DOI:10.19476/j.ysxb.1004.0609.2019.08.15

海洋钢微弧氧化膜层组织与性能

贺 星1, 2,宋仁国1, 2,孔德军2, 3

(1. 常州大学 材料科学与工程学院,常州 213164;

2. 常州大学 江苏省材料表面科学与技术重点实验室,常州 213164;

3. 常州大学 机械工程学院,常州 213164)

摘 要:采用激光熔覆与微弧氧化技术相结合在S355海洋钢表面制备了复合陶瓷膜层,运用扫描电子显微镜(SEM)、能谱仪(EDS)和X射线衍射仪(XRD)表征陶瓷膜层的微观结构,通过涂层结合力、显微硬度、残余应力、摩擦磨损和电化学等测试方法研究复合膜层的性能。结果表明:复合陶瓷膜层主要由内致密层和外疏松层组成,疏松层主要由γ-Al2O3组成,致密层主要由α-Al2O3组成。随着电流密度增大,膜层厚度与微孔孔径逐渐增大。复合膜层与基底层结合良好,其硬度较熔覆涂层的有明显提升。熔覆涂层表面残余应力为拉应力,复合膜层均为压应力。在电流密度为5 A/dm2时,复合膜层能明显改善基体与熔覆涂层的耐磨性与耐蚀性。

关键词:S355海洋钢;激光熔覆;微弧氧化;复合陶瓷膜层;显微组织

文章编号:1004-0609(2019)-08-1701-11 中图分类号:TG174.44 文献标志码:A

S355作为海洋平台特种用钢,因其使用环境苛刻,其水下结构长期受海水及海生物的侵蚀而产生腐蚀问题,且服役期长,受力强度高,易发生磨损腐蚀开裂等问题,因此,需要较高的耐蚀、耐磨性,还需具有高强度、高韧性、耐低温、抗疲劳等特性[1]。过去,海洋平台主要采用热喷涂金属涂层进行防腐,但海洋平台对其结构钢表面的防护提出了较高的要求,除了涂层本身防腐效果外,还包括涂层配套、厚度和表面处理等多方面配合。要求涂层与钢材表面及各道涂层之间有良好的附着力、抗老化、耐盐雾、耐海水性能好,能形成适当弹性的涂层,与阴极保护配套使用,工艺过程复杂,效果不佳。微弧氧化(Micro-arc oxidation, MAO)是近年来兴起的一种在金属表面原位生长陶瓷膜的新工艺。它采用较高的工作电压,通过微弧放电使得微区的金属原子与溶液中的氧原子结合生成一层以氧化物为主要成分的致密平整的陶瓷层,从而进一步提高基体的耐磨性和耐蚀性能[2]。但该技术目前主要适用于阀金属(铝、钛、镁)材料,而目前在钢铁表面进行微弧氧化的主要方法是在钢铁表面热浸渡铝后再进行微弧氧化[3]。如陶建冬等[4]在A3钢表面通过热浸渡铝和微弧氧化复合技术制备了微弧氧化陶瓷层。黄元林等[5]采用热浸镀技术在20钢基体表面制备了铝涂层,然后采用微弧氧化技术对铝涂层进行了氧化处理,形成了复合陶瓷涂层体系。但这种方法存在着很多缺陷,首先是结合强度不高,其次工艺过程复杂,成本较高。因此,考虑结合另一种成本较低,工艺过程简单的表面改性技术激光熔覆。激光熔覆(Laser cladding)是一种以不同的填料方式将粉末添加到熔覆基材表面,经激光辐照使之和基材表面薄层一起熔凝,并快速凝固使之与基材呈冶金结合的表面熔覆层,从而显著改善基材表面的耐磨、耐蚀、耐疲劳、抗氧化等的一种表面强化方法[6]。由于熔覆过程中常用的碳化物陶瓷粉末具有较高的硬度、耐磨性和耐蚀性等优异性能,但是陶瓷材料的熔点、弹性模量和热膨胀系数与基体相差很大,在激光熔覆过程中会带来一些问题[7],而CeO2具有细化晶粒、微合金化、改善晶界状态、减少内应力及抑制柱状晶生长等作用,何骅波等[8]研究表明CeO2含量为1%时,涂层的硬度与耐蚀性最佳。同时Ni具备良好的润湿性和抗氧化性能,可以有效降低涂层孔隙率,ZHANG等[9]研究表明,Ni含量为5%(质量分数)时,涂层在3.5%NaCl(质量分数)溶液中具备良好的耐腐蚀性能。因此,本文作者拟结合两种技术,即以激光熔覆+微弧氧化技术在海洋钢表面制备复合膜层。

目前,YANG等[10]在镁合金表面采用静电粉末喷涂(EPS)技术+微弧氧化技术成功制备双层复合膜层体系,结果表明该复合膜层的极化电阻明显要高于单一涂层,耐蚀性能得到显著提升。XIONG等[11]也通过激光重熔与微弧氧化技术在镁合金表面制备复合生物涂层,结果表明,与单一LSP层和MAO生物涂层相比,LSP/MAO复合生物涂层不仅可以显着提高镁合金基体的耐腐蚀性,而且可以提高其力学性能。上述通过激光加工工艺与微弧氧化技术结合的研究也主要集中在轻质合金上,而通过激光熔覆(LC)+微弧氧化(MAO)技术在海洋钢表面制备双层复合陶瓷膜层几乎很少。因此,本文作者先采用激光熔覆技术在S355钢表面制备Al-Ni-TiC-CeO2熔覆涂层。以该熔覆涂层作为基底层,在以硅酸盐为电解液的体系下,制备复合陶瓷膜层,研究不同电流密度下膜层组织与性能变化,并与Al-Ni-TiC-CeO2熔覆涂层进行对比。

