文章编号:1004-0609(2010)06-1149-06

Super-Ni叠层复合材料与18-8钢TIG焊接头区的显微组织

夏春智1, 李亚江1, 2, U.A. Puchkov2, 王 娟1

(1. 山东大学 材料液固结构演变与加工教育部重点实验室,济南 250061;

2. Department of Materials Science, Bauman Moscow State Technical University, Moscow 105005, Russia)

摘 要:采用填丝钨极氩弧焊(TIG)方法对复层厚度仅为0.3 mm的Super-Ni叠层复合材料与18-8不锈钢进行焊接试验。焊后对焊缝的微观组织及显微硬度、熔合区附近元素分布等进行分析。结果表明:叠层复合材料与焊缝形成可靠的熔合,Super-Ni复层侧熔合区附近的显微硬度升高(HM190);18-8不锈钢侧焊缝的显微硬度低于不锈钢母材的,不锈钢热影响区的显微硬度最高(290 HM);不锈钢一侧热影响区形成δ铁素体和碳化物析出;母材与焊缝间形成Fe与Ni元素的明显过渡,叠层复合材料侧元素过渡区域的宽度为80~85 μm,18-8不锈钢侧元素过渡区域的宽度约为20 μm;焊接中应使钨极氩弧偏向18-8不锈钢一侧,以避免Ni复层的过度烧损。

关键词:叠层复合材料;钨极氩弧焊;显微组织;元素分布;熔合区

中图分类号:TG 457.19 文献标志码:A

Microstructure of welding zone of super-Ni laminated composite and 18-8 steel TIG joint

XIA Chun-zhi1, LI Ya-jiang1, 2, U.A. Puchkov2, WANG Juan1

(1. Key Laboratory for Liquid-Solid Structural Evolution and Processing of Materials, Ministry of Education,

Shandong University, Ji’nan 250061, China;

2. Department of Materials Science, Bauman Moscow State Technical University, Moscow 105005, Russia)

Abstract: Super-Ni laminated composite (with 0.3 mm-thick cover layer) and 18-8 stainless steel were welded with filler alloy by tungsten inert gas welding (TIG). The microstructure, microhardness and element distributions in the welding zone were analyzed. The results show that a valid connection forms between the laminated composite and the weld metal, the microhardness (190 HM) near the fusion zone of Super-Ni cover layer side increases. The microhardness of the welding seam region on 18-8 steel side is lower than that of the base metal, and the highest microhardness (290 HM) appears in the heat-affected zone (HAZ) of 18-8 steel. δ ferrite and carbide phase form on the HAZ of 18-8 steel side. The transition of Fe and Ni elements obviously occurs between the base metal and the weld, with 80-85 μm-wide transition zone near the laminated composite side and about 20 μm-wide transition zone near the 18-8 steel side. In the welding process, the welding tungsten arc should be controlled towards the 18-8 steel side to avoid excessive melting loss of the Ni cover layer.

Key words: laminated composite; tungsten inert gas welding; microstructure; element distribution; fusion zone

高温合金具有独特的物理和力学性能,耐热和耐蚀性强,在石油化工、航空航天等领域得到广泛应用。Super-Ni叠层复合材料是近年来发展起来的一种新型高温结构材料[1-3]。粉末冶金Ni-Cr材料的研究始于20世纪60和70年代,至今制备技术已日趋成熟[4-6],本文作者所研究的叠层复合材料是由超级镍合金Super-Ni复层和NiCr基层真空压制成的叠层板。这种将高温材料与韧性材料(超级镍合金)压制成的叠层复合材料从一出现就受到欧美、俄罗斯等发达国家的重视。目前,针对这种复层厚度仅0.2~0.3 mm的高温叠层复合材料的焊接性[7]研究鲜见报道。近年来较多的研究是针对传统的大尺寸复合板(复层厚度>2 mm)的,与该课题的研究有本质的不同。

