中间退火对4343/3003/7072汽车热交换器用铝合金复合箔抗下垂性能的影响

张新明1,张静1,唐建国1,周德敬2,尹林1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 无锡银邦铝业有限公司,江苏 无锡,214122 )

摘要:采用光学显微镜、透射电镜及能谱分析研究冷轧中间退火温度和随后的轧制压下率对汽车热交换器用4343/3003/7072铝合金复合箔抗下垂性能的影响。研究结果表明:可通过增大芯材金属的晶粒尺寸来提高复合箔的抗下垂性能;当中间退火温度和成品轧制压下率分别为370 ℃和10%~35%,以及500 ℃和20%~35%时,高温钎焊后芯部金属的组织为粗大的再结晶晶粒组织,此时皮材中的Si沿晶界向芯材的渗透被限制,复合箔的抗下垂性能得到提高。

关键词:铝合金复合箔;抗下垂性能;再结晶;Si渗透;工艺参数

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2012)01-0059-07

Influence of intermediate annealing temperature on sagging resistance of 4343/3003/7072 layered aluminum foil for automobile exchanger

ZHANG Xin-ming1, ZHANG Jing1, TANG Jian-guo1, ZHOU De-jing2, YIN Lin1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Wuxi Yinbang Aluminum Industry Co. Ltd., Wuxi 214122, China)

Abstract: The effects of intermediate annealing temperature (IA) and cold rolling (CR) reduction on sagging resistance of 4343/3003/7072 layered aluminum foil were investigated by means of optical microscopy, transmission electron microscopy and energy dispersive spectrometer. The results show that the sagging resistance depends on the IA temperature and CR reduction. The microstructure examination shows that the grain size of the core material plays an important role. Under the conditions of 370 ℃/10%-35% and 500 ℃/20%-35%, coarse recrystallized grains are formed in the core material of the clad sheet during brazing, which prevents silicon element of the filler alloy from penetrating into the core material along the grain boundaries and the sagging resistance of the foil is improved.

Key words: composite brazing aluminum foil; sagging resistance; recrystallization; silicon penetration; technique parameters

汽车热交换器是由流体管道和散热翅片通过钎焊法装配而成[1]。在高温钎焊时,翅片强度降低发生软化变形,可能导致导管与散热翅片焊合不牢固,甚至产生虚焊或脱焊现象,影响水箱的散热效果。因此,抗下垂性能成为衡量钎焊箔质量的重要指标,而国内复合钎焊箔的抗下垂性能与国外的相比相对较差[2]。研究表明[3-5]:皮材中的Si向芯材渗透是导致钎焊下垂的主要原因。在高温钎焊过程中,当温度加热至580~610 ℃时,皮材中的Al-Si共晶合金在577 ℃时开始熔化,融化的金属液体一部分形成钎焊接头,另一部分沿着晶界向芯部金属扩散,在皮材和芯部金属界面处形成一层扩散带。国内外研究者围绕钎焊过程中的凝固过程以及钎焊接头的形成进行大量的研究[6-9],并对轧制成品率也进行了大量研究[10-15]。研究表明[5]:皮材中的Si主要沿着芯材晶界扩散形成α(Al)+Si共晶,从而降低芯材的强度,导致高温时发生软化变形。因此,增大晶粒尺寸减少晶界数量,即减少熔融的皮材向芯部金属的扩散渠道,是提高钎焊箔抗下垂性的关键。再结晶是调控铝合金晶粒尺寸最主要的手段,基于此,本文作者研究冷轧中间退火及随后冷轧变形量对芯材再结晶及复合箔抗下垂性能的影响。

1 实验材料与方法

以3003合金为芯材,一面包覆4343合金作为皮材,高温钎焊时熔化成为钎料,另一面包覆7072合金作为皮材,起到牺牲阳极、保护芯材免受腐蚀的作 用[3]。3层材料形成三明治结构,皮材厚度一般占复合铝箔厚度的10%左右。

合金设计成分如表1所示。将4343和7072铸锭均匀化后热轧至厚度2.5 mm,用传统方法对表面进行处理后,与均匀化后厚度为25 mm的3003铸锭热轧复合。首道次压下量为50%,热轧温度为500 ℃。最终将复合材料热轧至厚度2 mm,然后,将材料分别冷轧至厚度0.11~0.33 mm,并进行中间退火,退火温度分别为300,370,420和500 ℃,退火时间为1 h。最后进行成品轧制,轧制压下率为10%~85%,成品厚度为0.1 mm。

