湿法浸出粘土矿中钒的动力学

李浩然1,冯雅丽2,罗小兵2,王宏杰2,杜竹玮1

(1. 中国科学院过程工程研究所 生化工程国家重点实验室,北京 100080;

2. 北京科技大学 土木与环境工程学院,北京 100083)

摘 要:为了提高湿法浸出粘土矿中钒的综合浸出效率,并对湿法浸出粘土矿中钒提供理论依据,从动力学角度分析整个浸出过程。考察温度、液固比、硫酸质量分数和搅拌速率对浸出过程的影响。研究结果表明:在80 ℃、液固比为4?1以及硫酸质量分数为20%时,浸取8 h,粘土矿中钒的浸出率可达到92.3%。经正交实验和动力学推导,得到描述浸出过程的经验方程,粘土矿湿法浸出钒的动力学模型为收缩核动力学模型,浸出表观活化能为11.611 kJ/mol,该模型表明浸出过程中的控制步骤是决定于固膜扩散速率。提高温度、液固比和硫酸质量分数,均可加速钒的浸出速度,提高钒的浸出率。

关键词:粘土矿;浸出动力学;收缩核模型;活化能

中图分类号:TF803.2;TF841.3 文献标识码:A 文章编号:1672-7207(2008)06-1181-04

Leaching kinetics of extraction of vanadium pentoxide from

clay mineral

LI Hao-ran1, FENG Ya-li2, LUO Xiao-bing2, WANG Hong-jie2, DU Zhu-wei1

(1. State Key Laboratory of Biochemical Engineering, Institute of Process Engineering,

Chinese Academy of Sciences, Beijing 100080, China;

2. School of Civil and Environmental Engineering, University of Science and Technology Beijing,

Beijing 100083, China)

Abstract: In order to improve the leaching efficiency of vanadium pentoxide from clay mineral and provide its theoretical base, the leaching process was analyzed. The effects of reaction temperature, the liquid-solid ratio, sulphuric acid concentration and stir speed on the leaching rate were investigated. The results show that the leaching rate of vanadium pentoxide can reach 92.3% on the condition of temperature 80 ℃, liquid-solid ratio 4?1, mass fraction of sulfuric acid 20%, and leaching time 8 h. By means of orthogonal experiment and kinetic deduction, an empirical equation for the leaching process is established, and the apparent activation energy is 11.611 kJ/mol. The leaching process of clay mineral could be simulated with a shrinking core model, which indicates that the control factor of the leaching process is the diffusion rate of reacting reagents in a porous solid layer. The leaching rate and speed can be increased by enhanceing the temperature, liquid-solid ratio and sulfuric acid concentration.

Key words: clay vanadium mineral; leaching kinetics; shrinking core model; activation energy

地壳中的钒储量多但分散,通常伴生在钒钛磁铁矿、碳沥青、石煤、石油灰渣和钾钒矿等矿床中[1-2]。目前,我国从粘土、石煤等钒矿中提取五氧化二钒主要采用钠化焙烧—水浸—酸沉钒—碱溶—铵盐沉淀—偏钒酸铵热解工艺[3]。生产工艺中存在以下问题:没有专用的钠化焙烧炉,目前使用最广泛的平炉不仅占地面积大、生产效率低,而且焙烧温度很难控制,导致转化率不高,总回收率只有40%~50%;生产过程中产生大量的氯化物和氯气等有害气体,以及废水中含有大量的盐,对周围环境的严重污染。在环境保护备受关注的今天,此工艺受到极大限制。

近年来,人们对湿法浸出石煤[4]及粘土钒矿[5]中钒进行研究。本文作者在文献[6]工作的基础上进行浸取机理的研究,推导出浸出反应动力学数学模型,对其浸取理论进行补充。这种湿法浸取粘土矿中钒的方法简化了现有工艺流程,降低了能耗,具有一定的理论价值和现实意义。