1 实验

1.1 实验材料

实验材料为欧标S355结构钢(质量分数,%):C 0.17,Si 0.55,Mn 0.94,P 0.035,Cr 0.065,S 0.035,Ni 0.065,Mo 0.30,Zr 0.15,其余为Fe。熔覆粉末材料为Al粉(纯度99.0%,平均粒径50~95 μm)、TiC粉末(纯度99.5%,平均粒径40 μm)、Ni粉(纯度99.5%,平均粒径1.5 μm),按质量比6:3:1混合后加入1%CeO2(纯度99.0%,平均粒径20 nm),用球磨机充分混合均匀。

1.2 实验方法

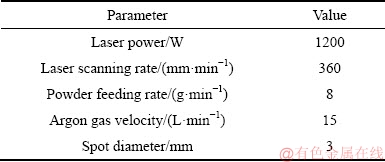

激光熔覆实验机器采用ZKSX-2008型2 kW固态激光器,熔覆方式采用送粉熔覆,以氩气作为送粉动力源,实现同步送粉熔覆,具体激光熔覆工艺参数如表1所示。

表1 激光熔覆工艺参数

Table 1 Laser cladding process parameters

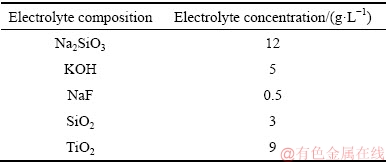

熔覆实验完成后将得到的式样用线切割的方法切割成大小为30 mm×25 mm×3 mm,表面用砂纸逐级打磨,预磨至1000#水磨砂纸,然后用Al2O3抛光液进行机械抛光,丙酮超声除油,除熔覆层表面外,其余面均用环氧树脂和固化剂密封后进行微弧氧化,微弧氧化实验采用恒流模式,电流密度采用3、5、8 A/dm2,氧化时间为30 min,控制电解液温度在30 ℃以下,电解液配方如表2所示。

表2 微弧氧化电解液配方

Table 2 MAO electrolyte formulation

试验完成后得到熔覆涂层(对比试样)和微弧氧化复合陶瓷层,将得到的熔覆涂层抛光打磨平整,微弧氧化陶瓷层截面逐级打磨抛光,用JSM-6510扫描电子显微镜(SEM)和能谱仪(EDS)观察熔覆涂层、微弧氧化陶瓷层的高倍组织与成分。采用X射线衍射仪(XRD)对涂层物相进行分析。涂层孔隙率主要由IPP软件对所获得的涂层表面形貌照片进行处理,测定5次取其平均值作为有效孔隙率大小。微弧氧化膜层结合力测试采用WS-2005型膜层附着力自动划痕仪。划痕装置所用的压头是金刚石锥形(120°)压头,压头施加载荷范围是0.01~200 N,施加载荷连续匀速加载。测试膜层划痕时采用声发射和摩擦力结合的方式,加载载荷40 N,划痕距离4 mm,压头移动速度为0.1 mm/s。试验结束后,利用显微镜观察划痕形貌。用 HMV-1T数字显微硬度计测量4种涂层的显微硬度,其中加载载荷为2 N,加载时间为15 s,在截面上涂层表面往基体方向每隔50 μm打一个点,同一深度水平上测量3次取平均值。采用X-350A型X射线应力测定仪测量涂层表面沿层深方向的纵向残余应力,以衍射晶面(400)的衍射面作为测试对象,入射角Ψ分别为0°、25°、35°、45°,应力常数:-130 MPa/(°),2θ扫描起始角到终止角为155°~135°,步距为0.1°,计数时间0.50 s。摩擦磨损试验采用CFT-1型材料表面性能综合测试仪,磨损介质为空气,涂层对磨材料为SiC陶瓷球,加载载荷为2 N,电机转速为500 r/min,采用往复滑动模式,磨痕半径为3 mm,运行时间为30 min,测量完成后采用BT25S电子分析天平称量磨损质量损失,磨损完后对磨损试样进行形貌观察分析。动电位极化测试采用CS350电化学工作站,测试介质是3.5% NaCl溶液(质量分数),测试面积为1 cm2,工作电极为试样,参比电极为饱和甘汞电极,辅助电极为铂电极,测试前先在3.5%NaCl(质量分数)溶液中浸泡30 min左右直到开路电位稳定,测试温度保持在(25±1) ℃。扫描速率1 mV/s,测试结束后进行Tafel拟合。

