DOI: 10.11817/j.issn.1672-7207.2015.08.009

7A55铝合金厚板的微观组织和性能不均匀性

冯迪1,2,张新明1,刘胜胆1,吴泽政1,郭奕文1,余翠娟1

(1. 中南大学 材料科学与工程学院,有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083;

2. 江苏科技大学 材料科学与工程学院,江苏省先进焊接技术重点实验室,江苏 镇江,212003)

摘要:采用金相显微镜、扫描电镜、透射电镜、织构分析、硬度、电导率、拉伸测试等实验手段研究7A55铝合金厚板T6态微观组织与性能沿厚度方向的演变规律。研究结果表明:在板材的厚度方向上,板材的微观组织和硬度、电导率、强度、织构等存在不均匀性。从板材表层到心部,其再结晶分数依次降低,残余第2相体积分数、电导率和强度依次升高,表层硬度比心部的高,1/4层的硬度最高。心部含有最多的轧制型织构为铜织构{112}<111>,黄铜织构{011}<211>和S织构{123}<634>,表层含有最多的再结晶织构为{001}<100>。轧制型织构具有更大的泰勒因子M,对强度贡献更大,表层的再结晶严重削弱了其力学性能,影响各层力学性能差异的主要因素是再结晶及织构。

关键词:7A55铝合金;厚板;不均匀性

中图分类号:TG166.3 文献标志码:A 文章编号:1672-7207(2015)08-2824-07

Inhomogeneity of microstructure and properties of 7A55 aluminum alloy thick plate

FENG Di1, 2, ZHANG Xinming1, LIU Shengdan1, WU Zezheng1, GUO Yiwen1, YU Cuijuan1

(1. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Provincial Key Lab of Advanced Welding Technology, Department of Materials Science and Engineering,

Jiangsu University of Science and Technology, Zhenjiang, 212003, China)

Abstract: The microstructure and properties evolution of 7A55 aluminum alloy thick plate along the thickness direction were investigated by optical microscopy, scanning electron microscopy, transmission electron microscopy, X-ray diffractometry, hardness, conductivity and tensile tests. The results show that the microstructure, texture and mechanical properties in different layers along the thickness direction are inhomogeneous. From the surface to the center layer,the fraction of recrystallization decreases while the volume fraction of coarse particles and conductivity as well as strength increase. The hardness of the surface layer is higher than that of the center layer, and the hardness of 1/4 layer is the highest. The center layer of the plate has more rolling texture than surface, such as copper texture{112}<111>, brass texture{011}<211> and S texture{123}<634> while surface layer has more recrystallization texture, such as {001}<100>. The Taylor factor M of rolling texture is larger and contributes more to the strength, and the high fraction of recrystallization sharply decreases the strength of the surface layer. Recrystallization and texture are the main factors of inhomogeneity in mechanical properties.

Key words: 7A55 aluminum alloy; thick plate; inhomogeneity

近年来,航空工业中往往采用整体结构件来代替由大量模锻件或挤压件组成的装配件,以降低成本、提高安全性。通过铆接、焊接等方式连接到一起的装配件,其连接强度比整体结构件低,可靠性低,铝合金厚板的应用使飞机制造中减少了结构件的数量,增强飞机可靠性,降低飞机制造成本及减轻机身质量[1-3]。随航空事业的发展,超大尺寸铝合金厚板的需求量进一步增大,对铝合金的综合性能要求也越来越高。20世纪90年代美国开发出7055铝合金[4],该合金强度高、密度低、断裂韧性好、抗应力腐蚀性能好,对航空、航天、高铁、汽车等机身质量减小效果明显,且能保证强度,多加工成大规格厚板,其T7751态在民用飞机的上翼面结构、水平安定面、龙骨架、座轨和运货滑轨等应用广泛[5]。铝合金厚板产品存在不均匀性,在不同的方向和厚度层上性能都存在差异。张新明等[6]在研究7050厚板时发现在厚度方向上板材的组织、织构、强度和断裂韧性等存在较大差异。Robinson等[7]研究7010-T765铝合金厚板时,发现从表层到心部,板材的长横向拉伸性能呈递减趋势。随着国内航空事业的发展,国内某厂开发了相应的30 mm厚的7A55铝合金,本文作者旨在探究引起7A55铝合金厚板在厚度方向上性能不均匀性的因素,以便为后续提高其均匀性提供参考。