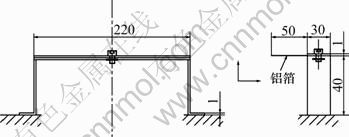

设计图1所示的实验装置来检测、分析成品铝箔的抗下垂性能。铝箔的外悬长度为50 mm,箔带宽度为22 mm。将加热炉升温到610 ℃,并稳定20 min,再将装配好的试样送入炉内进行加热,加热时间为5 min。然后,将试验装置平稳地移出炉外空冷,用游标卡尺测量试样的自由端自然下垂量即下垂值[12]。

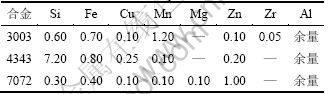

表1 芯材和皮材的合金设计成分(质量分数)

Table 1 Chemical compositions of core and filler alloys studied %

图1 抗下垂实验装置示意图(单位:mm)

Fig.1 Schematic of sagging test rig

试样经电解抛光和阳极覆膜后在POL YVARMET 型光学显微镜(OM)上进行显微组织观察;透射电镜观察在Tecnai G220型透射电镜上进行;在KYKY2800 型扫描电子显微镜(SEM)上进行显微组织观察及能谱分析。

2 结果与讨论

2.1 中间退火及冷变形对带材晶粒尺寸的影响

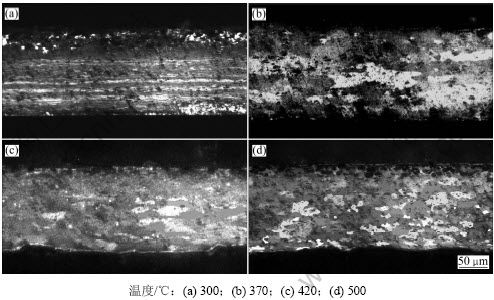

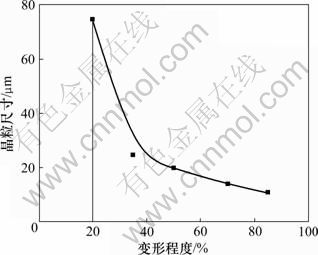

图2所示为中间退火后芯材的晶粒组织。从图2可以看出:在300 ℃退火时,芯部金属未发生再结晶;在370 ℃退火时,部分晶粒发生再结晶;在420 ℃退火时,晶粒全部发生再结晶;当退火温度升高至500 ℃时,晶粒发生粗化。

图2 成品前不同中间退火温度下芯材的显微组织

Fig.2 Microstructure of clad sheet intermediate-annealed at different temperatures

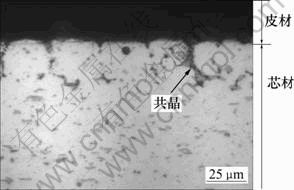

图3所示为抗下垂实验前芯部金属的金相显微组织。从图3可以看出:模拟钎焊后,Al-Si共晶熔化,并沿着芯部金属的晶界扩散,并在晶界形成Al-Si共晶,严重降低芯部金属的强度。

图3 抗下垂实验前芯部金属的显微组织

Fig.3 Microstructure of core material after brazing

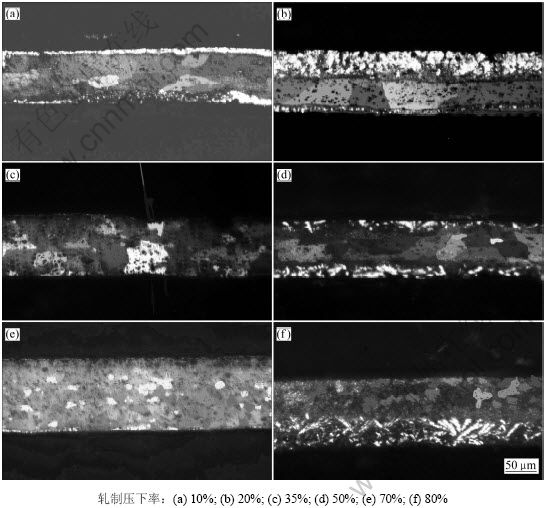

高温钎焊后不同退火温度和轧制压下率条件下的金相组织如图4~5所示。从图4可以看出:在相同的退火温度下,随着轧制压下率的增大,芯部金属的晶粒减小。从图5可以看出:在轧制压下率相同的情况下,在370 ℃和500 ℃中间退火时,经过高温钎焊后芯部金属的晶粒尺寸最粗大,其次是420 ℃中间退火,不退火和300 ℃中间退火的晶粒最细小。

