DOI:10.19476/j.ysxb.1004.0609.2019.01.02

高压扭转诱导新型Al-Zn-Mg-Cu合金第二相回溶

李萍,丁春慧,王薄笑天,吴广善,薛克敏

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:分别在380和400 ℃下对铸态Al-Zn-Mg-Cu合金进行高压扭转实验,随后对变形试样进行温度为100 ℃、时间为2~10 h的时效实验。采用X射线衍射仪、扫描电镜和维氏硬度分析Al-Zn-Mg-Cu合金在高压扭转变形过程中第二相形貌与含量变化以及时效过程中形变试样硬度的变化。结果表明:在高压扭转变形中,合金中第二相破碎、细化并回溶到基体中形成过饱和固溶体,第二相的回溶程度随着温度的升高和变形量的增加而增加。变形试样经100 ℃时效处理后,硬度随时效时间的增加先上升后下降。试样回溶程度越高,时效达到峰值所需的时间越短。

关键词:新型Al-Zn-Mg-Cu合金;高压扭转;第二相;回溶;时效

文章编号:1004-0609(2019)-01-0011-07 中图分类号:TG379 文献标志码:A

Al-Zn-Mg-Cu系超高强铝合金,是新一代优质结构铝合金,具有密度低、抗拉强度高以及加工性能好等优点,被认为是最有可能替代钢、铁的有色金属材料,广泛应用于航空航天、国防、军工、汽车工业、船舶工程以及核工业等领域,尤其是在航空航天领域已逐步取代了价格昂贵的钛合金材料[1-3]。杯形件作为典型回转体零件之一,广泛应用于汽车、航空航天、国防军工等领域。目前,应用于航空的薄壁类杯形件及回转体零件,多采用机械加工和锻压成形等技术。但传统加工工艺对合金晶粒细化效果以及性能改善有限,难以满足薄壁类杯形件及回转体零件日益严峻的服役环境。因此,急需新工艺来解决问题。

高压扭转(High pressure torsion, HPT)[4]是一种大塑性变形工艺,其原理是在试样的轴向施加压力的同时施加周向的剪切应力,可以在变形过程中同时获得较大的剪切变形和较高的静水压力,从而获得超细晶组织。因此,吸引了众多学者采用高压扭转工艺改善Al-Zn-Mg-Cu系超高强铝合金的组织性能[5-7]。早期对高压扭转后铝合金的研究重点集中在细化组织及诱导形成大角度晶界以获得高强度、超塑性等方面[8-10],而对合金中第二相粒子的变化行为等方面的研究较少。近期对经大塑性变形材料的内部组织研究表明,在变形过程中,合金中第二相颗粒会回溶到基体重新形成过饱和固溶体,当变形量达到一定程度,第二相再次以细小颗粒析出,使亚微米或纳米级晶粒具有较高的热稳定性[11-13]。但对Al-Zn-Mg-Cu系超高强铝合金大塑性变形过程中第二相粒子的变化情况鲜有报道。大塑性变形中的第二相粒子回溶是一个重要的微观现象,在某种程度上和固溶处理相似,且能保持大塑性变形后的超细晶组织[14],可以将其与金属材料的热处理工艺进行复合从而开发出更好的热处理工艺,以求获得稳定细化的组织和优异的性能。

本文采用高压扭转进行大尺寸杯形件的成形,借助于X射线衍射仪(X-ray polycrystalline diffractometer,XRD)与扫描电镜(Scanning electron microscope,SEM)研究在高压扭转过程中一种新型Al-Zn-Mg-Cu合金中第二相粒子的变化情况。对变形后的Al-Zn-Mg-Cu合金进行100 ℃的时效处理。同时进行力学测试,分析高压扭转对时效行为的影响。