1 实验

本实验所用的材料为30 mm厚7A55热轧板材,其化学成分如表1所示。

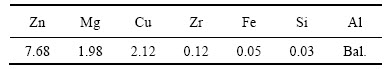

表1 7A55铝合金热轧板材的化学成分(质量分数)

Table 1 Chemical compositions of 7A55 aluminum alloyrolled plate %

对轧板进行470 ℃/1 h+480 ℃/1 h固溶处理以及T6人工时效(120 ℃/24 h)热处理。沿着板材厚度方向上从表面到心部取3层:表层(0~2 mm),1/4层(6~8 mm)和心部(12~14 mm)。所有实验都在这3层板材上进行。用FEI-Quanta型扫描电镜和XJP-6A型光学显微镜观察合金微观组织;采用TecnaiG220型分析电镜观察时效态微观组织,加速电压为200 kV,透射电镜样品直径为3 mm,厚度为0.08 mm,在含HNO3体积分数为20%的甲醇溶液中进行双喷减薄,温度控制在-25 ℃以下,电压为15~20 V。采用小负荷维氏硬度计(HV-10B)测量不同状态样品的硬度,按照GB/T12966—2008标准在涡流电导仪7501型上测量面电导率,每个样品测3点取平均值,单位为mS/m。按照GB/T228—2002规定加工拉伸试样,在CSS 44100电子万能试验机上进行拉伸性能测试。

织构试样长×宽×高为25 mm×15 mm×2 mm,试样表面采用氢氧化钠溶液腐蚀以减少表面的残余应变和应力。织构测定在Bruker D8 Discover型X线衍射仪上进行,采用Tang等[8]提出的方法进行织构分析。

2 实验结果

2.1 轧板中的第2相分布

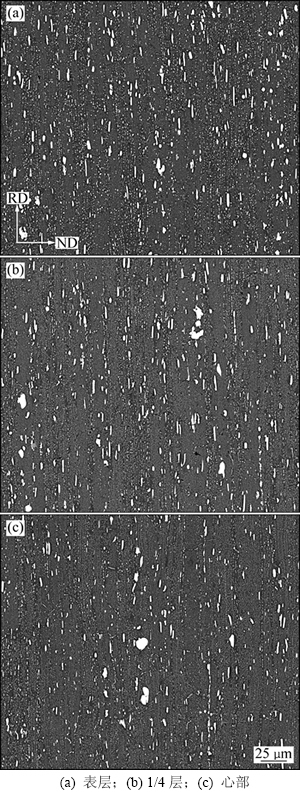

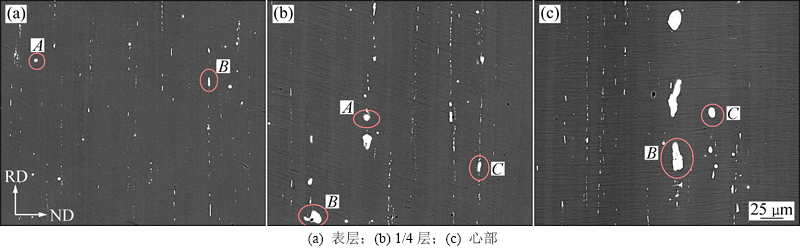

轧板中不同层的第2相SEM图如图1所示。图中RD代表轧向,ND为轧面法向。

从图1可以看出:轧板中从表层到心部均含有大量白色的第2相,经过轧制变形后,第2相沿着轧制方向被压扁呈带状分布,各层的第2相体积分数差别不大,但表层的第2相分布均匀,尺寸相对细小;而从表层到心部近圆形第2相增多且更粗大,第2相的拉长、破碎程度明显降低。这些圆形的第2相粒子破碎程度较低,聚集在一起使后续的固溶过程较难将其溶解,需更高的固溶温度或更长的固溶时间。