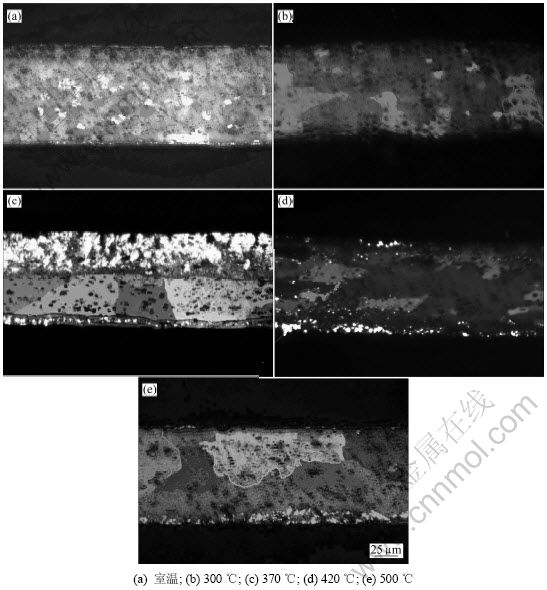

图6所示为中间退火温度为500 ℃、压下率为10%时,抗下垂试验后芯部金属的TEM组织。从图6可以看出:芯部金属中位错密度较大,存在大角度晶界。这说明在610 ℃模拟钎焊时,芯部金属并没有完全发生再结晶。

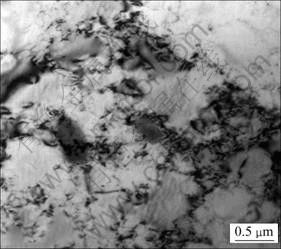

图7所示为变形程度和晶粒尺寸之间的关系。由图7可见:当变形程度达到εc时,晶界大规模迁移发生再结晶,且再结晶晶粒比较粗大,随着变形程度增大,再结晶晶粒不断细化。

2.2 中间退火及随后冷变形对抗下垂性能的影响

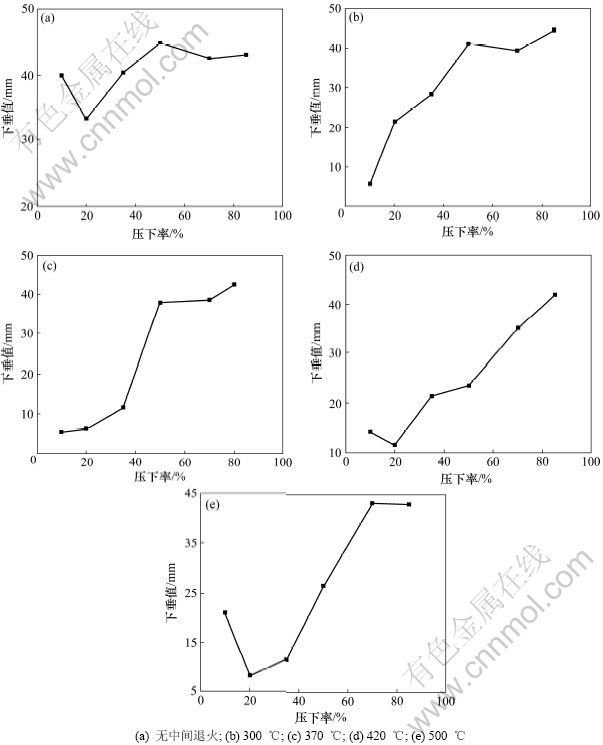

抗下垂实验结果如图8所示。由图8可以看出:无论在何种中间退火制度下,当成品压下率超过50%时,抗下垂性能很差;若不经过中间退火,无论压下率为多少,抗下垂性能都很差。抗下垂性能较好的工艺条件是370 ℃/10%~35%,420 ℃/10%~20%和500 ℃/ 20%~35%。

图4 在中间退火温度为370 ℃时、不同的轧制压下率下抗下垂实验后芯材的显微组织

Fig.4 Microstructures of post-brazing alloys after annealing at 370 ℃ through different reductions

图5 在轧制压下率为20%、不同退火温度下抗下垂实验后芯材的显微组织

Fig.5 Microstructures of post-brazing alloy after 20% cold rolling at different intermediate annealing temperatures

图6 中间退火温度为500 ℃、成品压下率为10%时,抗下垂实验后芯部金属的TEM组织

Fig.6 TEM image of core specimen intermediate-annealed at 500 ℃ after 10% cold-rolling

图7 500 ℃中间退火时变形程度对钎焊后晶粒尺寸的影响

Fig.7 Effect of cold-rolling reduction on grain size after brazing at intermediate annealing temperature of 500 ℃