1 实验

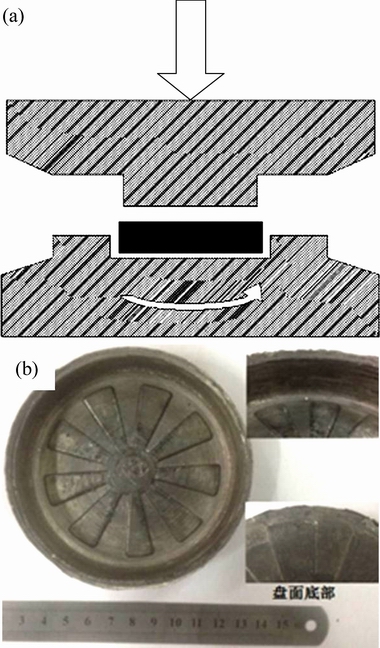

实验材料是经460 ℃、24 h均匀化处理后的铸态Al-Zn-Mg-Cu合金,是一种在7A60铝合金的基础上提高Zn含量而得到的新型铝合金,其主要化学成分如表1所列。采用电火花切割机切取d50 mm×35 mm的圆柱状试样,洁净表面后在YH-1000液压机下进行变形温度为380和400 ℃,压强为1 GPa,扭转圈数为0.5、1和5圈的恒温半限制型高压扭转实验。采用陶瓷保护电阻加热圈对模具加热,并使用电子控温装置调节温度以保证实验温度恒定,试样空冷。扭转角速度为0.3 rad/s,压下量为30 mm,成形件为d100 mm×4 mm的杯形件。工艺原理及成形件如图1所示。实验过程中温度向上浮动20~80 ℃,变形时间为6~105 s,三段式温度反馈装置可以实时有效的调整试验温度。在高压扭转变形中,剪切应变随着成形件半径和扭转圈数的增加而增加,优先选择在成形件的边缘部位取样。另外,考虑到同一个试样上剪切应变对后续测试及实验的影响,因此统一在距圆盘状样品中心35 mm处切取10 mm×5 mm的方形试样。

采用D/MAX2500V型X射线衍射仪进行物相分析,每个样品测3次取平均值。X射线衍射仪波长为0.1541 nm,靶材为Cu Kα,电压为40 kV,电流为150 mA,扫掠角度为10°~60°,扫描步长为0.0262°。同一试样经600#、800#砂纸打磨光滑后抛光,采用科勒试剂腐蚀后在JSM-6490LV扫描电子显微镜下进行微观组织观察与能谱测定。为深入分析Al-Zn-Mg-Cu合金 第二相的演化规律,采用Image Pro Plus 6.0软件定量统计微观组织图中第二相的尺寸分布信息。采用MH-3L维氏硬度计测量试样的维氏硬度,载荷为1.96 N,加载时间为15 s。在每个试样表面随机测7个点求取平均值。使用KSL-1100X箱式电阻炉对试样进行温度为100 ℃,时间为2~10 h的时效处理,并对比维氏硬度变化。

图1 高压扭转原理图及成形件

Fig. 1 Schematic diagram of high pressure torsion(a) and forming part(b)

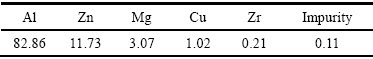

表1 Al-Zn-Mg-Cu合金主要化学成分

Table 1 Main chemical composition of Al-Zn-Mg-Cu alloy (mass fraction, %)