2.2 7A55厚板470 ℃/1 h+480 ℃/1 h固溶处理后的组织

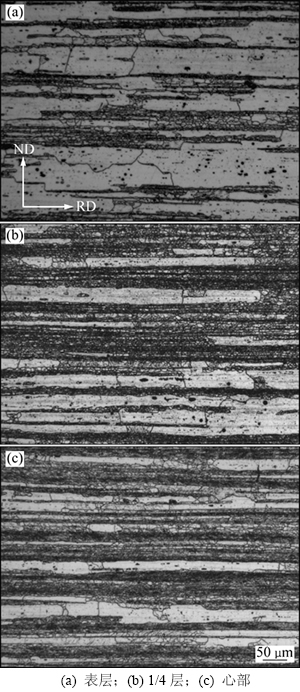

7A55厚板经固溶处理后纵截面的金相组织的SEM图如图2所示。

从图2可以看出:经固溶处理后,板材各层均发生了再结晶,基体组织中有大量的再结晶晶粒和细小亚晶组织,图中白色的组织为再结晶组织,晶粒较大,黑色的区域是亚晶组织。晶粒组织沿着轧向发生严重变形,被拉长、压扁,心部的再结晶晶粒尤为细长。表层再结晶程度最大,主要是大量的再结晶组织和少量的亚晶组织,变形组织保留的较少。再结晶程度由表层到心部逐渐减少,心部的再结晶程度最低,保留最多的是变形组织。用ImageJ软件进行统计,在470 ℃/1 h+480 ℃/1 h制度下,板材心部再结晶分数为26.1%,而1/4层的再结晶分数为43.5%,表层的再结晶分数最高为59.2%。

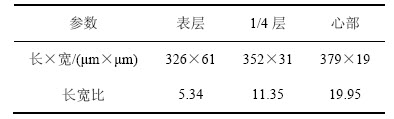

不同层的再结晶组织形貌不同,表层再结晶组织粗大,宽度大,但较短,长宽比最小,1/4层的再结晶组织宽度减小,但变得细长,长宽比增加,心部的再结晶晶粒宽度则进一步减小,变得更加细长。统计470 ℃/1 h+480 ℃/1 h固溶制度下不同层的再结晶晶粒的长宽比,如表2所示。从表2看出再结晶晶粒的长宽比由表层到心部逐渐增加。

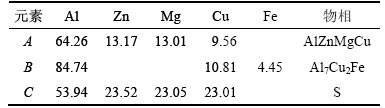

固溶处理后不同层的SEM图如图3所示,第2相的能谱分析见表3。由图3和表3可见:第2相以链状形式沿着轧向分布,从表层到心部第2相质量分数明显增多,第2相尺寸增大;经过固溶处理后,表层第2相溶解得较完全,经能谱分析(表3)表明只剩下细小的圆形相(图3中A点为AlZnMgCu相)和难溶的呈不规则链状分布的富Fe相(图3中B点为Al7Cu2Fe相),这2种相在板材3层中都可以看见。1/4层第2相质量分数增大,基体中还发现了S相(图3中C点为Al2CuMg相),心部的S相进一步增大,且Al7Cu2Fe相质量分数也增大,富集的元素增多。这些溶质原子聚集在一起,既降低了基体的过饱和度,又削弱后续时效强化潜力,容易成为裂纹源,对力学性能不利。

图1 7A55铝合金轧板中的第2相SEM图

Fig. 1 SEM images of coarse particles for the second phase of 7A55 aluminum alloy rolled plate