2 结果与分析

2.1 复合陶瓷膜层结构

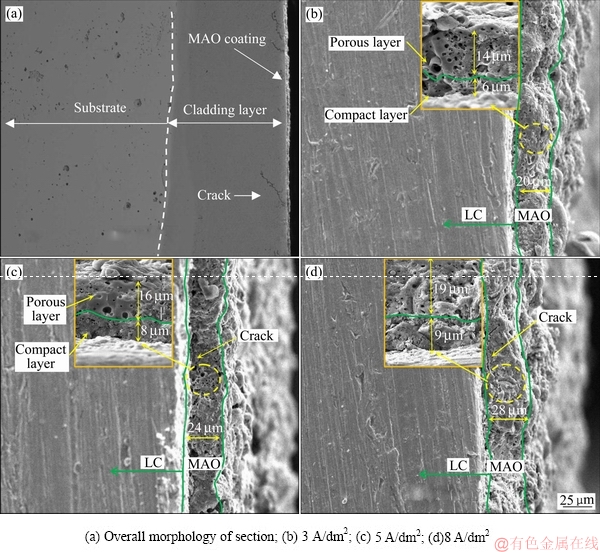

图1所示为复合陶瓷膜层的截面形貌。如图1(a)所示,复合涂层截面可以看到3个明显的区域,依次为基体、熔覆层、微弧氧化陶瓷层,其中基体区域出现了轻微的氧化,熔覆层区域较为平整,有3条明显的裂纹,微弧氧化涂层厚度在20 μm左右。通常制备的微弧氧化陶瓷膜层分为内致密层外疏松层的双层结构,如图1(b)、(c)所示,陶瓷层与基体之间呈现锯齿状冶金结合,界面良好,在电流密度为3 A/dm2和5 A/dm2时所制备的膜层可以看到明显的双层结构。在电流密度为3 A/dm2时,陶瓷层的外疏松层厚度为14 μm,且分布较多的微孔,内致密层为6 μm,微孔数量较少;当电流密度升至5 A/dm2时,陶瓷层的外疏松层厚度为16 μm,微孔数量较少,但孔径变大,内致密层厚度为8 μm,微孔数量极少;当电流密度进一步升至8 A/dm2,膜层出现了烧蚀现象,微孔数量较少,陶瓷层厚度增长到28 μm。这主要是由于电流密度较大,试样表面的电压较高,作用在陶瓷涂层上的电场强度和磁场强度亦有所增加,使得微弧氧化反应过程中的驱动力增加,从而促进膜层厚度进一步增加。另一方面,过高的电流密度会促使熔融氧化物与表层的陶瓷层发生重熔,在电解液的冷淬作用下迅速凝固,致使反应产物逐渐沉积在微孔内壁,使得微孔逐渐被填满[12]。

图1 不同电流密度时复合膜层的截面形貌

Fig. 1 Sectional morphologies of composite films at different current densities

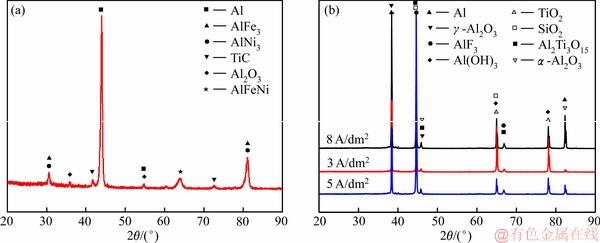

图2 熔覆涂层与复合膜层表面XRD谱

Fig. 2 XRD patterns of cladding layer(a) and composite films(b)

图2所示为熔覆涂层与不同电流密度下复合膜层表面的XRD复合谱。熔覆涂层以增强相TiC和连续相为主要物相,包括AlFe3相、AlNi3相、Al2O3相和AlFeNi相,如图2(a)所示。复合膜层除了基体Al物相外,其余是Al的化合物,包括Al2O3、AlF3和Al(OH)3等,这些物相说明电解液中的F-与溶液中的O2和Al在高压放电的情况下发生了化学反应。另外,溶液中还存在SiO2、TiO2和Al2Ti7O15相,SiO2和TiO2相的出现是由于电解液中添加剂所致,SiO2随着微弧氧化反应逐渐沉积到涂层表面,TiO2在溶液中与O2和Al3+参与微弧氧化反应并以Al2Ti7O15存在于涂层当中,如图2(b)所示。