2 结果与分析

2.1 X射线衍射物相分析

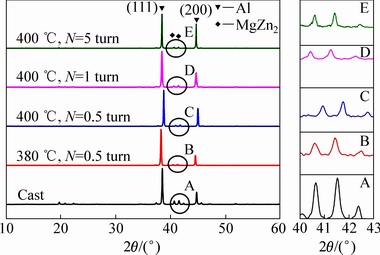

图2所示为铸态和不同变形条件下HPT变形的Al-Zn-Mg-Cu合金试样的XRD谱。与铸态试样衍射峰相比,380 ℃扭转0.5圈时MgZn2的衍射峰有明显的强度下降和峰形宽化,说明合金中的第二相含量减少。扭转圈数不变,温度提高到400 ℃,MgZn2的衍射峰的强度进一步降低,表明第二相含量继续减少。温度保持400 ℃不变,扭转圈数增加至1圈时,MgZn2的衍射峰的强度继续降低,虽然变化微小,但表明Al-Zn-Mg-Cu合金中的MgZn2的含量随着变形量的增加而减少。温度不变继续扭转至5圈时,峰宽变窄,强度上升,说明此条件下合金中第二相MgZn2含量又有所增加。许晓嫦等[15]对Al-Cu合金进行等径角挤压变形时发现了同样的情况,即合金中的第二相会随着变形量的增加而减少或增加。即对于含有大量亚稳相和平衡相的多元合金,大塑性变形会引起第二相破碎、细化、回溶到基体中形成过饱和固溶体,从而使得基体中的第二相含量减少;而对于含有过饱和固溶体的合金,则引起过饱和固溶体脱溶,析出平衡相,基体中第二相含量随之增加。综上所述可知,在HPT变形中,随着温度的升高和变形量的增加,Al-Zn-Mg-Cu合金中的第二相MgZn2回溶到基体中形成过饱和固溶体;扭转至5圈时,过饱和固溶体又会重新析出形成第二相。第二相的回溶与析出与变形温度和变形量有关。