粉末冶金零件的焊接性与材料内部存在的空隙及材料的相对密度有关,这与传统铸造及轧制零件的焊接不同。粉末冶金零件的焊接,从20世纪90年代至今的20年中有了重要进展[8-10]。根据粉末冶金材料相对密度的大小,可以选择不同的焊接工艺[10-11],通过严格控制焊接工艺参数并选择匹配的焊接填充合金,能有效控制母材的熔合比以及减少凝固裂纹的产生,实现铁基粉末合金的焊接,获得具有良好性能的焊 缝[9, 12 -13]。

Super-Ni叠层复合材料由于其特殊的结构形式及合金组成,焊接时具有较大的裂纹敏感性;并且叠层复合材料的Super-Ni复层与基层热物理性质不同,使其焊接成形有很大的难度[14-16]。本文作者采用填丝钨极氩弧焊(TIG)对一种新型叠层复合材料Super- Ni/NiCr与18-8不锈钢进行焊接,采用显微图像分析仪、显微硬度计、电子探针(EPMA)等,对焊接接头区组织、显微硬度及元素过渡进行研究。

1 实验

试验所采用的叠层复合材料是由超级镍合金Super-Ni复层(Ni%>99.5%)和Ni80Cr20基层通过真空烧结-压制而成的叠层板,是一种新型的高温结构材料。Super-Ni叠层复合材料的镍复层厚度约为0.3 mm,NiCr基层厚度约为2.0 mm。不锈钢为18-8奥氏体不锈钢;采用Cr25-Ni13系合金焊丝作为填充金属。试验用18-8奥氏体不锈钢及Cr25-Ni13焊丝的化学成分如表1所列。

表1 试验材料的化学成分

Table 1 Chemical compositions of experimental materials

试验中采用填丝钨极氩弧焊(TIG)实现叠层复合材料Super-Ni/NiCr与18-8不锈钢之间的连接。焊接时需要严格限制热输入,并控制电弧方向指向18-8不锈钢一侧。试验中采用的焊接参数如下:焊接电流79~81 A,焊接电压10~12 V,焊接速度0.2 cm/s,氩气流量8 L/min。焊接前采取严格的清理措施,清除母材和焊丝表面的污物和氧化膜。Super-Ni/NiCr叠层复合材料和18-8不锈钢平板对接的装配间隙控制在0.3 mm以下。

焊后用线切割方法在Super-Ni/NiCr叠层复合材料与18-8不锈钢异种材料TIG焊接头处切取试样,制备成系列金相试样。用HCl+HNO3+CH3COOH(体积比1?3?4)混合溶液浸蚀焊接接头区组织。采用XQF-2000显微图像分析仪对TIG焊接头区的显微组织进行观察和分析,采用JXA-8800R型电子探针显微分析仪(EPMA)测定接头熔合过渡区的元素分布。

2 结果与分析

2.1 叠层复合材料接头的组织特征

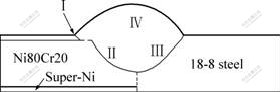

叠层复合材料由于其特殊的复层结构形式,使得焊接接头区划分变得复杂。Super-Ni/NiCr叠层复合材料与18-8不锈钢异种材料接头区截面如图1所示。接头区分为4个典型的区域:1) Ni复层侧熔合区(Ⅰ区);2) Ni80Cr20基层侧熔合区(Ⅱ区);3) 18-8不锈钢侧熔合区(Ⅲ区);4) 焊缝中心区(Ⅳ区)。填丝钨极氩弧焊可形成具有一定熔深、均匀过渡的焊缝。Super-Ni复层与焊缝熔合良好,焊缝表面平整光洁,Ni80Cr20基层与焊缝金属形成良好的过渡。

图1 Super-Ni叠层复合材料与18-8不锈钢TIG焊接头横截面示意图

Fig.1 Cross section of TIG joint of laminated composite and 18-8 steel

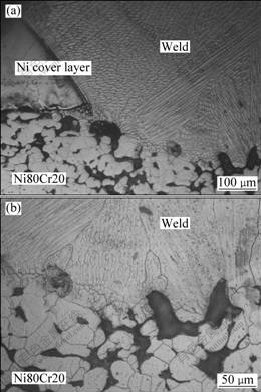

叠层复合材料侧熔合区的微观组织如图2所示。由图2可知,Super-Ni复层与焊缝金属熔合良好。Super-Ni复层的良好表面成形有利于保持叠层复合材料特有的耐热和耐腐蚀性能。由于焊接电弧温度梯度的作用,靠近熔合区的焊缝组织晶粒细小。焊缝与Ni80Cr20基层结合较弱,界面形成部分熔合。Ni80Cr20基层侧熔合区如图2(b)所示。与常规的镍基高温合金不同,Ni80Cr20基层由于其特殊的骨骼状结构,其熔合区组织形态也与常规的焊接接头不同。