图2 不同层的金相组织的SEM图

Fig. 2 SEM images of 7A55 aluminum alloy after solution heat treatment

表2 不同层的再结晶晶粒长宽比

Table 2 The aspect ratio of recrystallized grains in different layers

2.3 织构分析

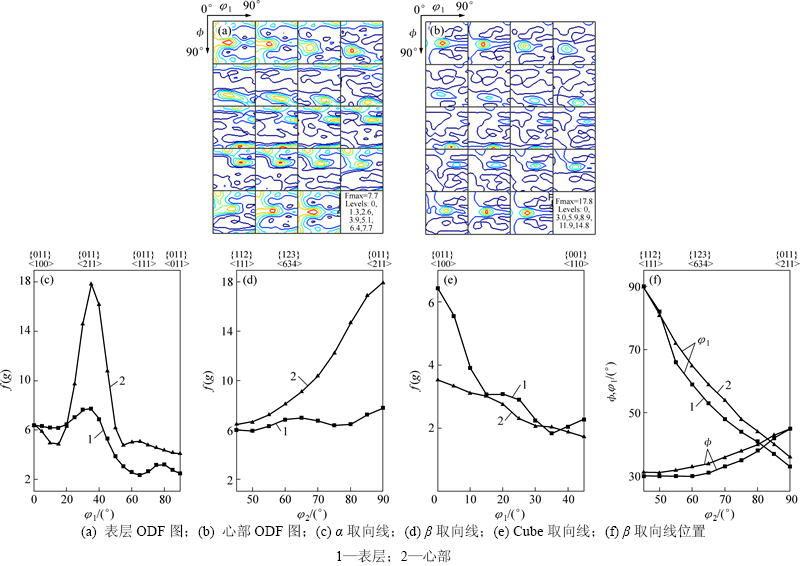

对板材表层和心部进行织构分析测试,结果如图4所示。

由图4可知:板材各层均存在铜织构({112}<111>)、黄铜织构({011}<211>)、高斯织构({011}<100>)和S织构({123}<634>);各层之间黄铜织构({011}<211>)强度差异最大,中心层强度为18,表层为8。除黄铜织构({011}<211>)外,α和β取向线上各织构强度差别不大。从Cube-ND取向线可以看出立方织构({001}<100>)强度差较大,立方织构为再结晶织构,间接反映样品的再结晶程度。

图3 固溶处理后第2相分布

Fig. 3 Coarse particles distribution of the second phase of 7A55 aluminum alloy after solution heat treatment

图4 固溶后表层和心部的ODF图像及分析结果

Fig. 4 ODF maps and analysis results of surface and center layer

表3 固溶后7A55铝合金中粗大第2相EDS分析结果(质量分数)

Table 3 EDS results of coarse particles in 7A55 aluminum alloy thick plate after solution treatment %

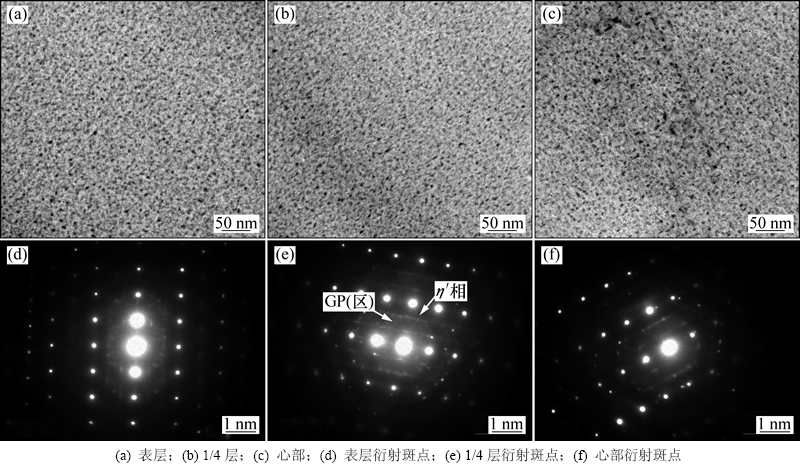

2.4 板材不同层的TEM分析

图5所示为时效态板材表层、1/4层和心部的TEM图。从图5可以看出:经过时效后,基体中出现了大量细小弥散的沉淀相,通过[112]Al透射斑点可知这些沉淀相包含η′相以及溶质原子偏聚区(GP区),3层的衍射斑点表明板材3层的时效析出物相都相同,在7A55铝合金中η′相为主要的强化相。