图2 HPT变形Al-Zn-Mg-Cu合金XRD谱

Fig. 2 XRD patterns of Al-Zn-Mg-Cu alloy under HPT deformation

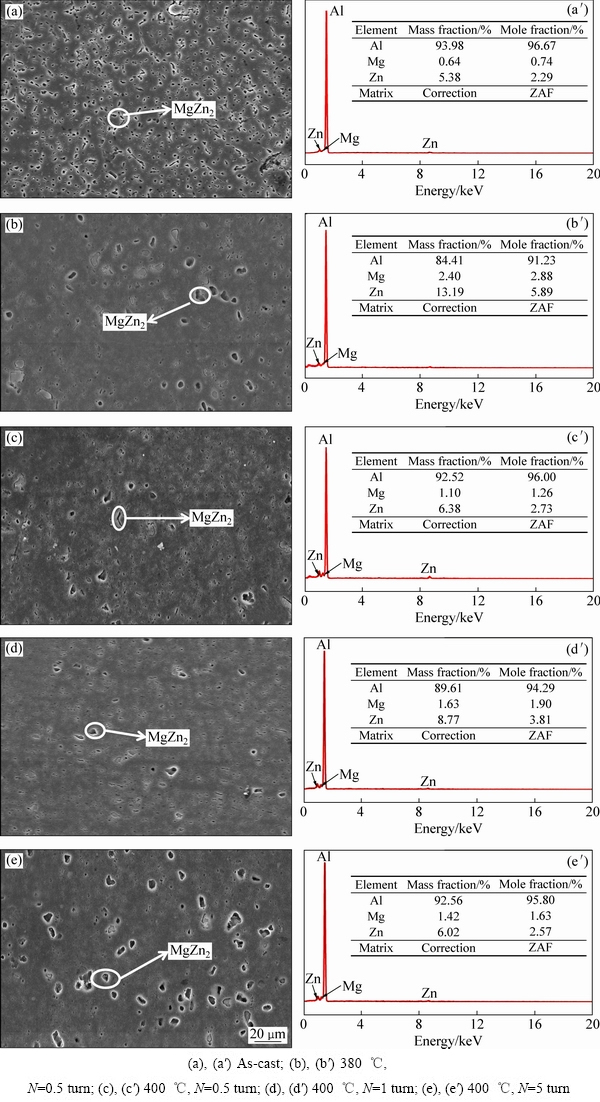

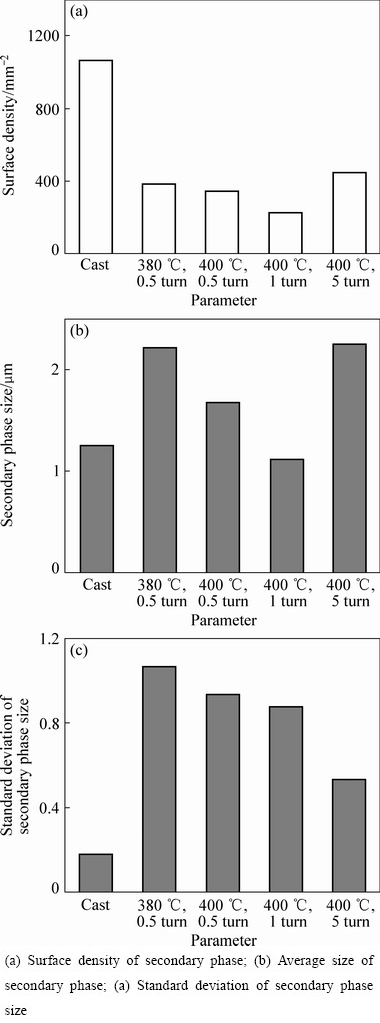

2.2 SEM像及成分分析

为了进一步分析Al-Zn-Mg-Cu合金中第二相在HPT变形过程中回溶与析出的变化规律,采用SEM和EDS对第二相形貌、数量和成分进行观察和表征。图3所示为铸态和不同变形温度、扭转圈数下HPT变形后Al-Zn-Mg-Cu合金的微观组织。图4所示为合金中第二相面密度、尺寸和尺寸标准差的统计柱状图。由图3(a)可见,铸态Al-Zn-Mg-Cu合金中的第二相主要沿晶界断续分布,只有少数细小的第二相颗粒分布于晶内,第二相的平均尺寸为1.3 μm,面密度为1062 mm-2,尺寸标准差为0.18。EDS结果显示,第二相成分主要为Mg和Zn,两者摩尔比接近2:1,结合XRD分析为MgZn2。经380 ℃、0.5圈HPT变形后,晶界已难以辨识,第二相数量大幅度减少,并呈现显著的团聚及粗化特征,如图3(b)所示。扭转圈数不变,温度升到400 ℃时,第二相尺寸略有减小,如图3(c)所示。当扭转圈数增至1圈时,第二相数量减少且更加细小弥散分布,其平均尺寸为0.9 μm,面密度为226 mm-2,如图3(d)所示。随扭转圈数增至5圈(见图3(e)),第二相数量显著增加,平均尺寸增至2.3 μm,呈较粗大的不规则块状。终上所述可知,在HPT变形初期,随着温度的升高和变形量的增加,第二相破碎、细化,回溶到基体中形成过饱和固溶体。变形温度不变,变形量累积到一定程度,第二相重新析出,长大。第二相含量先减少后增加,平均尺寸先减小后增大,尺寸标准差不断降低,第二相趋于均匀,如图4所示。

温度是影响第二相回溶的一个重要因素。第二相MgZn2回溶到基体中无论是形成置换型固溶体还是间隙型固溶体,都依赖于原子的扩散。温度是影响扩散速率的最主要因素之一,原子的扩散系数D可由式(1)确定[16]。

(1)

(1)

式中:D0为材料的扩散常数;Q为原子激活能;R为气体摩尔常数,为8.314 J/(mol·K);T为温度。

Zn、Mg和Cu在铝合金中的自扩散系数由大到小依次为Zn、Mg、Cu[17]。且温度越高,原子扩散得越快。以Zn的扩散为主解释。其中,D0=1.44×10-5 m2/s,Q=116.7 kJ/mol。380和400 ℃时的扩散系数分别6.65×10-15和1.26×10-14 m2/s。400 ℃下Zn的扩散系数大约是380 ℃条件下的2倍,因此,扭转圈数相同时,温度升高促进了第二相的回溶,使回溶的程度增加。