图2 Super-Ni叠层复合材料一侧熔合区的微观组织

Fig.2 Microstructures of fusion zone near Super-Ni/NiCr composite: (a) Transition zone near Super-Ni cover layer; (b) Transition zone near NiCr base layer

18-8不锈钢一侧熔合区的微观组织如图3所示。由图3可知,不锈钢侧焊缝结合良好,具有平滑过渡的熔合区。18-8不锈钢热影响区组织是奥氏体(γ)+铁素体(δ)。由于高温加热作用,不锈钢热影响区出现敏化区,导致δ铁素体及碳化物析出现象。焊缝组织呈柱状晶形态垂直于熔合区生长。

图3 18-8不锈钢侧熔合区的微观组织

Fig.3 Microstructure of fusion region near 18-8 steel

Super-Ni叠层复合材料与18-8不锈钢焊接时主要存在Ni复层烧损、NiCr基层熔合差及焊缝中间组织弱化等问题。在焊接过程中,Super-Ni复层金属由于优先受热,且其热导率(67.4 J/(cm?S?℃))远高于Ni80Cr20基层及18-8不锈钢的热导率。因此,焊接时迅速熔化,致使最后焊缝表面成形变宽,甚至在焊接电流较大时发生过度烧损,从而导致焊缝熔合较差。焊缝的微观组织如图4所示。由图4可知,焊缝中心为尺寸均匀的等轴状奥氏体组织。由于焊缝中奥氏体柱状晶的生长及低熔点偏析杂质的存在,使得焊缝中可能出现组织弱化,焊缝中的奥氏体柱状晶交错生长,大晶界之间也可能产生组织弱化,增加热裂纹敏感性。

图4 焊缝的微观组织

Fig.4 Microstructure of weld centre

叠层复合材料为Ni基合金复合结构,与18-8不锈钢焊接时热裂纹敏感性较大。对焊后的组织观察发现,焊缝中出现不同程度的热裂纹,热裂纹的产生与焊接热输入关系密切。采用较大焊接热输入的焊接接头热裂纹明显,而小焊接热输入的焊接接头裂纹显著减少。因此,应严格控制焊接热输入,以减少焊接热裂纹的产生,同时采用较小焊接热输入的钨极氩弧(如小电流柔和电弧)进行焊接时,Super-Ni复层烧损情况大大减少;NiCr基层在较柔和的电弧吹力情况下,也能更好地熔合,这有利于提高焊接接头区的整体性能。

2.2 熔合区附近的显微硬度

对Super-Ni叠层复合材料熔合区附近的显微硬度进行测定,试验结果如图5所示。采用的测定仪器为日本Shimadze型显微硬度计,载荷为0.5 N,加载时间10 s。由图5可见,熔合区附近的显微硬度高于Super-Ni复层以及焊缝,形成了显微硬度峰值区(190HM)。因为熔合区在焊接过程中冷却速度快,首先凝固结晶,出现淬硬倾向。焊缝中靠近熔合区处组织的化学成分不均匀,随显微组织生长,成分逐渐均匀化,显微硬度值变化很小(165HM)。

图5 叠层复合材料侧熔合区附近的微观组织及显微硬度分布

Fig.5 SEM image and microhardness distribution near fusion zone of laminated composite side: (a) SEM image showing testing location; (b) Microhardness profile