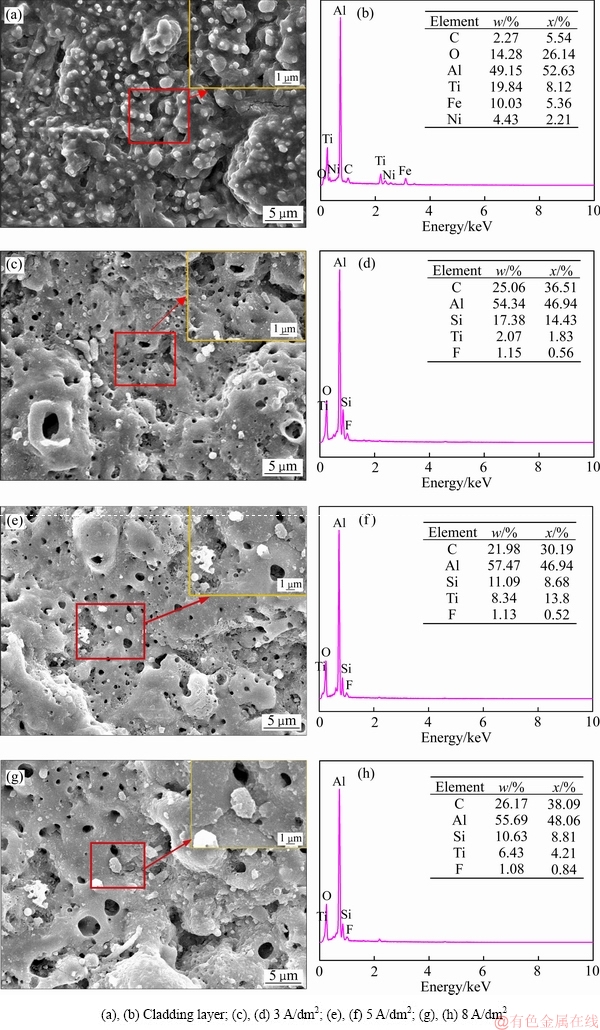

图3所示为熔覆涂层与复合涂层表面形貌与相应的EDS点能谱图。图3(a)所示为熔覆涂层表面形貌图,可以看到熔覆涂层表面有较大的孔洞,出现了一条明显的微裂纹,增强相TiC分布均匀,TiC形貌主要为细小颗粒状,且有连接长大的趋势。图3(b)所示为相应的点能谱分析结果,可以看到涂层表面元素主要为Al、C、Ti、Fe、O和Ni,这也与测试的XRD结果相吻合。涂层内的Fe元素主要来自基体和扩散层,表明涂层与基体形成较好的冶金结合。图3(c)、(e)和(g)所示为复合陶瓷膜层形貌,3种膜层呈现典型的疏松形貌,膜层表面分布着较多的微孔,微孔数量及孔径存在明显的差异。图3(c)中试样表面微孔细小而不均匀,且涂层表面出现了一些微裂纹。图3(e)和(g)中膜层呈典型的熔岩凝固的形貌特征。这主要是由于微弧氧化过程中击穿放电时间短,热量集中,容易形成熔化微区,生成熔融态氧化铝,且在放电通道中反应生成的气体压力和放电压力被升高,导致部分熔融的氧化铝从放电通道喷射而出,因此在周围形成了熔岩凝固的形貌[13]。此时涂层表面微孔数量减少,但孔径增大。图3(d)、(f)和(h)所示为相应的MAO试样表面能谱,可以看到,涂层表面主要元素为O、Al、Si、Ti、F。随着电流密度增加,Si和F的含量呈逐渐上升的趋势。这是由于涂层厚度随电流密度增加而增加,因此涂层有更多的空间容纳此类物质。

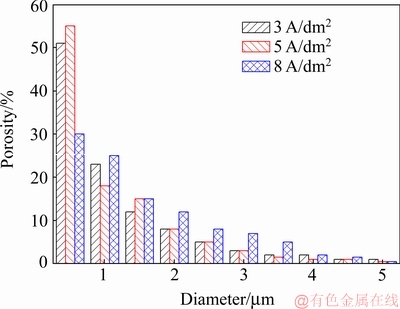

图4所示为陶瓷膜层的孔隙率及其孔径分布。由图4可看出,表面孔隙率有呈现先增加后趋于稳定的规律。在电流密度为3 A/dm2、孔径小于1 μm的微孔数量最多,约占56%。另外,随着电流密度的增加,氧化反应速度加快,陶瓷层厚度快速增加,难以发生放电击穿现象,因而在一些微小的孔隙处会产生一定程度的能量积聚,直至再次发生放电击穿,引起部分微孔的孔径变大[14],致使孔径在1 μm以内的微孔分布比例逐渐减小。

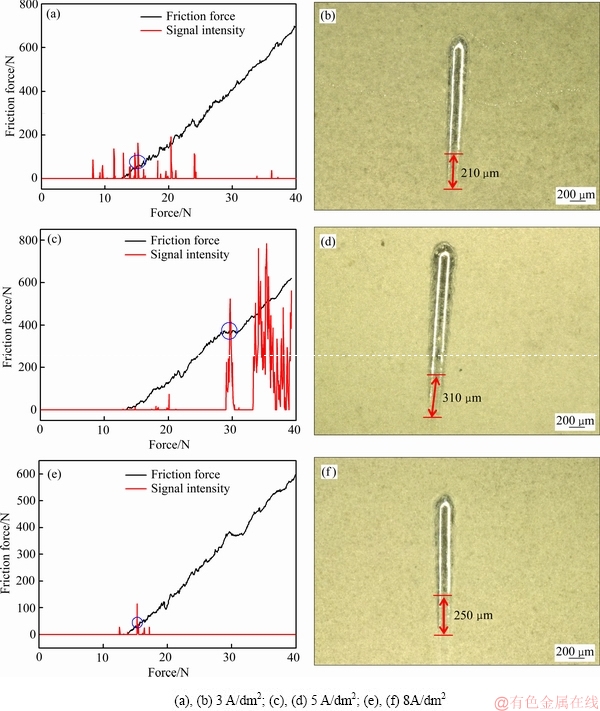

2.2 复合膜层结合力分析

涂层结合力是MAO膜层结合强度的重要指标。图5所示为不同电流密度下膜层的声信号和摩擦力曲线以及对应的划痕照片。图5(a)所示为电流密度为3 A/dm2的陶瓷层的结合强度,可以看到涂层划破时发出明显的声信号,摩擦力曲线急剧上升,如图中蓝色线圈所示。由图5(b)也可以看出,压头在划到较短距离处时,划痕沟槽底部出现了金属色区域,表明此时涂层已经划穿,此时划穿加载的载荷为临界载荷Fc[15],结合声、磨发射信号以及显微照片可知,电流密度为3 A/dm2的陶瓷层的Fc值为15.2 N。当电流密度加载到5 A/dm2时,加载力达到28.4 N时,声信号波动较大,陶瓷层划穿距离较短,如图5(c)和(d)所示,表明涂层的结合强度较好。当电流密度进一步增加到8 A/dm2,涂层的Fc值降到15.8 N, 破裂位置发生明显的提前,说明涂层的结合强度出现了下降,如图5(e)和(f)所示。

图3 熔覆涂层与不同电流密度下的复合陶瓷膜层表面形貌及相应的能谱图

Fig. 3 Surface morphologies and EDS spectra of cladding coating and composite ceramic film under different current densities