另外,在HPT变形过程中,材料受到很大的流变应力作用,产生强剪切变形,同时也会产生一定的形变热,结合数值模拟结果,通过 [18]计算可知,在变形过程中,温升为150~233.5 ℃。但实际温升为20~80 ℃且扭转时间较短,在上述条件下变形温升难以造成第二相体积分数、形态及分布的显著变化,因而可以忽略。故当变形温度相同时,引起第二相变化的主要原因应该是变形量。许晓嫦[19]对Al-Cu合金的二向反复挤压进行了研究,当变形30道次、累积应变量达到7.2、形变热低于100 ℃、加热时间低于10 min时,第二相含量和尺寸分布未发生显著变化。YAMAGUCHI等[20]在Al-Mg合金的等径角挤压的研究中发现,变形虽然获得 85 ℃的温升,但其对第二相的回溶影响不大,即变形过程中产生的温升可忽略不计。因此,变形温度相同时,可忽略形变热的影响。

[18]计算可知,在变形过程中,温升为150~233.5 ℃。但实际温升为20~80 ℃且扭转时间较短,在上述条件下变形温升难以造成第二相体积分数、形态及分布的显著变化,因而可以忽略。故当变形温度相同时,引起第二相变化的主要原因应该是变形量。许晓嫦[19]对Al-Cu合金的二向反复挤压进行了研究,当变形30道次、累积应变量达到7.2、形变热低于100 ℃、加热时间低于10 min时,第二相含量和尺寸分布未发生显著变化。YAMAGUCHI等[20]在Al-Mg合金的等径角挤压的研究中发现,变形虽然获得 85 ℃的温升,但其对第二相的回溶影响不大,即变形过程中产生的温升可忽略不计。因此,变形温度相同时,可忽略形变热的影响。

随着变形量的增加,一方面合金中硬脆的第二相MgZn2积累了大量的能量,同时,在机械力的作用下易发生破碎、细化溶入基体中;另一方面,MgZn2相与基体界面处存在的强应力场也会使原子脱离平衡位置,增大晶格畸变,增加位错密度[21],使第二相与基体界面处于非平衡状态,从而在界面能与界面应力释放过程中为第二相的溶解提供了高的驱动力[13]。同时,位错与晶界等晶体缺陷处的原子处于较高的能量状态,通过位错与晶界扩散所需的原子激活能是自扩散的0.6和0.5倍[17],原子更容易沿着位错和晶界扩散。在大塑性变形过程中,合金中的晶粒被显著细化,位错密度迅速上升,显著提高了原子扩散的能力。以上原因导致了HPT变形过程中MgZn2相的回溶以及回溶程度随着变形量的增加而增加。当变形温度不变,变形量累积达到一定程度,材料中缺陷累积速度显著降低,而基体中Mg、Zn元素过饱和度显著增加,界面浓度梯度重新成为主导相变进行方向的关键因素,变形产生的位错和晶界也促进了基体中的Mg、Zn元素向外扩散;于是,MgZn2又重新析出。由于新析出的MgZn2相尺寸较小且面密度较高,其过剩的相界面能引发吉布斯-汤普森效应,从而导致新生相的迅速粗化。

图3 铸态和HPT变形Al-Zn-Mg-Cu合金的显微组织及EDS能谱图

Fig. 3 Microstructures and EDS spectra of as-cast and HPT deformation Al-Zn-Mg-Cu alloy

