镍钼矿提钼渣中镍的浸出工艺

张刚1, 2,赵中伟1, 2,霍广生1, 2,李洪桂1, 2

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 中南大学 稀有金属冶金与材料制备湖南省重点实验室,湖南 长沙,410083)

摘 要:在硫酸溶液中,使用常压氧化浸出法处理镍钼矿提钼渣以回收有价金属镍。考察搅拌速度、液固比、硫酸用量、氧化剂用量以及浸出时间对镍浸出过程的影响。试验结果表明:搅拌速度与液固比对浸出过程影响不明显;在未加入氧化剂时,主要发生镍氢氧化物简单的酸溶反应,而添加氧化剂后硫化物也被氧化浸出;此外,镍浸出率随浸出时间、温度及硫酸用量的增加而增大。最佳工艺条件如下:搅拌速度为500 r/min,液固比为 4?1, 氧化剂加入量为矿量的0.2倍,浸出温度为90 ℃,硫酸浓度为0.4 mol/L,浸出时间为8 h,镍浸出率可达95%左右。

关键词:镍钼矿;提钼渣;镍;浸出

中图分类号:TF111.3 文献标志码:A 文章编号:1672-7207(2010)04-1263-05

Leaching process of nickel from leaching residue of metalliferous black shales

ZHANG Gang1, 2, ZHAO Zhong-wei1, 2, HUO Guang-sheng1, 2, LI Hong-gui1, 2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Hunan Province for Metallurgy and Material Processing of Rare Metals,

Central South University,Changsha 410083, China)

Abstract: Molybdenum can be selectively extracted from metalliferous black shales in the hydrometallurgical process using air as oxidant. By the process, nickel keeps in residue. The residue is treated by oxidative leaching in sulfuric acid solution for extraction of nickel. The effects of experimental conditions were investigated, such as agitation speed, concentration of sulphuric acid, liquid-solid ratio, the amount of oxidant, temperature and leaching time. The results show that agitation speed and liquid-solid ratio affect nickel recovery little, while long enough leaching time, high enough temperature and concentration of sulphuric acid are necessary. Even if oxidant reagent is not added to leaching solution, most part of nickel existing as hydroxide can be leached through simple acid-dissolution. Other parts that exist as sulfide can only be leached under oxidative condition. The optimum parameters are as follows: agitation speed is 500 r/min, concentration of sulphuric acid is 0.4 mol/L, liquid-solid ratio is 4?1, the amount of oxidant is 0.2 times of the ore, temperature is 90 ℃ and leaching time is 8 h. Under the above experimental conditions, the recovery of nickel can reach about 95%.

Key words: metalliferous black shales; leaching residue; nickel; leaching

镍钼矿属黑色岩系,富含Ni,Mo,V,Cu,Co,Pb,Zn,P,Au,Ag,Os,Ir,Pt,Rh,Ru,Cd,Se,Ti,Rb和Cs等多种金属元素 [1-4],以厚度不大的金属层为主要组成部分。由于元素镍、钼的富集程度较高,因此,该部分通常被称为“镍钼矿多金属层” [4-7]。由于各地地质构造和生化环境等因素的差异,导致镍钼矿富集层的矿物组成有一定的差异,大体上由以下矿物组成:黄铁矿、针镍矿、方硫镍矿、锑硫镍矿、硫钼矿、黄铜矿、闪锌矿、炭泥质、水云母、高岭石、绢云母、胶磷矿、方解石和重晶石等。其中镍以方硫镍矿、硫铁镍矿、硫镍矿、针镍矿和辉砷镍矿等矿物为主,含镍质量分数为2%~5%;钼主要以硫化钼矿的形式存在[5-7],其质量分数为2.5%~6%。镍钼矿矿相组成复杂,采用传统的物理及化学选矿技术,较难将有价元素富集,冶炼工艺也无法将镍和钼进行有效提取,因此,镍钼矿长期以来未得到有效开发利用。随着高品位矿物资源的日益匮乏及金属价格的不断升高,镍钼矿的开发利用引起了广大冶金工作者的关注与重视。目前,关于镍钼矿处理工艺方面的研究,国外至今未见报道,国内虽然开展了很多从镍钼矿中提取有价金属的研究工作[8-14],但大都直接套用处理辉钼矿冶炼工艺,采用比较极端的试验手段,如焙烧和次氯酸钠浸出工艺等,试剂消耗量较大,且成本较高,对镍钼矿这种杂质含量高和组成复杂的矿物来说工业应用前景不大。因此,开发合理和有效处理镍钼矿新工艺的任务显得尤为迫切。为此,本文作者依据镍钼矿自身特点,提出了常压空气直接氧化浸出镍钼矿提取钼的新型绿色工艺。该工艺的特点是:以空气作为氧化剂,在常压下实现钼的高效浸出,工艺简单,无有害气体排出,设备投资少和成本较低,钼浸出率可达98%左右,实现了钼的选择性浸出与矿物的分离富集,即元素镍得到富集并全部留在浸出渣中,实现了镍钼矿资源的综合开发利用。