图4 复合膜层表面孔隙率及其孔径分布

Fig. 4 Surface porosity and pore size distribution of composite films

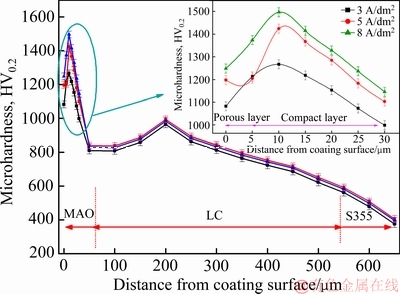

2.3 显微硬度分析

图6所示为复合涂层纵截面显微硬度分布曲线。由图6可看出,尽管电流密度不同,但复合涂层的硬度值均是由外向内先升高至最大值,然后逐渐下降。在电流密度为3 A/dm2时,陶瓷层在距表面区域10 μm左右,硬度逐渐上升,再距表面12 μm左右达到最大值1267 HV0.2,比熔覆涂层硬度最大值964.3 HV0.2提高了约31.4%,约为基体硬度(384.4 HV0.2)的3.29倍。在电流密度达到5 A/dm2时,膜层显微硬度分布整体上要高于电流密度为3 A/dm2时陶瓷层的,在距表面13 μm处膜层硬度达到最大值1424.3 HV0.2。在电流密度进一步提高时,陶瓷层显微硬度进一步提高,最大能达到1496.7 HV0.2。由于陶瓷层的相组成和致密性是影响膜层硬度的主要因素,随着电流密度的增加,陶瓷层厚度逐渐增加,致密层和疏松层厚度也逐渐增加。同时,致密层中含有更多的α-Al2O3相,促使其硬度值升高。另一方面,随着电流密度的增加,陶瓷层体现出向内生长机制,使得膜层过渡区域变小,硬度下降趋势更明显[16]。

图5 不同电流密度下MAO膜层的结合强度曲线以及对应的划痕照片

Fig. 5 Compressive strength curves((a), (c), (e)) and corresponding scratch photos((b), (d), (f)) of MAO coatings under different current densities

图6 熔覆涂层与复合膜层显微硬度分布

Fig. 6 Microhardness distribution of cladding layer and composite films

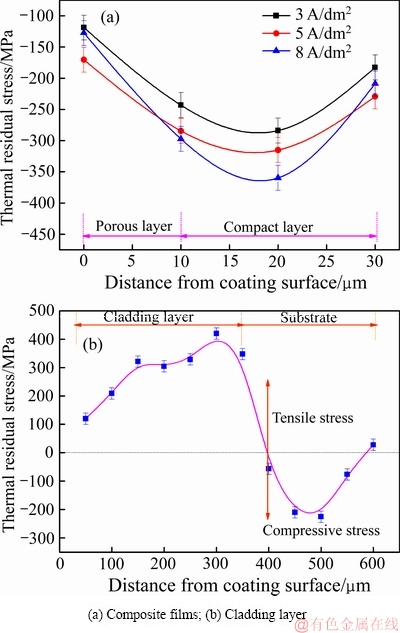

2.4 残余应力分析

根据样品XRD衍射峰的情况,选择衍射晶面(400)的衍射面作为测试对象。X 射线衍射分析计算残余应力的基本公式为

(1)

(1)

式中:E为弹性模量; 为泊松比;θ0为所选晶面在无应力情况下的衍射角;

为泊松比;θ0为所选晶面在无应力情况下的衍射角; 为材料表面法线与产生衍射的晶面法线的夹角;θ为所选晶面实际测量的衍射角。陶瓷层主要为氧化铝,其弹性模量E取390 GPa,泊松比

为材料表面法线与产生衍射的晶面法线的夹角;θ为所选晶面实际测量的衍射角。陶瓷层主要为氧化铝,其弹性模量E取390 GPa,泊松比 取0.26[17]。通过计算得到复合涂层截面残余应力分布,如图7所示。由图7可以看到,3种不同电流密度制备的MAO膜层在区域内的残余应力表现为压应力,且随着距离的加大,压应力逐渐增大,在距表面20 μm处达到最大值,后又逐渐减小。对于电流密度为3、5和8 A/dm2的膜层,其表面残余应力依次约为-118、-170.42和-127.51 MPa。可以看到,电流密度为3 A/dm2和8 A/dm2的膜层压应力较电流密度为5 A/dm2的膜层压应力要小,这主要是由于陶瓷层不能承受较高的压应力而出现微裂痕,从而释放了部分残余应力,这也与膜层表面形貌观察到的结果一致。熔覆涂层区域内残余应力均为拉应力,在距涂层表面300 μm处残余应力达到最大值439.61 MPa。较大的残余应力会影响材料表面开裂程度,增大裂纹敏感性。因此,在使用微弧氧化处理后,涂层裂纹敏感性能得到一定程度的控制。

取0.26[17]。通过计算得到复合涂层截面残余应力分布,如图7所示。由图7可以看到,3种不同电流密度制备的MAO膜层在区域内的残余应力表现为压应力,且随着距离的加大,压应力逐渐增大,在距表面20 μm处达到最大值,后又逐渐减小。对于电流密度为3、5和8 A/dm2的膜层,其表面残余应力依次约为-118、-170.42和-127.51 MPa。可以看到,电流密度为3 A/dm2和8 A/dm2的膜层压应力较电流密度为5 A/dm2的膜层压应力要小,这主要是由于陶瓷层不能承受较高的压应力而出现微裂痕,从而释放了部分残余应力,这也与膜层表面形貌观察到的结果一致。熔覆涂层区域内残余应力均为拉应力,在距涂层表面300 μm处残余应力达到最大值439.61 MPa。较大的残余应力会影响材料表面开裂程度,增大裂纹敏感性。因此,在使用微弧氧化处理后,涂层裂纹敏感性能得到一定程度的控制。