图4 不同条件下第二相变化图

Fig. 4 Change of secondary phase under different conditions

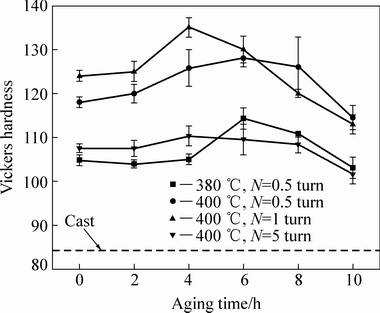

2.3 力学性能分析

大塑性变形过程中,合金中第二相回溶形成过饱和固溶体,与热处理工艺中的固溶相似。经过大塑性变形的合金在进行低温时效时,合金中第二相重新析出产生时效硬化[22]。分别对HPT变形Al-Zn-Mg-Cu合金试样进行温度为100 ℃,时间为2~10 h的时效处理,结果如图5所示。铸态Al-Zn-Mg-Cu合金的维氏硬度为85 HV,经高压扭转变形后硬度上升。HPT变形后Al-Zn-Mg-Cu合金经100 ℃时效处理后,硬度随时效时间的增加先上升后下降,大约在4~6 h达到最大值。扭转0.5圈后,随着温度由380 ℃上升至 400 ℃,硬度升高15 HV。扭转温度为400 ℃时,随着扭转圈数的增加,硬度先上升后下降。在1圈时达到最大值124 HV。后续时效处理过程中,在380和400 ℃扭转0.5圈时,均在6 h达到时效峰值。其中,380 ℃扭转0.5圈,时效6 h后维氏硬度的增幅最大,可达到10%。400 ℃扭转1圈和5圈,硬度均在4 h达到时效峰值,扭转1圈时效4 h时后,硬度最高为135 HV,而扭转5圈无明显变化。与图2分析结合,HPT变形后试样时效达到时效峰值所需要时间随着高压扭转变形量的增加而减少,而第二相的回溶随着变形量的增加而增加。即高压扭转工艺通过影响合金中第二相的回溶程度来影响最佳的时效时间。

图5 HPT变形Al-Zn-Mg-Cu合金时效硬度

Fig. 5 Hardness of Al-Zn-Mg-Cu alloy under HPT deformation after aging

3 结论

1) Al-Zn-Mg-Cu合金在高压扭转变形过程中受到强烈的剪切应变,合金中第二相回溶到基体中,当变形量达到一定程度,又从基体中析出。第二相的回溶和析出与温度、变形量有关。

2) Al-Zn-Mg-Cu合金经高压扭转变形后,经100℃时效处理,出现时效硬化现象,硬度随时效时间的增加先上升后下降,在4~6 h达到时效峰值。

3) 高压扭转通过影响第二相的回溶程度来影响最佳时效时间,即回溶程度越高,时效达到峰值所需时间越短。

REFERENCES

[1] 丁永根, 王博笑天, 李 萍, 薛克敏. 高压扭转变形的Al-Zn-Mg-Cu-Zr合金微观组织及织构析[J]. 中国有色金属学报, 2017, 27(6): 1125-1131.

DING Yong-gen, WANG Bo-xiao-tian, Li Ping, XUE Ke-min. Microstructures and textures of Al-Zn-Mg-Cu-Zr alloy after high pressure torsion[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1125-1131.

[2] 刘 斌, 汪明朴, 雷 前, 段雨露, 刘林贤, 虞洪春. 喷射沉积法制备Al-Zn-Mg-Cu-Zr合金的显微组织与性能[J]. 中国有色金属学报, 2015, 25(7): 1773-1780.

LIU Bin, WANG Ming-pu, LEI Qian, DUAN Yu-lu, LIU Lin-xian, YU Hong-chun. Microstructure and properties of Al-Zn-Mg-Cu-Zr alloy prepared by spray deposition method[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1773-1780.

[3] 薛 杰, 王有为, 张志豪, 谢建新. 挤压温度对Al-Zn-Mg-Cu合金动态再结晶、时效组织和力学性能的影响[J]. 中国有色金属学报, 2017, 27(11): 2204-2211.

XUE Jie, WANG You-wei, ZHANG Zhi-hao, XIE Jian-xin. Effects of extrusion temperature on dynamic recrystallization, aging microstructure and mechanical properties of Al-Zn-Mg-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(11): 2204-2211.