1 实 验

1.1 实验材料

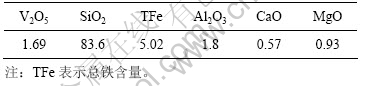

粘土钒矿是以SiO2(占矿石总质量80%左右)为基体的粘土质矿物,90%左右的钒赋存于粘土质伊利石的硅-氧四面体微晶结构中,另有8%左右的钒赋存于结晶程度很差的钒云母中,钒云母是该矿中惟一被发现的独立钒矿物。粘土钒矿石的化学成分及含量见表1。

表1 矿样的化学成分

Table 1 Chemical composition of mineral %

1.2 实验方法

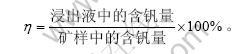

称取一定量的试样,移入800 mL烧杯中,加入一定量的硫酸及氧化剂溶液,加热并强烈搅拌,经过一段时间浸取后,过滤分离,用硫酸亚铁铵滴定法测定溶液中五氧化二钒的量。浸取最佳工艺条件是:液固比为4?1,硫酸质量分数为20%,氧化剂用量为3%,温度为80 ℃,浸出时间为8 h。浸出率 的计算公式如下:

的计算公式如下:

2 浸出钒的动力学分析及结果

2.1 钒浸出过程扩散控制的确定

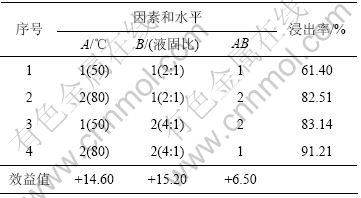

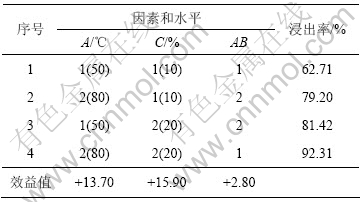

利用一定浓度的硫酸从粘土钒矿中浸出回收钒是固-液多相反应,经历吸附、扩散和化学反应等几个阶段,浸出速度一般由这几个阶段中速度最小者决定,吸附很快达到平衡,多相反应的速度主要由化学反应和反应物扩散决定。表2和表3所示为矿浆液固比、硫酸质量分数与温度的正交实验结果。

表2 矿浆液固比与温度的正交实验结果

Table 2 Orthogonal experimental results of liquid-solid ratio and temperature

表3 硫酸质量分数与温度的正交实验结果

Table 3 Orthogonal experimental results of H2SO4 mass fraction and temperature

正交实验结果表明矿浆液固比、硫酸质量分数和温度对钒的浸出率有显著影响,其效益值r为正,矿浆液固比和硫酸质量分数的效益值均比温度效益值大,即矿浆液固比和硫酸质量分数影响力大于后者。

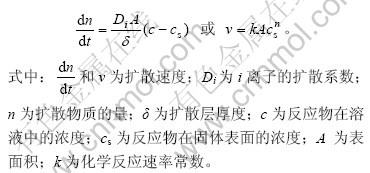

扩散速度控制方程为[6]:

由表2和表3中的实验结果,可以判定此多相反应为扩散控制,即浸出反应受反应物浓度c和扩散层厚度δ影响。若浸出反应速度是由化学反应速度控制(速度控制方程[6] ),在颗粒表面积A稳定时温度是影响反应速度的主要因素,温度变化影响反应k变化,最终使速度发生变化,则反应温度的影响力将远大于矿浆液固比和硫酸质量分数的影响力,但实验结果与此不相符。

),在颗粒表面积A稳定时温度是影响反应速度的主要因素,温度变化影响反应k变化,最终使速度发生变化,则反应温度的影响力将远大于矿浆液固比和硫酸质量分数的影响力,但实验结果与此不相符。

2.2 钒浸出固膜扩散控制步骤的确定

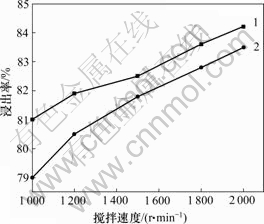

根据前面提到的一般多相浸出反应过程的速度控制规律,若确定该浸出过程中传质扩散是关键历程和决定步骤,需进行搅拌强度和相流动状态试验,考查液膜层厚度对反应的影响,结果如图1所示。