图7 复合膜层与熔覆涂层残余应力分布

Fig. 7 Residual stress distribution of cladding layer and composite films

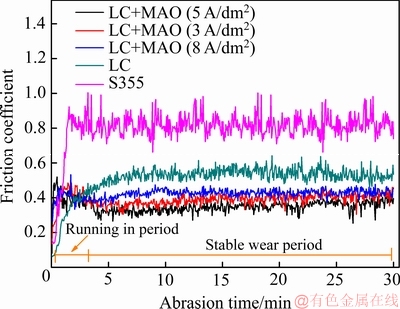

2.5 耐磨性分析

图8所示为基体与涂层试样的摩擦因数随时间变化曲线。由图8可以看到,试样磨损可以分为两个阶段,磨损阶段和稳定阶段,在0~1 min内基体摩擦因数迅速上升至1.0左右,之后,逐渐稳定在0.9左右。对于熔覆涂层,其磨损阶段发生在0~5 min内,之后摩擦因数逐渐稳定在0.5左右。对于复合膜层试样,其磨损阶段发生在0~2 min,曲线缓慢平滑上升,这主要是由于MAO涂层致密层的存在。随着磨损时间的延长,摩擦力不断增加,最终划破膜层达到稳定阶段。但复合涂层稳定时摩擦因数较熔覆涂层要低,说明微弧氧化涂层具有一定的减磨作用。

图8 不同试样摩擦因数随时间变化曲线

Fig. 8 Fiction coefficients of cladding layer and MAO coatings obtained under current density

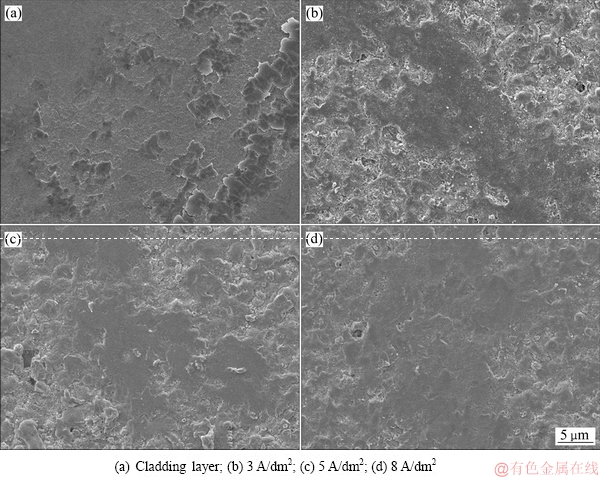

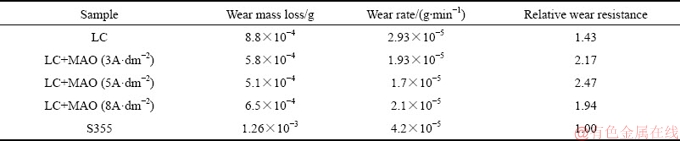

图9所示为不同涂层试样磨损后的表面形貌。由图9可以看到,熔覆涂层(见图9(a))表面磨痕较宽,涂层表面出现了破损和剥落,磨损表面基本无塑性变形和粘着磨损。这主要是由于涂层表面硬度较高,使得其在与摩擦副对磨过程中起到了阻磨作用,阻碍了涂层基底的塑性变形,利于提高涂层的耐磨性。相对熔覆涂层来说,MAO涂层的磨痕宽度进一步减小,磨损面积也较小,且表面较为平整、磨痕呈现片状。这主要是由于涂层在磨损过程中,MAO涂层外疏松层表面孔洞熔融物很容易被破坏,而内致密层由于含有坚硬相,硬度高,使得磨损后局部逐渐趋于平整,但却有高低之差,致使磨痕呈现片状。在电流密度为5 A/dm2时,涂层只是表现出轻微的擦划,并未被磨穿。孔洞较少以及硬度较大的α-Al2O3相的存在可能导致涂层耐磨性的提高。表3所列为试样磨损质量损失、磨损速率以及相对耐磨性。其中相对耐磨性为标准试样的磨损量与被测试样磨损量之比,文中标准试样为S355钢基体。由表3可以发现,涂层试样的磨损质量损失要比基体的小一个数量级,复合膜层的磨损量要比单纯的熔覆涂层试样的少26%~42%。在电流密度为5 A/dm2时,复合涂层的磨损速率和相对耐磨性都表现为最佳。

2.6 动电位扫描曲线分析

图9 不同试样磨损后表面形貌

Fig. 9 Worn morphologies of cladding layer and MAO coatings obtained under different current densities

表3 不同试样摩擦磨损测试结果

Table 3 Friction and wear tests results of different samples

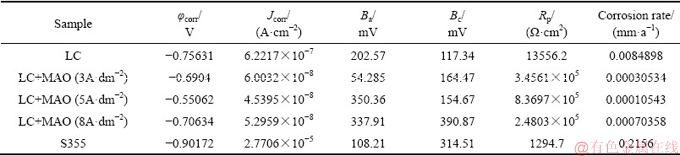

表4 涂层与基体极化曲线拟合值

Table 4 Fitting results of polarization curves between coating and substrate

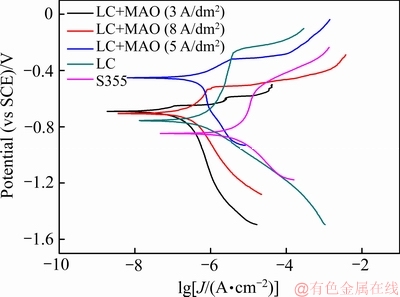

图10 基体和涂层试样的极化曲线

Fig. 10 Potentiodynamic polarization curves of substrate and coatings in 3.5% NaCl solution