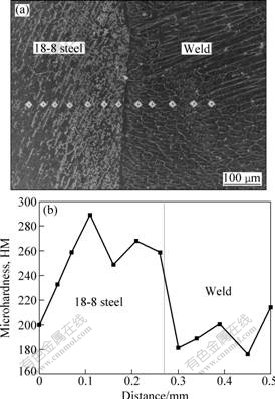

18-8不锈钢一侧熔合区附近的微观组织及显微硬度分布如图6所示,测定参数与叠层复合材料一侧的相同。在18-8不锈钢侧熔合区附近的热影响区出现显微硬度峰值(290HM),高于不锈钢母材及焊缝的。18-8不锈钢一侧热影响区因析出δ铁素体及碳化物,致使显微硬度升高。焊缝靠近熔合区处的显微硬度值也有较大波动,这主要与不锈钢母材熔入焊缝造成的化学成分不均匀有关。

图6 18-8不锈钢侧熔合区附近的SEM像及显微硬度分布

Fig.6 SEM image and microhardness distribution near fusion zone of 18-8 steel side: (a) SEM image showing testing location; (b) Microhardness profile

2.3 熔合区附近的元素分布

焊接熔合区的组织性能与元素过渡有很大关系。采用JXA-8800R型电子探针显微分析仪(EPMA)对叠层复合材料熔合区的元素分布进行测试,结果如图7 所示。对叠层复合材料与焊缝的典型元素分布进行分析发现,母材与焊缝之间形成了宽80~85 μm的元素过渡区域,Fe元素从焊缝向母材扩散,而Ni元素正好相反,从母材向焊缝中扩散,Cr元素无明显的扩散现象。Fe、Ni和Cr这3种主要元素的扩散趋势与其在母材及所采用焊丝中的浓度梯度方向一致。焊缝金属与母材之间的元素过渡行为有利于形成稳定的熔合区,从而保证焊缝金属与母材之间形成有效的冶金连接。从母材过渡到焊缝中的Ni元素与焊缝中的Fe、Cr元素形成γ固溶体。

图7 叠层复合材料侧熔合区附近的SEM像及元素分布

Fig.7 SEM image of element distribution near fusion zone of laminated composite: (a) SEM image showing measured location; (b) Element distribution

18-8不锈钢侧熔合区附近的微观组织及元素分布如图8所示。由图8可知,焊缝中Ni含量高于18-8不锈钢母材中Ni含量。因此,Fe、Ni元素形成了沿18-8不锈钢至焊缝的明显过渡,由图8(b)测得的过渡区域宽度约为20 μm;虽然18-8不锈钢母材与Cr25-Ni13填充金属中Cr含量不同,但因为Cr元素扩散速度慢,而Mn元素含量很低,从18-8不锈钢母材至焊缝Cr和Mn元素含量变化不大,扩散不明显。由以上分析可知,叠层材料与18-8钢焊接时,Fe、Ni元素在焊缝两侧熔合区均形成了明显的过渡。

图8 18-8不锈钢侧熔合区附近的SEM像及元素分布

Fig.8 SEM image and element distribution near fusion zone of 18-8 steel: (a) SEM image showing measured location; (b) Element distribution

3 结论

1) 采用填丝钨极氩弧焊可使Super-Ni叠层复合材料与焊缝熔合良好,焊缝表面平整光洁。NiCr基层与焊缝形成可靠的熔合,但焊接中应使钨极氩弧偏向18-8不锈钢一侧,以免Super-Ni复层熔合区过渡烧损。

2) Super-Ni复层侧熔合区显微硬度升高(190 HM),叠层复合材料一侧焊缝的显微硬度变化很小。18-8不锈钢一侧焊缝显微硬度值低于不锈钢母材,不锈钢热影响区的显微硬度值最高(290 HM)。不锈钢一侧热影响区析出δ铁素体和碳化物。

3) 叠层复合材料侧熔合区形成了明显的元素过渡,Ni元素由母材向焊缝过渡,而Fe元素由焊缝向母材过渡,过渡区域宽度为80~85 μm;18-8不锈钢侧过渡区域的宽度约为20 μm,Fe和Ni元素过渡明显。

REFERENCES

[1] CORREA E O, COSTA S C, SANTOS J N. Weldability of iron-based powder metal materials using pulsed plasma arc welding process[J]. Journal of Materials Processing Technology, 2008, 198(1/3): 323-329.