[4] 孙大智, 薛克敏, 王成国, 李 萍. SiC颗粒粒径对高压扭转SiCp/Al复合材料致密度和拉伸性能的影响[J]. 稀有金属与硬质合金, 2016, 42(2): 64-67.

SUN Da-zhi, XUE Ke-min, WANG Cheng-guo, LI Ping. Effects of SiC particles size on density and tensile properties of high-pressure torsion SiCp/Al composites[J]. Rare Metals and Cemented Carbides, 2016, 42(2): 64-67.

[5] PATIL D C, DAS M, DAS G, KORIS A, VENKATESWARLU K. Evaluating the mechanical properties of HPT processed aluminium alloys using automated ball-indentation technique[J]. Procedia Materials Science, 2014, 5: 379-386.

[6] DESCHAMPS A, GEUSER F D, HOEITA Z, LEE S, RENOU G. Precipitation kinetics in a severely plastically deformed 7075 aluminium alloy[J]. Acta Materialia, 2014, 66: 105-117.

[7] PATIL D C, KORIS A, VENKATESWARLU K, DAS G, ALHAJERI S N, LANGDON T G. Using ball indentation to determine the mechanical properties of an Al-7475 alloy processed by high-pressure torsion[J]. Journal of Materials Science, 2013, 48: 4773-4779.

[8] CHO T S, LEE H J, AHN B, KAWASAKI M, LANGDON T G. Microstructural evolution and mechanical properties in a Zn-Al eutectoid alloy processed by high-pressure torsion[J]. Acta Materialia, 2014, 72: 67-79.

[9] HORITA Z, LANGDON T G. Achieving exceptional super plasticity in a bulk aluminum alloy processed by high-pressure torsion[J]. Scripta Materialia, 2008, 58(11): 1029-1032.

[10] DOBAKIN S V. On the increase o f thermal stability of ultra fine grained material obtained by severe plastic deformation[J]. Materials Science Forum, 2003, 426/432: 2699-2704.

[11] MURAYAMA M, HORITA Z, HONO K. Microstructure of two-phase Al-1.7at%Cu alloy deformed by equal-channel angular pressing[J]. Acta Materialia, 2001, 49: 21-29.

[12] OH-ISHI K, HASHI Y, SADAKATA A, KANEKO K, HORITA Z, LANGDON T G. Microstructural control of an Al-Mg-Si alloy using equal-channel angular pressing[J]. Materials Science Forum, 2002: 396/402: 333-338.

[13] FATAY D, BASTARASH E, NYILAS K, DOBATKIN S, GUBICZA J, UNGAR T. X-ray diffraction study on the microstructure of an Al-Mg-Sc-Zr alloy deformed by high-pressure torsion[J]. International Journal of Materials Research, 2003, 94(7): 842-847. (in Germany)

[14] 许晓嫦, 刘志义, 党 鹏, 于文斌, 谭曼玲, 吴 纯. 研究强塑性变形过程中第二相回溶现象的现状及发展趋势[J]. 金属热处理, 2005, 30(4): 1-5.

XU Xiao-chang, LIU Zhi-yi, DANG Peng, YU Wen-bin, TAN Man-ling, WU Chun. Current situation and development of the research on re-dissolution of second phases during severe plastic deformation[J]. Heat Treatment of Metals, 2005, 30(4): 1-5.

[15] 党 鹏, 许晓嫦, 刘志义, 于文斌, 宁爱林, 曾苏民. Al-Cu合金θ′析出相在等径角挤压中的回溶机理[J]. 金属热处理, 2007, 32(8): 28-31.

DANG Peng, XU Xiao-chang, LIU Zhi-yi, YU Wen-bin, NI Ai-lin, ZENG Su-ming. Dissolution mechanisms of θ′ precipitates in Al-Cu alloy deformed by equal-channel angular pressing[J]. Heat Treatment of Metals, 2007, 32(8): 28-31.