图10所示为基体和涂层的动电位极化曲线。通常较低的腐蚀电流密度、较高的极化电阻和腐蚀电位代表低的腐蚀速率和较好的耐蚀性能。结合表4中极化曲线拟合后得到的数据,其中自腐蚀电位(φcorr),腐蚀电流密度(Jcorr)和阳极/阴极Tafel常数(Ba,Bc)等电化学参数通过Tafel拟合方法直接得到。极化电阻(Rp)通过Stern-Geary方程计算获得

(2)

(2)

腐蚀速率由式(3)得出

(3)

(3)

式中:M为金属的原子量;n为金属的原子价;F为法拉第常数。由表4可以看到,基体的自腐蚀电位约为-0.90 V,腐蚀电流密度为2.77×10-5 A/cm2;熔覆涂层腐蚀电位-0.75 V,腐蚀电流密度要比基体高两个数量级;复合膜层腐蚀电位较熔覆涂层进一步增大,腐蚀电流密度较熔覆涂层提高一个数量级。显然经过微弧氧化处理后,试样的耐蚀性能进一步提高[18]。在电流密度达到5 A/dm2时,复合膜层极化电阻达到最大值8.3697×105 Ω·cm2。这主要是由于膜层的结构造成的,此时膜层致密层厚度较大,孔洞尺寸较小且为闭孔,无明显裂纹,使得腐蚀介质很难透过膜层与基体接触。当电流密度进一步升高时,复合膜层表面由于热应力导致裂纹的产生,且此时气孔孔径较大,使得腐蚀介质更容易进入膜层内部破坏膜层,从而使得涂层耐蚀性降低。综合腐蚀速率来看,可以发现熔覆涂层腐蚀速率要比基体的低2个数量级,复合膜层的要比基体的低3个数量级,即在S355钢表面制备复合膜层能极大地提高基体的抗腐蚀能力。当制备复合膜层电流密度为5 A/dm2时,膜层耐蚀性能最佳。

3 结论

1) 通过激光熔覆与微弧氧化复合处理技术在海洋钢上制备微弧氧化复合陶瓷层,其与基体的结合强度较高,疏松层主要由γ-Al2O3组成,致密层主要由α-Al2O3组成。随着电流密度增加,膜层厚度逐渐增加,微孔数量减少,孔径增加。

2) 随着电流密度的增加,复合涂层体现出向内生长机制,硬度逐渐减小,但仍比熔覆涂层硬度高31.4%,能显著改善基材的硬度。复合涂层残余应力表现为压应力,而熔覆涂层为拉应力。

3) 复合膜层摩擦因数要比熔覆涂层低20%~ 30%,在电流密度为5 A·dm2时,复合膜层的磨损速率和相对耐磨性都表现为最佳。

4) 复合膜层自腐蚀电流密度较低,极化电阻较高,能明显降低涂层的腐蚀速率。

REFERENCES

[1] 郝文魁, 刘智勇, 王显宗, 李晓刚. 海洋平台用高强钢强度及其耐蚀性现状及发展趋势[J]. 装备环境工程, 2014, 11(2): 50-58.

HAO Wen-kui, LIU Zhi-yong, WANG Xian-zong, LI Xiao-gang. Current situation and prospect of studies on strength and corrosion resistance of high strength steel for ocean platform[J]. Equipment Environmental Engineering, 2014, 11(2): 50-58.

[2] 陈妍君, 冯长杰, 邵志松, 王春霞, 周 雅. 铝合金微弧氧化技术的研究进展[J]. 材料导报, 2010, 24(9): 132-136.

CHEN Yan-jun, FENG Chang-jie, SHAO Zhi-song, WANG Chun-xia, ZHOU Ya. Research progress of micro-arc oxidation on the aluminum alloys[J]. Materials Review, 2010, 24(9): 132-136.

[3] 解世岳, 王从曾, 寇斌达, 苏学宽, 马 捷. 碳钢热浸镀铝及微弧氧化研究[J]. 轻合金加工技术, 2003, 31(9): 35-38.

XIE Shi-yue, WANG Cong-zeng, KOU Bin-da, SU Xue-kuan, MA Jie. Research of hot-dip aluminum and micro arc oxidation on surface of carbon steel[J]. Light Alloy Fabrication Technology, 2003, 31(9): 35-38.

[4] 陶建东, 赵志龙, 胡 鹏, 马连辉, 艾昌辉. A3钢热浸镀铝层微弧氧化复合转化层的微观组织特性[J]. 电镀与环保, 2010, 30(1): 25-28.

TAO Jian-dong, ZHAO Zhi-long, HU Peng, MA Lian-hui, AI Chang-hui. Microstructure characteristics of hot-dip aluminum and micro-arc oxidation multilayer conversion coating on A3 steel[J]. Electroplating & Pollution Control, 2010, 30(1): 25-28.

[5] 黄元林, 孙晓峰, 李占明, 宋 巍. 20钢基体表面热浸镀铝+微弧氧化复合处理研究[J]. 装甲兵工程学院学报, 2015, 29(3): 105-107.

HUANG Yuan-lin, SUN Xiao-feng, LI Zhan-ming, SONG Wei. Study on composite treatment of 20 steel substrate by hot dip aluminum and micro-arc oxidation[J]. Journal of Academy of Armored Force Engineering, 2015, 29(3): 105-107.

[6] 袁庆龙, 冯旭东, 曹晶晶, 苏志俊. 激光熔覆技术研究进展[J]. 材料导报, 2010, 24(3): 112-116.

YUAN Qing-long, FENG Xu-dong, CAO Jing-ling, SU Zhi-jun. Research progress in laser cladding technology[J]. Materials Review, 2010, 24(3): 112-116.