1 试验

1.1 试验原料

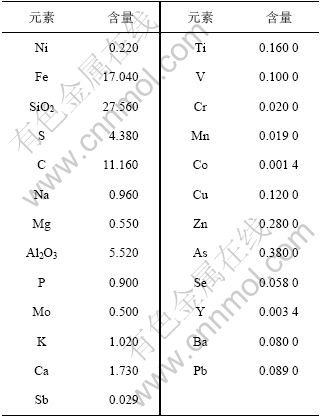

试验原料为来自贵州某地镍钼矿经湿法过程提取钼后的浸出渣,渣中水的质量分数为40%左右;原料经烘干后测得渣中其化学成分(质量分数)如表1所示。

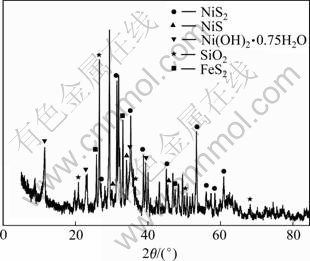

为确定渣中镍的赋存状态,进行了X线衍射分析,结果如图1所示。从图1可以看出:镍主要以氢氧化物形式存在。这是由于镍钼矿在氧化碱浸提钼过程中,镍的硫化物也被空气氧化转变为氢氧化物,但由于氧化不彻底,尚有部分镍仍以硫化物状态存在。

试验所用的硫酸和氧化剂等试剂均为化学纯,实验用水为去离子水。

表1 镍钼矿浸出渣化学成分

Table 1 Chemical composition of residue %

图1 镍钼矿提钼渣的XRD图谱

Fig.1 XRD pattern of residue

1.2 试验方法

试验在250 mL的锥形瓶中进行,配置可变速式搅拌器,并以接点温度计、调压器、水浴锅、电阻炉组成控温调节装置。首先将浸出湿渣与一定量的水混合调浆放入锥形瓶中,待试验温度到达后,在搅拌状态下加入硫酸与氧化剂开始进行反应。试验结束后,将矿浆过滤,洗涤滤饼并烘干备用。浸出液以及浸出渣中元素Ni的含量用原子吸收光谱法检测。

1.3 工艺原理

根据浸出渣的成分以及镍的赋存状态,选择硫酸介质中加入氧化剂的工艺对镍进行提取,在浸出过程中,主要发生以下反应:

对于简单酸溶,Ni(OH)2+H2SO4=NiSO4+2H2O;

氧化剂

对于氧化酸浸, 。

。

因此,镍的浸出主要涉及氢氧化物的简单酸溶反应和与硫化物的氧化酸浸过程。

2 结果及讨论

2.1 搅拌速度的影响

通过试验考察了不同搅拌速度对镍浸出效果的影响,试验条件为:硫酸初始浓度为0.8 mol/L,反应温度为90 ℃,浸出时间为8 h,液固比为4?1,氧化剂用量为矿量的0.2倍,结果如图2所示。

图2 搅拌速度对镍浸出的影响

Fig.2 Effect of stirring speed on nickel extraction

从图2可以看出:搅拌速度的改变对镍的浸出率变化不大,但为防止在浸出过程中矿物颗粒沉积,试验中选择搅拌速度为500 r/min。

2.2 液固比的影响

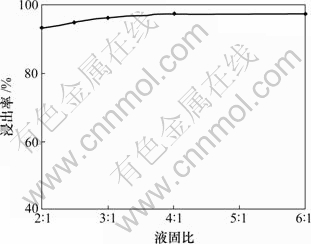

在硫酸初始浓度为0.8 mol/L,反应温度为90 ℃,浸出时间为8 h,氧化剂用量为矿量的0.2倍,搅拌速度为500 r/min的条件下,考察了液固比对镍浸出效果的影响,结果如图3所示。由图3可见:液固比对镍浸出率的影响也不甚明显。当液固比由2?1增加到4?1时,浸出率仅提高4%左右,达到97%;继续增加液固比,浸出率基本保持不变。为保持固体颗粒良好的分散性,选取液固比4?1为宜。