2.5 硬度、电导率及拉伸力学性能

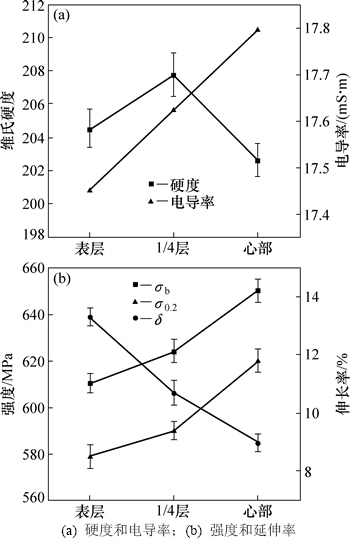

对固溶时效后的板材进行硬度、电导率及拉伸力学性能测试,如图6所示。

从图6可以看出:板材经T6处理后电导率从表层到心部依次增大,电导率主要与基体内溶质原子的固溶度以及共格脱溶相周围的应变能有关,电导率越大,溶质原子的固溶程度越低,这意味着表层的固溶度最大,心部的最小;与SEM分析相对应,固溶后心部粗大粒子多,溶质原子大量聚集,基体的过饱和度最低。从硬度的变化规律来看,1/4层的硬度最高,表层的硬度其次,心部的硬度最低。但是心部的抗拉强度最高,从心部到表层抗拉强度依次降低。表层的抗拉强度最低,延伸率最高,延伸率从表层到心部依次降低。

3 分析与讨论

轧板组织从表层到心部具不均匀性,表层的第2相较为细小,而心部出现了更粗大的第2相。这与铸锭组织的不均匀有关,铸锭组织在铸造过程中,由于铸锭表层到心部的冷却速度逐渐降低,非平衡凝固程度降低,结晶相的尺寸增大。在轧制过程中,各层的变形程度不同,表层应变量大,发生塑性变形的程度更大,心部应变量小,塑性变形程度更低[9],因此,粗大第2相在轧制过程中从表层到心部破碎程度逐渐降低,心部保持了大量粗大近圆形的第2相,而表层相对较少,如图1所示。这些大尺寸的第2相聚集了大量的溶质原子,在固溶过程中需要更长时间来扩散,因而更难溶解,固溶之后心部仍存在尺寸较大的残余第2相,如图3所示。固溶处理将溶质原子溶入到合金基体中,淬火之后形成过饱和固溶体,在随后的时效过程中,溶质原子从基体中析出,形成弥散第2相,使合金性能强化[10]。图3表明:固溶后,表层粗大第2相大大减少,而心部仍有大尺寸的第2相,因此,固溶淬火之后从表层到心部过饱和度逐渐降低,这与电导率的变化趋势相符。经硬度测试,表层硬度比心部的高,1/4层的最高,差异为4。而表层硬度比1/4层的低是因为表层再结晶程度太高(见图2),达59%,再结晶晶粒尺寸比1/4层的大,更接近等轴状,因此其硬度比1/4层的低。经拉伸测试,表层的抗拉强度为610 MPa,屈服强度为580 MPa,而心部抗拉强度为650 MPa,屈服强度为621 MPa,表层与心部的屈服强度差异达41 MPa,与析出强化的趋势不相符,这种差异主要是由再结晶程度及织构引起的。

图5 不同层的TEM图

Fig. 5 TEM images of different layers

图6 不同层的力学性能测试

Fig. 6 Mechanical properties of different layers

根据Dixit等[11]的研究,合金的屈服强度与织构和微观组织相关,合金总的屈服强度 为

为

(1)

(1)

其中: 为晶界强化强度;

为晶界强化强度; 为固溶强化强度;

为固溶强化强度; 为位错强化强度;

为位错强化强度; 为析出相强化强度;

为析出相强化强度; 为层错强化强度;

为层错强化强度; 为模量强化强度;M为泰勒因子。对于厚板表层和心部来说,表层的析出相密度比心部的大,根据文献中的计算公式[12]

为模量强化强度;M为泰勒因子。对于厚板表层和心部来说,表层的析出相密度比心部的大,根据文献中的计算公式[12]  ,固溶强化效应

,固溶强化效应 强度、位错强化强度

强度、位错强化强度 、层错强化强度

、层错强化强度 和模量强化强度

和模量强化强度 均差别不大,但析出相强化强度

均差别不大,但析出相强化强度 大于

大于 。Marthinsen等[13]的研究公式为

。Marthinsen等[13]的研究公式为

(2)

(2)

其中:G为Al的剪切模量,为26 GPa[14];b为伯格斯矢量;fRex为再结晶分数;δ为未再结晶区域的亚晶粒尺寸;α2为常数[15],一般为2。因此,表层和心部的屈服强度差异受再结晶程度的影响,该厚板表层与心部的再结晶程度相差很大,晶界强化效果表层比心部的小, <