[7] 程西云, 何科杉, 何 俊. 氧化铈对镍基碳化钛复合涂层微观结构及摩擦学性能影响[J]. 摩擦学学报, 2010, 30(3): 250-255.

CHENG Xi-yun, HE Ke-shan, HE Jun. Influence of CeO2 on tribological properties and microstructure of laser-cladding TiC4 ceramic layer[J]. Tribology, 2010, 30(3): 250-255.

[8] 何骅波, 戴姣燕, 杨梦梦, 黄晓波, 徐金富. 稀土CeO2对Ni60A激光熔覆层组织与性能的影响[J]. 兵器材料科学与工程, 2017, 40(6): 83-87.

HE Hua-bo, DAI Jiao-yan, YANG Meng-meng, HUANG Xiao-bo, XU Jin-fu. Effect of CeO2 on microstructures and properties of Ni60A laser cladding layer[J]. Ordnance Material Science and Engineering, 2017, 40(6): 83-87.

[9] ZHANG H, ZHANG C H, WANG Q, WU C L, ZHANG S, CHEN J, ABDULLAH A O. Effect of Ni content on stainless steel fabricated by laser melting deposition[J]. Optics & Laser Technology, 2018, 101: 363-371.

[10] YANG W, XU D P, WANG J L, YAO X F, CHEN J. Microstructure and corrosion resistance of micro arc oxidation plus electrostatic powder spraying composite coating on magnesium alloy[J]. Corrosion Science, 2018, 136: 174-179.

[11] XIONG Y, HU Q, SONG R G, HU X X. LSP/MAO composite bio-coating on AZ80 magnesium alloy for biomedical application[J]. Materials Science and Engineering C, 2017, 75: 1299-1304.

[12] YANG Y, WU H. Effects of current density on microstructure of titania coatings by micro-arc oxidation[J]. Journal of Materials Science & Technology, 2012, 28(4): 321-324.

[13] YANG Y, WU H. Effect of current density on corrosion resistance of micro-arc oxide coatings on magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S2): s688-s692.

[14] 杨 巍, 蒋百灵, 时惠英. LY12铝合金微弧氧化膜层的形成与生长机制[J]. 中国有色金属学报, 2010, 20(10): 1949-1954.

YANG Wei, JIANG Bai-ling, SHI Hui-ying. Formation and growth mechanism of microarc oxidation coating on LY12 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1949-1954.

[15] LU J P, CAO G P, QUAN G F, WANG C, ZHUANG J J, SONG R G. Effects of voltage on microstructure and corrosion resistance of micro-arc oxidation ceramic coatings formed on KBM10 magnesium alloy[J]. Journal of Materials Engineering and Performance, 2018, 27(1): 147-154.

[16] CAO G P, SONG R G. Microstructure and properties of ceramic coatings prepared by micro-arc oxidation on 7075 aluminum alloy[J]. Materials Research Express, 2018, dio.org/10.1088/2053-1591.

[17] MAO W G, WAN J, DAI C Y, DING J, ZHANG Y, ZHOU Y C, LU C. Evaluation of microhardness, fracture toughness and residual stress in a thermal barrier coating system: A modified Vickers indentation technique[J]. Surface and Coatings Technology, 2012, 201(26): 4455-4461.

[18] ZHUANG J J, GUO Y Q, XIANG N, XIONG Y, HU Q, SONG R G. A study on microstructure and corrosion resistance of ZrO2-containing PEO coatings formed on AZ31 Mg alloy in phosphate-based electrolyte[J]. Applied Surface Science, 2015, 357: 1463-1471.

Microstructure and properties of micro-arc oxidation coatings on offshore steel

HE Xing1, 2, SONG Ren-guo1, 2, KONG De-jun2, 3

(1. School of Materials Science and Engineering, Changzhou University, Changzhou 213164, China;

2.Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University, Changzhou 213164, China;

3. School of Mechanical Engineering, Changzhou University, Changzhou 213164, China)

Abstract: The composite ceramic films were prepared on the surface of S355 offshore steel by laser cladding combined with micro-arc oxidation technology, and the composite films structures were evaluated by SEM, EDS and XRD. The properties of the composite coatings were studied by a coating scratch tester, microhardness tester, X-ray stress measurement instrument, friction and wear test machine and electrochemical workstation. The results show that the composite ceramic film is mainly composed of an inner dense layer and an outer loose layer, the loose layer is mainly composed of γ-Al2O3, and the dense layer is mainly composed of α-Al2O3. With the increase of current density, the film thickness and the micropore diameter gradually increase. The composite film is well integrated with the substrate layer. Compared with cladding coating, the hardness of composite films is improved significantly. The residual stress on the surface of the cladding coating is tensile stress, and the residual stress of the composite film is compressive stress. When the current density is 5 A/dm2, the composite film can significantly improve the wear resistance and corrosion resistance of the substrate and the cladding layer.

Key words: S355 offshore steel; laser cladding; micro-arc oxidation; composite ceramic films; microstructure

Foundation item: Project(BE2016052) supported by the Key Research and Development Project of Jiangsu Province, China

Received date: 2018-07-30; Accepted date: 2018-10-16

Corresponding author: SONG Ren-guo; Tel: +86-519-86330069; E-mail: songrg@hotmail.com

(编辑 李艳红)

基金项目:江苏省重点研发计划资助项目(BE2016052)

收稿日期:2018-07-30;修订日期:2018-10-16

通信作者:宋仁国,教授,博士;电话:0519-86330069;E-mail:songrg@hotmail.com