图8 不同中间退火和成品轧制压下率对抗下垂性的影响

Fig.8 Sagging distance vs cold rolling reduction at different intermediate annealing temperatures

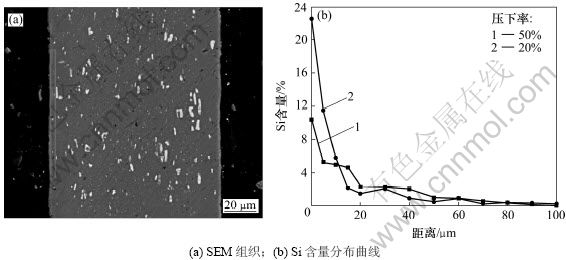

对抗下垂实验后的复合箔截面进行能谱分析,以检测皮材中的Si元素在芯材中的扩散结果。图9所示为420 ℃中间退火、成品压下率分别为20%和50%时,沿铝箔横截面相同面积内Si元素的分布情况。从图9可见:随着到复合箔表面距离的增加,当压下率为20%时,Si元素的含量下降比50%压下率时的快,说明压下率为20%时Si元素的扩散较压下率为50%时的少。

从图8(a)可以看出:不经过中间退火时,压下率对下垂距离影响不大,且抗下垂性能都很差。这是由于不经过中间退火的箔材在钎焊前已具有非常大的变形量,因此,在经过高温钎焊后,再结晶晶粒非常细小(见图5(a))。因此,Si元素沿晶界的扩散增大,导致抗下垂性能下降。

图9 在370 ℃中间退火、成品压下率为20%和50%时,经过抗下垂实验后芯部金属中Si含量的分布

Fig.9 Si content of brazed core specimen annealed at 370 ℃, then 20% and 50% cold-rolled

从图8(b)可见:在300 ℃退火且压下率为10%时下垂距离很大;压下率为20%~35%时,下垂距离略有所减小;然后,随压下率的增大,下垂距离不断增大,性能变差。但相对于其他退火温度,各个变形量下的下垂距离都比较大。通过观察此退火温度后的金相组织(图2(a)所示)可以看出:在300 ℃下,芯部金属并未发生再结晶,冷轧过程中储存的能量并未完全释放,导致在钎焊过程中,再结晶晶粒比较细小,如图5(b)所示。

从图8(c)可见:在370 ℃退火、压下率为10%~20%时,抗下垂性能较好;随着变形量的继续增大,下垂距离越来越大;370 ℃中间退火后,芯部金属中只有部分晶粒再结晶完成,所以,中间退火后还保留一部分储能。因此,在最后一道次变形量为10%时,变形量已经超过了临界变形量,使芯部金属发生再结晶,且晶粒较大(如图4(a)所示),下垂距离较小,抗下垂性能较好。但随变形量的增大,储能也不断增大,因此,高温钎焊后,晶粒也不断变小,如图4所示。因此,下垂距离增大。

420 ℃退火后,晶粒已全部发生再结晶(如图3(c)所示),之前冷轧的储能全部释放,但再结晶晶粒尺寸非常小。由于原始晶粒尺寸非常小,原有大角度界面增多,因此,经过变形和高温钎焊以后的再结晶晶粒比500 ℃退火时的小,如图5(d)所示;在10%~35%时,下垂距离变化不大,且下垂距离相对较大,如图8(d)所示。

在500 ℃退火、压下率为10%时,由于变形程度较小,变形后的变形储能很小,在高温钎焊时,并未达到临界变形程度εc,经过高温钎焊后的芯部金属仍然保留了较多的位错和大角度晶界,如图6所示。皮材熔化后,沿着位错密度较大的区域进行渗透,因此,下垂距离较大。而当变形程度达到临界变形程度20%时,高温钎焊时发生了再结晶,且晶粒较大(如图5(e)所示),下垂距离较小。之后,随着变形程度的不断增大,晶粒也越来越小,下垂距离随之增大。

3 结论

(1) 抗下垂性能与芯部金属再结晶程度有密切关系,而芯部金属的再结晶受压下率和中间退火温度 控制。

(2) 4343/3003/7072铝合金复合箔中间退火温度与成品压下率在370 ℃/10%~35%以及500 ℃/20%~ 35%时,芯部金属再结晶晶粒较大,限制了皮材中的Si向芯材的渗透,抗下垂性能较好。

参考文献:

[1] 祖国胤, 王宁, 于九明, 等. 复合钎焊铝箔技术在汽车热交换器生产中的应用[J]. 汽车工艺与材料, 2003(12): 37-38.