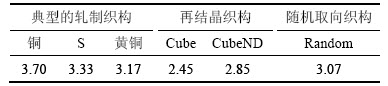

< 。再结晶在一方面减少了亚晶界,弱化合金的强度,另一方面减少了轧制织构,增加了随机取向织构和再结晶织构。泰勒因子M一般用来表示织构和拉伸方向对屈服强度的影响,对于典型的轧制织构,M比再结晶织构的大15%以上,如表4所 示[16]。从表4可以看出:轧制型织构Copper,S,Brass的M均比再结晶织构Cube,CubeND以及随机取向织构Random的大。

。再结晶在一方面减少了亚晶界,弱化合金的强度,另一方面减少了轧制织构,增加了随机取向织构和再结晶织构。泰勒因子M一般用来表示织构和拉伸方向对屈服强度的影响,对于典型的轧制织构,M比再结晶织构的大15%以上,如表4所 示[16]。从表4可以看出:轧制型织构Copper,S,Brass的M均比再结晶织构Cube,CubeND以及随机取向织构Random的大。

表4 常见的泰勒因子M

Table 4 Common Taylor factor M

在轧制过程中,厚板沿着厚度方向变形不均匀,表层与心部的应变量差异较大,板材表层直接与轧辊接触,轧制时即使在润滑剂的作用下依然会产生很大的摩擦力,造成表面受到很大的剪切应力,产生剪切应变。剪切应变使表层晶粒转向稳定的{001}<110>取向,形成剪切织构。心部应变量更小,板材中心层处于理想的平面应变状态,在平面应变状态下,晶粒组织转向稳定的轧制型织构[17]。由于变形量的差异,表层和心部的形变储能相差很大,表层的储能比心部的高,因此,在固溶过程中表层发生了严重的再结晶,达到59%的再结晶程度,再结晶晶粒更接近等轴状,且表层的亚晶粒尺寸比心部的大,心部的再结晶程度为26%。当再结晶分数超过50%时,合金的力学性能会严重下降[18]。由式(2)可以得出, <

< 。再由织构分析可知,板材各层均有变形织构铜织构({112}<111>)、黄铜织构({011}<211>)、高斯织构({011}<100>)、S织构({123}<634>),从表层到心部逐渐减少,各层之间黄铜织构({011}<211>)强度差异最大,表层再结晶织构最多,因此,表层的泰勒因子M最小,由表层到心部逐渐增大。虽然

。再由织构分析可知,板材各层均有变形织构铜织构({112}<111>)、黄铜织构({011}<211>)、高斯织构({011}<100>)、S织构({123}<634>),从表层到心部逐渐减少,各层之间黄铜织构({011}<211>)强度差异最大,表层再结晶织构最多,因此,表层的泰勒因子M最小,由表层到心部逐渐增大。虽然 >

> ,但M表<M心,

,但M表<M心, <

< ,故造成表层的屈服强度低于心部的屈服强度。

,故造成表层的屈服强度低于心部的屈服强度。

4 结论

1) 固溶时效态7A55板材沿着厚度方向存在组织的不均匀性,从表层到心部再结晶程度降低,表层再结晶程度达59%,而心部的再结晶程度约为26%。表层残余第2相结是程度最低,到心部逐渐升高。

2) 7A55板材沿着厚度方向存在性能的不均匀性,从表层到心部电导率、拉伸力学性能逐渐升高,延伸率逐渐降低,硬度在1/4层最高,心部最低。

3) 7A55板材沿着厚度方向的力学性能的不均匀性主要由再结晶程度及织构类型决定。表层再结晶程度高,轧制型织构少,M最小,屈服强度最低。

参考文献:

[1] 韩念梅, 张新明, 刘胜胆, 等. 双级时效对7050 铝合金厚板断裂韧性的影响[J]. 中南大学学报(自然科学版), 2011, 42(3): 624-628.

HAN Nianmei, ZHANG Xinming, LIU Shengdan, et al. Influence of two-step aging on fracture toughness of 7050 aluminum alloy plate[J]. Journal of Central South University (Science and Technology), 2011, 42(3): 624-628.