[16] 胡赓祥, 蔡 珣, 戎咏华. 材料科学基础[M]. 第3版. 上海: 上海交通大学出版社, 2010: 154-156.

HU Geng-xiang, CAI Xun, RONG Yong-hua. Fundamentals of materials science[M]. 3rd ed. Shanghai: Shanghai Jao Tong University Press, 2010: 154-156.

[17] CAMPBELL C E, BENDERSKY L A, BOETTINGER W J, LVESTER R. Microstructural characterization of Al-7075-T651 chips and work pieces produced by high-speed machining[J]. Materials Science & Engineering A, 2006, 430: 15-26.

[18] PEREIRA P H R, FIGUEIREDO R B, HUANG Y, CETLIN P R, LANGDON T G. Modeling the temperature rise in high-pressure torsion[J]. Materials Science & Engineering A, 2014, 593: 185-188.

[19] 许晓嫦. 强变形诱导铝合金析出相低温回溶现象及应用基础研究[D]. 长沙: 中南大学, 2008.

XU Xiao-chang. Basic investigation on the phenomenon of severe plastic deformation induced re-dissolution of precipitated phase[D]. Changsha: Central South University, 2008.

[20] YAMAGUCHI D, HORITA Z, NEMOTO M, LANGDON T G. Significance of adiabatic heating in equal-channel angular pressing[J]. Scripta Materialia, 1999, 41(8): 791-796.

[21] GRIDNEV V N, GAVIRILYMK V G. Macromechanics and structure formation by equal channel angular pressing[J]. Metal-Physics, 1982, 14(3): 135-139.(in Russia)

[22] 赵凤晓, 许晓嫦, 张 奇, 徐浩浩, 刘海全, 曾慧颖. 固溶原子及析出相对强变形 Al-4Cu 合金晶粒细化效果的影响[J]. 中国有色金属学报, 2014, 24(2): 395-402.

ZHAO Feng-xiao, XU Xiao-chang, ZHANG Qi, XU Hao-hao, LIU Hai-quan, ZENG Hui-ying. Effect of solute atom and precipitated phase on grain refinement of Al-4Cu alloy by severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 395-402.

Dissolution of secondary phase in novel Al-Zn-Mg-Cu alloy reduced by high pressure torsion

LI Ping, DING Chun-hui, WANG Bo-xiao-tian, WU Guang-shan, XUE Ke-min

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: As-cast Al-Zn-Mg-Cu alloy was deformed by high pressure torsion at 380 ℃ and 400 ℃, respectively, and then proceeded aging treatment at 100 ℃ for 2-10 h. The changes of morphology and content of the secondary phase of Al-Zn-Mg-Cu alloy during high pressure torsion as well as the hardness of the samples deformed by high pressure torsion under aging were studied by X-ray polycrystalline diffraction, scanning electron microscopy and Vickers hardness. The results show that the secondary phase is broken and dissolved into matrix, and then form the supersaturated solid solution, the dissolution degree of the secondary phase increases with increase of the temperature and deformation. The hardness of the samples deformed by high pressure torsion increases and then decreases with the increase of the aging time during aging at 100 ℃. The higher the dissolution degree, the shorter the time reaching the peak of the samples during aging.

Key words: novel Al-Zn-Mg-Cu alloy; high pressure torsion; the secondary phase; dissolution; aging

Foundation item: Project (51575153) supported by the National Natural Science Foundation of China

Received date: 2017-11-28; Accepted date: 2018-05-22

Corresponding author: XUE ke-min; Tel: +86-551-62901368; E-mail: xuekm0721@sina.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51575153)

收稿日期:2017-11-28;修订日期:2018-05-22

通信作者:薛克敏,教授,博士;电话:0551-62901368;E-mail:xuekm0721@sina.com