浸出时间/h:1—7; 2—5

图1 搅拌速度对V2O5浸出率的影响

Fig.1 Effect of stirring speed on leaching rate

在固-液多相浸出反应中,当液膜扩散为控制步骤时,搅拌强度对浸出率影响非常大,通常可提高浸出率40%~70%。但从实验结果(图1)可知,搅拌强度对综合浸出率影响不大,影响程度为5%~10%,只体现出一般固相物系在液相中充分分散所产生的浸出率提高的效果。由此可以判断,浸出反应控制步骤非液膜扩散控制应是固膜扩散控制。实验中进行搅拌可加强两相流动状态,其主要作用一是使矿物质在液体中充分分散;二是适当降低传质边界层的厚度,加速传质过程。

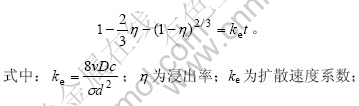

2.3 固膜扩散过程中收缩核动力学模型

根据以上分析,利用硫酸从粘土矿浸出的过程中,固膜扩散是决定步骤(控制步骤),固膜扩散速度为控制速度。该浸出反应遵循固-液反应固膜扩散控制下的动力学方程式[7-8]:

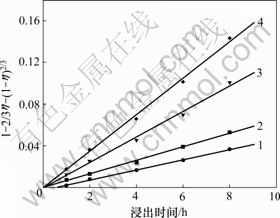

该方程表示浸出率与浸出时间的关系,又称收缩核模型[9]。将试验结果按 对时间t作图,结果如图2所示。

对时间t作图,结果如图2所示。

温度/K:1—293; 2—333; 3—343; 4—353

图2 不同温度下浸出动力学曲线

Fig.2 Leaching dynamic curves at different temperatures

由图2可以看出,实验数据与“收缩核模型”基本符合,所得图形均近似直线,表明在任意温度下所得ke都为常数,即ke是温度的函数。

同理,可导出化学控制动力学方程,即混合控制动力学方程,但所得数学模型均为曲线,不是直线,说明在同一温度下是有变化的,这不符合浸取反应速度常数在一定温度下ke是常数,即只与温度有关、随温度变化而变化的原理。因此,可以推断,硫酸浸出粘土矿中钒的反应过程是受固膜扩散控制,遵循收缩核动力学模型。

2.4 钒浸出过程因素分析

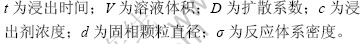

由图2可求出不同温度下浸出反应扩散速度系数ke,根据Arrhenius定理[10]:

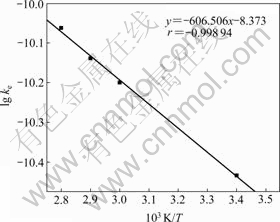

根据不同温度时的lg ke对1/T作图,得到Arrhenius线形图,如图3所示。

由图3可计算出活化能Ea=11.611 kJ/mol,该活化能较小,进一步说明该过程控制步骤是固膜扩散控制,即浸出速率是由最慢的固膜扩散速率决定。

图3 lg ke—1/T曲线

Fig.3 Curve of lg ke—1/T

根据上述动力学研究,推断硫酸浸出粘土矿中钒经历以下步骤:

a. 经过固体表面上的液膜层,液相中的反应物向粘土矿物表面的传质扩散;

b. 反应物经过固相产物膜层或残留的不被浸出的硅酸盐矿物物料膜层的传质扩散;

c. 在被浸出的钒化合物表面上进行化学反应;

d. 被溶解的钒化合物经固相膜层由反应表面向外扩散;

e. 被溶解的钒化合物质经过固相表面上的液膜层向液相扩散。

其中通过粘土矿物固相膜层的内外扩散速率是整个浸出反应的控制速率,即步骤b和d是决定步骤,改变这两个阶段影响固膜扩散速率条件,即随硫酸质量分数、温度以及液固比增大,固膜扩散速率加快,将使整个反应浸出率和浸出速率有很大变化。