2.3 氧化剂用量的影响

在硫酸初始浓度为 0.8 mol/L,反应温度为90 ℃,浸出时间为8 h,液固比为4?1,搅拌速度为500 r/min时,考察了氧化剂用量对镍浸出效果的影响,结果如图4所示。

图3 液固比对镍浸出的影响

Fig.3 Effect of liquid-solid ratio on nickel extraction

图4 氧化剂用量对镍浸出的影响

Fig.4 Effect of amount of oxidant on nickel extraction

图4显示:镍浸出率随氧化剂加入量的增大而升高。在未加入氧化剂的情况下,主要发生的是镍氢氧化物的简单酸溶反应,镍浸出率为78.54%;加入氧化剂后,硫化矿物被氧化,镍浸出率迅速增加;当氧化剂加入量为矿量的0.2倍时,已经达到97%左右;而继续增大氧化剂加入量,对于镍的提取影响不明显。因此,选择氧化剂用量为矿量的0.2倍为宜。

2.4 温度的影响

图5所示为不同浸出温度对镍浸出效果的影响。试验条件如下:硫酸初始浓度为0.8 mol/L,浸出时间为8 h,氧化剂用量为矿量的0.2倍,液固比为4?1,搅拌速度为500 r/min。

图5 温度对镍浸出的影响

Fig.5 Effect of temperature on nickel extraction

从图5可知:温度对镍的浸出过程影响较大。随着浸出温度的升高,镍的浸出率不断增大,但当浸出温度超过90 ℃时,浸出率曲线基本保持平稳。因此,可选择浸出温度为90 ℃。

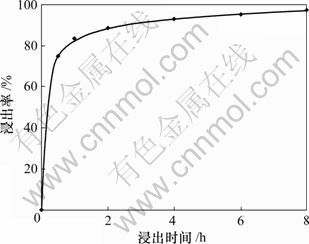

2.5 浸出反应时间的影响

在硫酸初始浓度为 0.8 mol/L,反应温度为90 ℃,氧化剂用量为矿量0.2倍,液固比为4?1,搅拌速度为500 r/min的条件下考察浸出时间对镍浸出效果的影响,结果如图6所示。由图6可见:当浸出时间达到8 h时,浸出率为97.7%,镍的浸出过程基本完成。

图6 浸出时间对镍浸出的影响

Fig.6 Effect of leaching time on nickel extraction

2.6 硫酸浓度的影响

固定反应温度为90 ℃,浸出时间为8 h,氧化剂用量为矿量的0.2倍,液固比为4?1,搅拌速度为500 r/min,考察了硫酸浓度对镍浸出效果的影响,结果如图7所示。

图7 硫酸浓度对镍浸出的影响

Fig.7 Effect of sulfuric acid concentration on nickel extraction

由图7可以看出:当硫酸浓度达到0.4 mol/L时,浸出率已经达到95%,其后继续增加硫酸浓度,浸出率变化不明显。

选取硫酸浓度为0.4 mol/L时的浸出渣(渣率近似为近1),分析其化学成分(质量分数),如表2所示。与表1中数据对比可知:镍基本被全部浸出,其他元素如铁等则被抑制在渣中。

表2 提镍渣化学成分

Table 2 Chemical composition of slag %

3 结论

(1) 在空气氧化浸出镍钼矿提钼渣中,镍主要以氢氧化物形式存在,部分仍以硫化物状态存在。

(2) 使用氧化剂,在硫酸介质中常压下就可实现镍钼矿提钼渣中镍的选择性浸出。最佳浸出条件如下:搅拌速度为500 r/min,液固比为 4?1, 氧化剂加入量为矿量的0.2倍,浸出温度90 ℃,硫酸浓度0.4 mol/L,浸出8 h,镍浸出率可达95%左右。

参考文献:

[1] 范德廉, 杨秀珍, 王连芳, 等. 某地下寒武统含镍钼多元素黑色岩系的岩石学及地球化学特点[J]. 地球化学, 1973, 3: 143-164.

FAN De-lian, YANG Xiu-zhen, WANG Lian-fang, et al. Petrological and geochemical characteristics of nickel- molybdenum-multi-element-bearing lower-Cambrian black shale from a certain district in south China[J]. Geochimica, 1973, 3: 143-164.

[2] 潘家永, 马东升, 夏菲, 等. 湘西北下寒武统镍-钼多金属富集层镍与钼的赋存状态[J]. 矿物学报, 2005, 25(13): 283-288.

PAN Jia-yong, MA Dong-sheng, XIA Fei, et al. Study on nickel and molybdenum minerals in Ni-Mo sulfide layer of the lower Cambrian black rock series, northwestern Hunan[J]. Acta Mineralogica Sinica, 2005, 25(13): 283-288.