[2] 陈亚莉. 未来航空发动机涡轮叶片用材的最新形式——微叠层复合材料[J]. 航空工程与维修, 2001(5): 10-12.

CHEN Ya-li. Microlaminated composites: The next generation material of turbine blade[J]. Aviation Maintenance & Engineering, 2001(5): 10-12.

[3] 郭 鑫, 马 勤, 季根顺, 刘龙江. 金属间化合物基叠层复合材料研究进展[J]. 材料导报, 2007, 21(6): 66-69.

GUO Xin, MA Qin, JI Gen-shun, LIU Long-jiang. The research evolution of intermetallic based laminated composites[J]. Materials Review, 2007, 21(6): 66-69.

[4] BELITSKII M E. A method of manufacture and some properties of sintered 20Cr-80Ni nichrome[J]. Powder Metallurgy and Metal Ceramics, 1965, 4(9): 741-745.

[5] KUZNETSOV E I, SATANIN V A. Effect of high-temperature oxidation in liquid fuel combustion products on the strength characteristics of sintered sealing material nichrome Kh20N80-boron nitride[J]. Strength of Materials, 1983, 15(12): 1756-1758.

[6] SOROKIN V K. Strength of porous sintered sheet materials[J]. Powder Metallurgy and Metal Ceramics, 1988, 27(2): 171-175.

[7] 周瑞发, 韩雅芳, 李树索, 高温结构材料[M]. 北京: 国防工业出版社, 2006.

ZHOU Rui-fa, HAN Ya-fang, LI Shu-suo. High temperature structure materials[M]. Beijing: National Defense Industry Press, 2006.

[8] HAMILL J A. P/M joining processes, materials and techniques[J]. International Journal of Powder Metallurgy, 1991, 27(14): 1-19.

[9] KURT A, ATES H, DURGUTLU A, KARACIF K. Exploring the weldability of powder metal parts[J]. Welding Journal, 2004, 83(12): 34-37.

[10] HAMILL J A. Weld techniques give powder metal a different dimension[J]. Metal Powder Report, 2007, 62(5): 22-24, 26-27, 29-31.

[11] HAMILL J A. What are the joining processes, materials and techniques for powder metal parts?[J]. Welding Journal, 1993, 72(2): 37-37.

[12] CORREA E O, COSTA S C, SANTOS J N. Welding of iron based sintered alloys for structural applications using the pulsed TIG process[J]. CIT Informacion Tecnologica(Chile), 2000, 11(2): 109-115.

[13] CORREA E O, COSTA S C, SANTOS J N. Studies on weldability of iron-based powder metal alloys using pulsed gas tungsten arc welding process[J]. Journal of Materials Processing Technology, 2009, 209(8): 3937-3942.

[14] OJO O A, RICHARDS N L, CHATURVEDI M C. Study of the fusion zone and heat-affected zone microstructures in tungsten inert gas-welded INCONEL 738LC superalloy[J]. Metallurgical and Materials Transactions A, 2006, 37(2): 421-433.

[15] 陈国庆, 张秉刚, 何景山, 冯吉才. TiAl 基合金电子束焊接头组织及转变规律[J]. 焊接学报, 2007, 28(5): 81-84.

CHEN Guo-qing, ZHANG Bing-gang, HE Jing-shan, FENG Ji-cai. Microstructure and transformation of electron beam welded joints of TiAl base alloy[J]. Transactions of the China Welding Institution, 2007, 28(5): 81-84.

[16] 路文江, 中尾嘉邦, 筱崎贤二. 镍基合金焊接热影响区的液化裂纹敏感性[J]. 焊接学报, 1993, 14(3): 186-194.

LU Wen-jiang, NAKAO Y, KENJI S. Susceptibility of liquation crack in HAZ of nickel base alloys[J]. Transactions of the China Welding Institution, 1993, 14(3): 186-194.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50874069);高等学校博士学科点专项科研基金资助项目(200804220020)

收稿日期:2009-06-18;修订日期:2010-01-30

通信作者:李亚江,教授,博士;电话:0531-86656082;E-mail: yajli@sdu.edu.cn