16?500?500; (c) CuCl2?InCl3? H2SeO3:Na-citrate?KCl=10?100?20?500?500

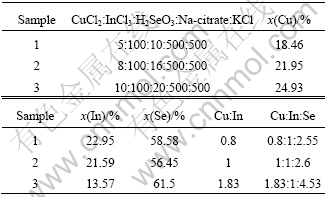

表3所列为EDX检测的不同电解质浓度下恒电位沉积CIS薄膜退火后的化学组成。

表3 不同电解质浓度下恒电位沉积CIS薄膜退火后的化学组成

Table 3 Composition of electrodeposited CIS films at different electrolyte concentrations

从表3可以看到,薄膜中各组分含量的变化趋势与电解液中电解质浓度变化的趋势是基本一致的。薄膜中Cu/In摩尔比的变化与电解液体系中CuCl2和InCl3的摩尔比的变化一致。

3 结论

1) 采用线性电位扫描法确定了沉积电位的范围为-0.6~-0.8 V(vs SCE);采用热重-差热分析确定了硒化退火的温度范围为440~610℃。

2) 对电沉积薄膜退火前后的组成与形貌变化分析表明,适当的热处理是获得具有黄铜矿结构、结晶程度高、晶粒粗壮、组成接近理想化学计量比的CuInSe2多晶薄膜的必要步骤。

3) 在不同的沉积电位下电沉积并硒化退火可制备出具有黄铜矿晶型的CuInSe2多晶薄膜,在(112)、(204)、(312)面表现出较强择优取向;随着沉积电位的负移,薄膜中CuInSe2的含量增加,晶型完善,且杂相减少;铜铟摩尔比在沉积电位为-0.7和-0.8 V(vs SCE)时接近理想值1。

4) 不同电解质浓度下电沉积并硒化退火可以获得具有黄铜矿晶型的CuInSe2多晶薄膜;随着电解质浓度的增加,退火后的电沉积CuInSe2的结晶程度变好,颗粒变得粗壮,致密性有所改善;Cu/In摩尔比与电解液中CuCl2和InCl3的摩尔比的变化趋势一致。

REFERENCES

[1] 孙 云,王俊清,杜兆峰,等. CIS和CIGS薄膜太阳电池的研究[J]. 太阳能学报,2001, 22(4): 192-195.

SUN Yun, WANG Jun-qing, DU Zhao-feng, et al. Research on cis and cigs thin film solar cells[J]. Acta Energiae Solaris Sinica, 2001, 22(4): 192-195.

[2] Delahoy A E, Chen L. Advanced CIGS Photovoltaic Technology[R]. Colorado: National Renewable Energy Laboratory, 2004.

[3] Eberspacher C, Pauls K L, Serra J P. Non-vacuum processing of CIGS PV[A]. Proc 19th European PV Solar Energy Conf[C]. Paris, 2004.

[4] Rega N, Siebentritt S, BeckersI E, Beckmann J, Albert J, Lux-Steiner M. Growth and transport properties of CuInSe2/ZnO heterostructure solar cell[J]. Mater Sci Eng B, 2006, B127(1): 12-16.

[5] 耿新华,孙 云,王宗畔, 等. 薄膜太阳电池的研究进展[J]. 物理,1999, 28(2): 96-102.

GENG Xin-hua, SUN Yun, WANG Zong-pan, et al. Thin film solar cells [J]. Physics, 1999, 28(2): 96-102.

[6] Jehad A M, Shama A, Johnston S, Noufi R. Bandlike and localized defect states in CuInSe2 solar cells[J]. Journal of Physics and Chemistry of Solids, 2005, 66(11): 1855-1857.

[7] Moharram A H, Hafiz M M, Salem A. Electrical properties and structural changes of thermally co-evaporated CuInSe films[J]. Applied Surface Science, 2001, 172: 61-67.