[2] Heinz A, Haszler A, Keidel C, et al. Recent development in aluminium alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[3] 刘兵, 彭超群, 王日初, 等. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chaoqun, WANG Richu, et al. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[4] Lukasak D A, Hart R M. Strong aluminum alloy shaves airframe weight[J]. Advanced Materials & Processes, 1991, 140(4): 46-49.

[5] 江志邦, 宋殿臣, 关云华. 世界先进的航空用铝合金厚板生产技术[J]. 轻合金加工技术, 2005, 33(4): 1-8.

WANG Zhibang, SONG Dianchen, GUAN Yunhua. Global advanced process technology of aluminium alloy plates for aircraft and aerospace[J]. Light Alloy Fabrication Technology, 2005, 33(4): 1-8.

[6] 张新明, 韩念梅, 刘胜胆, 等. 7050铝合金厚板织构、拉伸性能及断裂韧性的不均匀性[J]. 中国有色金属学报, 2010, 20(2): 202-208.

ZHANG Xinming, HAN Nianmei, LIU Shengdan. Inhomogeneity of texture, tensile property and fracture toughness of 7050 aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 202-208.

[7] Robinson J S, Cudd R L, Tanner D A, et al. Quench sensitivity and tensile property inhomogeneity in 7010 forgings[J]. Journal of Materials Processing Technology, 2001, 119(1/2/3): 261-267.

[8] TANG Jianguo, ZHANG Xinming, DENG Yunlai, et al. Texture decomposition with particle swarm optimization method[J]. Computational Materials Science, 2006, 38(2): 395-399.

[9] 李权, 唐广波, 刘正东, 等. 板带热轧变形过程中的非均匀应变问题分析[J]. 钢铁研究学报, 2007, 19(6): 52-56.

LI Quan, TANG Guangbo, LIU Zhengdong. Analysis of nonuniform strain in hot strip rolling deformation process[J]. Journal of Iron and Steel Research, 2007, 19(6): 52-56.

[10] Xu D K, Rometsch P A, Birbilis N. Improved solution treatment for an as-rolled Al-Zn-Mg-Cu alloy (Part II): Microstructure and mechanical properties[J]. Materials Science and Engineering A, 2012(534): 244-252.

[11] Dixit M, Mishra R S, Sankaran K K. Structure–property correlations in Al 7050 and Al 7055 high-strength aluminum alloys[J]. Materials Science and Engineering A, 2008, 478(1/2): 163-172.

[12] Clausen B, Lorentzen T, Leffers T. Self-consistent modelling of the plastic deformation of FCC polycrystals and its implications for diffraction measurements of internal stresses[J]. Acta Materialia, 1998, 46(9): 3087-3098.

[13] Marthinsen K, Nes E. A general model for metal plasticity[J]. Materials Science and Engineering A, 1997(234/235/236): 1095-1098.

[14] Hornbogen E, Jr. Starke E A. Overview no. 102 theory assisted design of high strength low alloy aluminum[J]. Acta Metallurgica et Materialia, 1993, 41(1): 1-16.

[15] Nes E, Pettersen T, Marthinsen K. On the mechanisms of work hardening and flow-stress saturation[J]. Scripta Materialia, 2000, 43(1): 55-62.

[16] Starink M J, Wang S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51(17): 5131-5150.

[17] Choi C, Kwon J, Oh K H, et al. Analysis of deformation texture inhomogeneity and stability condition of shear components in FCC metals[J]. Acta Materialia, 1997, 45(12): 5119-5128.

[18] Dorward R C, Beerntsen D J. Grain structure and quench-rate effects on strength and toughness of AA7050 Al-Zn-Mg-Cu-Zr alloy plate[J]. Metallurgical and Materials Transactions A, 1995, 26(9): 2481-2484.

(编辑 刘锦伟)

收稿日期:2014-08-23;修回日期:2014-10-26

基金项目(Foundation item):国家重点基础研究发展规划(“973”计划)项目(2012CB619500)(Project (2012CB619500) supported by the National Basic Research Program (973 program) of China)

通信作者:冯迪,博士,讲师,从事铝及铝合金的组织、织构理论与塑性加工技术研究;E-mail:difeng1984@aliyun.com