ZU Guo-yin, WANG Ning, YU Jiu-ming, et al. Application of composite brazing aluminium foil technology in automotive heat exchanger production[J]. Automobile Technology & Material, 2003(12): 37-38.

[2] 赵海军, 刘磊, 朱建华, 等. 汽车铝质热交换器的研究进展[J]. 焊接工艺, 2004, 33(2): 3-5.

ZHAO Hai-jun, LIU Lei, ZHU Jian-hua, et al. Progress in study of automobile aluminium heat-exchangers[J]. Welding Technology, 2004, 33(2): 3-5.

[3] 潘春旭. A4343/A3003铝合金薄板钎焊接头的显微组织特征[J]. 中国有色金属学报, 2002, 12(3): 481-485.

PAN Chun-xu, Dusanp.Sekulic. Microstructural charateristics of AA4343/AA3003 Al-alloy sheet brazed joint[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 481-485.

[4] Turriff D M, Corbin S F, Kozdras M. Diffusional solidification phenomena in clad aluminum automotive braze sheet[J]. Acta Materialia, 2009, 58(4): 1332-1341.

[5] Sekulic D P, Galenko P K, Krivilyov M D, et al. Dendritic growth in Al-Si alloys during brazing[J]. Heat and Mass Transfer, 2004, 48(12): 2372-2384.

[6] Marshall G J, Bolingbroke R K, Gray A. Micostructural control in an aluminum core alloy for brazing sheet applications[J]. Metallurgical Transactions, 1993, 24(9): 1935-1942.

[7] GAO Feng, ZHAO Hui, Sekulic D P, et al. Solid state Si diffusion and joint formation involving aluminum brazing sheet[J]. Materials Science and Engineering A, 2001, 337(2): 228-235.

[8] Tierce S, Pebere N, Blanc C, et al. Corrosion behavior of brazing material AA4343[J]. Electrochimica Acta, 2006, 52(9): 1092-1100.

[9] Yoshino M, Edo M, Kuroda S, et al. Effect of additional Fe, Ni, and Mn on corrosion resistance of sacrificial anode fin stock for automotive heat exchangers[J]. Journal of Japan Institute of Light Metals, 2008, 59(3): 101-107.

[10] ZHAO Hui, Sekulic D P. Diffusion-controlled melting and re-solidification of metal micro layers on a reactive substrate[J]. Heat Mass Transfer, 2005, 42(6): 464-469.

[11] 祖国胤, 李兵, 李鸿, 等. 冷轧复合对铝合金复合箔组织与性能的影响[J]. 东北大学学报: 自然科学版, 2008, 29(5): 689-692.

ZU Guo-yin, LI Hong, YU Jiu-ming. Effect of cold-rolling cladding on microstructure and properties of composite aluminum alloy foil[J]. Journal of Northeasten University: Natural Science, 2008, 29(5): 689-692.

[12] 孙海安, 张文斌, 戴玉光. 铝合金复合带材抗下垂性能的研究[J]. 轻合金加工技术, 2002, 30(9): 44-47.

SUN Hai-an, ZHANG Wen-bin, DAI Yu-guang. Study about Hang-down resistance of 464-H14 aluminium alloy composite strip[J]. Light Alloy Fabrication Technology, 2002, 30(9): 44-47.

[13] 黄光杰, 段成银. 加工工艺对钎焊箔材抗下垂性能的影响[J]. 材料导报, 2007, 21(5A): 414-430.

HUNG Guang-jie, DUAN Cheng-yin. Effect of processing craft on Hang-down resistance of brazing foil[J]. Materials Review, 2007, 21(5A): 414-430.

[14] Yoon J S, Lee S H, Kim M S. Fabrication and brazeability of a three-layer 4343/3003/4343 aluminum clad sheet by rolling[J]. Journal of Material Processing Technology, 2001, 111(3): 85-89.

[15] Sung J, Kim M S, Jung D. Brazeability of cold rolled three layer Al-7.5Si/Al-1.2Mn-2Zn-(0.04-1.0)Si/Al-7.5Si(wt.%) clad sheets[J]. Journal of Materials Processing Technology, 2002, 130(10): 240-244.

(编辑 何运斌)

收稿日期:2011-01-16;修回日期:2011-03-21

基金项目:科技基础设施建设计划—江苏省企业院士工作站(BM2010470)

通信作者:张新明(1946-),男,湖南常德人,教授,从事材料科学与工程研究;电话:0731-88830265;E-mail: xmzhang@csu.edu.cn