[3] 张爱云, 伍大茂, 郭丽娜, 等. 海相黑色页岩建造地球化学与成矿意义[M]. 北京: 科学出版社, 1984: 161-185.

ZHANG Ai-yun, WU Da-mao, GUO Li-na, et al. Petrological significance and geochemical of submarine black shale[M]. Beijing: Science Press, 1984: 161-185.

[4] 李有禹. 湘西北镍钼多金属喷气沉积矿床的地球化学特征[J]. 地球化学, 1997, 26(3): 89-95.

LI You-yu. Geochemistry of Ni-Mo poly metallic exhalation sediment ore deposit in northwestern Hunan[J]. Geochimica, 1997, 26(3): 89-95.

[5] 丁佑良, 李有禹. 湘西北镍钼多金属矿床的元素组合及微量元素地球化学[J]. 湖南地质, 1997, 16(2): 98-100.

DING You-liang, LI You-yu. Elements association and geochemistry of trace elements of Ni-Mo polymetallic deposits in northwestern Hunan[J]. Hunan Geology, 1997, 16(2): 98-100.

[6] Kao L S, Peacor D R, Raymond M C J R, et al. A C/MoS2 mixed-layer phase (MoSC) occurring in metalliferous black shales from southern China, and new data on jordisite[J]. American Mineralogist, 2001, 86(7/8): 852-861.

[7] Michael S, Zhu M Y, Zao Y L, et al. Lower Cambrian burgess shale-type fossil associations of south China[J]. Palaeogeography, Palaeoclimatology, Palaeoecology, 2005, 220: 129-152.

[8] 何旭初. 一种选冶结合的镍钼矿镍、钼分离方法: 中国, 1134865A[P]. 1996-11-06.

HE Xu-chu. The process of separation molybdenum and nickel from black shales by mineral and metallurgy processing: China, 1134865A[P]. 1996-11-06.

[9] 皮关华, 徐徽, 陈白珍, 等. 从难选镍钼矿中回收钼的研究[J]. 湖南有色金属, 2007, 23(1): 9-12.

PI Guan-hua, XU Hui, CHEN Bai-zhen, et al. Study on recovering molybdenum from rocky-select Ni-Mo ores[J]. Hunan Nonferrous Metals, 2007, 23(1): 9-12.

[10] 邹贵田. 用稀酸从钼镍共生矿提取钼和镍盐的方法: 中国, 1267739A[P]. 2000-09-27.

ZOU Gui-tian. Recovery of molybdate and nickel salt from Ni-Mo ore by dilute acid: China, 1267739A[P]. 2000-09-27.

[11] 邹贵田. 用弱碱从钼镍共生矿提取钼和镍盐的方法: 中国, 1267740A[P]. 2000-09-27.

ZOU Gui-tian. Recovery of molybdate and nickel salt from Ni-Mo ore by dilute acid: China, 1267740A[P]. 2000-09-27.

[12] 伍宏培, 冯光芬. 钼镍矿的浓酸熟化浸出解聚溶剂萃取工艺: 中国, 1033784A[P]. 1989-07-12.

WU Hong-bei, FENG Guang-fen. Treatment of Ni-Mo ore by the method of acid curing leaching & solvent extraction: China, 1033784A[P]. 1989-07-12.

[13] 秦纯. 用碳酸钠转化处理黑色页岩分离钼镍的工艺: 中国, 1177012A[P]. 1998-03-25.

QIN Chun. The process of separation molybdenum and nickel from black shales by the method of sodium carbonate conversion treatment: China, 1177012A[P]. 1998-03-25.

[14] 李青刚, 肖连生, 张贵清, 等. 镍钼矿生产钼酸铵全湿法生产工艺及实践[J]. 稀有金属, 2007, 23(1): 9-12.

LI Qing-gang, XIAO Lian-sheng, ZHANG Gui-qing, et al. Process and practice of ammonium molybdate production from Ni-Mo ore by hydrometallurgy[J]. Chinese Journal of Rare Metals, 2007, 23(1): 9-12.

收稿日期:2009-08-17;修回日期:2009-11-01

基金项目:国家高技术研究发展计划(“863”计划)项目(2006AA06Z122);湖南省国土资源厅矿产资源与合理开发利用科研专项计划项目(2006K06)

通信作者:赵中伟(1966-),男,河北永年人,教授,从事冶金及功能材料的研究;电话:0731-88830476;E-mail: zhaozw@mail.csu.edu.cn

(编辑 任楚威)