3 结 论

a. 湿法浸出粘土矿中钒的浸出反应属于不生成固体产物层的“反应核收缩”模型:  ,其表观活化能为11.611 kJ/mol,浸出过程由固膜扩散控制。

,其表观活化能为11.611 kJ/mol,浸出过程由固膜扩散控制。

b. 在温度为80 ℃、液固比为4?1以及硫酸质量分数为20%时,浸取8 h,粘土矿中钒的浸出率可达92.3%,说明硫酸溶液能很好地将难选粘土矿中的钒浸出。

c. 提高硫酸质量分数和温度以及增大液固比,均可提高粘土矿中钒的浸出率及速度;而提高搅拌速率,对钒浸出速度影响不大。

参考文献:

[1] 朱德庆, 郭宇峰, 邱冠周, 等. 钒钛磁铁精矿冷固球团催化还原机理[J]. 中南工业大学学报: 自然科学版, 2000, 31(3): 208-211.

ZHU De-qing, GUO Yu-feng, QIU Guan-zhou, et al. Catalyzing the direct reduction of cold-bound pellets from titanomagnetite concentrate[J]. Journal of Central South University of Technology: Natural Science, 2000, 31(3): 208-211.

[2] 陈振兴, 卢 伟, 方忠和, 等. 铷-铯-钒系催化剂上二氧化硫氧化反应本征动力学[J]. 中南工业大学学报: 自然科学版, 2000, 31(2): 127-130.

CHEN Zhen-xing, LU Wei, FANG Zhong-he, et al. Intrinsic kinetics of sulphur dioxide oxidation on Rb-Cs-V catalyst[J]. Journal of Central South University of Technology: Natural Science, 2000, 31(2): 127-130.

[3] 江苏省煤炭工业局. 石煤的综合利用[M]. 北京: 煤炭工业出版社. 1980.

Jiangsu Province Bureau of Coal Industry. Utilization of coal [M]. Beijing: Coal Industry Press, 1980.

[4] 漆明鉴. 酸浸法从石煤中提钒的中间试验研究[J]. 湿法冶金, 2000, 19(2): 8-17.

QI Ming-jian. Pilot-scale experiment for recovering V2O5 from stone coal by acid leaching[J]. Hydrometallurgy of China, 2000, 19(2): 8-17.

[5] 罗小兵, 冯雅丽, 李浩然, 等. 湿法浸出粘土钒矿中钒的研究[J]. 矿冶工程, 2007, 27(6): 48-53.

LUO Xiao-bing, FENG Ya-li, LI Hao-ran, et al. Investigation on extraction of V2O5 from clay containing vanadium by acid process[J]. Mining and Metallurgical Engineering, 2007, 27(6): 48-53.

[6] Balaz P, Ficcriova J, Sepelak V. Thiourea leaching of silver from mechanically activated tetrahedrite[J]. Hydrometallurgy, 1996, 43(1/3): 367-377.

[7] Chi R, Zhu G, Xu S, et al. Kinetics of manganese reduction leaching from weathered rare-earth mud with sodium sulfite[J]. Metallurgical and Materials Transactions B, 2002, 33B: 41-46.

[8] Sonmez S, Aktas S, Acma E. A study on the treatment of wastes in hot dip galvanizing plants[J]. Canadian Metallurgical Quarterly, 2003, 42(3): 289-300.

[9] 朱国才, 徐颖惠, 池汝安, 等. 氯化铵焙烧回收脱锰矿泥中的稀土及其动力学[J]. 化工冶金, 2000, 21(1): 14-17.

ZHU Guo-cai, XU Ying-hui, CHI Ru-an, et al. Recovery of RE from panxi rare earth mud and the kinetics of RE chlorination with NH4Cl roasting[J]. Engineering Chemistry & Metallurgy, 2000, 21(1): 14-17.

[10] 韩其勇. 冶金过程动力学[M]. 北京: 冶金工业出版社, 1983: 29-32.

HAN Qi-yong. Kinetics of metallurgical process[M]. Beijing: Metallurgical Industry Press, 1983: 29-32.

收稿日期:2008-01-18;修回日期:2008-03-23

基金项目:国家自然科学基金资助项目(20576137)

通信作者:李浩然(1967-),男,甘肃庆阳人,博士,硕士生导师,从事矿物加工方面的研究工作;电话:010-82627064;E-mail: hrli@home.ipe.ac.cn