[8] Calixto M E, Sebastian P J, Bhattacharya R N, Noufi R. Compositional and optoelectronic properties of CIS and CIGS thin films formed by electrodeposition[J]. Solar Energy Materials and Solar Cells, 1999, 59(1): 75-84.

[9] Müller J, Nowoczin J, Schmitt H. Composition, structure and optical properties of sputtered thin films of CuInSe2[J]. Thin Solid Films, 2006, 496(2): 364-370.

[10] Vidyadharan Pillai P K, Vijayakumar K P. Characterization of CuInSe2/CdS thin-film solar cells prepared using CBD[J]. Solar Energy Materials and Solar Cells,1998, 51(1): 47-54.

[11] Rega N, Siebentritt S, Beckers I E, Beckmann J, Albert J, Lux-Steiner M. Defect spectra in epitaxial CuInSe2 grown by MOVPE[J]. Thin Solid Films, 2003, 431 /432: 186-189.

[12] White F R, Clak A H, Gxaf M C. Molecular beam epitaxy techniques fox preparing CuInSe2 thin films[J]. Apply Physics, 1979, 50: 544-554.

[13] Terasako T, Uno Y, Kariya T, Shirakata S. Structural and optical properties of In-rich Cu-In-Se polycrystalline thin films prepared by chemical spray pyrolysis[J]. Solar Energy Materials and Solar Cells, 2006, 9(3): 262-275.

[14] Kannan M D, Balasundaraprabhu R, Jayakumar S, Ramanathaswamy P. Preparation and study of structural and optical properties of CSVT deposited CuInSe2 thin films[J]. Solar Energy Materials and Solar Cells, 2004, 81: 379-395.

[15] Kazmerski L L. Photovoltaics R & D: at the tipping point[A]. Proceedings of the 2004 DOE Solar Energy Technologies Program Review Meeting[C]. Denver, Colorado, 2004.

[16] 何 青,孙 云,李凤岩,等. 效率为12.1%的Cu(In,Ga)Se2薄膜太阳电池[J]. 太阳能学报, 2004, 25(6): 782-784.

HE Qing, SUN Yun, LI Feng-yan, et al. A 12.1% efficient Cu(IN, Ga)Se2 thin-film solar cell[J]. Acta Energiae Solaris Sinica, 2004, 25(6): 782-784.

[17] Bhattacharya R. Electrodeposition of CuIn1-xGaxSe2 Materials for Solar Cells Final Report(24 April 1995-31 December 2001)[R]. Colorado: National Renewable Energy Laboratory, 2002: 32775.

[18] Kois J, Bereznev S, Mellikov E, ?pik A. Electrodeposition of CuInSe2 thin films onto Mo-glass substrates[J]. Thin Solid Films, 2006, 511/512: 420-424.

[19] Kang S H, Kim Y K, Choi D S, Sung Y E. Characterization of electrodeposited CuInSe2 (CIS) film[J]. Electrochimica Acta. 2006, 51(21): 4433-4438.

[20] Bhattacharya R N, Hiltner J F, Batchelor W, Contreras M A, Noufia R N, Sites J R. 15.4% CuIn1-xGaxSe2-based photovoltaic cells from solution-based precursor films[J]. Thin Solid Films, 2000, 361/362: 396-399.

[21] 周绍民. 金属电沉积—原理与研究方法(第1版)[M]. 上海:上海科学技术出版社,1987: 310-317.

ZHOU Shao-min. Metal Electrodeposition—Principle and Reseach Method[M]. Shanghai: Shanghai Science and Technology Press, 1987: 310-317.

[22] 张加友. CIS薄膜的生长机理研究[D]. 天津:南开大学,2003.

ZHANG Jia-you. Growth Mechanism of CIS Films[D]. Tianjin: Nankai University, 2003.

收稿日期:2006-09-11;修订日期:2006-01-11

通讯作者:张治安,博士;电话:0731-8876454; E-mail: zhianzhang@sina.com

(编辑 何学锋)